Fuel treating system and natural gas well-washing and wax-cleaning equipment

A technology of fuel processing and natural gas, applied in mechanical equipment, equipment discharged from pressure vessels, cleaning appliances, etc., can solve the problems of equipment cost price increase, volume increase, and upload quality increase, so as to facilitate layout and transportation , cost reduction, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

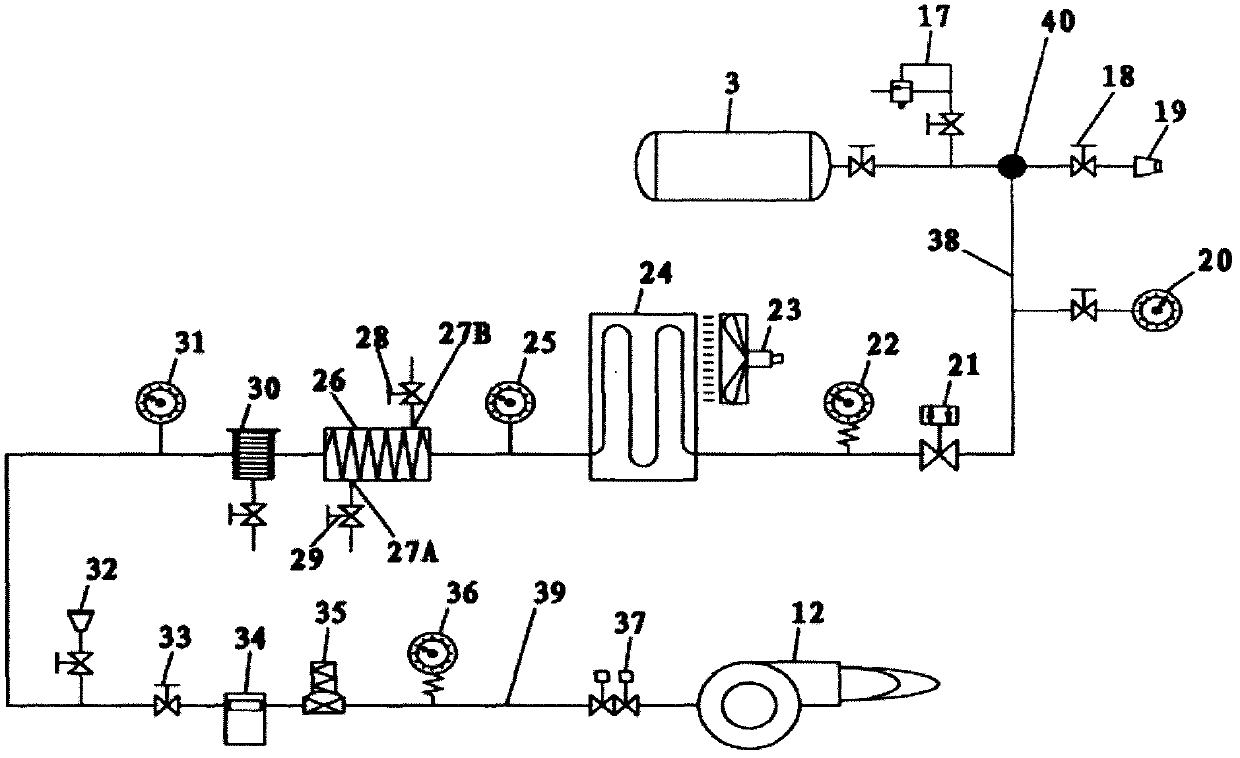

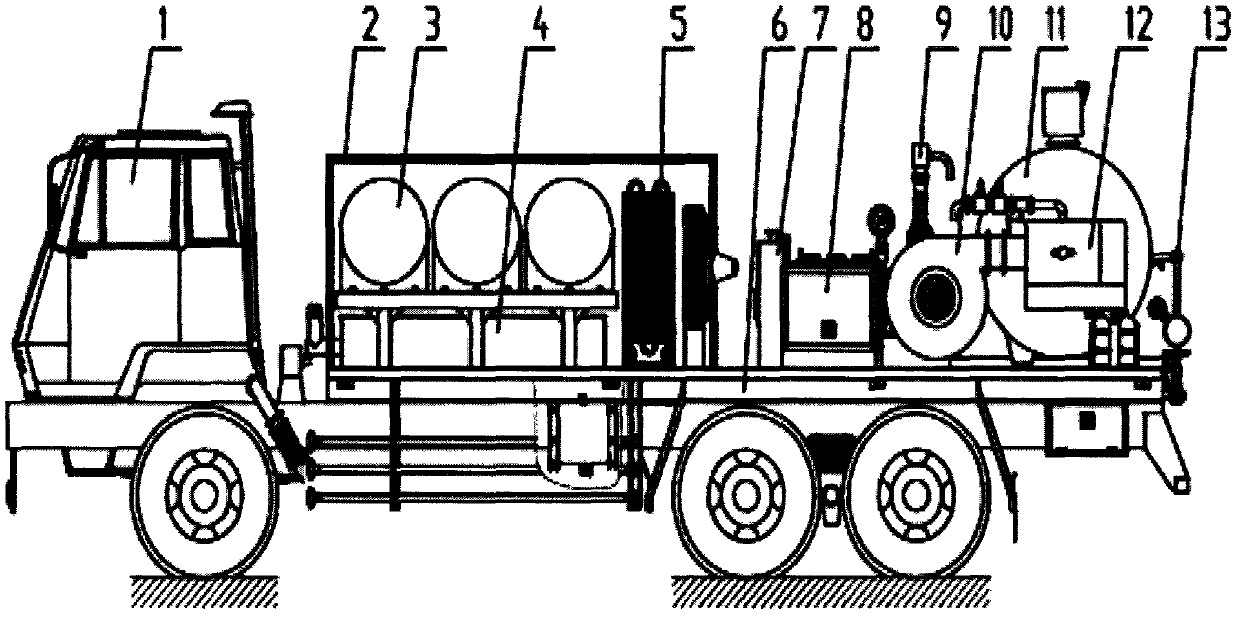

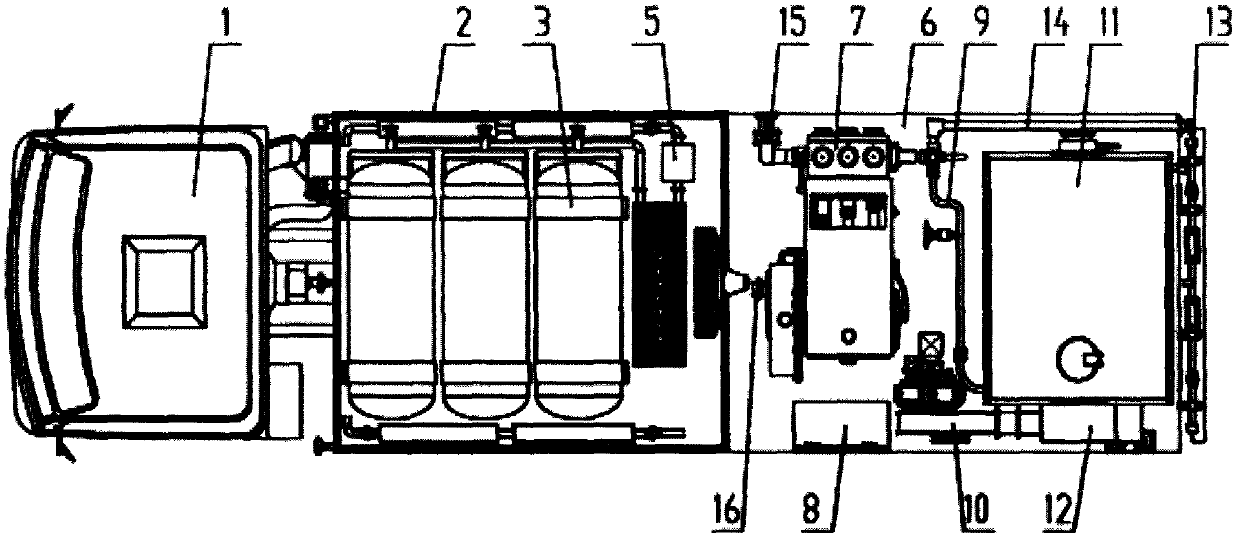

[0027] Such as figure 1 As shown, the fuel processing system provided by the present invention includes a fuel pipeline with a predetermined length, which is divided into a gasification heat exchange pipeline 38 and a decompression treatment pipeline 39 from the beginning to the end along the flow direction of the fuel; The beginning of the gasification heat exchange pipeline 38 communicates with the external fuel storage device 3 , and the end of the decompression treatment pipeline 39 communicates with the external combustion device 12 .

[0028] Along the flow direction of the fuel, an emergency cut-off valve 21 , a gasifier 24 and a heat exchanger 26 are arranged in series on the gasification heat exchange pipeline 38 . A safety valve 17 , a tee 40 and a pressure gauge 20 are arranged in sequence between the fuel storage device 3 and the emergency cut-off valve 21 . The three ports of the tee 40 communicate with the fuel storage device 3 , the emergency cut-off valve 21 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com