Patents

Literature

326results about How to "Implement automatic addition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

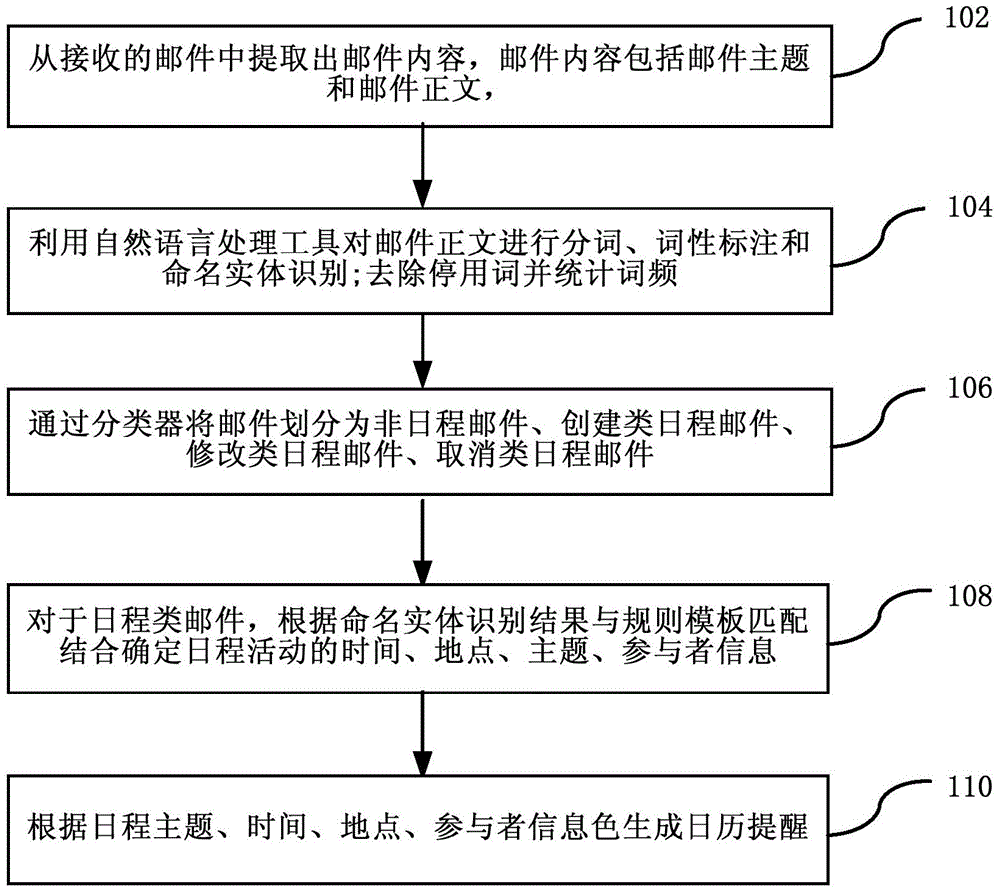

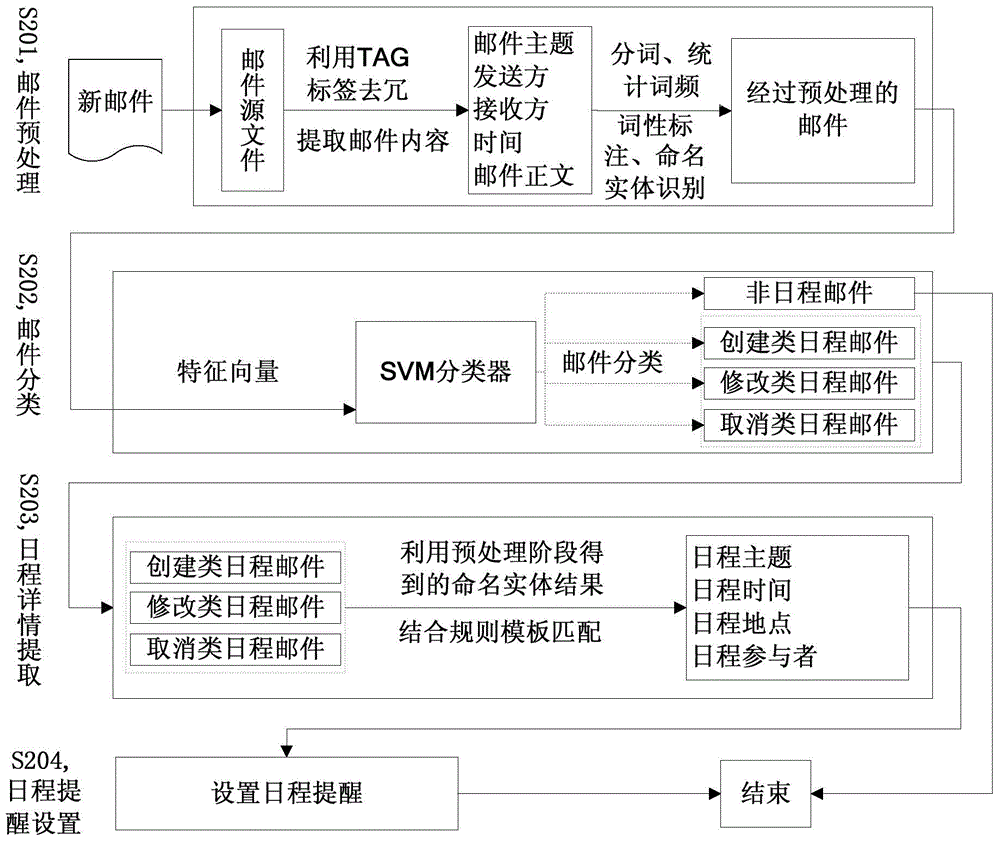

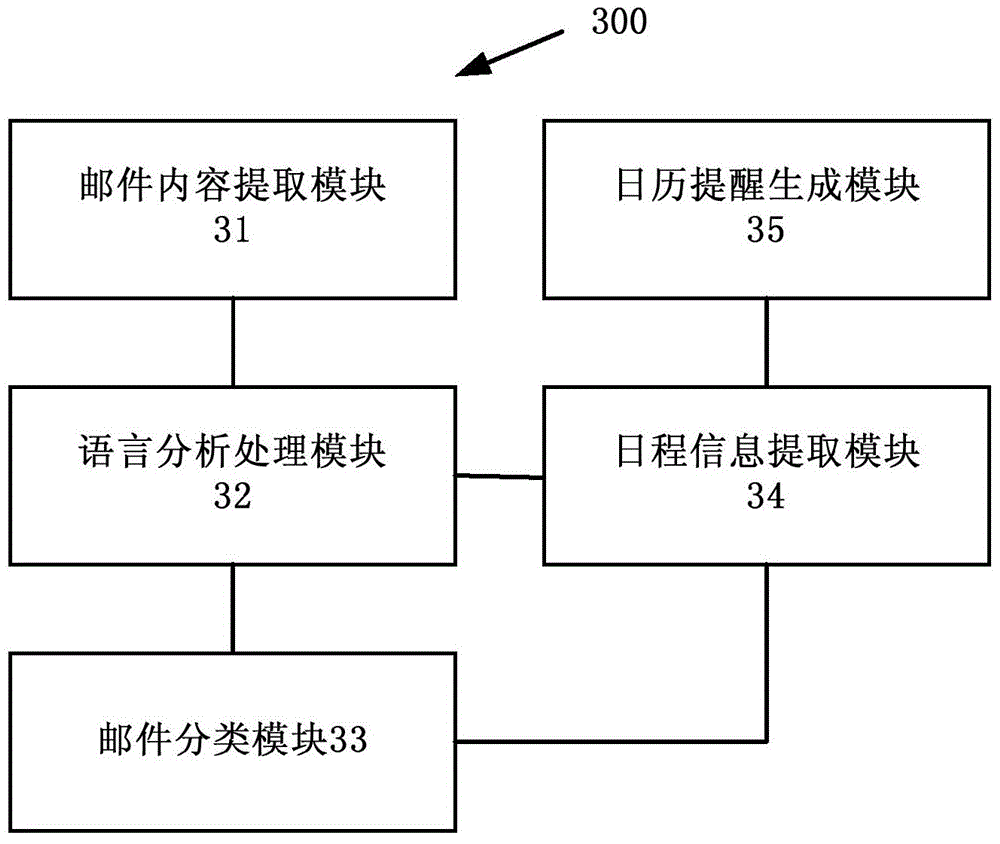

Method and device for generating calendar reminding

The invention discloses a method and device for generating calendar reminding, and relates to the technical field of the mobile internet. The method comprises the steps that through a natural language processing technology and a classifier, whether a mail is a schedule mail or not is automatically judged, then schedule details are automatically extracted from an unstructured mail text, and calendar reminding is finally set automatically. The complexity of a user for using a mail system is lowered, the use experience of the user is improved, meanwhile, an electronic calendar product can automatically extract schedule information from the mail through the technology, a schedule content source is enriched, and the user utilization rate and activity degree of the product are improved.

Owner:CHINA TELECOM CORP LTD

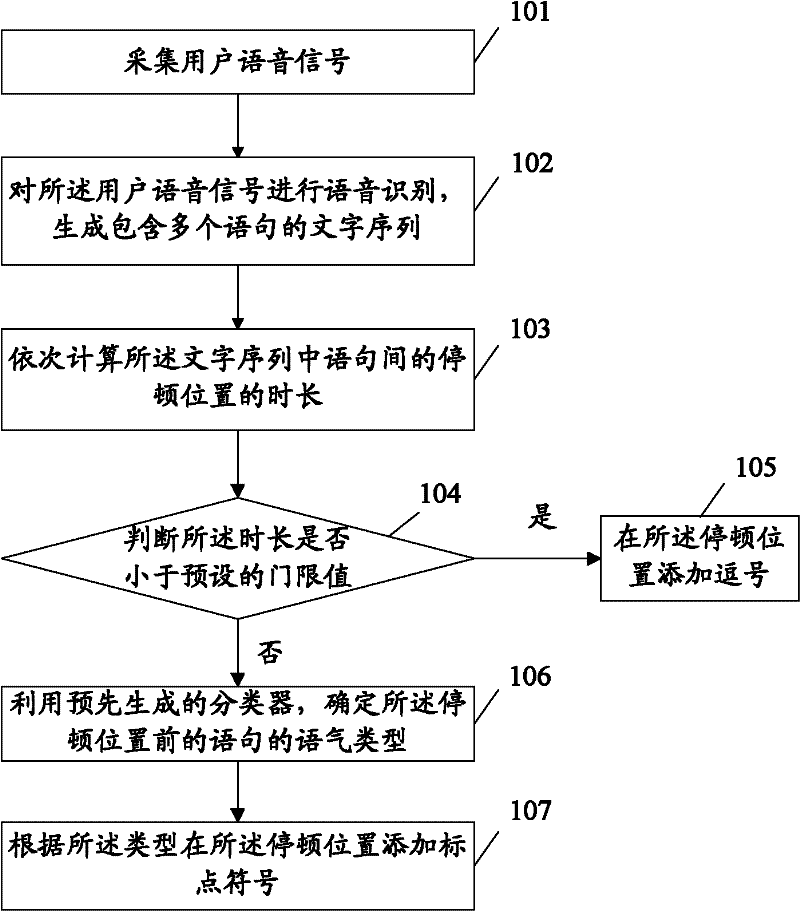

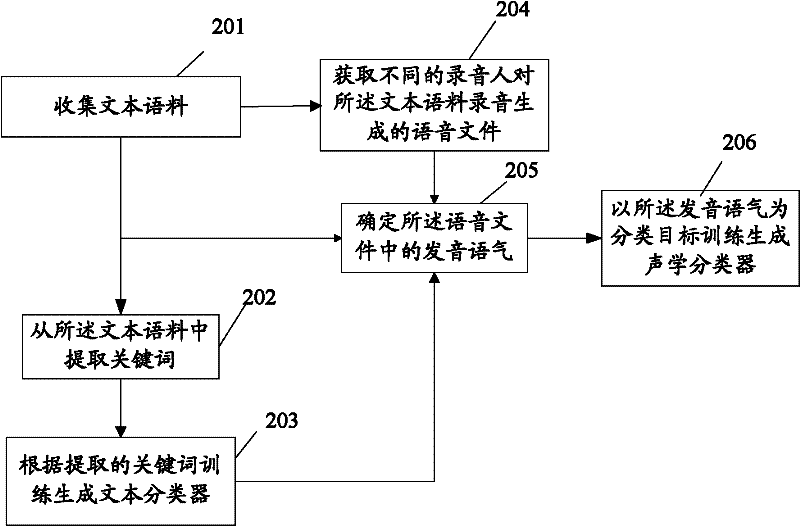

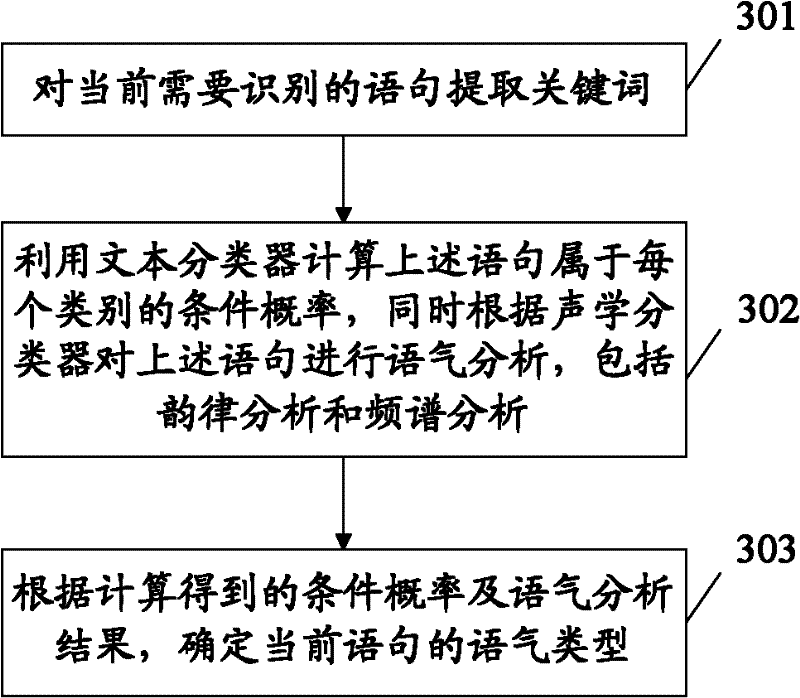

Method and system for realizing automatic addition of punctuation marks in speech recognition

ActiveCN102231278AImplement automatic additionAutomatically add simple and efficientSpeech recognitionSpeech soundComputer science

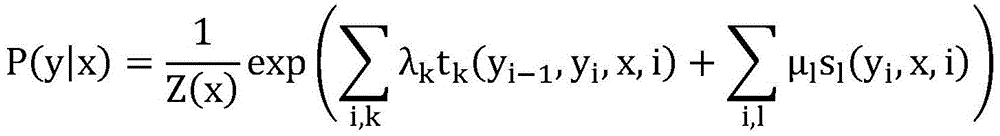

The invention relates to the technical field of speech recognition and discloses a method and system for realizing automatic addition of punctuation marks in the speech recognition. The method comprises the steps of: collecting user speech signals; carrying out the speech recognition on the user speech signals so as to generate a character sequence containing a plurality of sentences; sequentially calculating duration of pause positions between the sentences in the character sequence; if the duration is less than a preset threshold value, adding commas at the pause positions; and if the duration is greater than or equal to the preset threshold value, confirming the mood types of the sentences in front of the pause positions by utilizing a pre-generated classifier and adding punctuation marks at the pause positions according to the types. By utilizing the method and system which are provided by the invention, the automatic addition of the punctuation marks can be simply and conveniently realized and the accuracy and the flexibility of adding the punctuation marks are increased.

Owner:IFLYTEK CO LTD

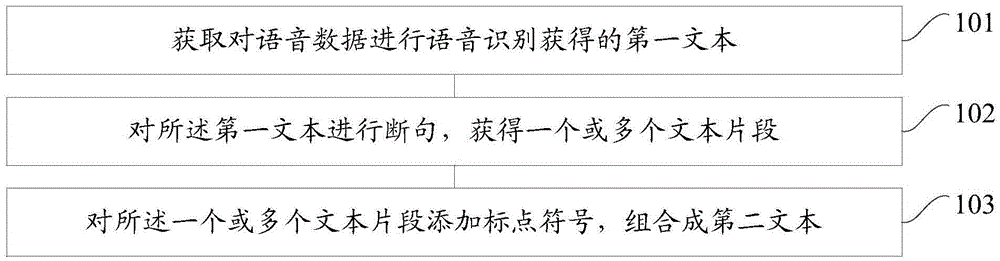

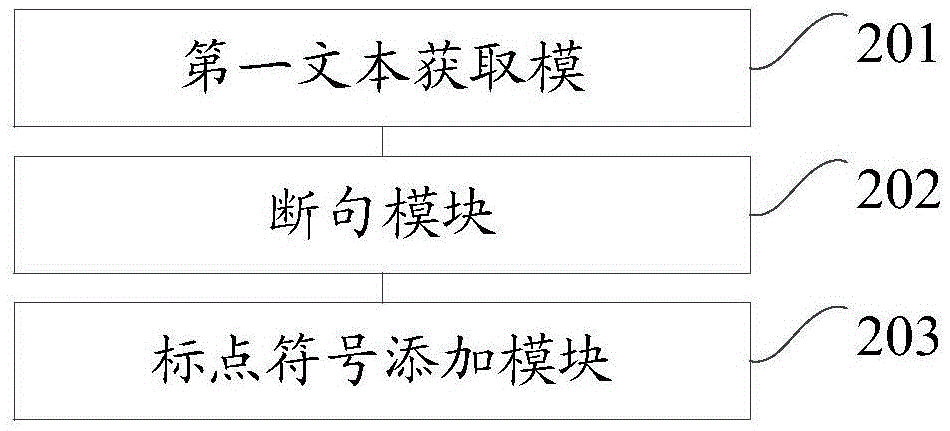

Text processing method and device based on voice identification

InactiveCN105609107AEasy to solveImplement automatic additionNatural language data processingSpeech recognitionSpeech identificationSpeech sound

The embodiment of the invention provides a text processing method and a device based on voice identification. The method comprises a step of obtaining a first text which is obtained by the voice identification of voice data, a step of punctuating the first text, and obtaining one or more text segments, and a step of adding punctuations to the one or more text segments, and forming a second text through combination. According to the embodiment of the invention, the automatic adding of the punctuations is realized, the manual positioning and punctuation adding of a user are avoided, and the convenience of voice input is improved greatly.

