Method and device for controlling a polyphase electrical machine

A multi-phase motor and control circuit technology, applied in the direction of output power conversion device, control system, motor control, etc., can solve the problem of increasing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

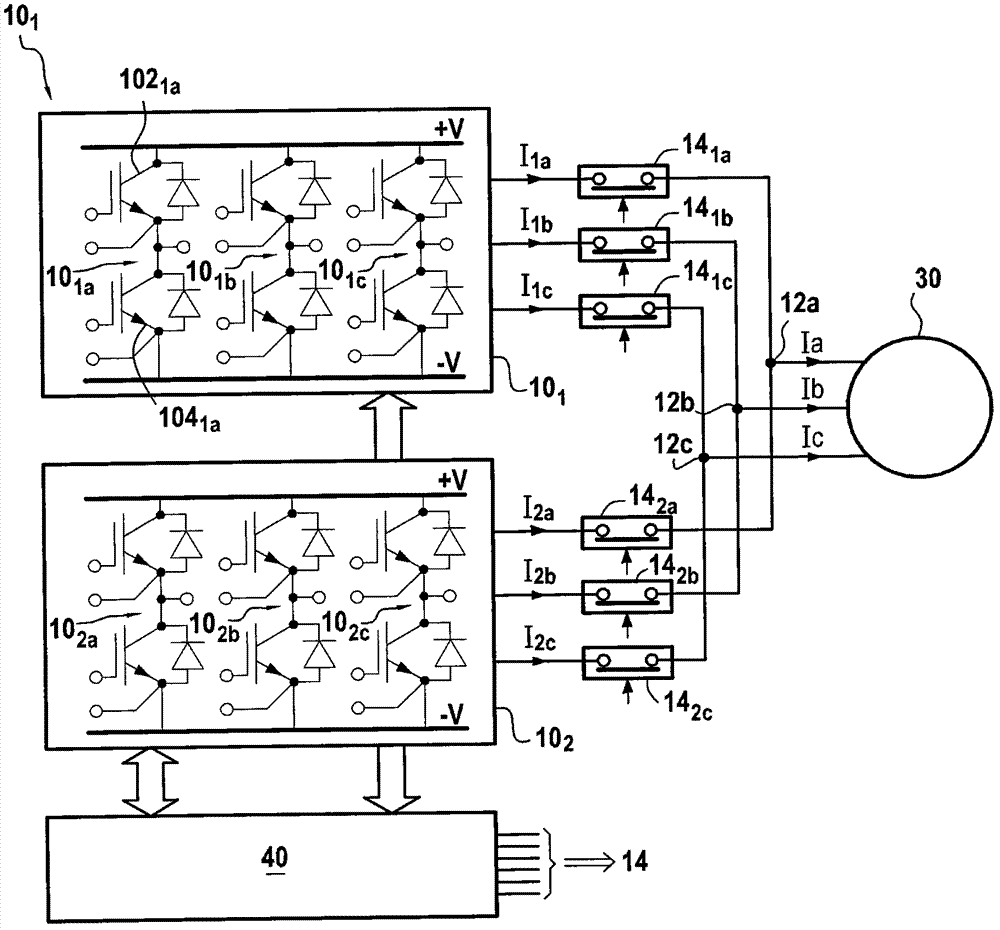

[0037] image 3 An embodiment of the control device of the present invention is shown, the control device shown is through two three-phase inverters 10 connected in parallel 1 and 10 2 To control the three-phase motor 30.

[0038] As mentioned above, the invention is particularly applicable in the field of aviation. Electric machine 30 may be a system for starting an aircraft engine (eg, a turbine engine). An electric motor is mechanically coupled to the shaft of the engine to drive the engine at start-up, for which purpose the electric motor is controlled by means of an electric motor. The electric machine 30 may also be a machine used to start an auxiliary power unit (APU) or to start an actuator.

[0039] Inverter 10 1 with three branches 10 1a , 10 1b and 10 1c , respectively through the control device output 12 a , 12 b and 12 c Deliver AC I 1a , I 1b , and I 1c . Similarly, the inverter 10 2 with three branches 10 2a , 10 2b and 10 2c , also respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com