Turning motion structure and multi-layer food baking tunnel furnace

A technology of moving structure and tunnel oven, which is applied in food oven, baking, food science, etc. It can solve the problems of high energy consumption, affecting food processing efficiency, and small size of baking tunnel oven.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

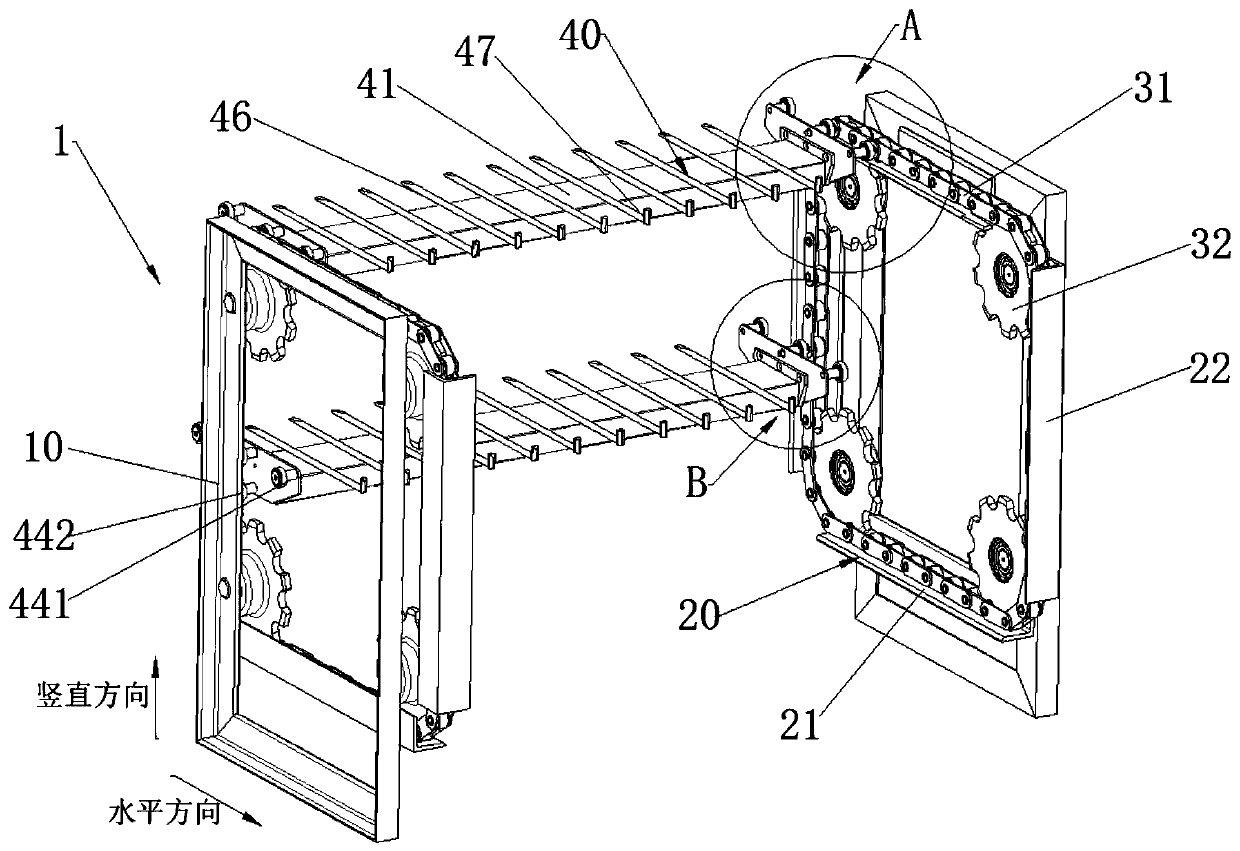

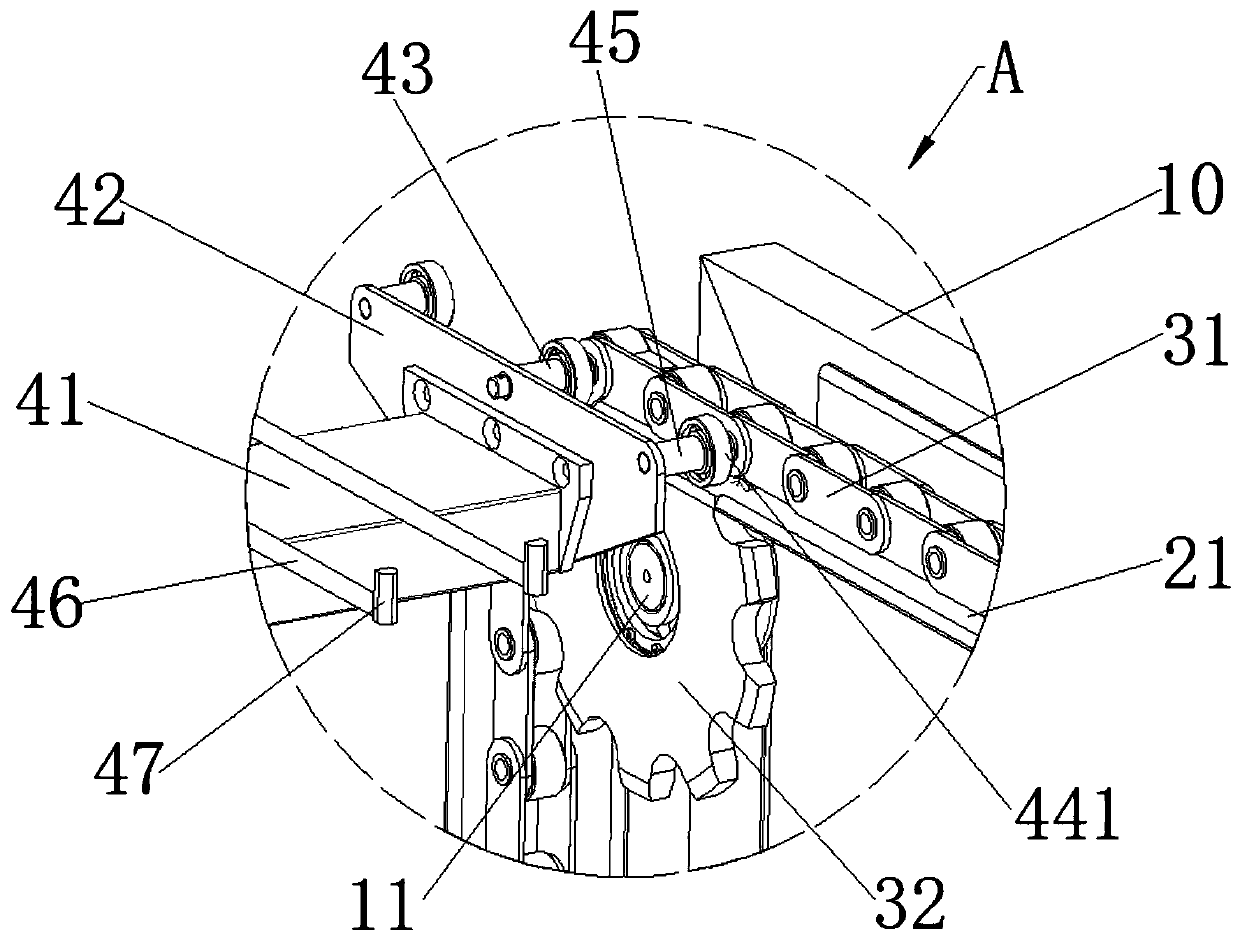

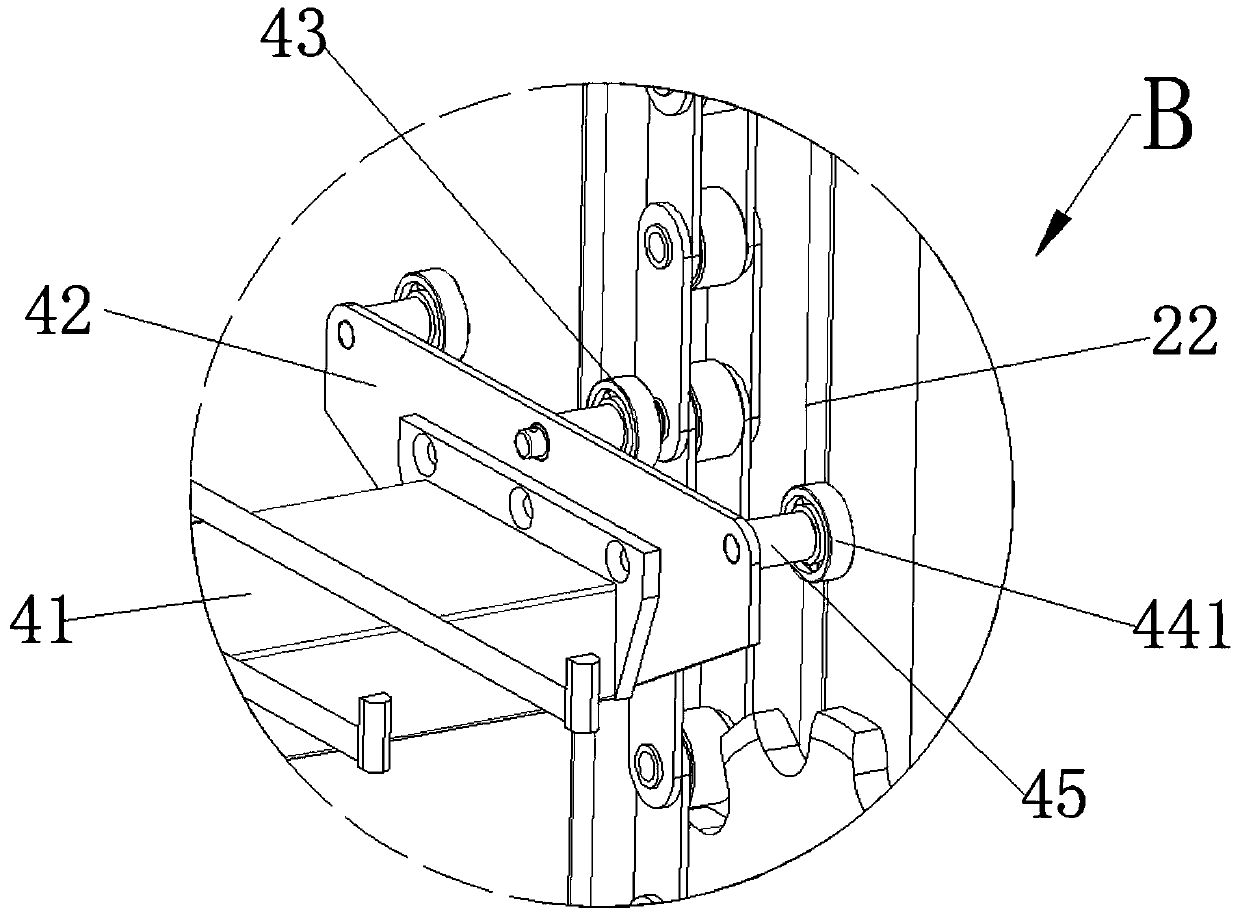

[0013] See Figure 1-4 As shown, the present invention provides a turning structure 1 , which includes a frame 10 , a guide rail 20 , a chain 31 , a bracket 40 and a sprocket 32 .

[0014] The two sets of frames 10 are vertically arranged opposite each other, the bracket 40 is located between the two sets of frames 10 , and the guide rails 20 , chains 31 and sprockets 32 are connected by the frames 10 .