Owner:BEIJING QIHOO TECH CO LTD +1

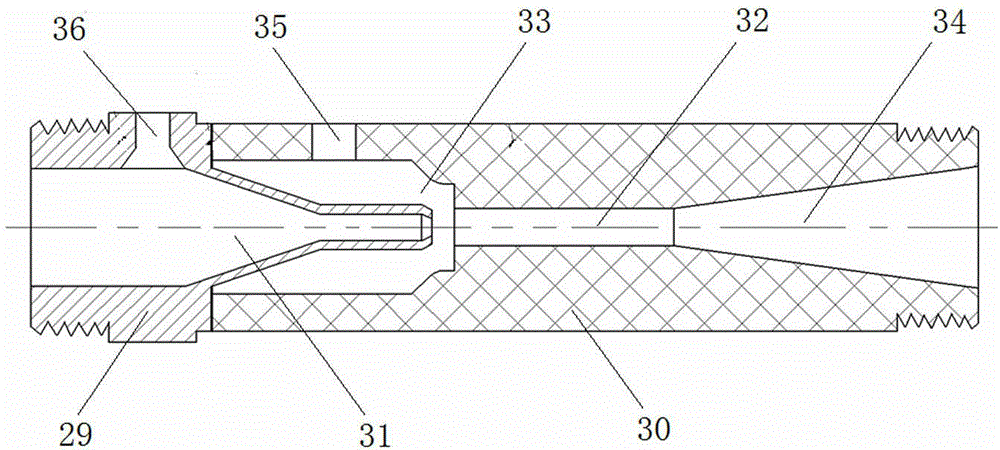

Automatic detergent feeding system

ActiveCN102041664APrevent backflowReduce pollutionOther washing machinesTextiles and paperWater flowInlet valve

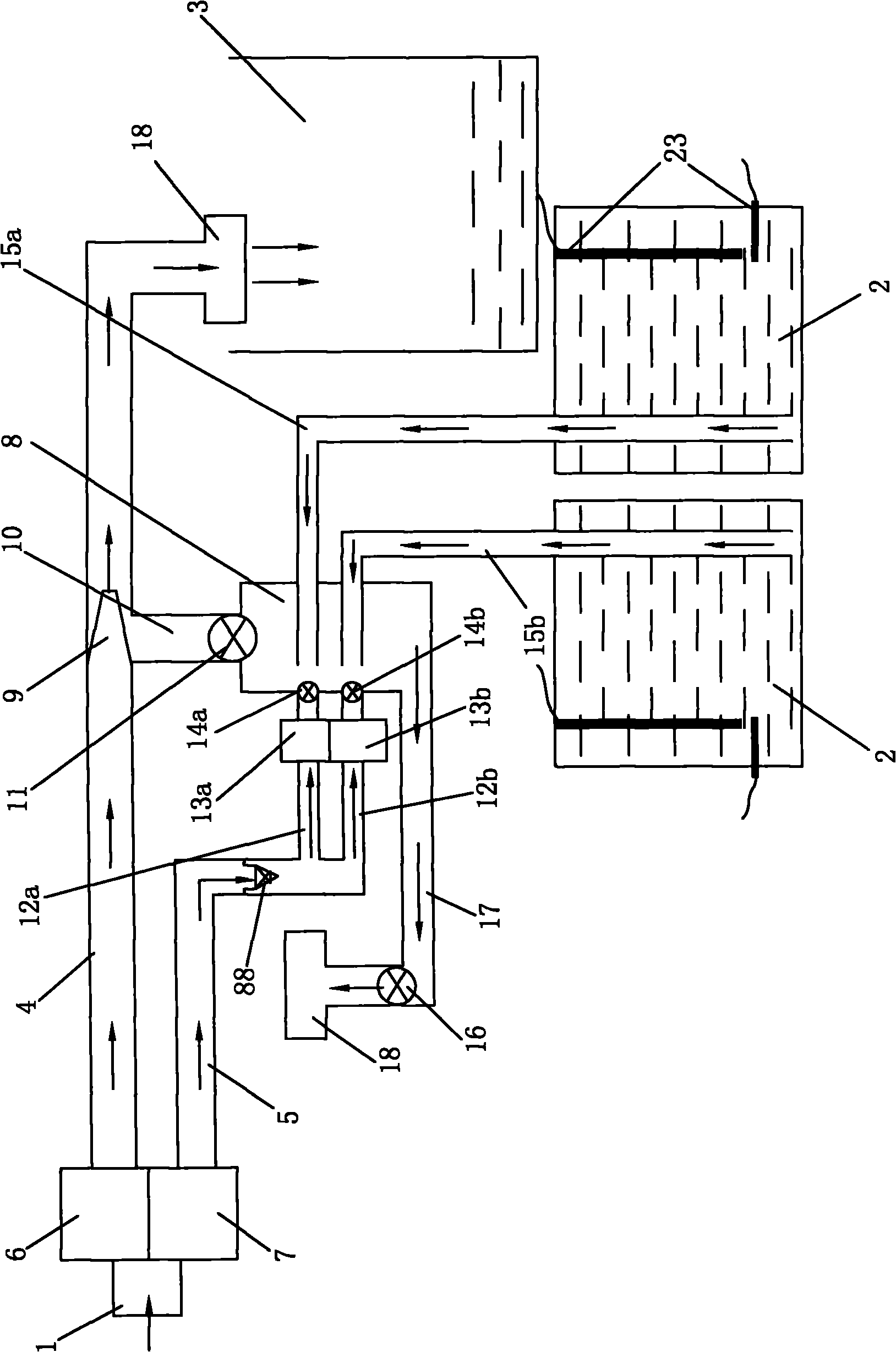

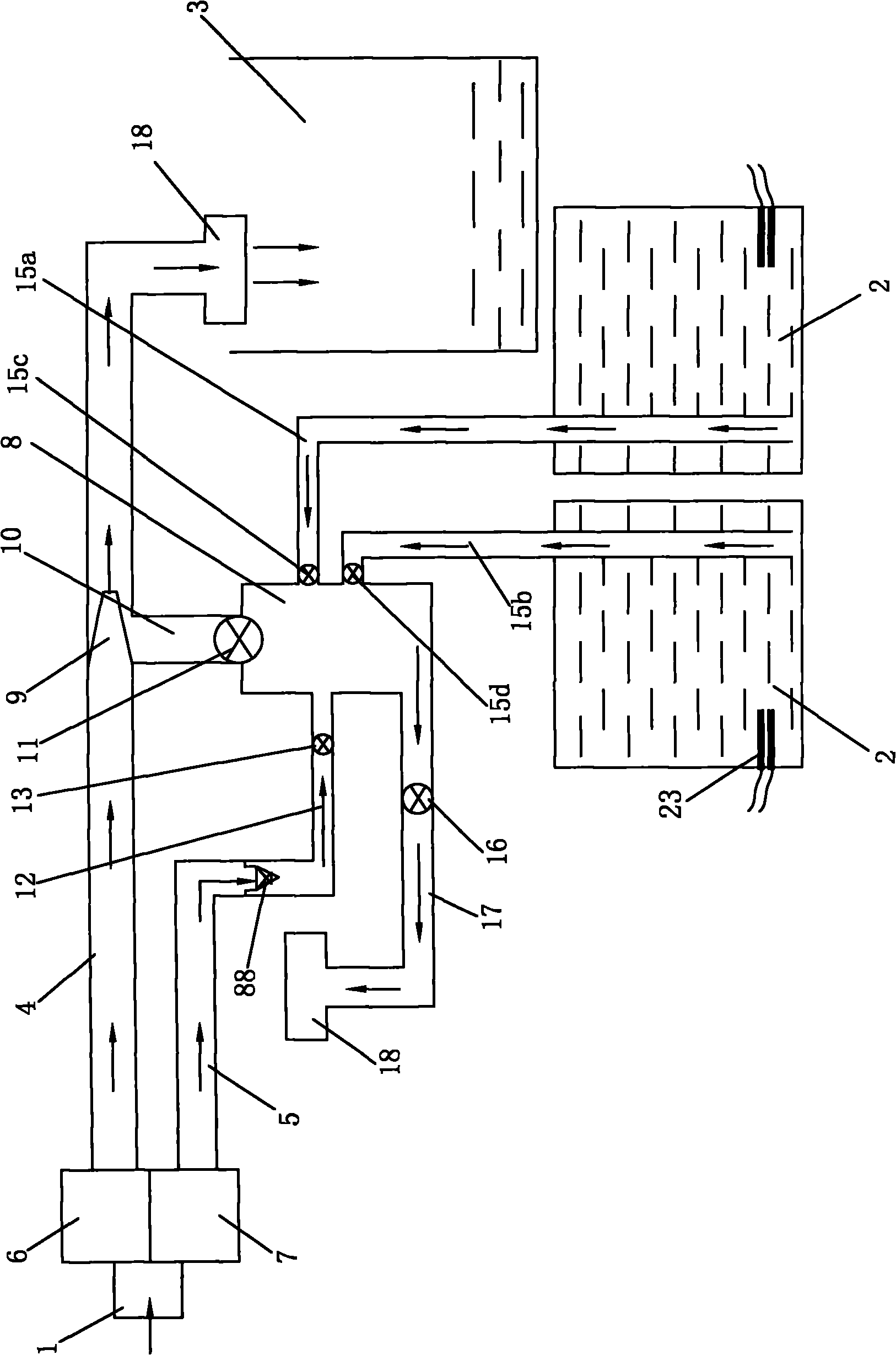

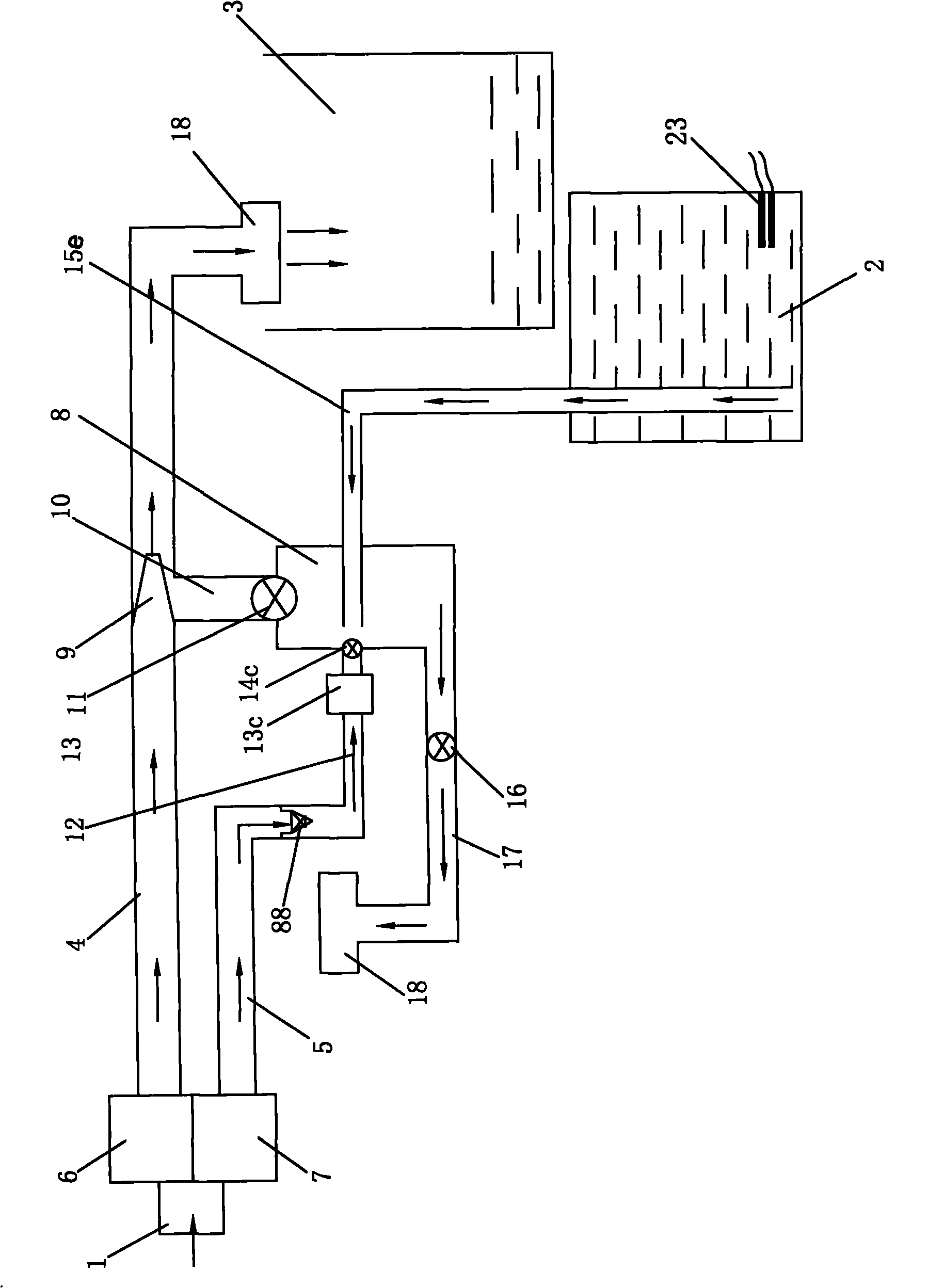

The invention discloses an automatic detergent feeding system, which is arranged between a washing drum and a water inlet of a washing machine. The automatic feeding system comprises a main water inlet passage, a cleaning water passage, a detergent container and a constant volume container, wherein the main water inlet passage is provided with a venturi pipe capable of generating negative pressure when water flows, the rear side of the outlet of the venturi pipe is provided with a bypass branch pipe for extracting the negative pressure, the bypass branch pipe is communicated with the constant volume container, the cleaning water passage and the detergent container are communicated with the constant volume container respectively, the constant volume container is communicated with the washing drum through a water outlet pipeline, and a one-way valve for preventing a detergent from reflowing to the water inlet is also arranged in the cleaning water passage; and a main water inlet valve is arranged between the main water inlet passage and the water inlet, a cleaning water valve is arranged between the cleaning water passage and the water inlet, a cleaning control valve is arranged at the connected position of the cleaning water passage and the constant volume container, a closing control valve for closing a connected port is arranged at the connected port of the constant volume container and the bypass branch pipe, and the water outlet pipeline is provided with a water outlet control valve. The automatic feeding system has simple structure and improves the clothes washing efficiency.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

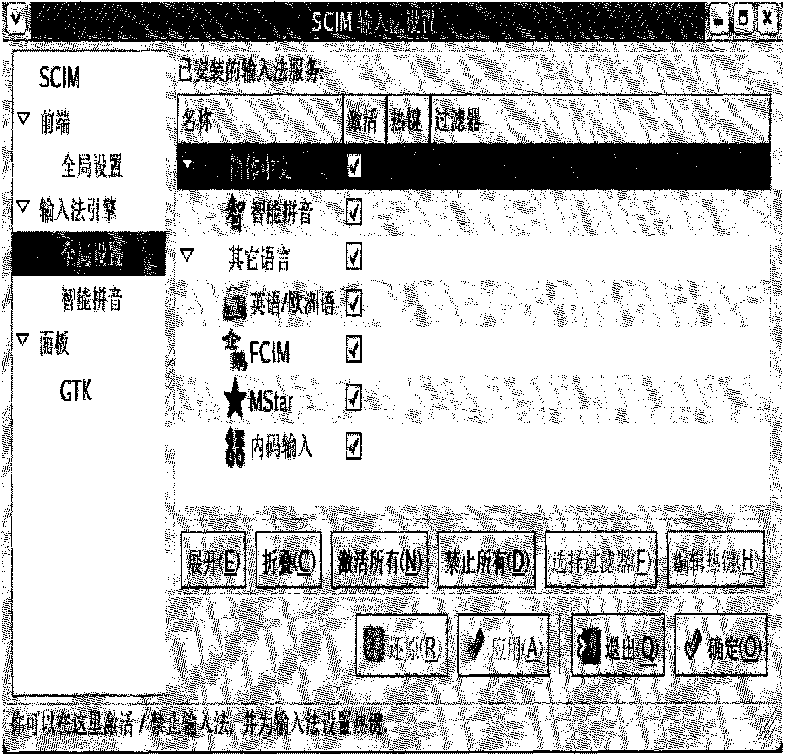

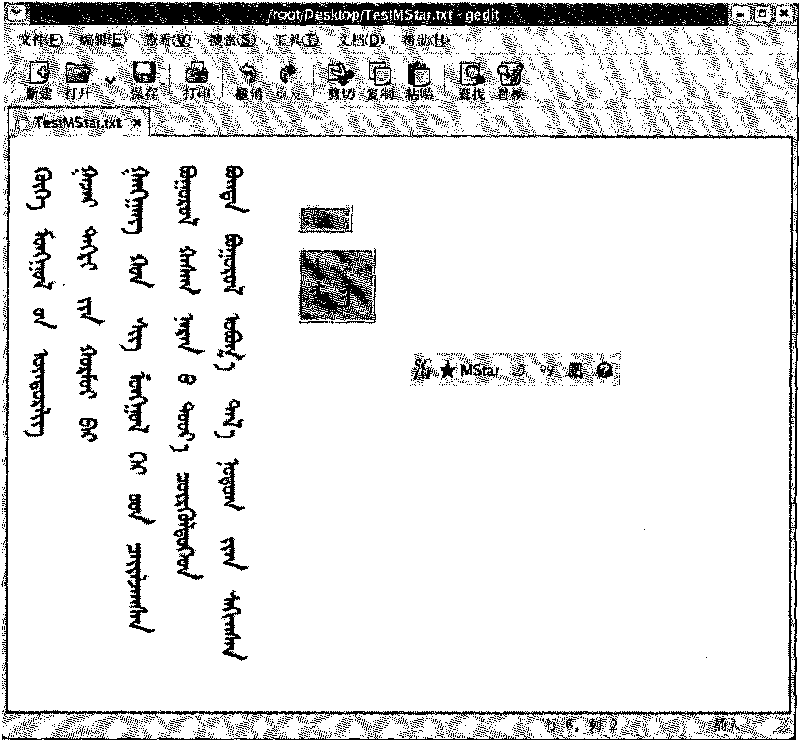

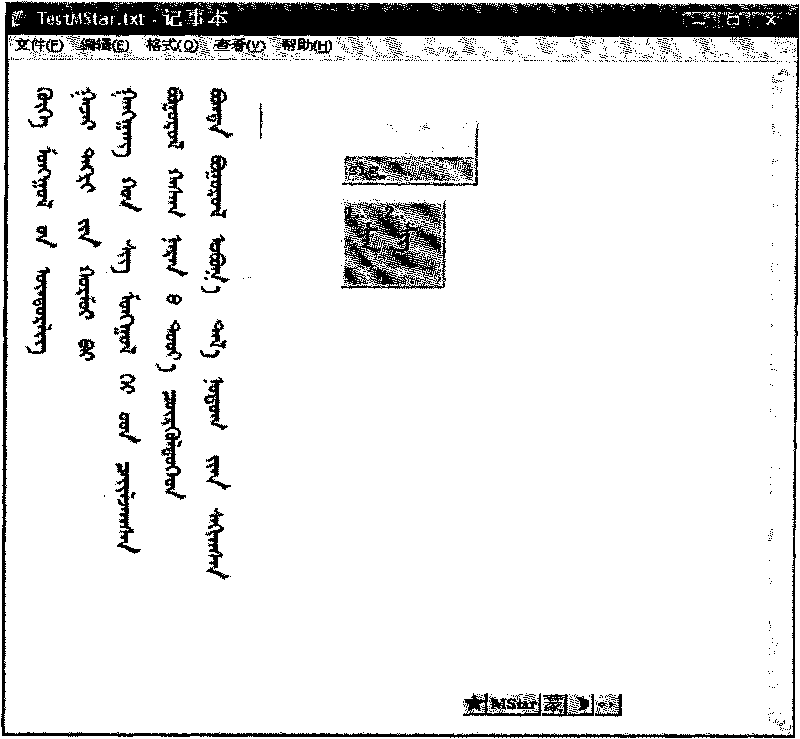

Cross-platform Mongolian display and intelligent input method based on Unicode

InactiveCN101694603AImplement automatic additionControl automatic additionSpecial data processing applicationsInput/output processes for data processingOperational systemProcess module

The invention relates to a method for displaying Mongolian on a GNOME desktop system platform of an LINUX system. The method comprises steps of building a Mongolian processing system engine in a Pango system processing word language in the GNOME desktop system, registering a name of the Mongolian processing system to the Pango system executing word langue processing, forming an interface between the Mongolian processing system engine and a word langue processing module of an operation system, generating a Mongolian processing module based on rules and structures of an Open Type font in the Mongolian processing system engine, constructing an font section engine to select and replace the Open Type Mongolian font, and finally obtaining correct Mongolian display results after font selecting replacement. Mongolian display and intelligent input thereof on the basis of the Unicode in the Linux operation system are realized by the method, and the Mongolian display and the intelligent input method thereof can be used together with Chinese or other language input methods which are loaded and can not affect original functions and applications thereof.

