Low-concentration viscose wastewater and waste gas treatment system

A viscose fiber and waste gas treatment technology, which is applied in gas treatment, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of complex composition and poor effect of low-concentration waste gas, and improve the removal efficiency of waste gas And the removal rate of pollutants, prolonging the reaction time, reducing the effect of explosion risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

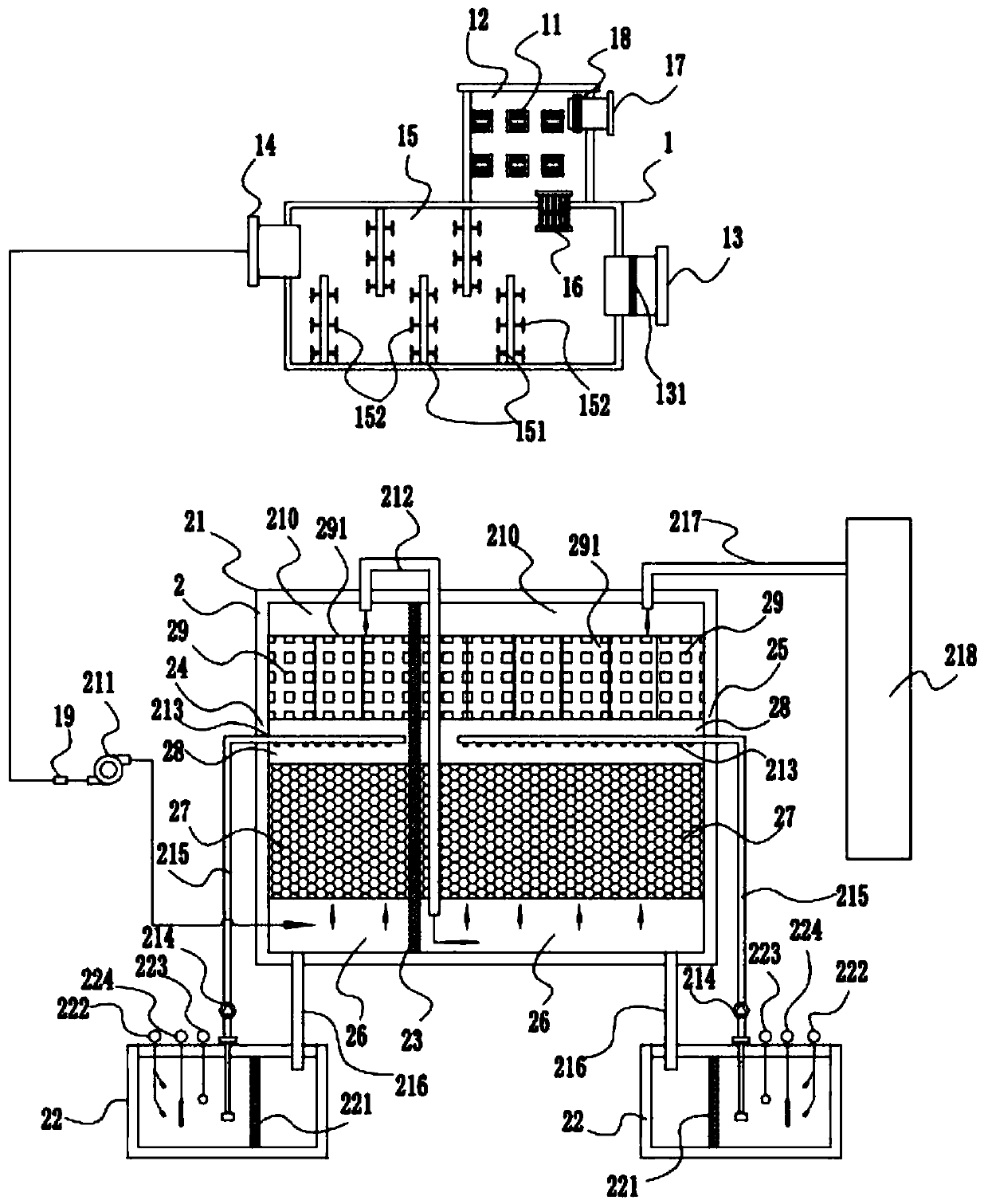

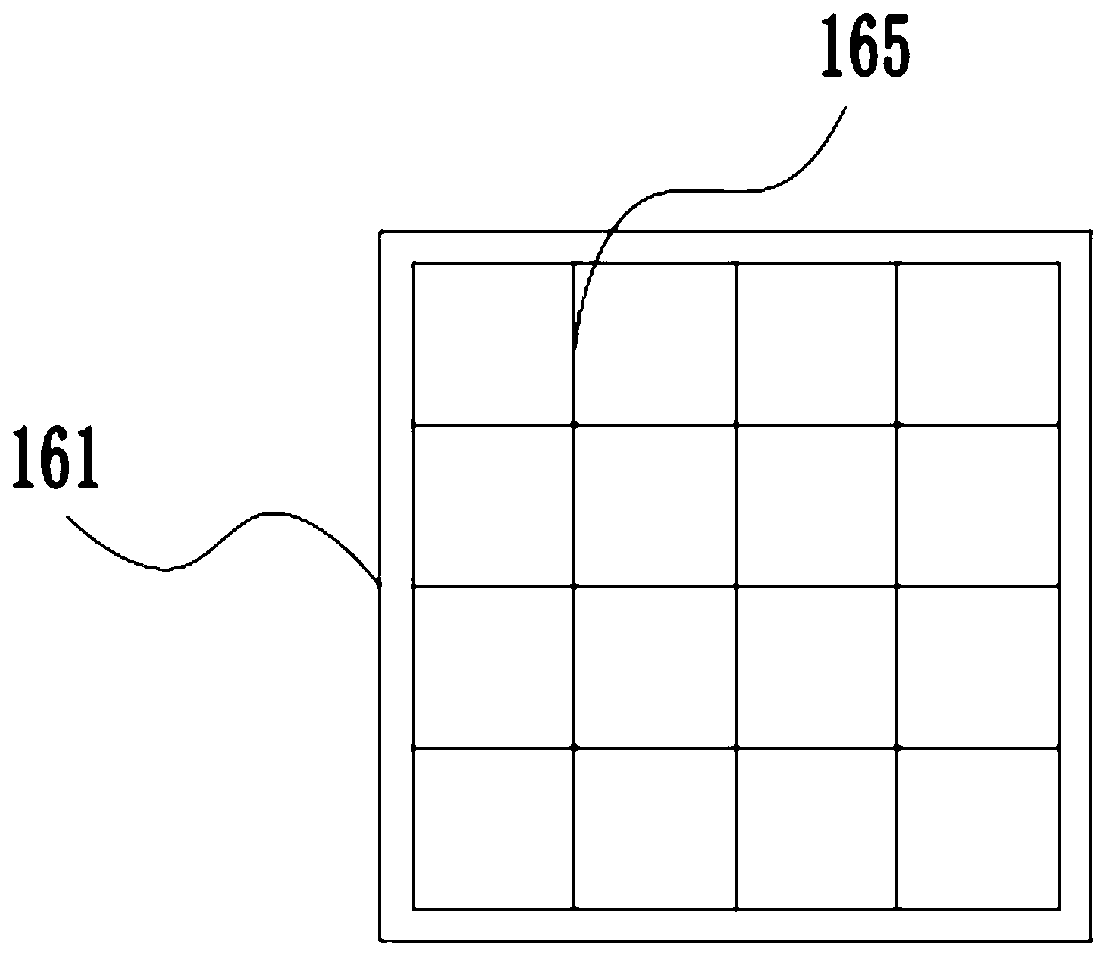

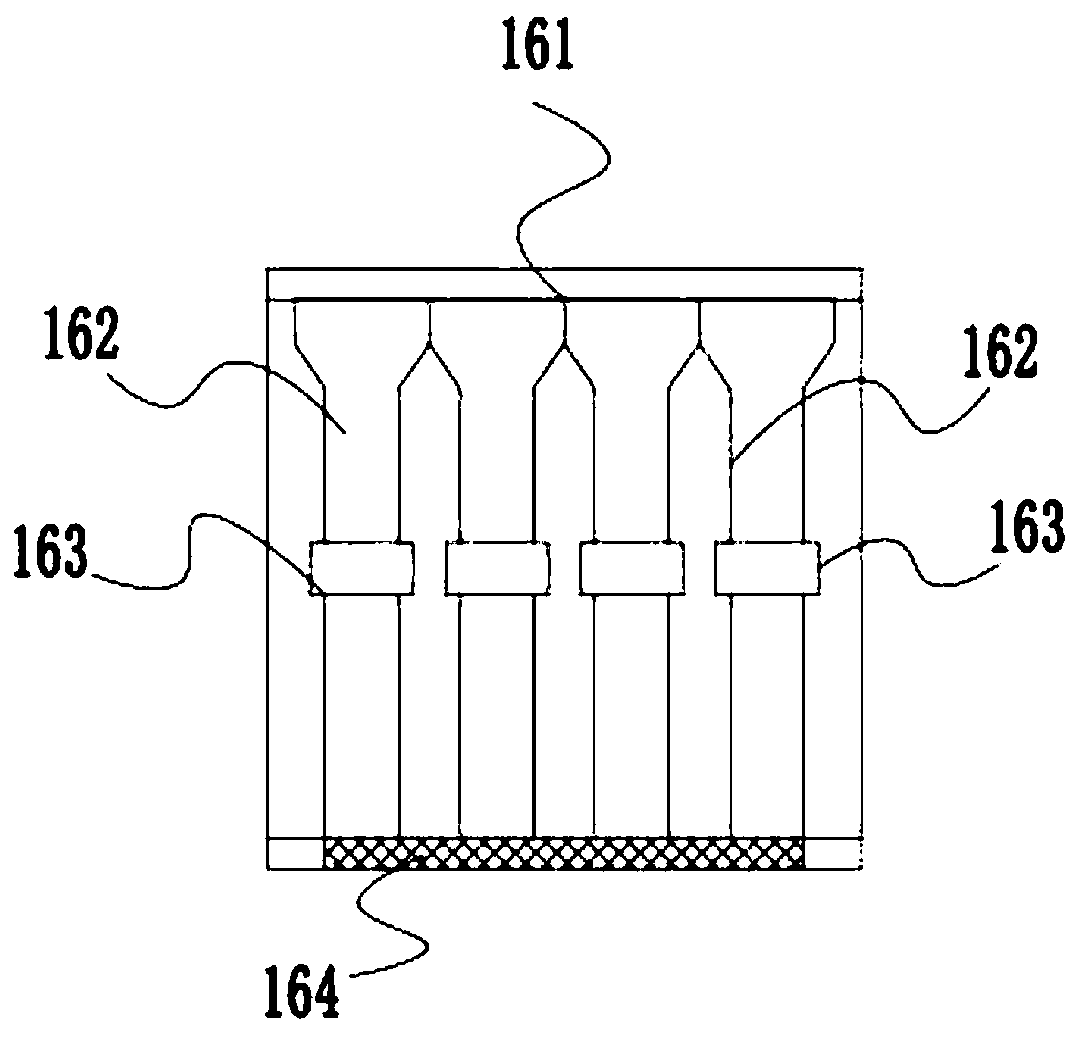

[0038] Such as figure 1 As shown, a low-concentration viscose fiber wastewater and waste gas treatment system is composed of a plasma deodorization device 1 and a biological deodorization device 2 connected in series. The plasma deodorization device 1 includes a plasma generation