[0015] The guide rail 20 is fixedly arranged on the frame 10 , and the guide rail 20 includes a horizontal guide rail 21 and a vertical guide rail 22 , so as to guide the movement of the bracket 40 in the horizontal direction and the vertical direction.

[0016] The sprocket 32 is rotatably connected with the rotating shaft 11 fixedly arranged on the frame 10. A plurality of sprockets 32 are arranged along the horizontal direction and the vertical direction of the frame 10 respectively. The chain 31 is connected with the sprocket 32 by transmission. Drive the chain 31 ...

Embodiment 2

[0023] refer to Figure 4 As shown, this embodiment provides a multi-layered food baking tunnel oven, which includes the turning structure 1 provided in Embodiment 1, and also includes a conveyor belt 2 , an output belt 3 , a hydraulic cylinder 4 and a fixed plate 5 .

[0024] The baking chamber 6 is formed by the insulation board 61, the turning motion structure 1, the hydraulic cylinder 4 and the fixed plate 5 are accommodated in the baking chamber 6, and the temperature insulation board 62 is arranged in the baking chamber 6, and the temperature insulation board 62 is arranged along the horizontal direction, and the baking chamber 6 is divided into multi-layer passages 63 in the vertical direction by the heat insulating plate 62, and the baking pan is driven by the turning motion structure 1 to carry out horizontal or vertical direction in the multi-layer passage 63. Wherein, those skilled in the art can select the setting positions of the frame, the sprocket and the chain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com