Owner:MINZU UNIVERSITY OF CHINA

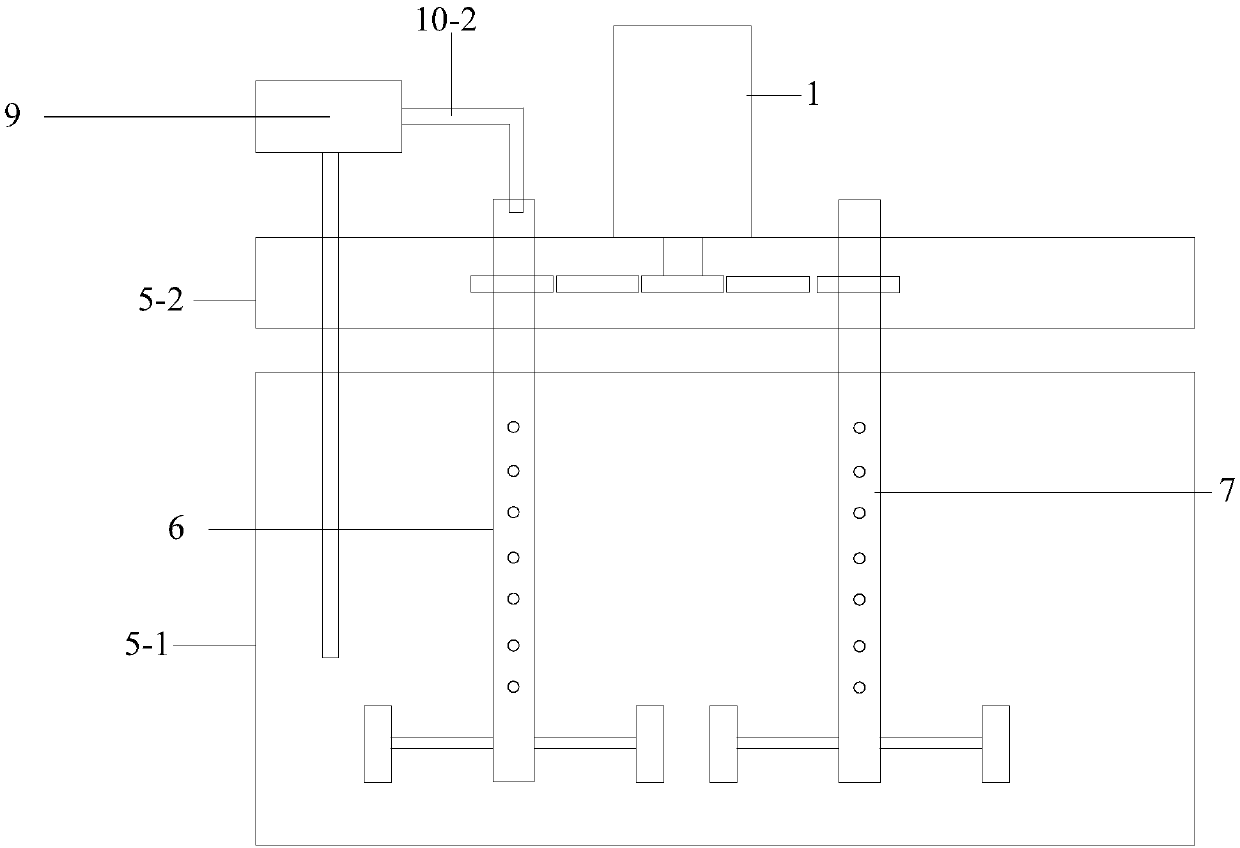

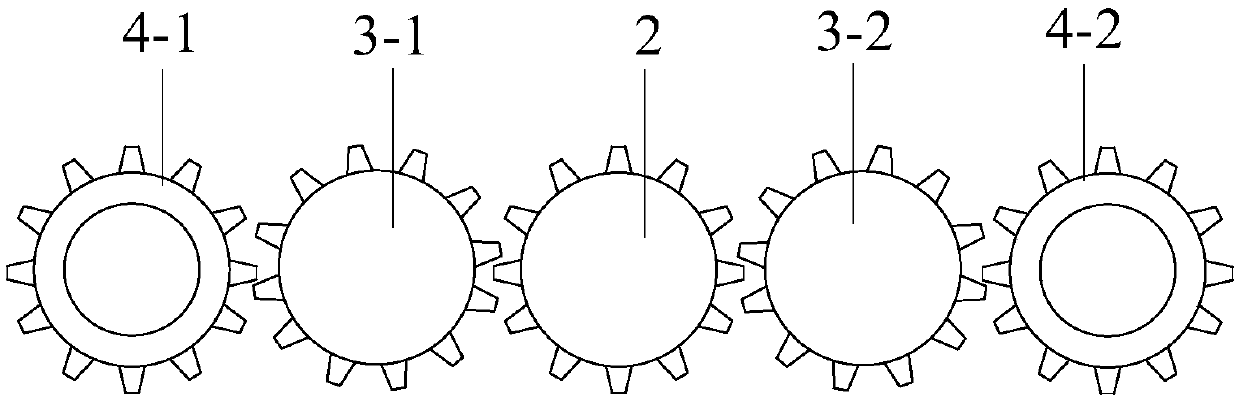

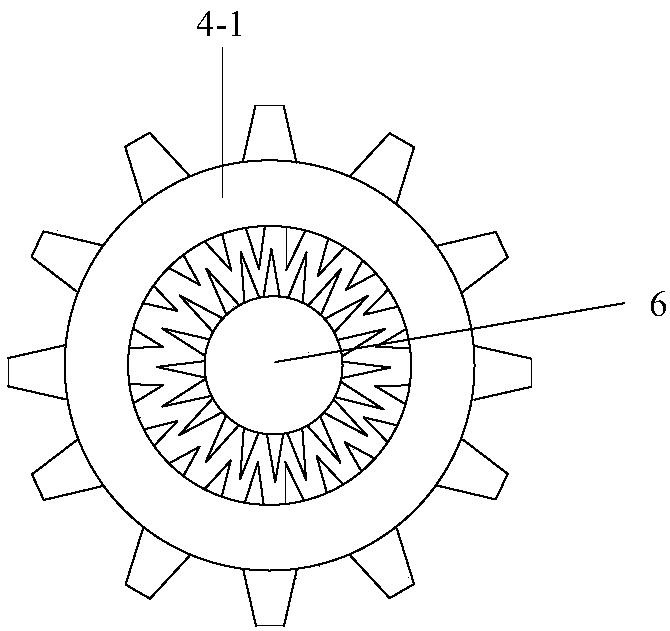

Temperature-controlled concrete stirring device

ActiveCN105643801AOvercome the problem of deviation in use effectImprove qualityDischarging apparatusMixing operation control apparatusTemperature controlStopped work

The invention discloses a temperature-controlled concrete stirring device comprising a stirring barrel body, wherein two sides of a first driving gear are meshed with second driven gears; the second driven gears are fixedly arranged on driven shafts; a plurality of temperature probes are arranged inside the left side wall of the stirring barrel body; a ceramic heating body is arranged inside a cavity; the bottom of the right side wall of the stirring barrel body is provided with a first discharging pipe; a second discharging pipe is connected with an auxiliary unloading hose; the top of the stirring barrel body is also provided with an additive introducing device; and a pipeline of a liquid control switch and an additive delivery pump is provided with a horizontal section pipeline, a first elbow pipeline, a second elbow pipeline and a third elbow pipeline. By using the temperature-controlled concrete stirring device, the temperature of inside concrete can be controlled, the automatic and quantitative addition of water is realized, the problem of deviation caused by different heights is overcome, and the retention phenomenon cannot be generated after the additive delivery pump stops working.

Owner:河南国龙矿业建设有限公司

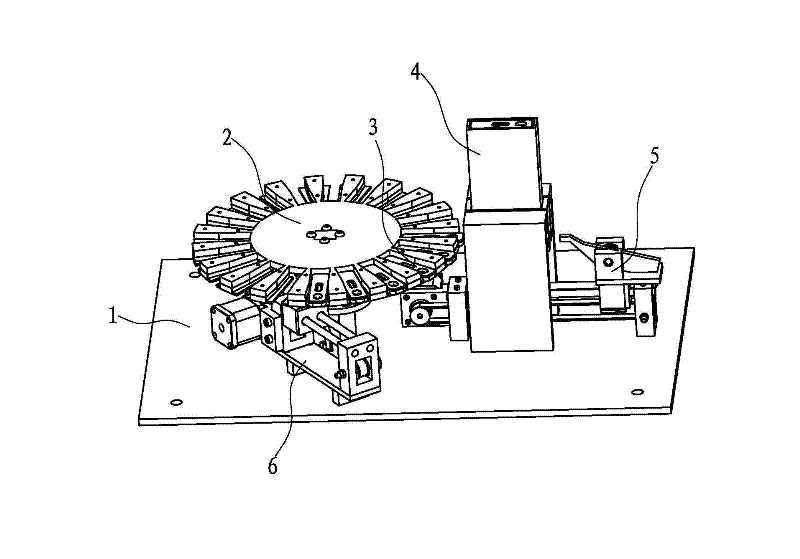

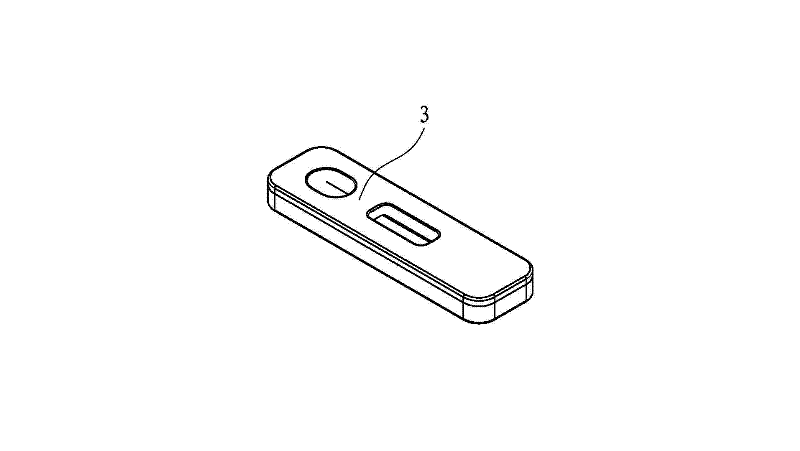

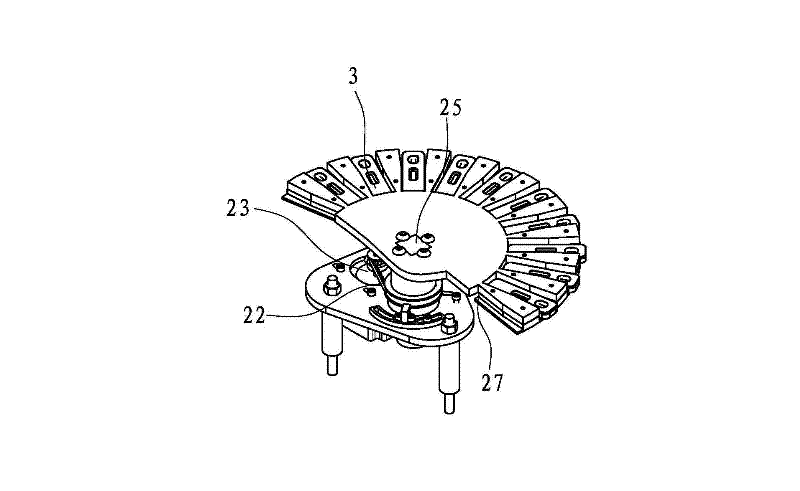

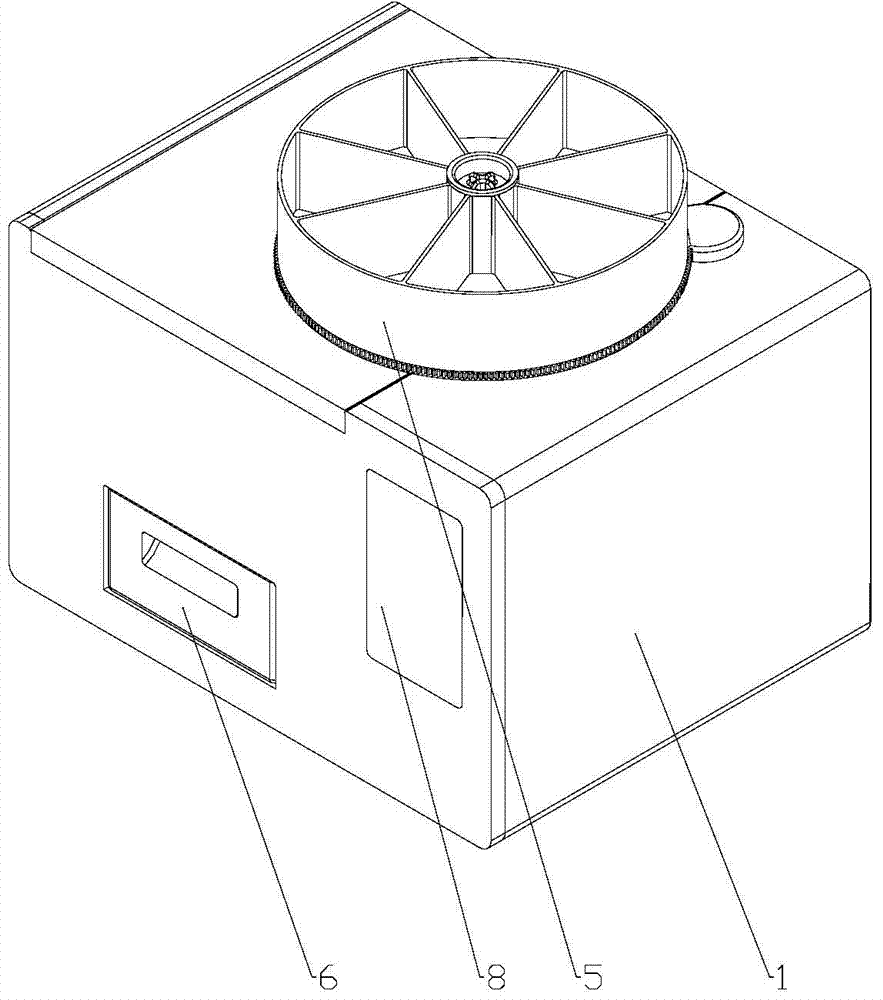

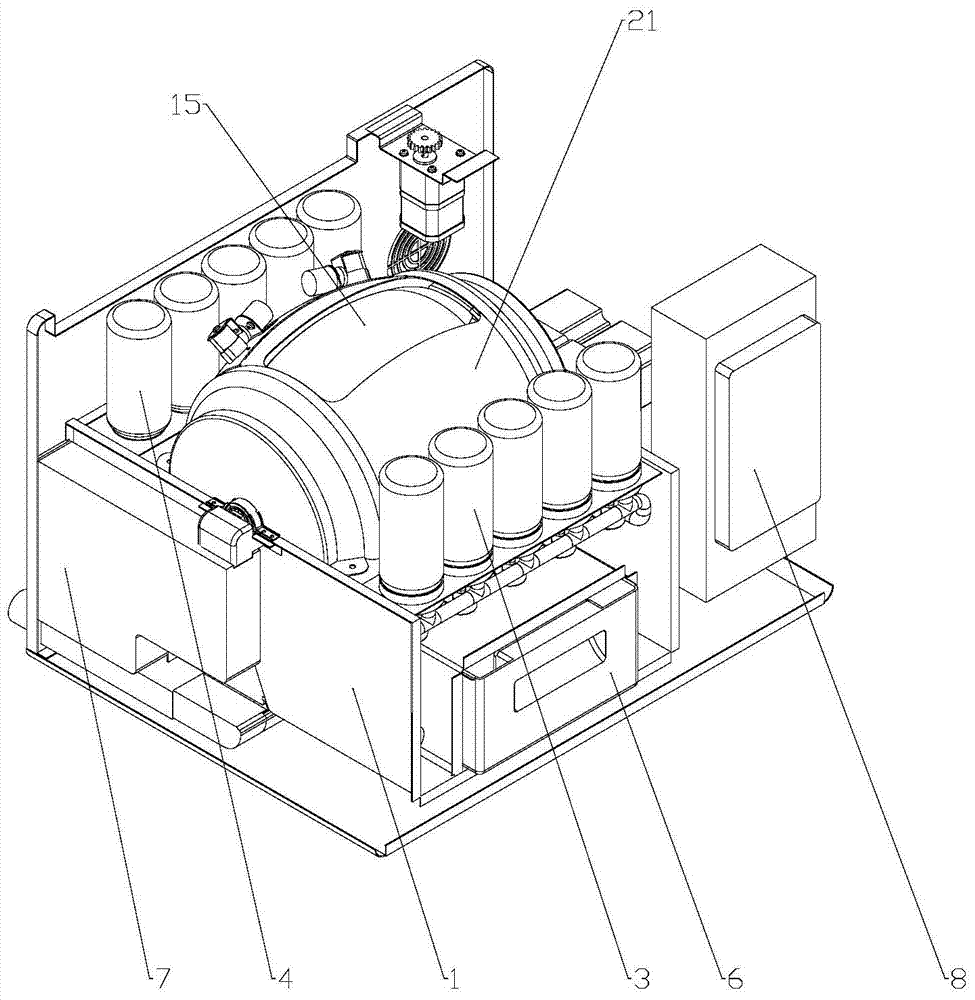

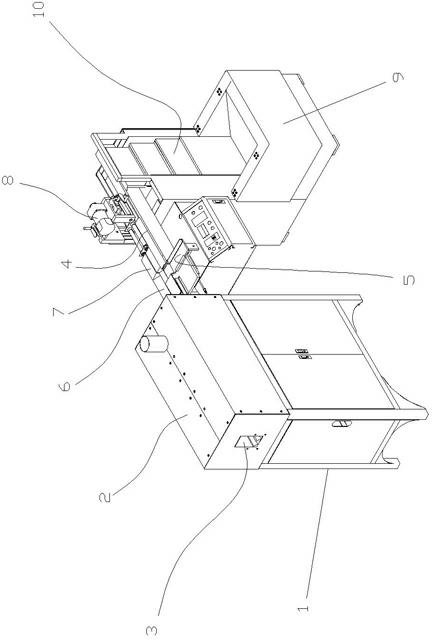

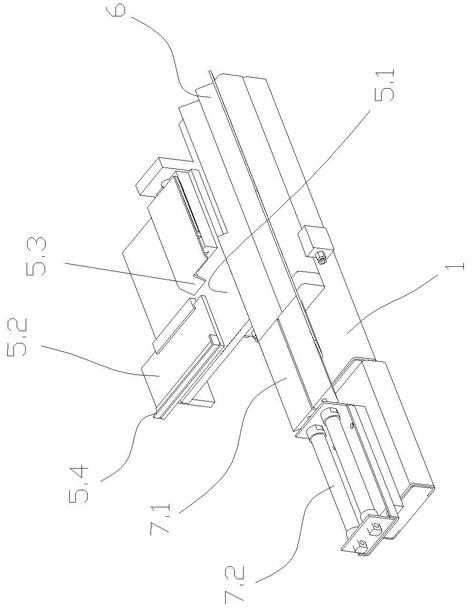

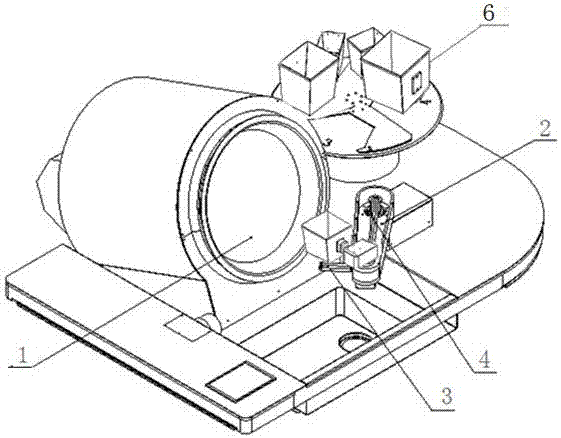

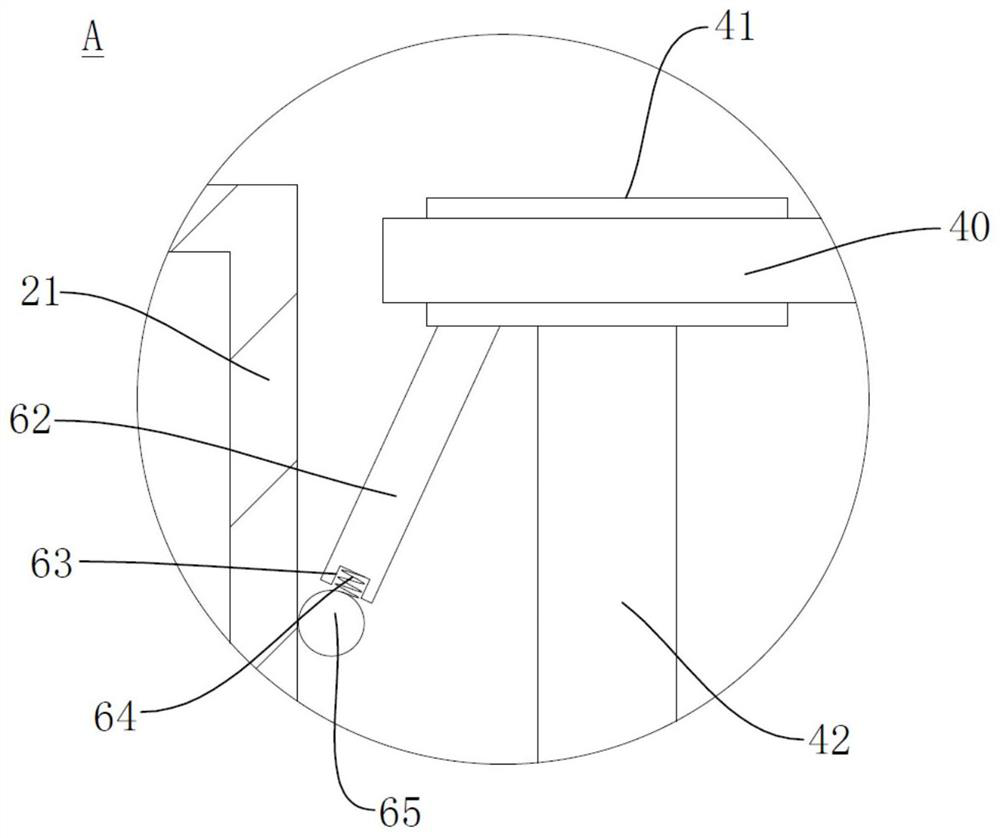

Adding and push-out device suitable for plate-type reagent

The invention discloses an adding and push-out device suitable for plate-type reagents. A plate-type reagent setting tray is driven to rotate by a motor and a transmission mechanism, and a plurality of reagent troughs are formed at periphery in a radial direction; a kit setting mechanism is located near the plate-type reagent setting tray, and plate-type reagents are stacked in the kit; an outletand a pushing opening for the plate-type reagents are formed at the lower part of the kit; a pushing mechanism is located near the kit setting mechanism; a pushing rod is mounted on a pedestal by a rotating shaft, and the pushing rod is in the same central line as the kit setting position and one trough of the plate-type reagent setting tray; the pushing rod is tilted anteriorly and sunk posteriorly in a natural state, and the pedestal and the pushing rod are driven to reciprocate by the motor and the transmission mechanism; a pushing mechanism comprises the motor, the transmission mechanism,and the pushing rod; the pushing rod is in the same central line as one trough of the plate-type reagent setting tray; the pushing rod is driven to reciprocate by the motor and the transmission mechanism. The mechanism realizes the automatic adding and automatic collection of plate-type reagents.

