Differential pressure mining dust removing agent automatic adding device

A technology of automatic addition and dedusting agent, which is applied in safety devices, dust prevention, mining equipment, etc., can solve the problems of complex structure, high energy consumption, high failure rate, etc., and achieve the goal of reducing dust concentration, precise adjustment of addition amount, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

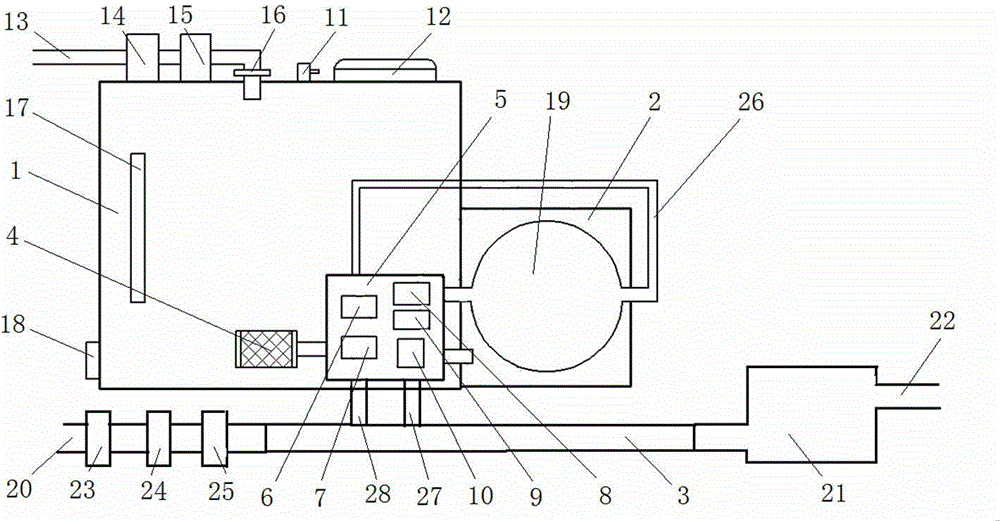

[0014] Differential pressure mine dust suppressant automatic adding device, including liquid storage tank 1, dosing tank 2 and jet negative pressure tube 3;

[0015] The bottom of the liquid storage tank 1 is provided with a filtrate net 4 and a valve body integration box 5 connected to the filtrate net 4. The valve body integration box 5 is equipped with a one-way throttle valve 6, a back pressure valve 7, a quantitative valve 8, and a flow meter. 9. The water inlet control valve 10, the top of the liquid storage tank 1 is provided with an exhaust valve 11, a liquid filling port 12, a pressure air pipe 13 connected with the downhole air pressure port, and the pressure air pipe 13 is sequentially provided with a pressure reducing valve 14 and a pressure relief valve. Table 15, one-way valve 16, the side wall of the liquid storage tank 1 is provided with a liquid level gauge 17, and the bottom of the side wall of the liquid storage tank 1 is provided with a liquid discharge port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com