Hub motor stator water cooling structure for electric motor vehicle

A technology for in-wheel motors and electric vehicles, which is applied in the direction of electric vehicles, motors, magnetic circuit shape/style/structure, etc., and can solve problems such as inability to meet the heat dissipation requirements of in-wheel motors, increased reactive power loss and noise, and demagnetization of permanent magnet materials , to achieve the effect of simple structure, avoiding temperature gradient and uniform cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The content of the present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited thereto.

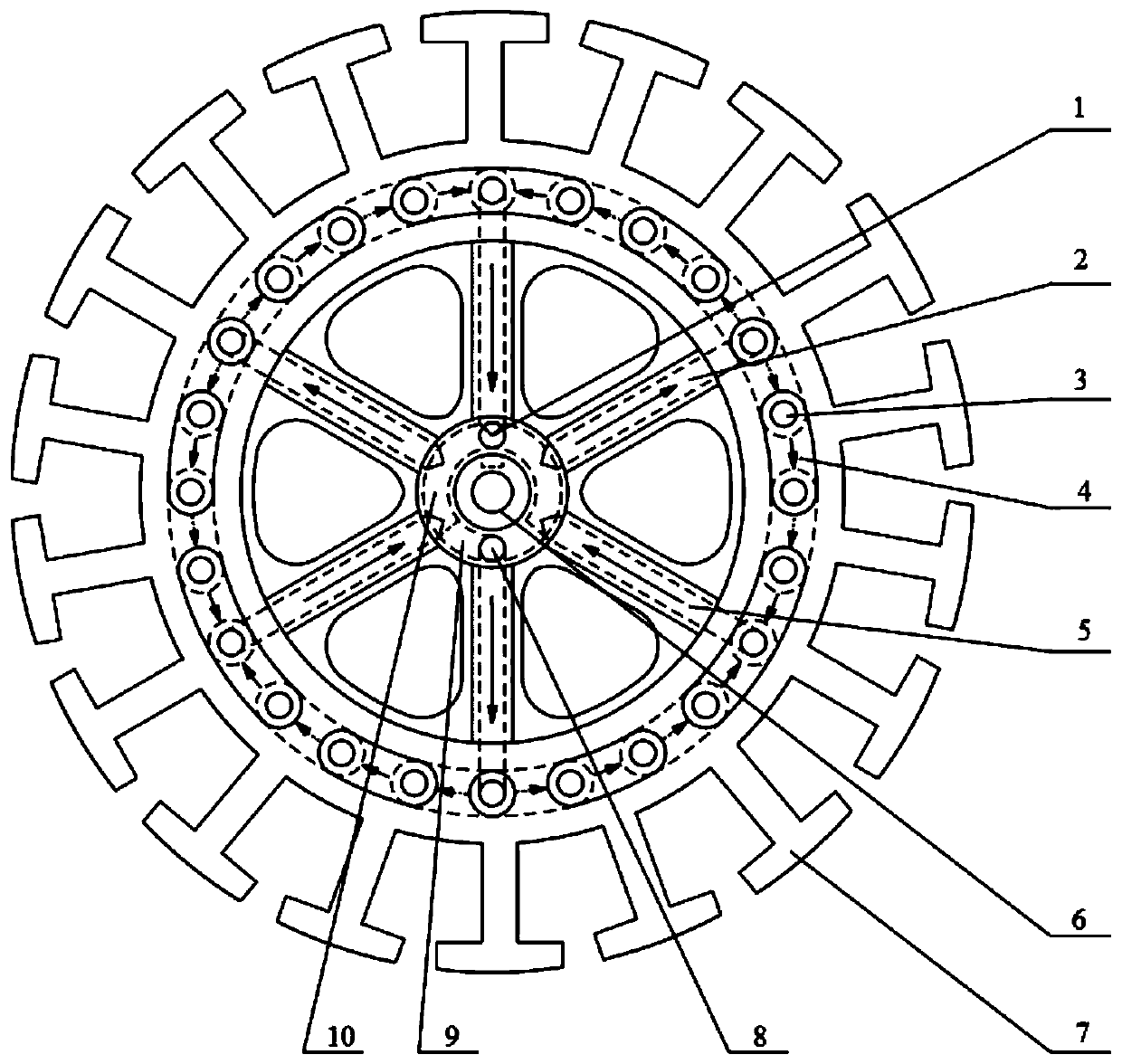

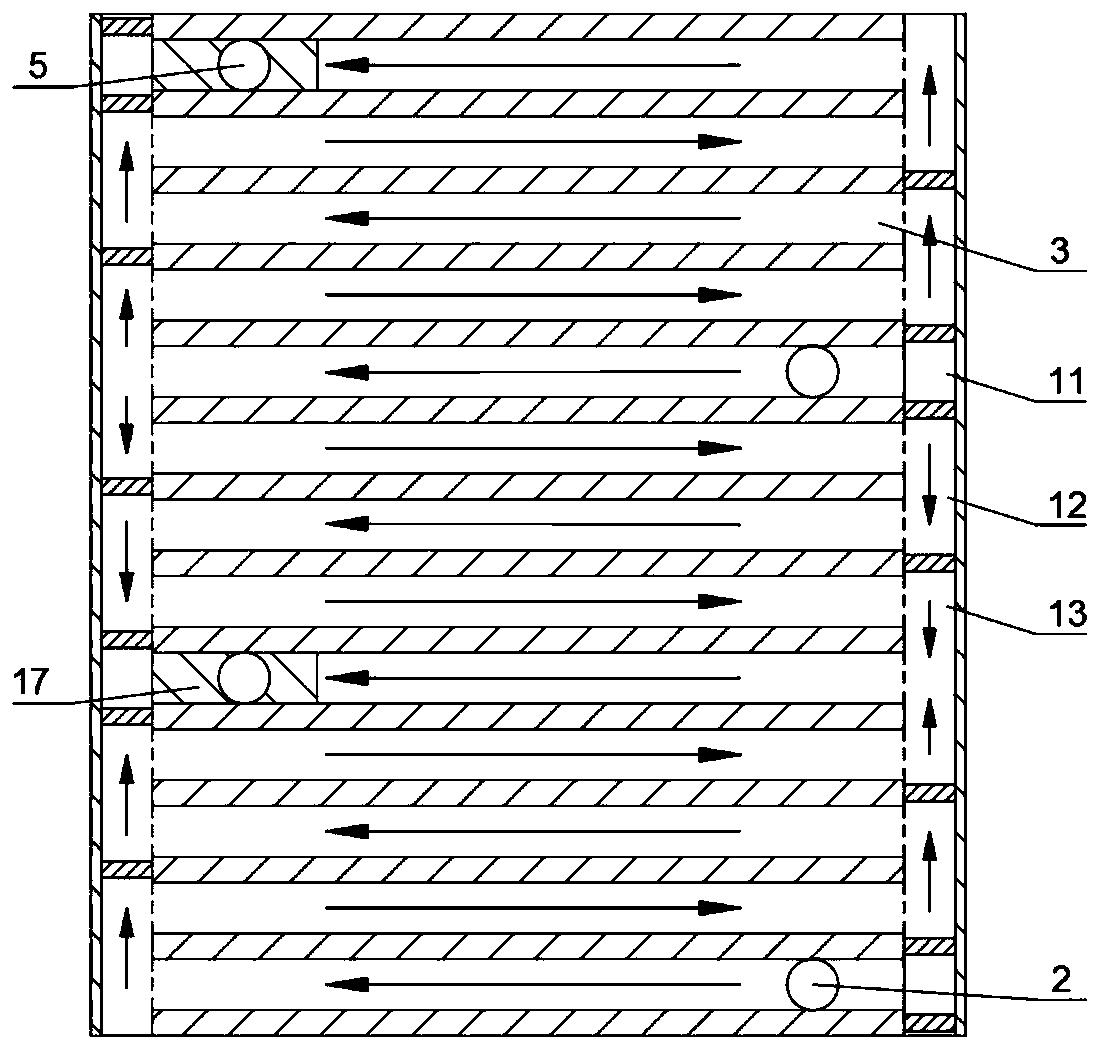

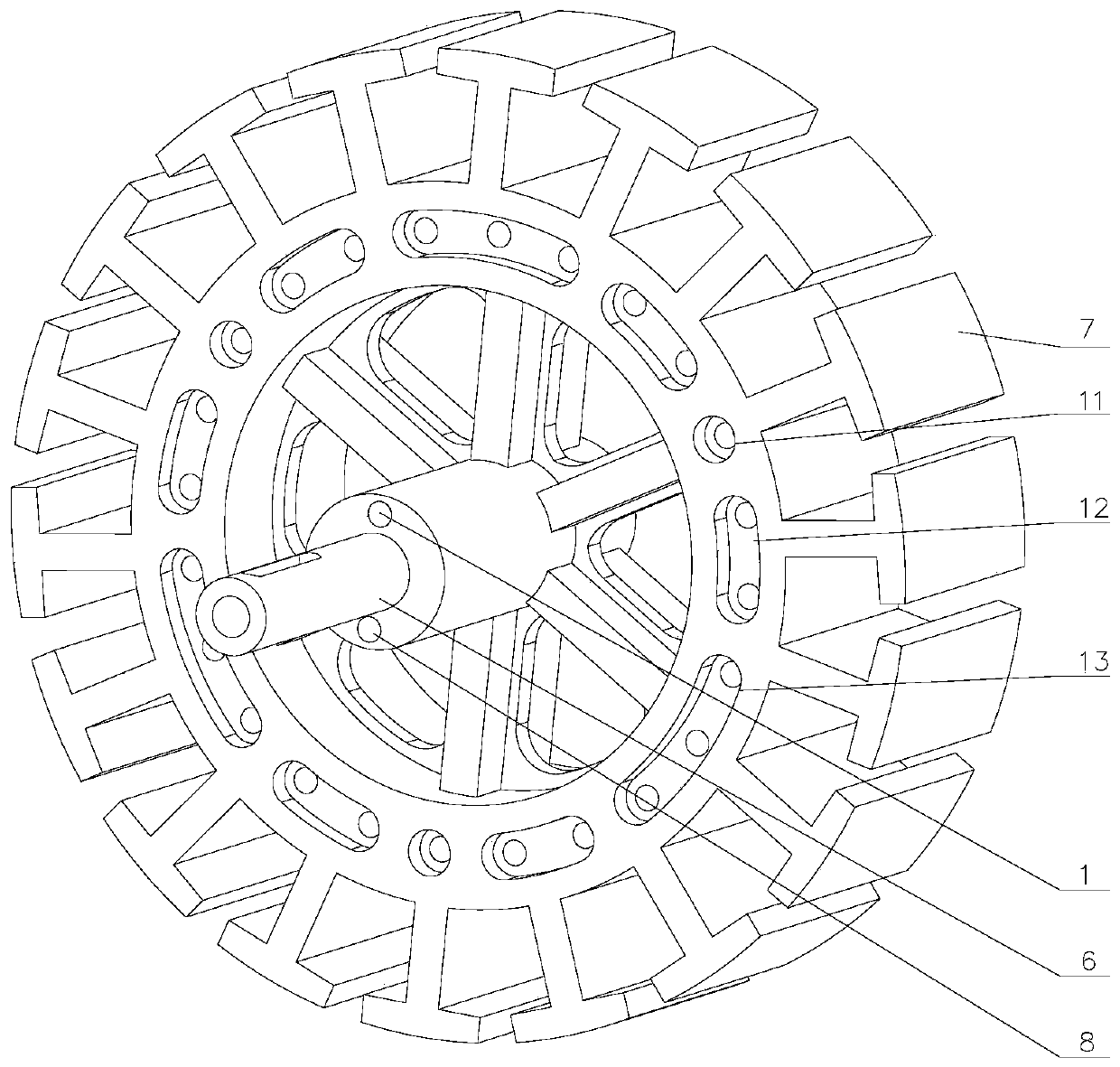

[0026] refer to figure 1 , image 3 , the present invention provides a hub motor stator water cooling structure for electric vehicles, the hub motor is an outer rotor motor, and the water cooling structure includes a coolant inlet channel 8, a water outlet channel 1, and a water inlet ring arranged on the motor stator shaft 6 9 and the water outlet ring 10, as well as the cold water channel 2, the hot water channel 5, the cooling water channel 3, the arc groove 4 and the arc groove cover arranged on the stator yoke of the motor, the cold water channel 2 and the hot water channel 5 are arranged axially at intervals in the motor Stator yoke. The water inlet ring 9 is on the same plane as the cold water channel 2, and is located on the side away from the extending direction of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com