Owner:XIAMEN SCIENDOX BIOLOGICAL TECH CO LTD

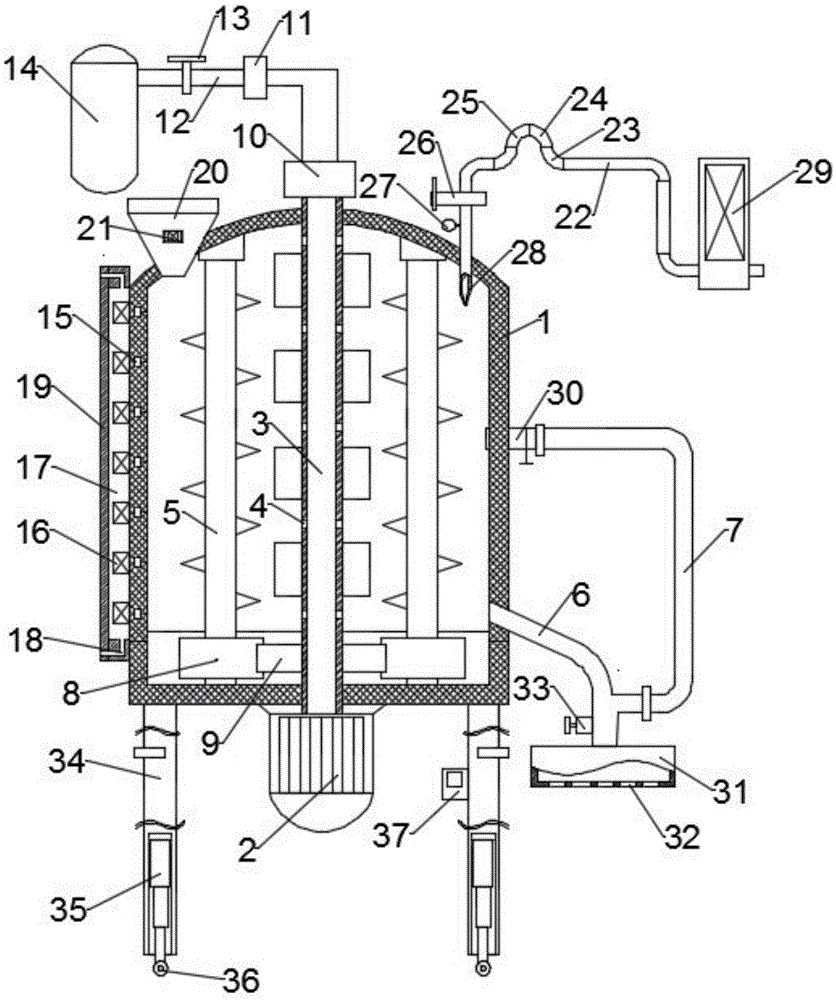

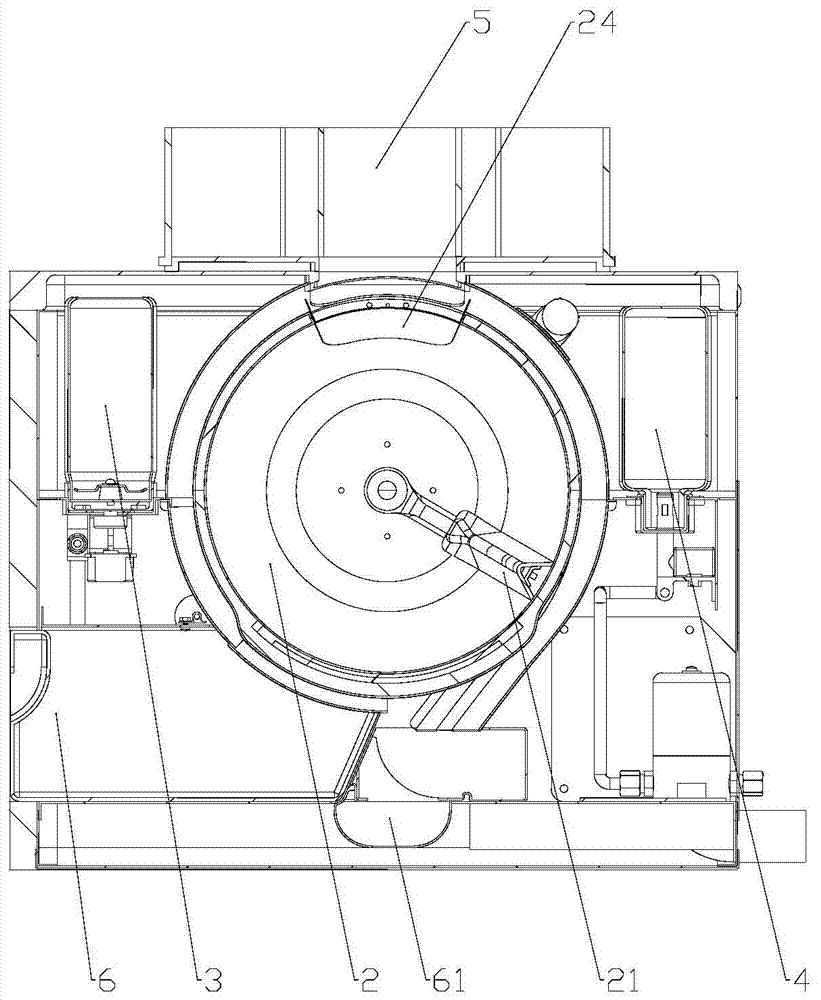

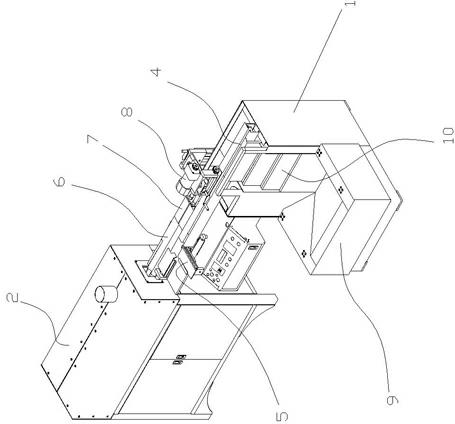

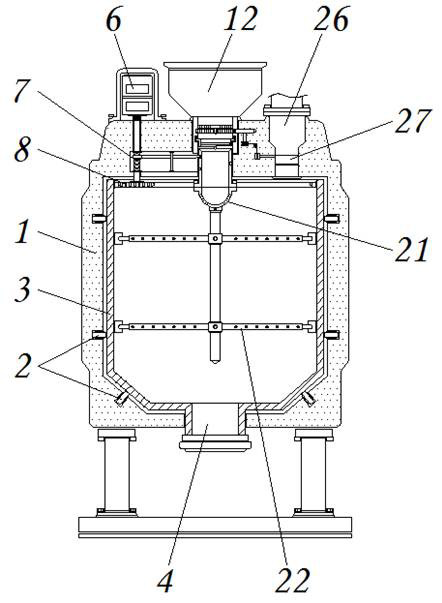

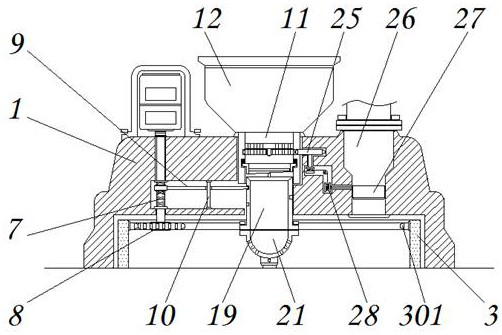

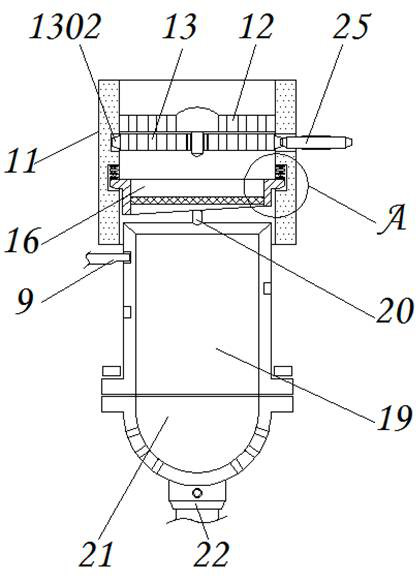

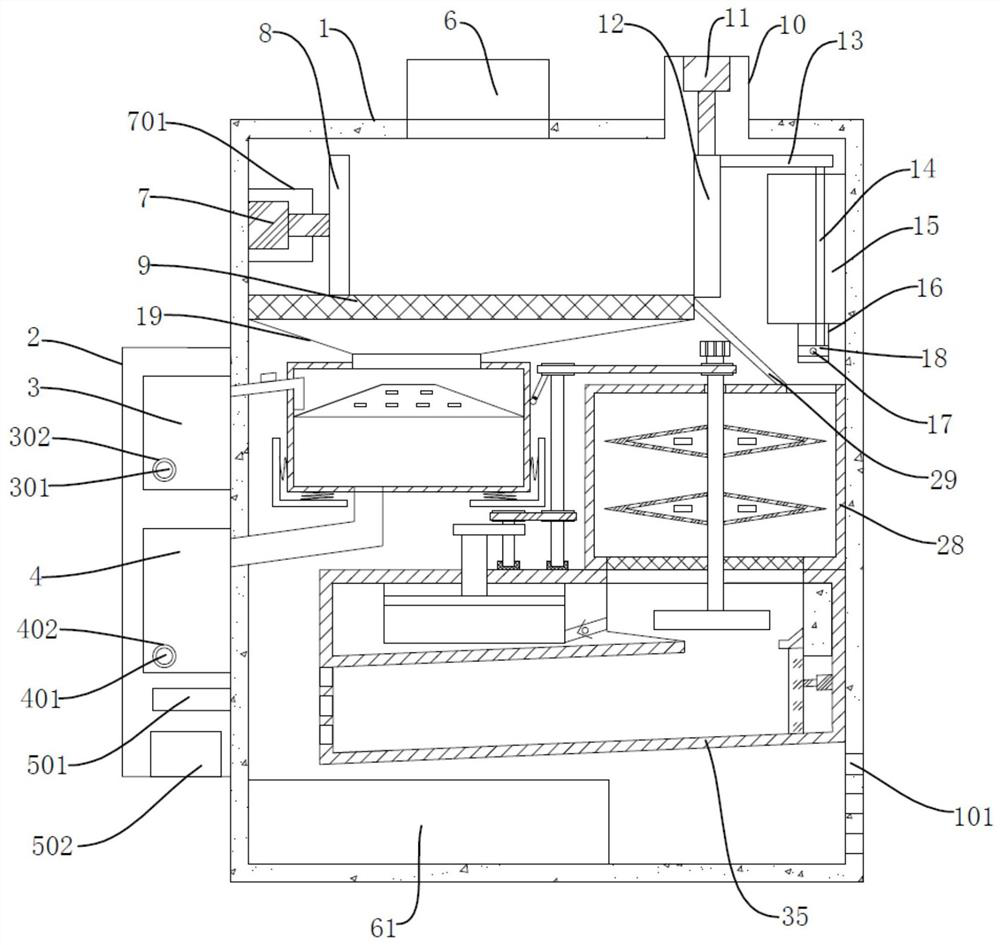

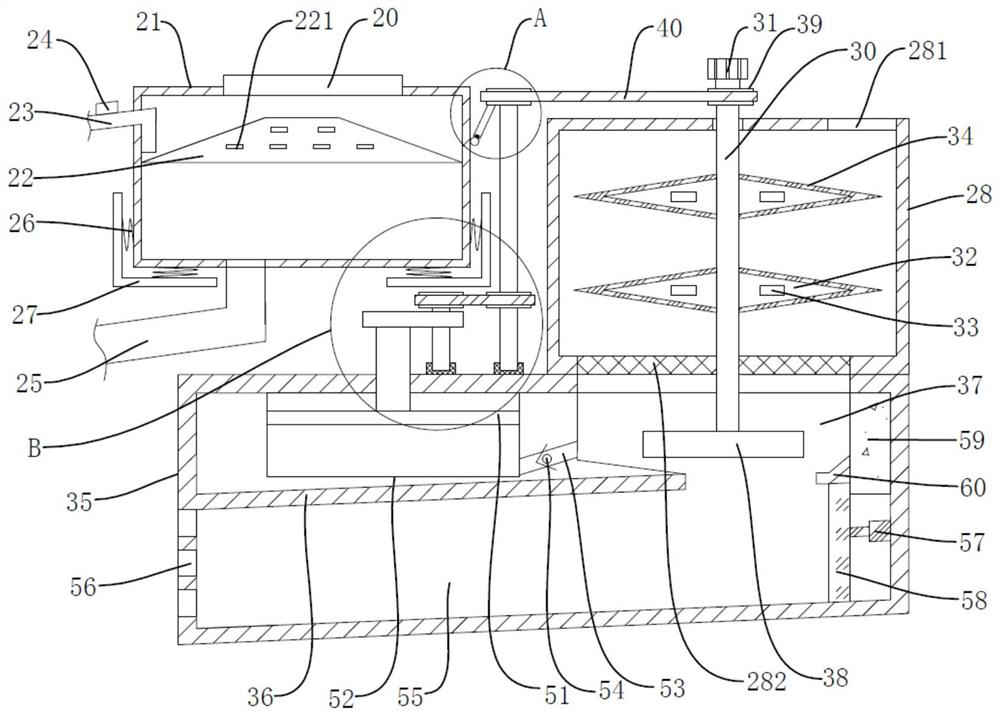

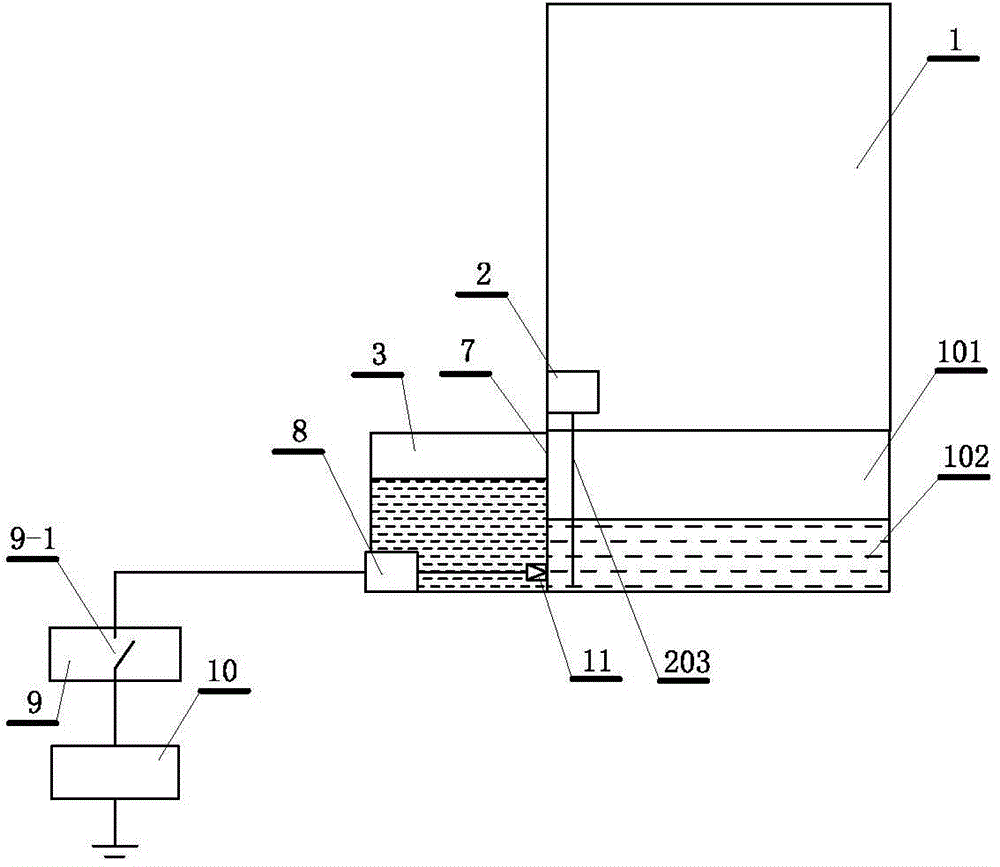

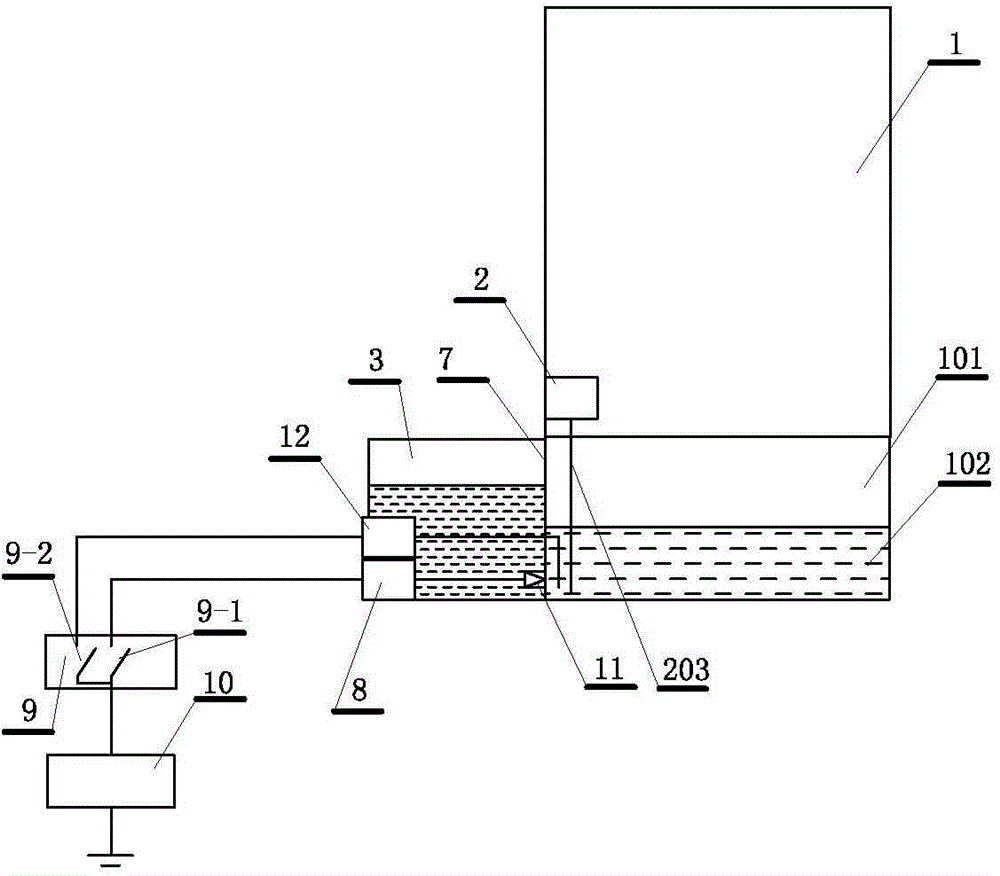

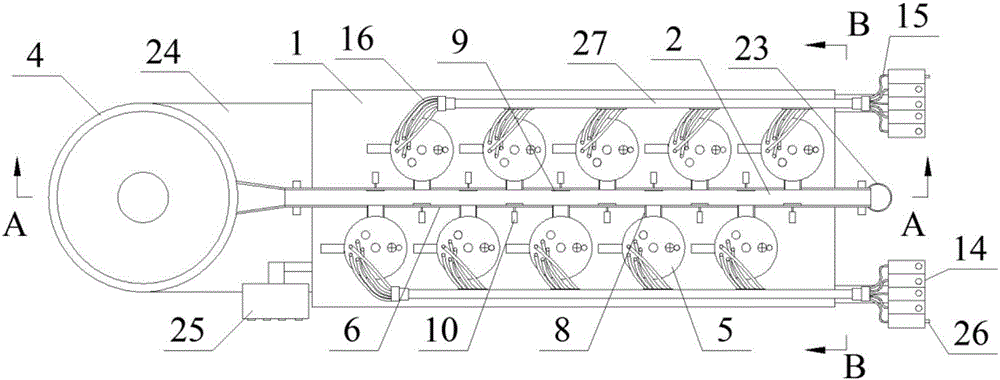

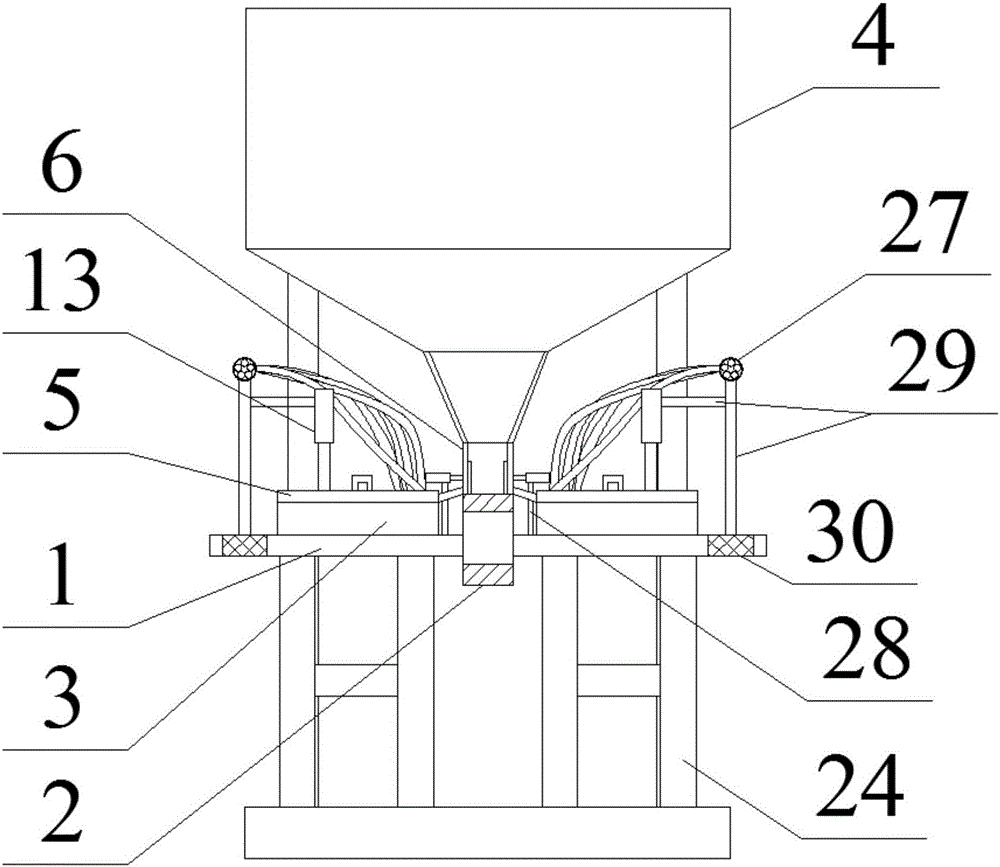

Automatic cooker

ActiveCN103494502ARealize automatic cooking functionImplement automatic additionCooking insertsEngineeringShovel

The invention relates to cooking equipment, in particularly to an automatic cooker. The automatic cooker comprises a shell (1), wherein a cooking device is arranged in the shell (1), the cooking device is connected with a particle seasoning device, a liquid seasoning device, a dish outlet and drainage device, a smoke filtering and exhausting device and a control device (8), the cooking device comprises a pot body (2), a sliding cover (24) is arranged above the pot body (2), the pot body (2) is provided with a pot body inner layer (201) and a heat insulating layer (202) in sequence from inside to outside, a heating layer (203) is arranged between the pot body inner layer (201) and the heat insulating layer (202), a rotary shovel (10) is arranged in the pot body (2), a left shovel shaft (22) and a right shovel shaft (23) are arranged on the two sides of the rotary shovel (10) respectively, and the rotary shovel (10) is connected with the pot body (2) through the left shovel shaft (22) and the right shovel shaft (23). The automatic cooker has the advantages that the automatic cooking function is achieved, particle seasoning can be added automatically through the particle seasoning device, and liquid seasoning can be added automatically through the liquid seasoning device.

Owner:杭州天厨星智能科技有限公司

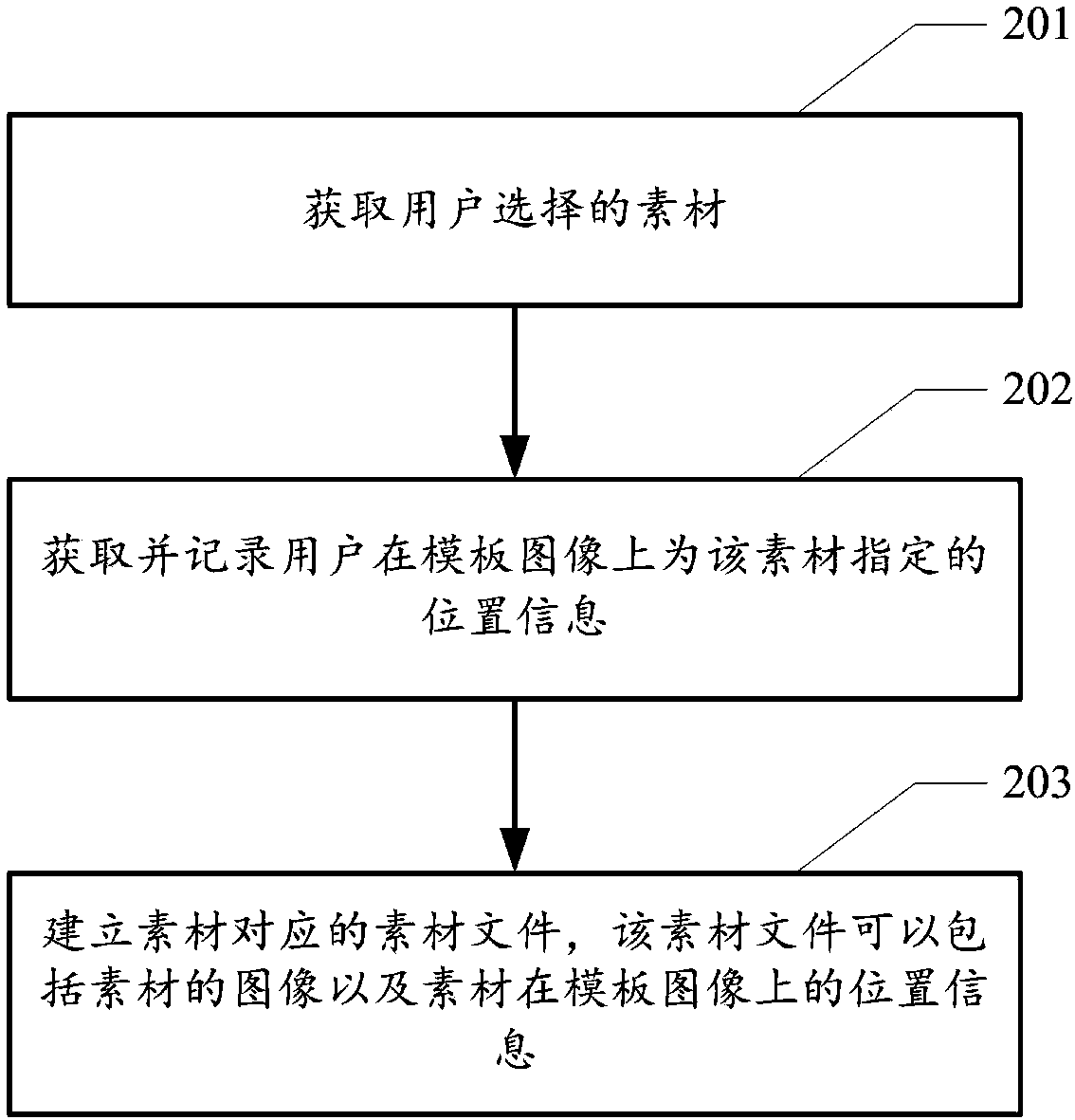

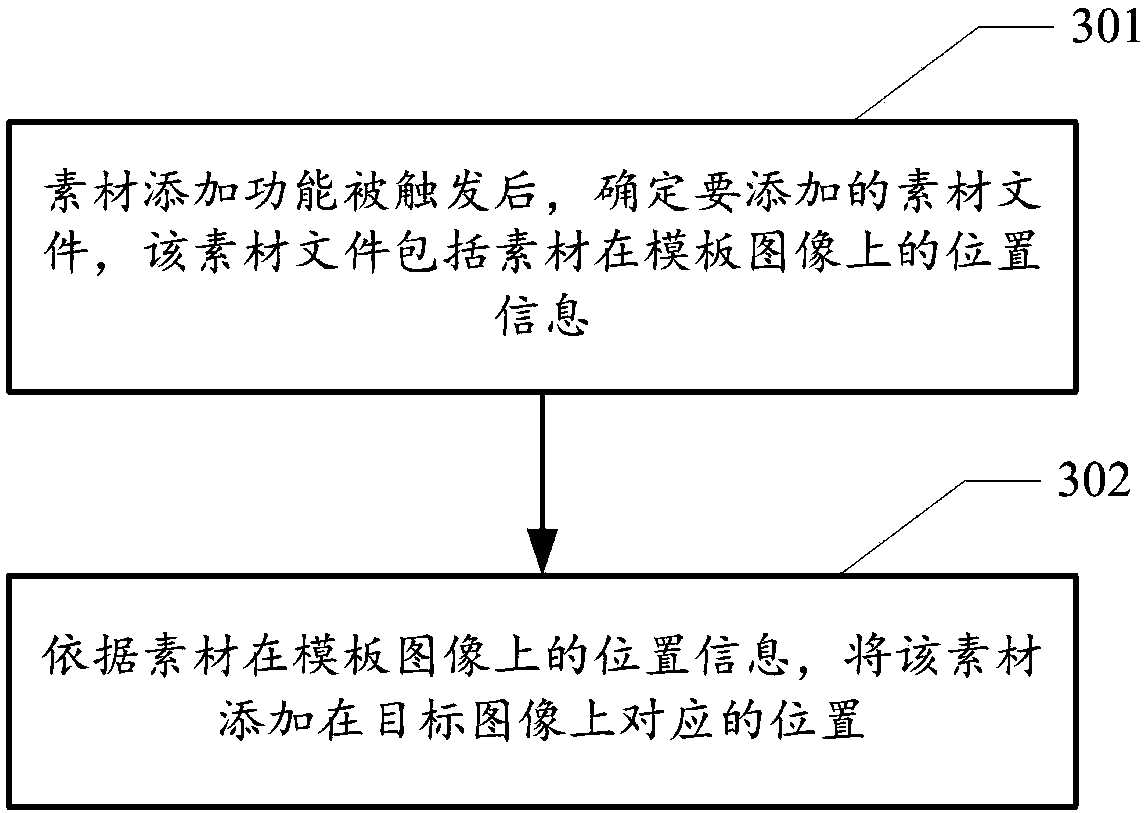

Image processing method, device, equipment and computer storage medium

ActiveCN108346171AImplement automatic additionIncrease flexibilityEditing/combining figures or textImaging processingComputer graphics (images)

