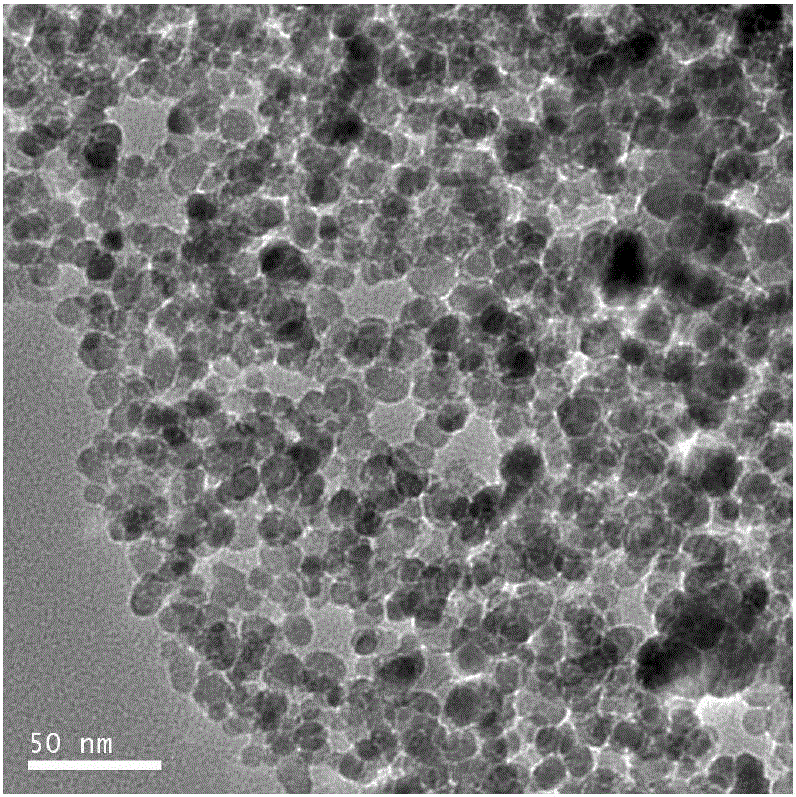

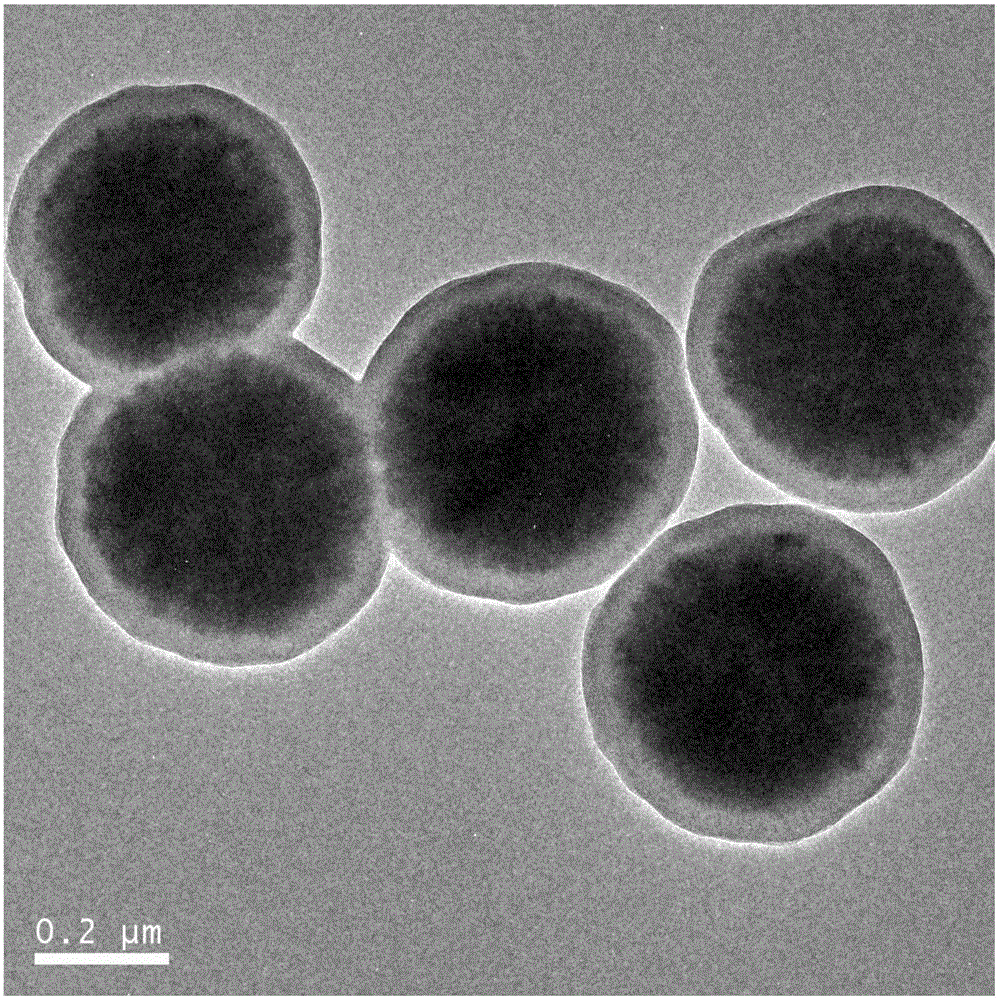

Monodisperse strong-magnetism immunologic nanoparticles and preparation method thereof

A nano-microsphere and magnetic nanotechnology, applied in the direction of magnetic materials, magnetic objects, inorganic materials, etc., can solve the problems of reduced magnetic content of magnetic nanoparticles, reduced practical application effect, difficulty in achieving monodispersion, etc., and achieve particle size distribution Narrow, easy to industrialized mass production, good suspension and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] A method for preparing monodisperse strong magnetic immune nano-microspheres of the present invention comprises the following steps:

[0052] Step 1, preparation of iron ferric oxide nanoparticles;

[0053]Step 2, preparation of monodisperse silanol magnetic nano-microspheres;

[0054] Step 3, preparation of monodisperse aminated magnetic nanospheres;

[0055] Step 4, preparation of monodisperse strong magnetic immune nano-microspheres.

[0056] Specifically, each step includes the following in detail:

[0057] Step one includes the following steps:

[0058] S1. Take Fe with a concentration of 0.1-3mol / L 3+ salt solution and Fe 2+ 1:1 to 10:1 by volume, take 10-100mL of the mixed solution, add it to 5-500mL aqueous solution containing 0.1%-10% emulsifier, and mix well to obtain the mixed solution 1;

[0059] S2. Add 20%-80% polyethylene glycol-6000 aqueous solution 20-100mL to the mixed solution 1 to obtain the mixed solution 2;

[0060] S3. Heat the mixed soluti...

Embodiment 1

[0081] Include the following steps:

[0082] S1. Accurately weigh 8.94g of ferric sulfate and 4.34g of ferrous sulfate, dissolve them in 200mL of aqueous solution with 0.25mL of emulsifier added, and mix well to obtain mixed solution 1;

