Thermal resistance analysis method

An analysis method and thermal resistance technology, applied in the field of device thermal characteristics measurement, can solve the problems of serious air convection, increase the volume of static air test box, and large volume, achieve a wide range of applications, shorten thermal resistance analysis time, and ensure accurate degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

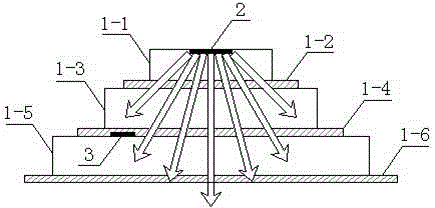

[0030] This embodiment discloses a thermal resistance analysis method. The test object of this embodiment is a high-power device 1 including a six-layer structure, which is respectively recorded as the first layer 1-1, the second layer 1-2, and the third layer. 1-3, the fourth floor 1-4, the fifth floor 1-5 and the sixth floor 1-6, such as figure 1 The material parameters are shown in Table 1.

[0031] The parameters of the six-layer structure of the high-power device in Table 1 Example 1

[0032] A=1mm 2 λ[W / m.k] ρ[g / cm 3 ] c[J / gK] d[mm] R[K / W] C[J / K] 1-1 148 2.33 0.7 0.2 1.351 3.262×10 -4

[0033] 1-2 1.6 3.8 0.48 0.05 31.25 9.12×10 -5 1-3 350 8.89 0.385 1 2.85714 3.423×10 -3 1-4 0.73 2.8 1 0.03 41.0959 8.4×10 -5 1-5 180 27 0.963 1 5.5556 0.026 1-6 0.18 1.18 1.424 0.05 277.78 8.4016×10 -5

[0034] The heat source 2 of the high-power device 1 is located at the first layer 1...

Embodiment 2

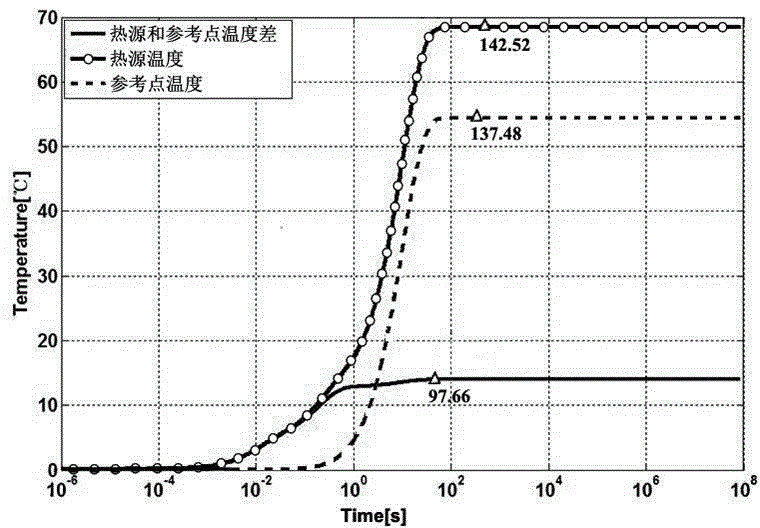

[0040] This embodiment discloses a thermal resistance analysis method in which the temperature of the heat source and the reference point are both stable. Similar to Embodiment 1, the test object of this embodiment is also a high-power device 1 including a six-layer structure, which is respectively recorded as the first layer 1-1, the second layer 1-2, the third layer 1-3, the fourth layer 1-4, the fifth layer 1-5 and the sixth layer 1-6, different from embodiment 1, the first layer of this embodiment The material parameters of the six layers are different from those in Example 1, and their material parameters are shown in Table 3.

[0041] Table 3 The parameters of the six-layer structure of the high-power device in Example 2

[0042] A=1mm 2 λ[W / m.k] ρ[g / cm 3 ] c[J / gK] d[mm] R[K / W] C[J / K] 1 148 2.33 0.7 0.2 1.351 3.262×10 -4 2 1.6 3.8 0.48 0.05 31.25 9.12×10 -5 3 350 8.89 0.385 1 2.85714 3.423×10 -3 4 0.73 2.8 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com