The invention provides an image processing method, device, equipment and a computer storage medium. The method comprises steps: a material selected by a user is acquired; the position information specified by the user on a template image for the material is acquired and recorded; a material file corresponding to the material is built, wherein the material file comprises the material image and theposition information of the material on the template image; and after a material adding function is triggered, a to-be-added material file is determined, and according to the position information of the material on the template image, the material is added to the corresponding position on a target image. Thus, the user can add any favorite material on the target image without being restricted by amaterial provided by an application, and the material use flexibility is improved. Manual calibration of the position information of the material by a developer is not needed, and the workload of thedeveloper is reduced.

Owner:BANMA ZHIXING NETWORK HONGKONG CO LTD

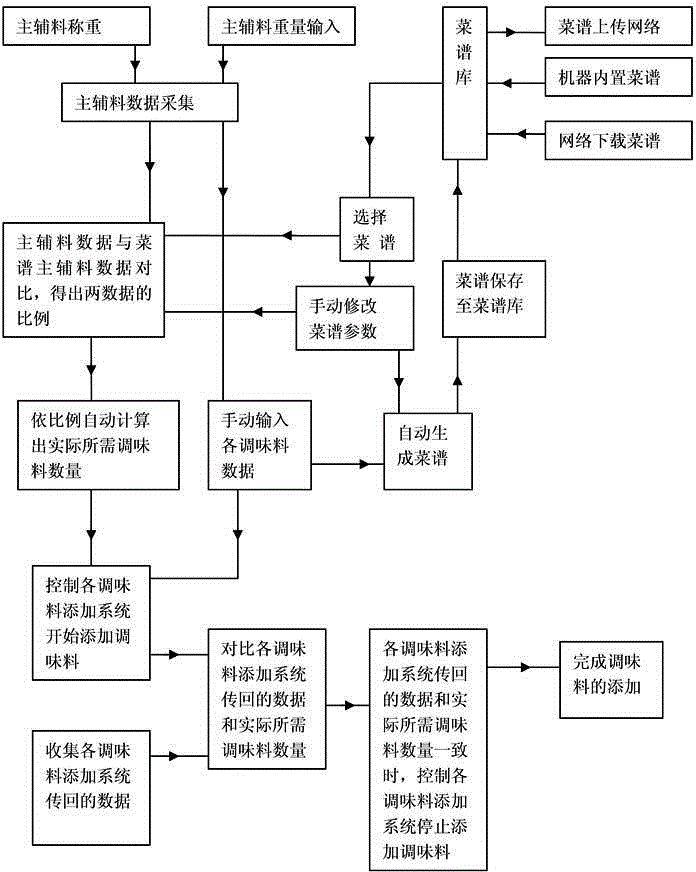

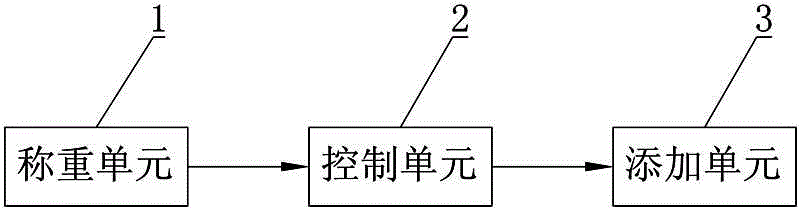

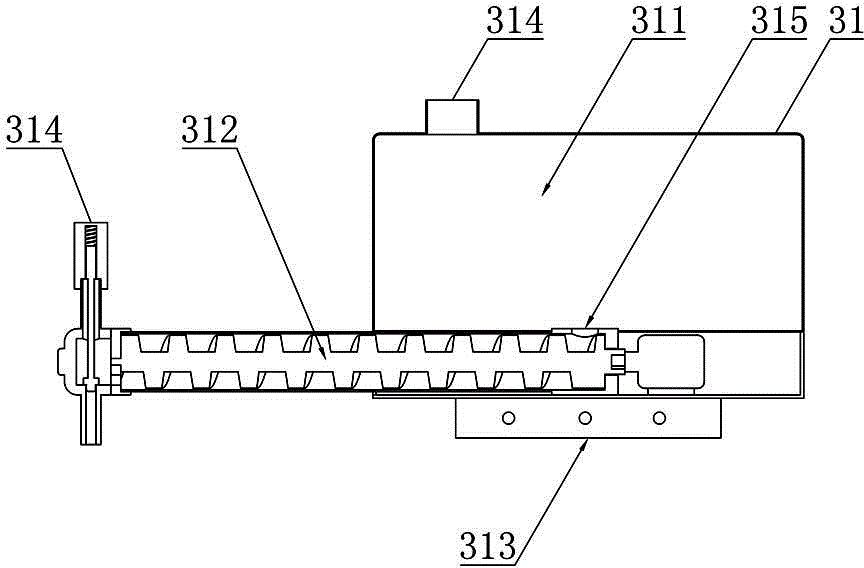

Seasoning adding method and system

InactiveCN104944088AAchieve standard deliveryImplement automatic additionControl devices for conveyorsPackagingChemistryControl unit

The invention discloses a seasoning adding method. The seasoning adding method includes the steps that S1, weight signals of main auxiliary materials are acquired; S2, corresponding seasoning varieties are selected and corresponding weight signals are calculated according to a menu and the weight signals of the main auxiliary materials; S3, before the main auxiliary materials are processed or when the main auxiliary materials are processed, seasonings are added to the main auxiliary materials. The invention discloses a seasoning adding system. The seasoning adding system comprises a weighing unit, a control unit and an adding unit. The weighing unit acquires the weight signals of the main auxiliary materials and transmits the weight signals to the control unit. The control unit selects the seasoning varieties, calculates the corresponding weight signals and transmits the weight signals to the adding unit according to the menu and the weight signals of the main auxiliary materials. The adding unit automatically adds the seasonings in corresponding weight to the main auxiliary materials before the main auxiliary materials are processed or when the main auxiliary materials are processed. The method and system are simple in structure and easy and convenient to operate and have the advantage that the seasonings are automatically and accurately added.