[0083] S2. Add 100 mL of 25% polyethylene glycol 6000 aqueous solution to the mixed solution 1 to obtain the mixed solution 2;

[0084] S3. Heat the mixed solution 2 to 20° C., and slowly add 0.1 ml of ammonia diluent with a concentration of 20% dropwise at the same time, keep the temperature and continue to react for 1 hour to obtain the particle 1;

[0085] S4. Wash the particles 1 three times with absolute ethanol and ultrapure water respectively, and perform magnetic separation on the particles 1, and dry them at a temperature of 65° C. for 2 hours to obtain the ferric oxide nanoparticles;

[0086] S5. Disperse the ferric ferric oxide nanoparticles in 3% sodium dodecylbenzenesulfonate aqueous solution, then add 100 mL of a mixed solution...

Embodiment 2

[0098] S1, take Fe with a mass ratio of 3 3+ salt solution and Fe 2+ salt solution, mixed uniformly at a volume ratio of 1:1, took 10 milliliters and added it to an aqueous solution containing 0.1% emulsifier, and mixed thoroughly to obtain a mixed solution 1;

[0099] S2. Add 20 ml of 20% polyethylene glycol 6000 aqueous solution to the mixed solution 1 to obtain the mixed solution 2;

[0100] S3. Heat the mixed solution 2 to 50° C., and slowly add 0.5 ml of ammonia diluent with a concentration of 75% dropwise at the same time, keep the temperature and continue to react for 3 hours to obtain the particle 1;

[0101] S4. Wash the particles 1 three times with absolute ethanol and ultrapure water respectively, and perform magnetic separation on the particles 1, and dry them at a temperature of 65° C. for 2 hours to obtain the ferric oxide nanoparticles;

[0102] S5. Disperse the ferric ferric oxide nanoparticles in an aqueous solution containing 1% sodium dodecylbenzenesulfona...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com