Lophobic or oleophobic micro-nano composite structure and preparation method thereof

A composite structure, micro-nano technology, applied in the direction of metal material coating technology, etc., can solve the problems of low production and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

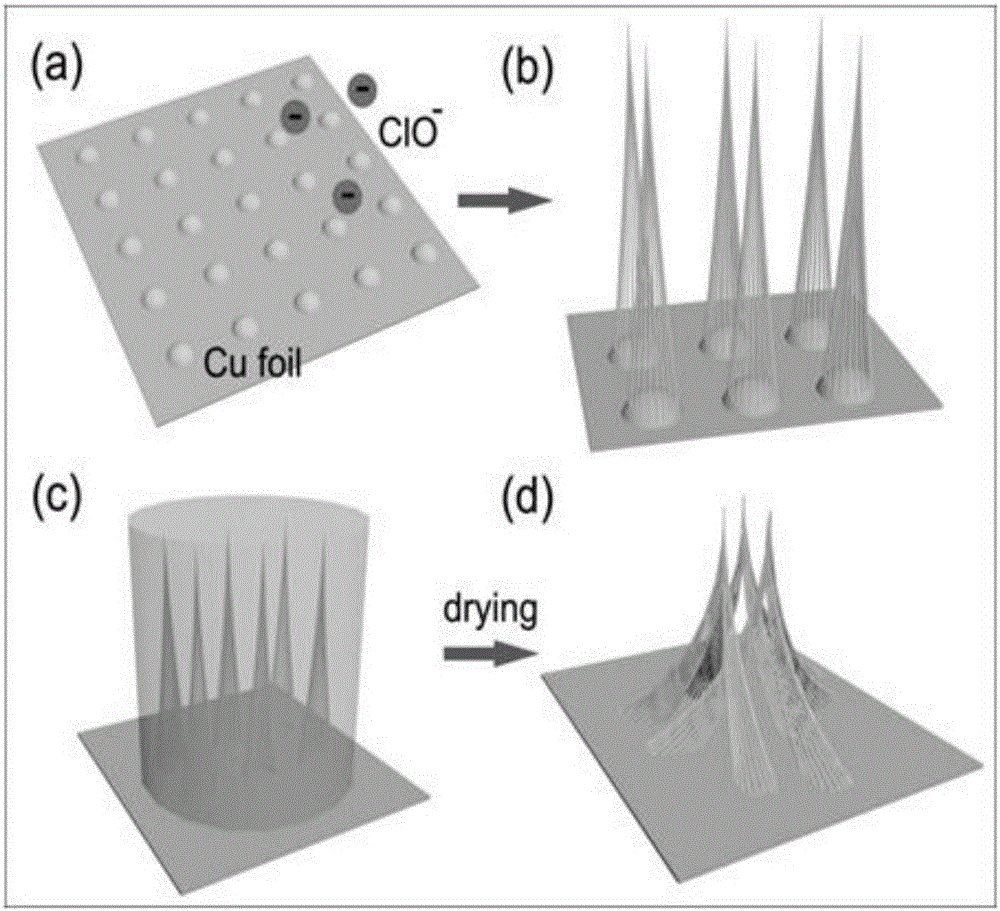

[0033] Such as Figure 7 As shown, a method for preparing a hydrophobic or oleophobic micro-nano composite structure of the present invention comprises the following steps:

[0034] Step 1, configuring an antiformin solution with a VF (volume fraction) of 5% to 40%, wherein VF is defined as the volume of the antiformin liquid / (volume of the antiformin liquid+volume of deionized water) ;

[0035] Step 2, put the copper base into the antiformin solution in step 1, and react at room temperature for 0.083 to 30 minutes;

[0036] Step 3. Take out the copper base after step 2, rinse it with deionized water and absolute ethanol successively, and then quickly dry it with a hair dryer at a temperature of 70°C to obtain a one-dimensional nano-bean sprout line structure with copper oxide on the surface and Copper base of copper oxide three-dimensional network structure;

[0037] Step 4, such as Figure 4 As shown in (a), adopt stearic acid solution to directly soak the copper base af...

Embodiment 1

[0043] (1) preparing an antiformin solution with a volume fraction VF of 40% as an oxidizing agent and stirring evenly;

[0044](2) Put the red copper sheet into the antiformin diluent at an angle, and the reaction time at room temperature is 10s.