Owner:周波

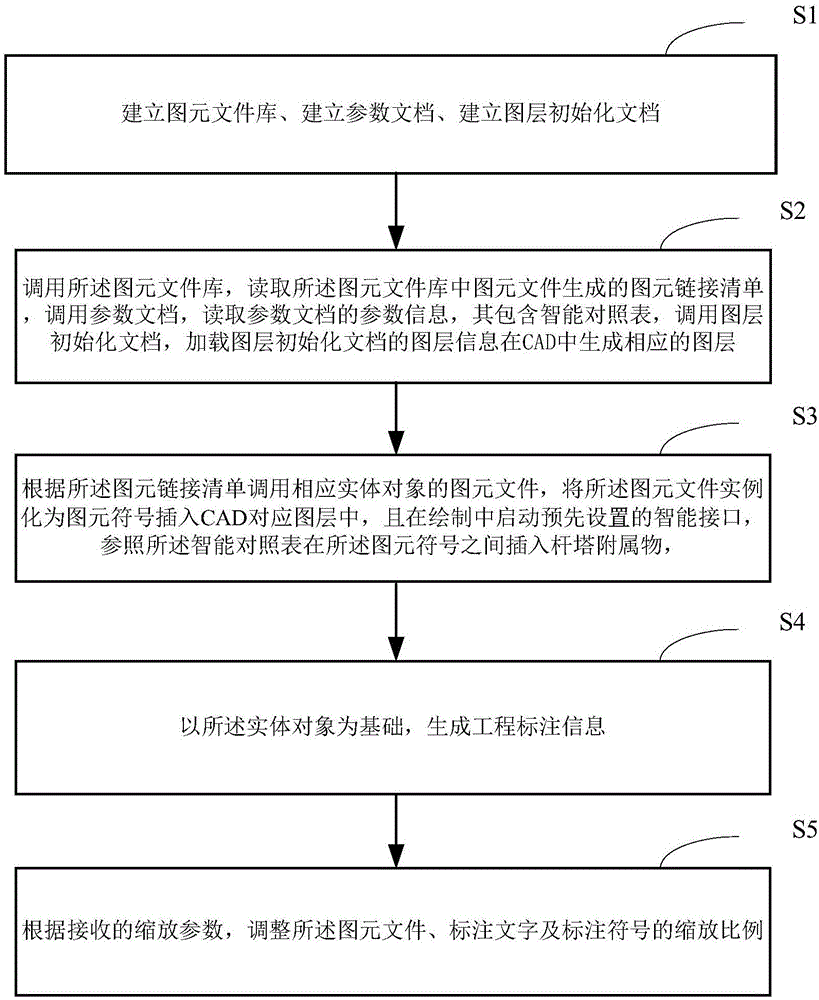

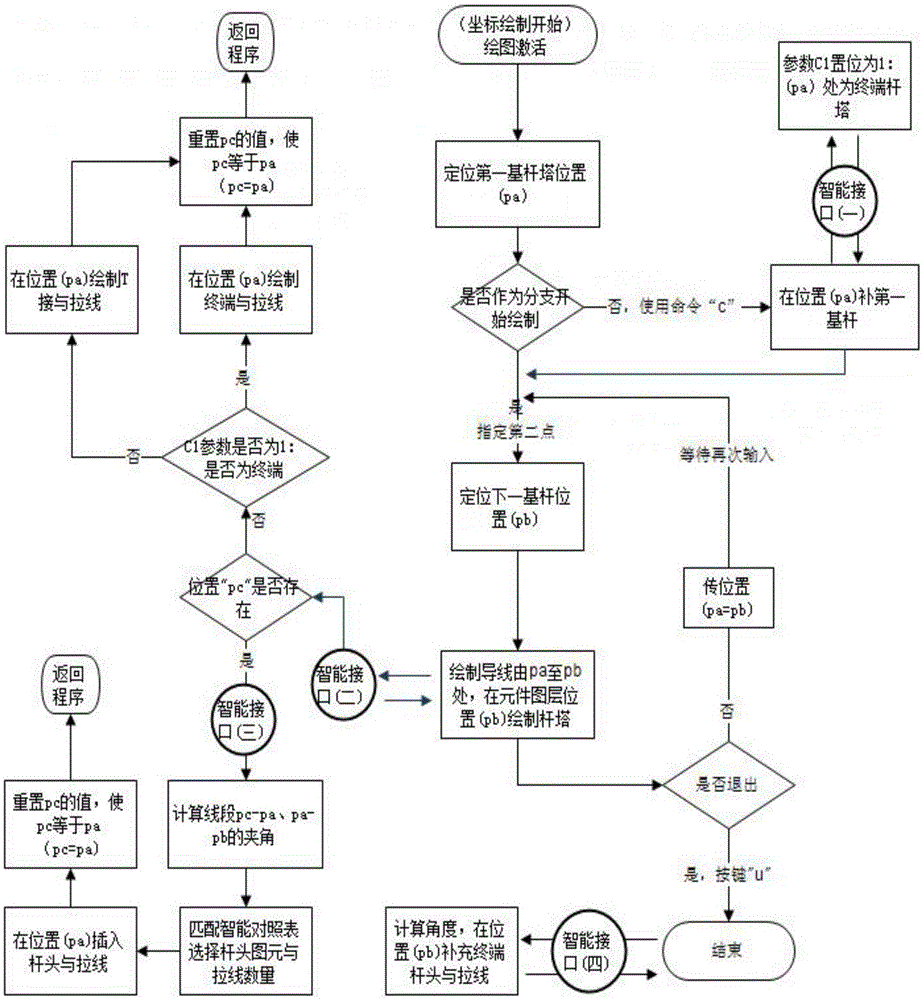

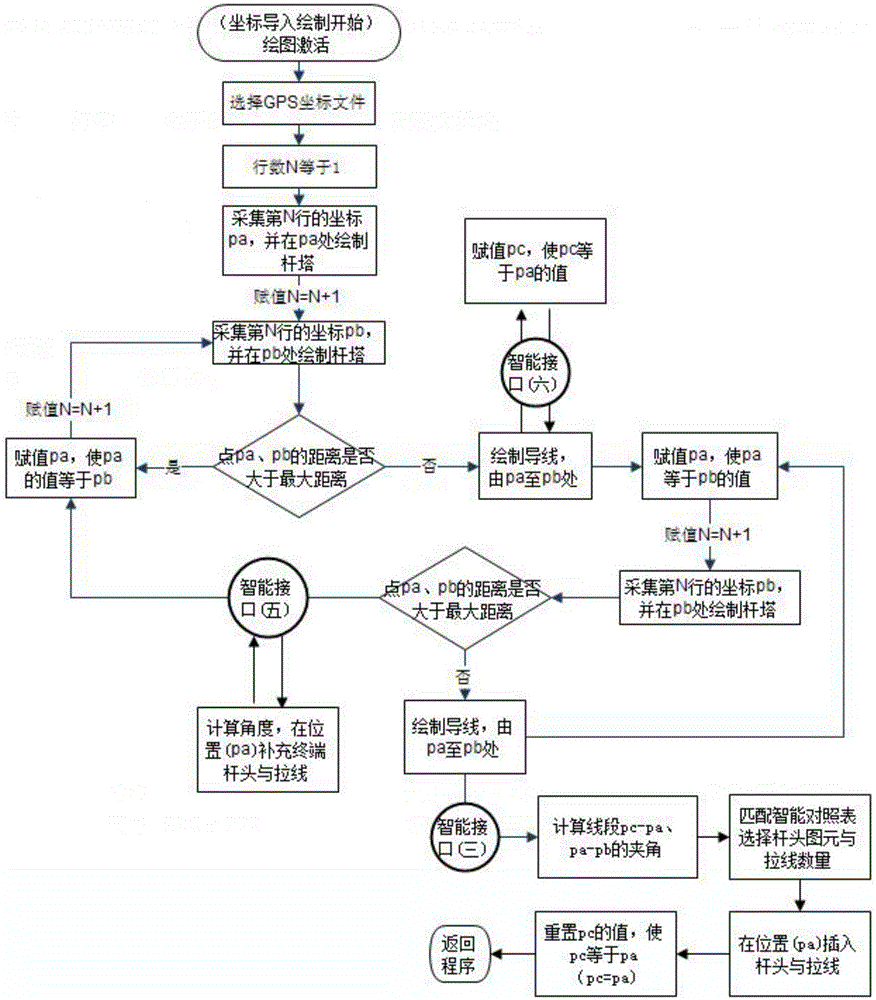

Rapid distribution line drawing method

ActiveCN105138793AImplement automatic additionQuick drawSpecial data processing applicationsTowerDocumentation

The invention relates to the technical field of power distribution networks, in particular to a rapid distribution line drawing method. The method includes the steps of S1, establishing a component document library, a parameter document and a layer initiating document; S2, calling the component document library, reading a component link list generated through component documents in the component document library, calling the parameter document, reading parameter information, containing an intelligent comparison table, of the parameter document, calling the layer initiating document, and loading layer information of the layer initiating document onto a corresponding layer generated in CAD; S3, calling the component documents of an entity object according to the component link list, instantiating the component documents into component symbols, inserting the component symbols into the corresponding layer in the CAD, starting a preset intelligent interface in drawing, and inserting pole and tower appurtenance between the component symbols in reference to the intelligent comparison table. By setting the intelligent interface, the pole and tower appurtenance is automatically generated in the drawing process, and the power distribution network drawing efficiency is improved.

Owner:STATE GRID SHANDONG QINGYUN POWER SUPPLY +1

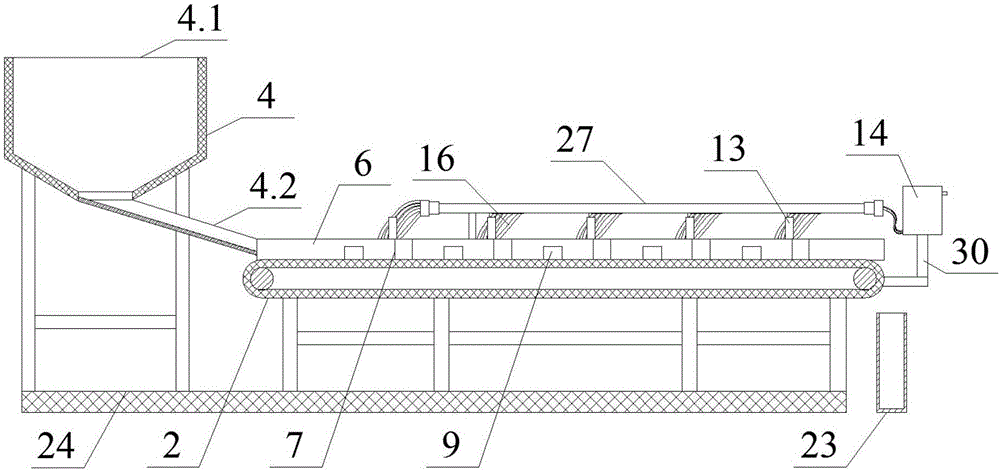

Heating furnace

InactiveCN102538449AImprove heating efficiencyHigh degree of automationFurnace typesEngineeringHeating furnace

The invention relates to a heating furnace, which comprises a framework. A heating chamber is arranged on the framework, a feeding device and a conveying device are disposed on the framework, the conveying device is used for conveying a workpiece to be processed into the heating chamber, a discharge outlet of the feeding device is communicated with the conveying device, the conveying device is communicated with the heating chamber, and a discharge outlet is disposed at the tail of the heating chamber. Special auxiliary equipment is configured for the heating chamber, the workpiece to be processed is automatically fed to the conveying device by the feeding device, the workpiece is conveyed into the heating chamber to be heated by the conveying device, and is discharged from the discharge outlet after being heated, automation degree of an integral heating process is high, labor intensity of workers is greatly reduced, heating efficiency of the workpiece is greatly improved, and the heating furnace is suitable for batch production and is favorable for lowering production cost.

Owner:NINGBO SHENGAN ROBOT TECH CO LTD

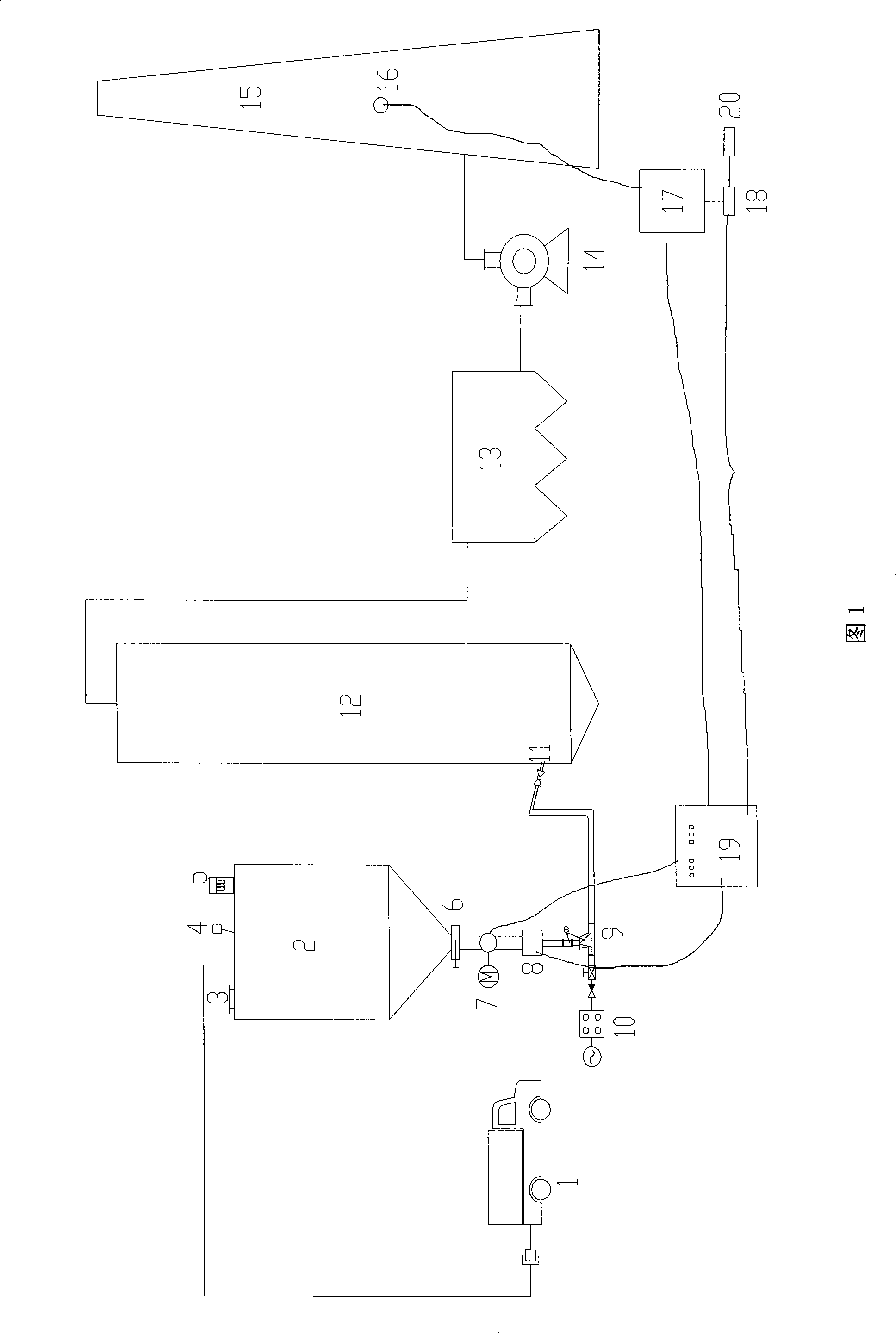

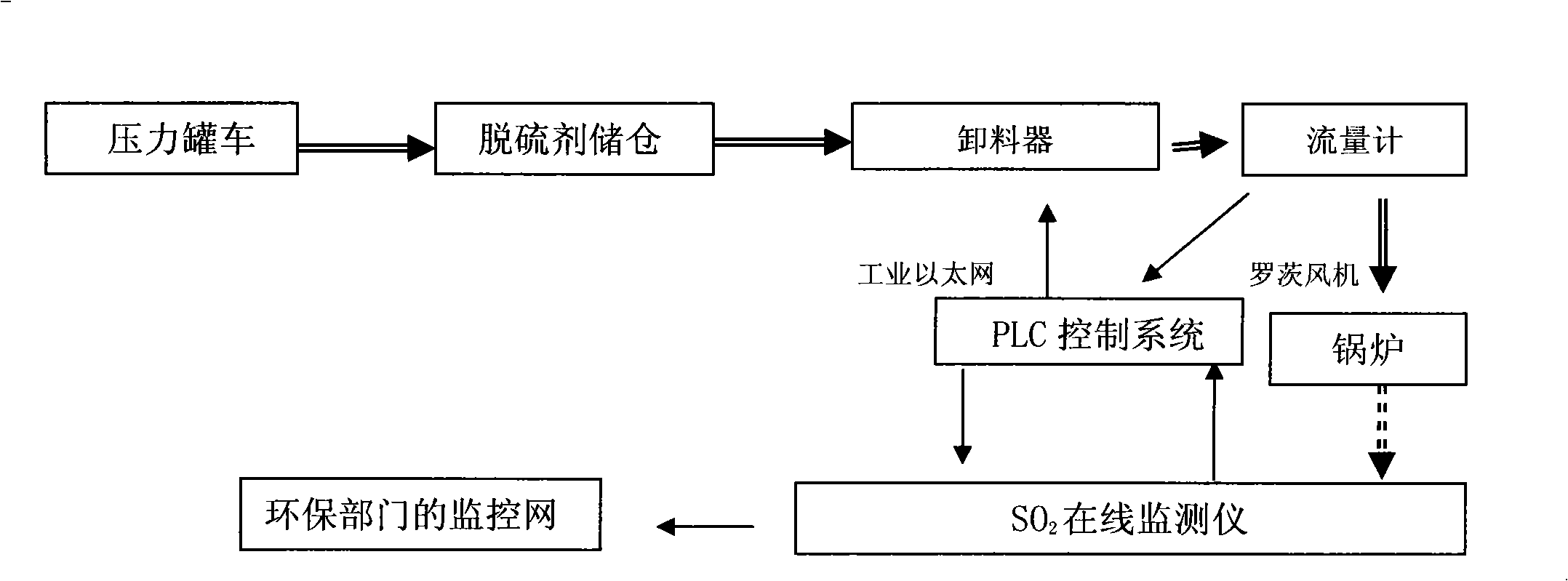

Dry desulfurizing process implementing automatic control based on environment friendly monitoring network and numeration table

InactiveCN101318101AImprove desulfurization efficiencyRealize automatic controlVolume/mass flow measurementDispersed particle separationAutomatic controlAutomatic train control

The invention discloses a dry desulfurization process with automatic control realized based on a monitoring network for environmental protection and a digital meter; wherein, the process comprises the steps that: a gate valve arranged below a bin is opened, and a discharger is started; powder enters an air lock and wind powder mixing device after being metered by a flow meter and then is blown into a boiler by a blower through a closed pipeline; after going through a ,pyrolysis, the powder reacts with SO2; a flue gas monitoring device arranged on a chimney transmits the monitored concentration value of SO2 as an analog quantity output signal to a PLC control system; according to the analog quantity output signal, the rotating speed of an electric motor of the discharger is controlled by the PLC control system to regulate the feeding; the instant flow and accumulated flow value provided by the flow meter arranged on a powder conveying pipeline are uploaded as an analog quantity signal to the PLC control system; on one hand, the instant flow and accumulated flow value function as data storage of the PLC control system, and on the other hand the data are transmitted in real time to an online monitoring network for environment-protection department. In the dry desulfurization process, the environmental-protection department realizes a distant monitoring of the dosage of desulfurizer, thus saving the dosage of limestone powder saved and simultaneously lowering the working intensity of the operating stuff.

Owner:山东国仁节能科技有限公司

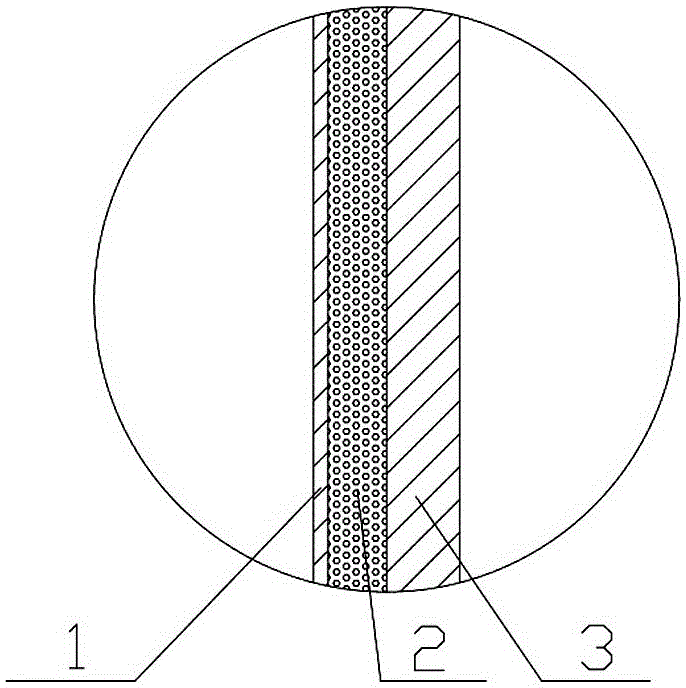

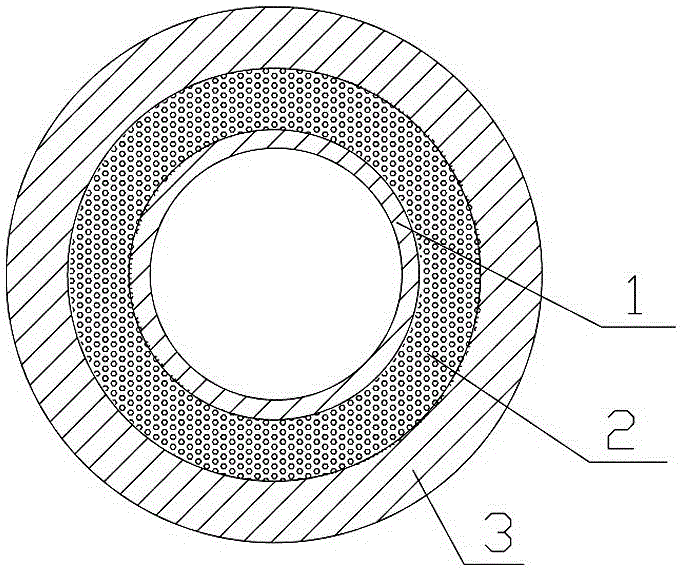

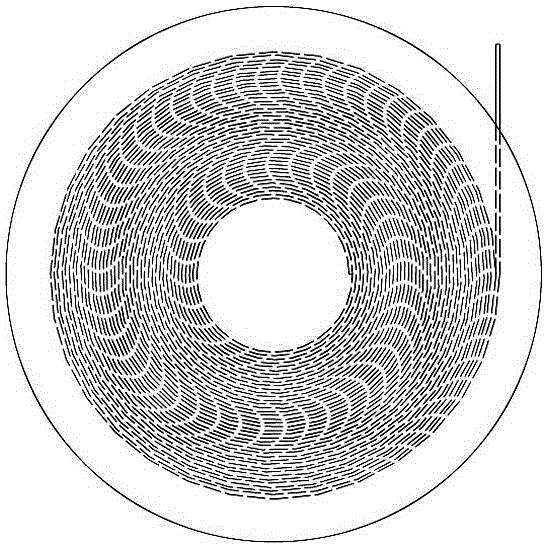

Layered composite brazing coating material and preparation method thereof

ActiveCN106112307AImplement automatic additionConsistent proportionLaminationLamination apparatusCemented carbideFiller metal

The invention discloses a layered composite brazing coating material. The layered composite brazing coating material is a belt-shaped structure consisting of a brazing filler metal alloy inner layer, a mixture middle layer including hard alloy particles and a brazing flux and a brazing filler metal alloy outer layer, or a drawn pipe-shaped structure. The brazing filler metal alloy inner layer is 0.01-1 mm thick; the mixture middle layer is 0.1-4 mm thick; and the brazing filler metal alloy outer layer is 0.1-2 mm thick. In the mixture middle layer, the weight percentage of the hard alloy particles is 80-99%. The layered composite brazing coating material has the brazing flux, is excellent in formability, and realizes quantitative and automatic adding of the brazing flux; the brazing filler metal alloy and the hard alloy are consistent in proportion to effectively guarantee the brazing coating quality; the rolled layered composite brazing coating material can be wound as a disc or a shaft; and the automatic production can be realized in the brazing coating process. Compared with a traditional suspension pulp-shaped brazing coating material or a piece-shaped brazing coating material, the layered composite brazing coating material is simple in preparation process, is convenient for storage and transportation, and can realize automatic production in the brazing coating process.