chamber 12 provided with a plasma tube assembly 11. Have the plasma reaction chamber 15 of air inlet 13 and air outlet 14, as figure 1 As shown, the air inlet 13 is provided with an activated carbon electrostatic adsorption filter 131. Compared with a simple activated carbon filter, the activated carbon electrostatic adsorption filter 131 can absorb and intercept tiny dust in the airflow, effectively reducing the dust in the plasma reaction chamber 15. concentration, thereby reducing the risk of explosion. Such as figure 1 As shown, the plasma reaction chamber 15 is staggered with partition plates 151, and a plurality of disturbance small fans 152 are arranged on both sides of the partition plate 15...

Embodiment 2

[0049] This embodiment is basically the same as Embodiment 1, except that the biological filler in the biological filler layer in this embodiment includes: 8% soft magnetic powder, 6% titanate coupling agent, 6% S- Carboxyethylisothiourea betaine, 4% zinc carbonate, 1.5% dispersant, the balance is PP pellets. The titanate coupling agent can significantly improve the dispersibility of the soft magnetic powder and enhance its affinity. The soft magnetic powder is made of ferric oxide or ferric oxide with a particle size of 100-200nm, which can promote microbial activity, thereby Obtain better purification and deodorization effects; S-carboxyethylisothiourea betaine and zinc carbonate can be used as a combined catalyst to assist microorganisms in decomposing odorous gases such as carbon disulfide; polyethylene wax can be selected as the dispersant.

[0050] Described microbial filler ball, the preparation method of described microbial filler ball comprises the following steps:

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com