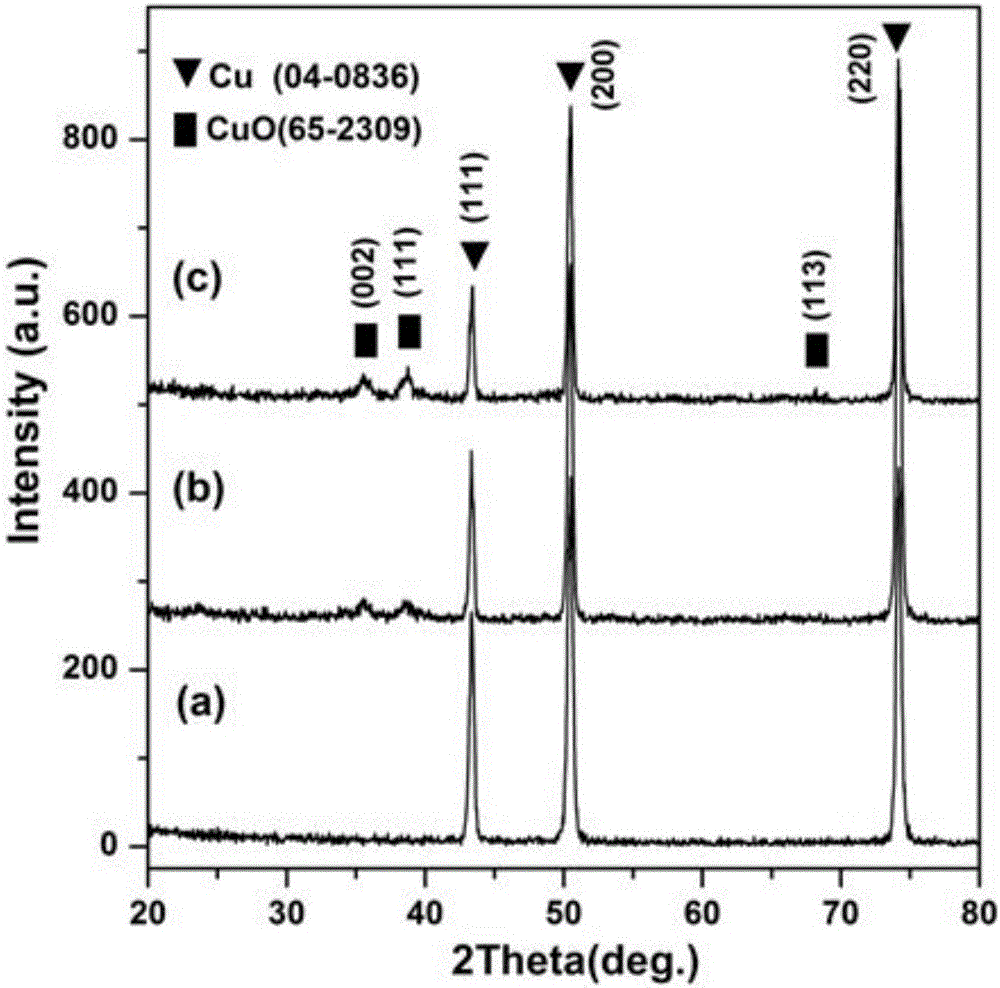

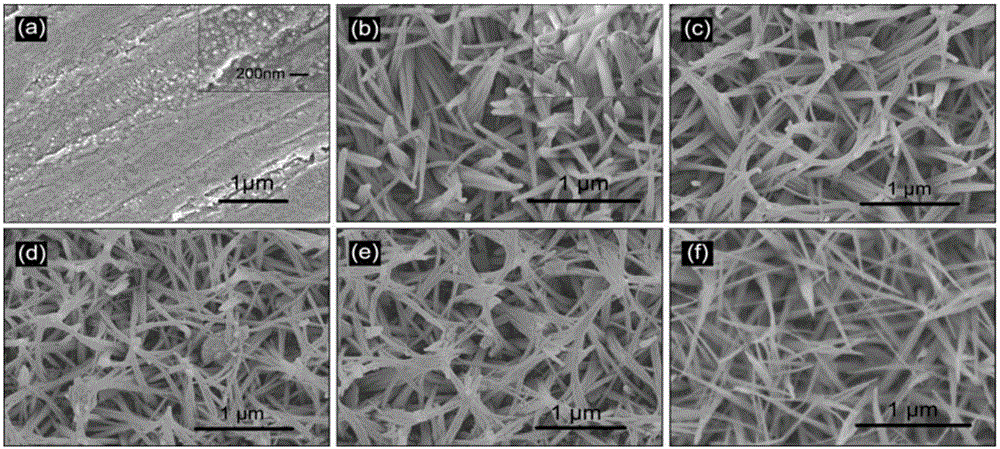

[0045] (3) After the above reaction is completed, the sample is taken out, rinsed with deionized water and absolute ethanol successively, and dried quickly with a hair dryer at a drying temperature of about 70°C. That is, a copper oxide micro-nano composite morphology with a one-dimensional line structure is obtained on the copper surface (morphology such as image 3 As shown in (b), the diffraction effect is as figure 2 (b)).

[0046] (4) Dissolve stearic acid solid powder in absolute ethanol, and ultrasonically oscillate until completely dissolved, and the concentration of stearic acid is 0.03mol / L. Place the red copper sheet after (3) obliquely in the ethanol solution of stearic acid for 15 minutes, remove the red copper she...

Embodiment 2

[0049] (1) Prepare an antiformin solution with a volume fraction VF of 40% as an oxidizing agent and stir evenly.

[0050] (2) Put the red copper sheet into the antiformin diluent at an angle, and the reaction time is 1 min at room temperature.

[0051] (3) After the above reaction is completed, the sample is taken out, rinsed with deionized water and absolute ethanol successively, and dried quickly with a hair dryer at a drying temperature of about 70°C. That is, a copper oxide micro-nano composite morphology with a three-dimensional network structure is obtained on the copper surface (morphology such as image 3 As shown in (c), the diffraction effect is as figure 2 (b)).

[0052] (4) Dissolve stearic acid solid powder in absolute ethanol, and ultrasonically oscillate until completely dissolved, and the concentration of stearic acid is 0.03mol / L. Place the oxidized copper sheet obliquely in the ethanol solution of stearic acid for 15 minutes, remove the copper sheet, was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com