Owner:CHINA INNOVATION ACADEMY OF INTELLIGENT EQUIP CO LTD

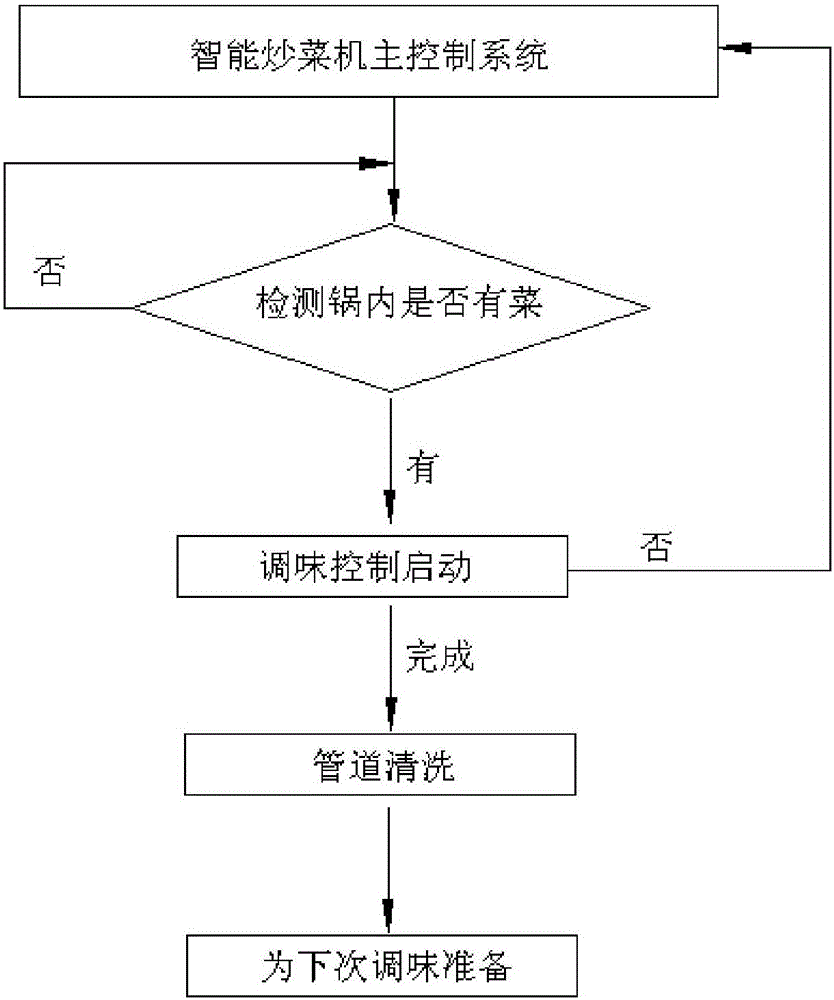

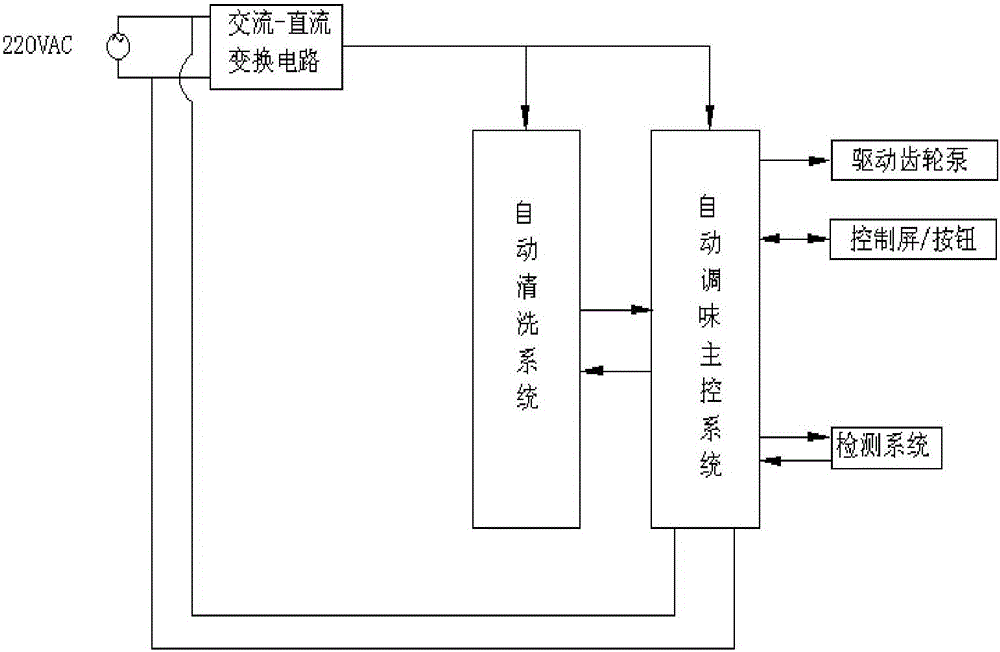

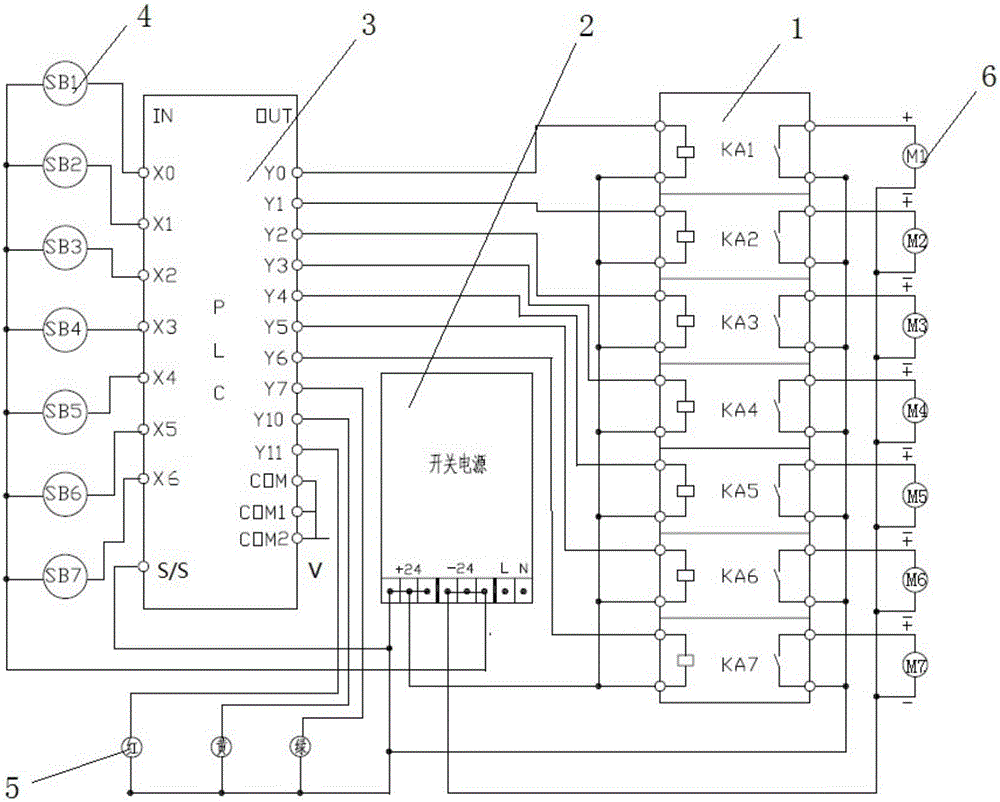

Automatic seasoning control method of intelligent cooking machine

ActiveCN106094703AImplement automatic additionEasy to add automaticallyProgramme control in sequence/logic controllersControl systemEngineering

The invention discloses an automatic seasoning control method of an intelligent cooking machine. The automatic seasoning control method comprises steps of 1) manufacturing various seasoners into fluid seasoners and adding the fluid seasoners into a fluid seasoner delivery device, wherein the fluid seasoner delivery device comprises a delivery channel and a gear pump which adds the fluid seasoner into a pot through the delivery channel; 2) detecting whether a main course is in the pot; 3) if yes, controlling a gear pump to work through a gear pump control system and transmitting various fluid seasoners into the cooking pot according to a preset proportion, if not, repeating the step 2); and 4) cleaning the whole fluid seasoner delivery pipe through an automatic cleaning system after the cooking is finished. The automatic seasoning control method of the invention easily realizes automatic adding of the various seasoners and is simple in operation. In the meantime, when the cooking is finished, the automatic cleaning system can automatically finish automatic cleaning of the seasoner delivery channel, which is clean and sanitary.

Owner:FOSHAN POLYTECHNIC

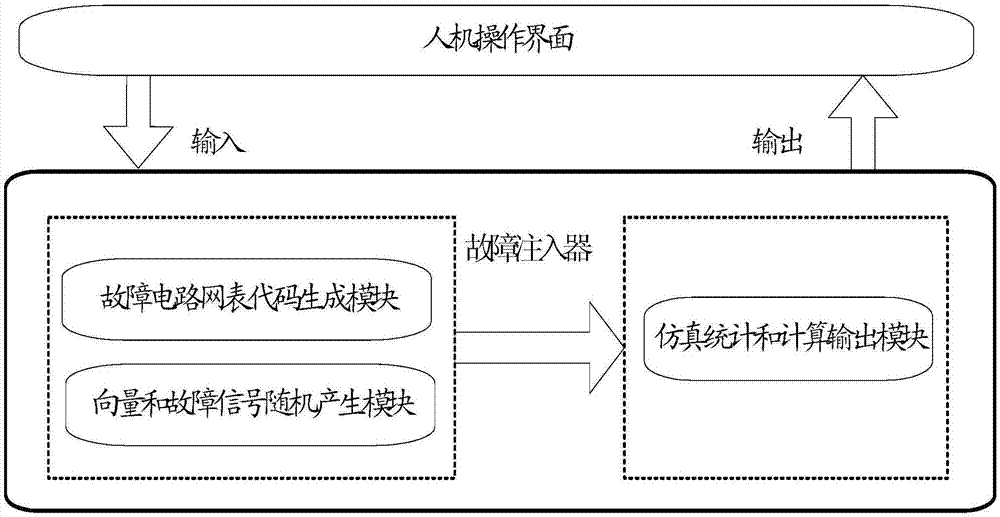

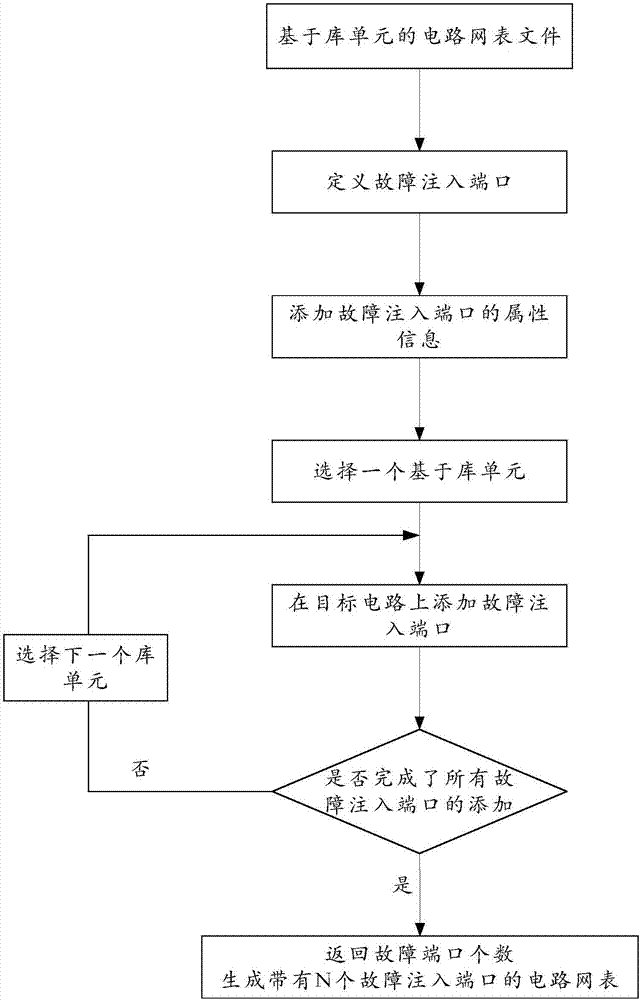

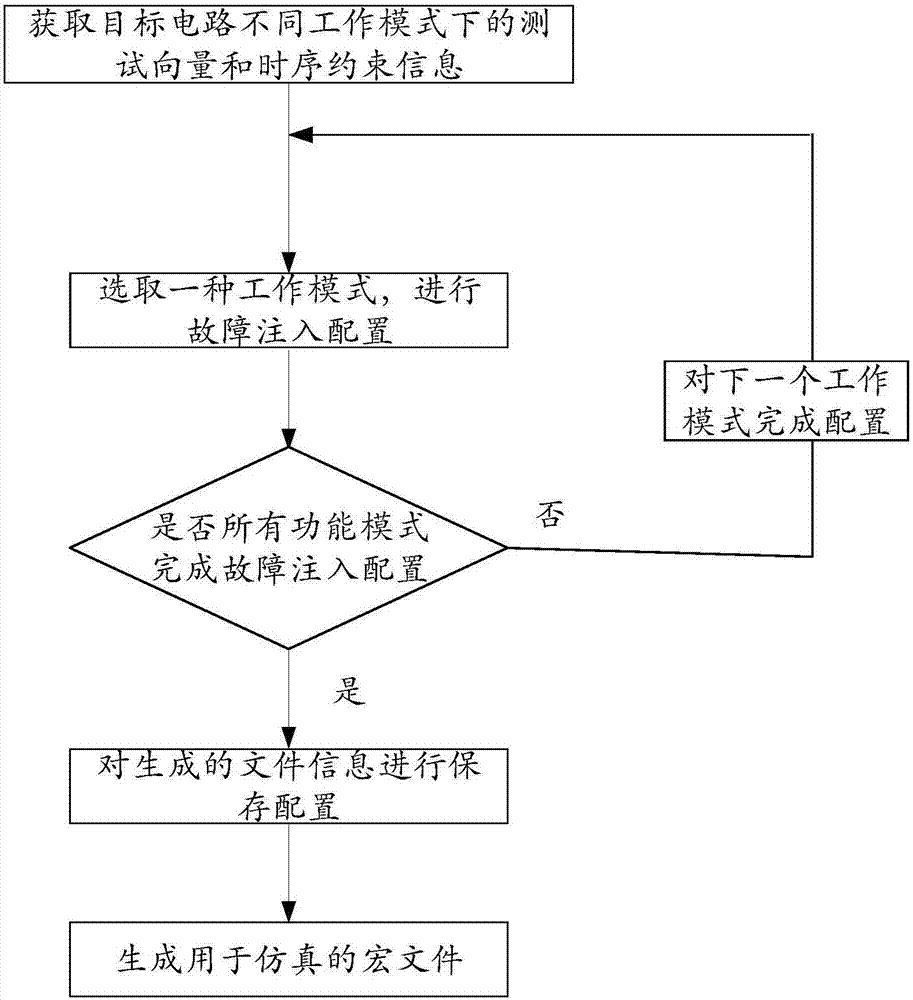

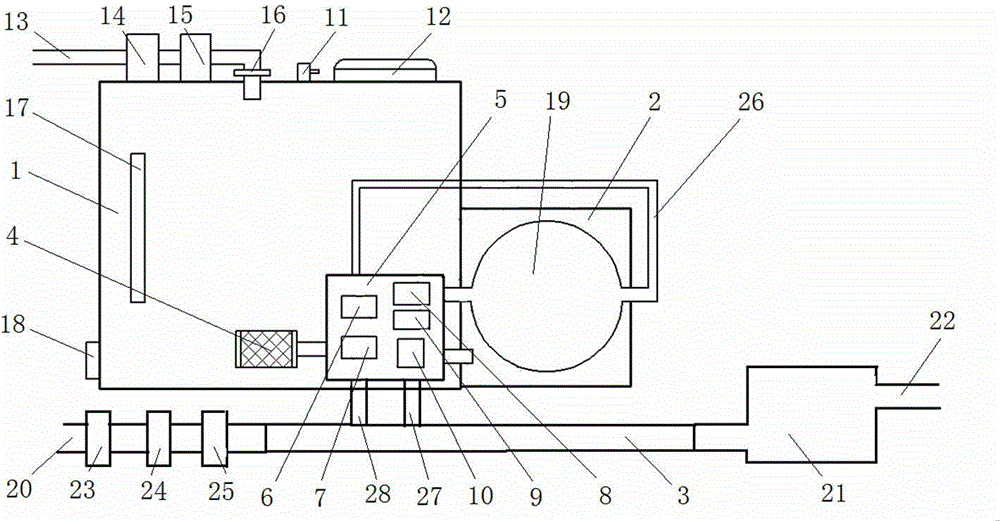

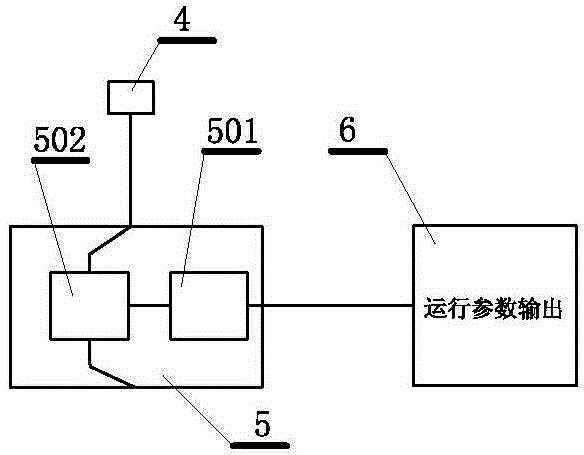

Fast, low-overhead and full-automatic digital integrated circuit single-particle fault injection system

The present invention discloses a fast, low-overhead and full-automatic digital integrated circuit single-particle fault injection system. The system comprises a man-machine operation interface and a fault injector; the fault injector comprises a fault circuit netlist code generation module, a function vector and fault random signal generation module and a simulation statistics and calculation output module. With the system of the invention adopted, full automatic single-particle fault injection is realized; a process files is processed in real time, so that influence on simulation performance caused by memory explosion due to excessively large storage quantity can be avoided; and the overhead of a calculator for simulation can be reduced.

Owner:BEIJING MXTRONICS CORP +1

Tubular braze coating material

InactiveCN105382439ASimple preparation processGood formabilityWelding/cutting media/materialsSoldering mediaCemented carbideAdhesive

The invention discloses a tubular braze coating material. The tubular braze coating material is of a double-layer filament-shaped or strip-shaped structure shaped like a belt core, the outer layer is a brazing alloy wrapping layer, and the inner layer is composed of mixtures of hard alloy particles and brazing flux. The mixtures are composed of, by weight, the hard alloy particles of 80-90% and the balance brazing flux. Compared with traditional suspending slurry braze coating materials or sheet braze coating materials formed by powdery brazing filler metal, hard alloy particles, adhesives, organic matter and the like, the tubular braze coating material has the advantages that the brazing flux is contained internally, quantitative and automatic addition of the brazing flux is realized in the braze coating process, the proportion of brazing alloy and the proportion of the hard alloy particles are uniform, the hard alloy particles are uniformly distributed after braze coating, and storage, transportation and use are convenient.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

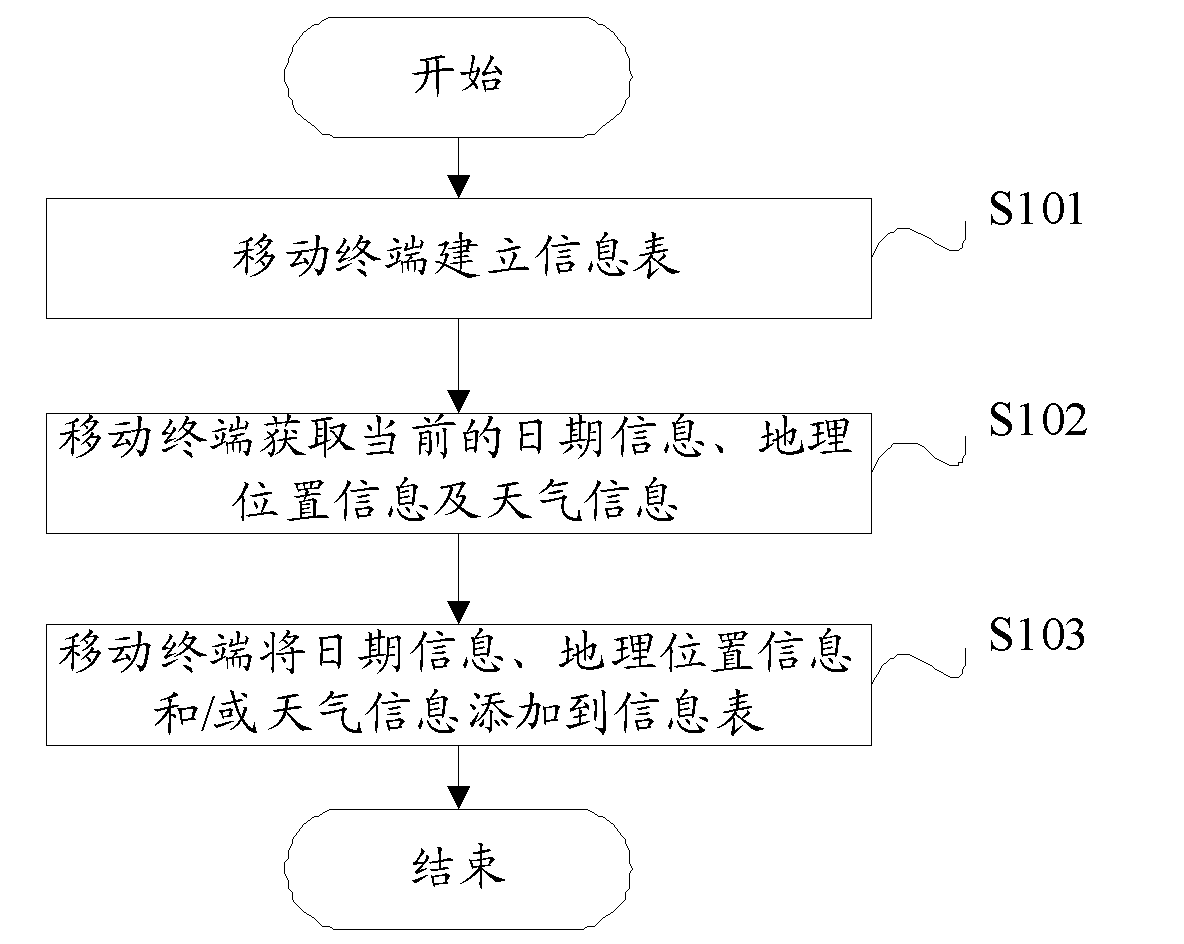

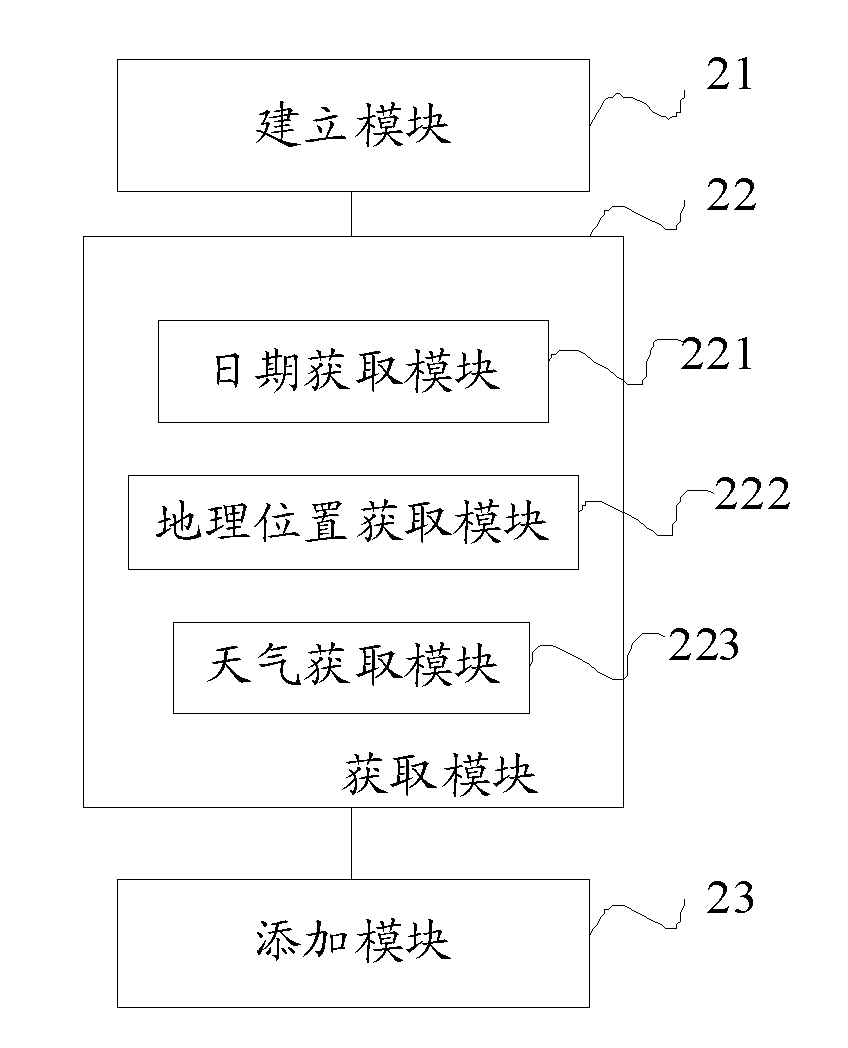

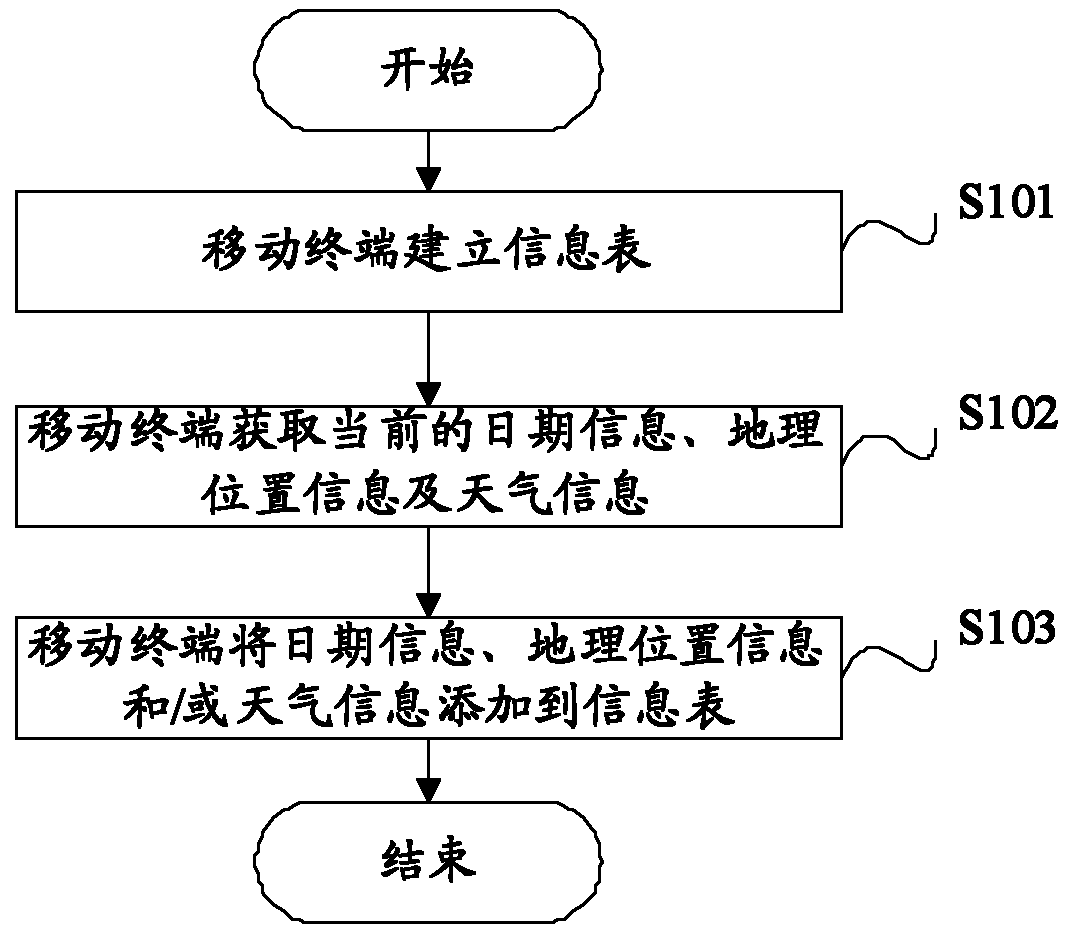

Mobile terminal information generating method and mobile terminal

InactiveCN101964843AEasy to useImplement automatic additionLocation information based serviceTelephone set constructionsGeolocationComputer terminal

Owner:SHENZHEN COSHIP ELECTRONICS CO LTD

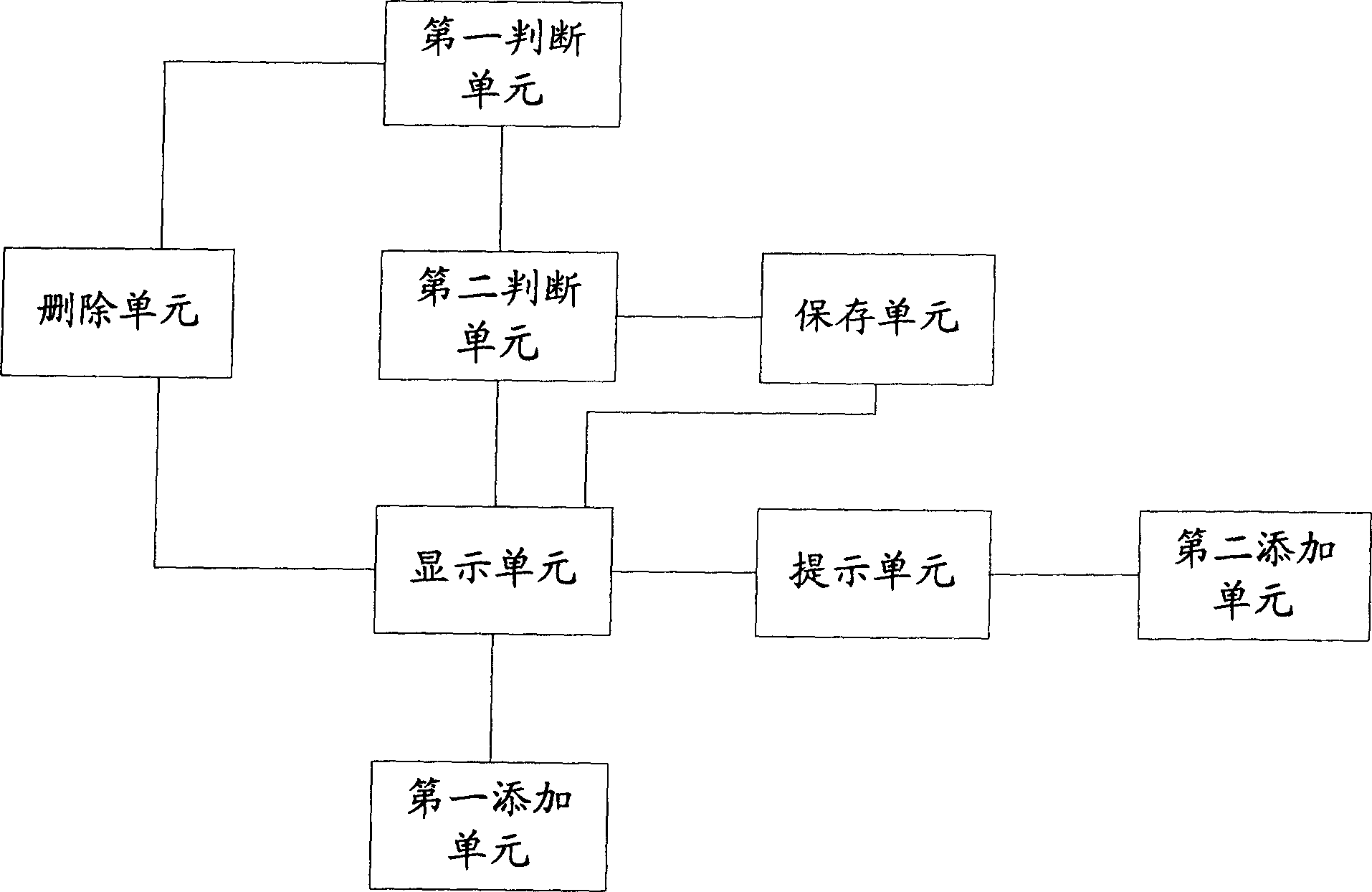

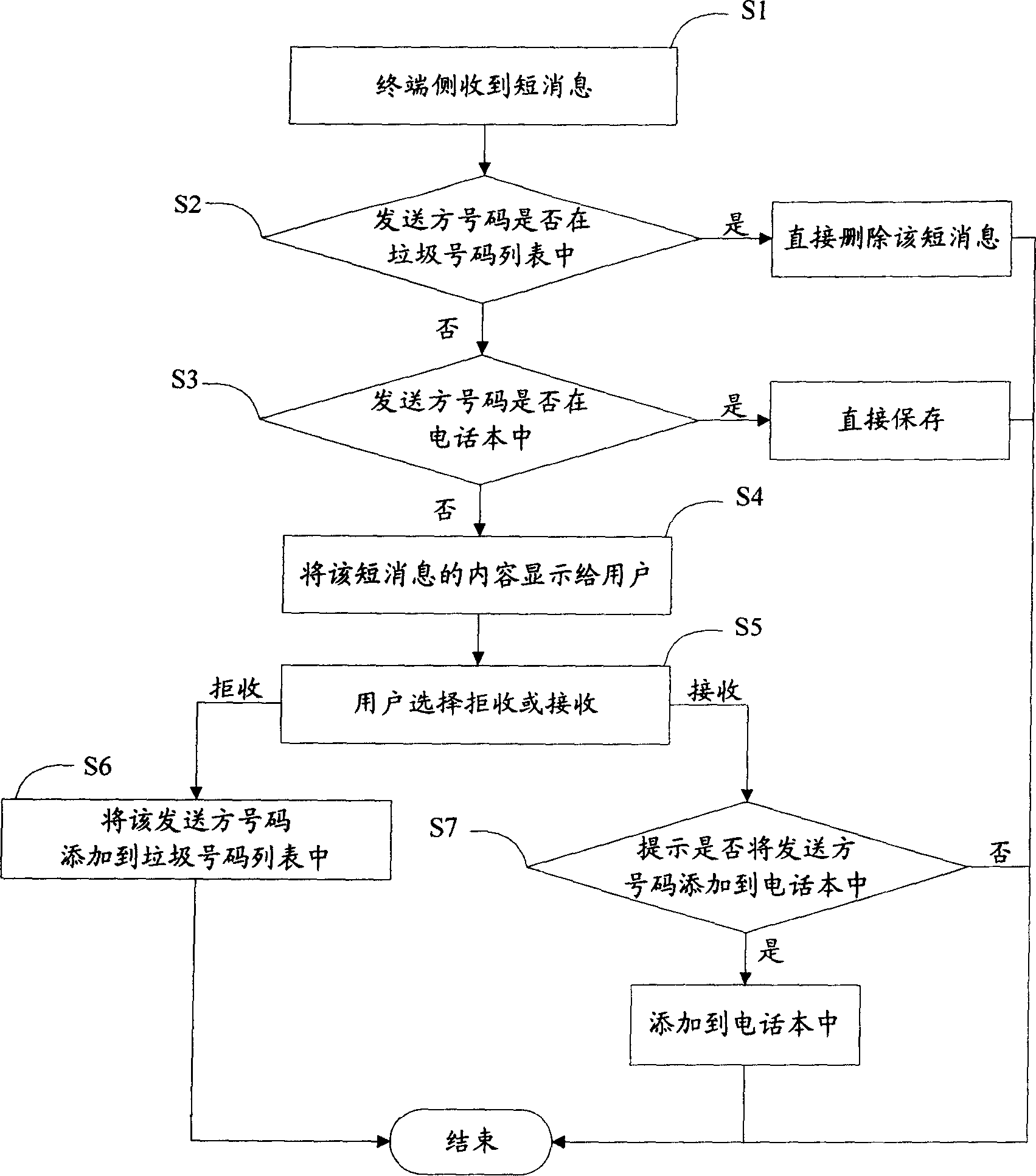

Method for filtering short message and mobile terminal

InactiveCN1889423ASave storage spaceAchieve maintenanceUnauthorised/fraudulent call preventionSpecial service for subscribersTelecommunicationsComputer terminal

This invention discloses a method for filtering short messages and a mobile terminal, in which, the method includes: when the terminal side determines that the sending party number of the received short message is not in the current rubbish number list or the current phone book of the local end, it displays said short message to the user, when the user refuses it, it adds the number of the sending party to the rubbish number list, by which, numbers of the sending party refused by users can be added to the rubbish number list automatically.

Owner:HUAWEI TECH CO LTD

Differential pressure mining dust removing agent automatic adding device

InactiveCN104632269AReduce dust concentrationImprove working environmentFlow mixersTransportation and packagingImpellerWater pipe

The invention particularly relates to a differential pressure mining dust removing agent automatic adding device and solves problems of high energy consumption, complicated structure and high fault rate in terms of existing dust removing devices. A filtrate net and a valve body integrated box are arranged at the bottom inside a liquid storing tank, a vent valve, a liquid adding opening and a pressure ventilation pipe are arranged at the top of the liquid storing tank, a liquid bag is disposed inside an agent adding box, a water inlet pipe is disposed at one end of a jet flow negative pressure pipe, an impeller stirrer is mounted at the other end of the jet flow negative pressure pipe, a flow guide water pipe is arranged between the valve body integrated box and a liquid inlet of the liquid bag, a single-way throttling valve and a back pressure valve are disposed on the flow guide water pipe, an agent adding pipe is disposed between a liquid outlet of the liquid bag and the side wall of the jet flow negative pressure pipe, a flowmeter and a proportional valve are disposed on the agent adding pipe, a side pressure water inlet pipe is disposed between the agent adding box and the jet flow negative pressure pipe, and a water inlet control valve is disposed on the side pressure water inlet pipe. According to the differential pressure mining dust removing agent automatic adding device, automatic adding of an agent is achieved, dust concentration on an excavation surface is effectively lowered, and working environment of an excavation work face is greatly improved.

Owner:TAIYUAN UNIV OF TECH

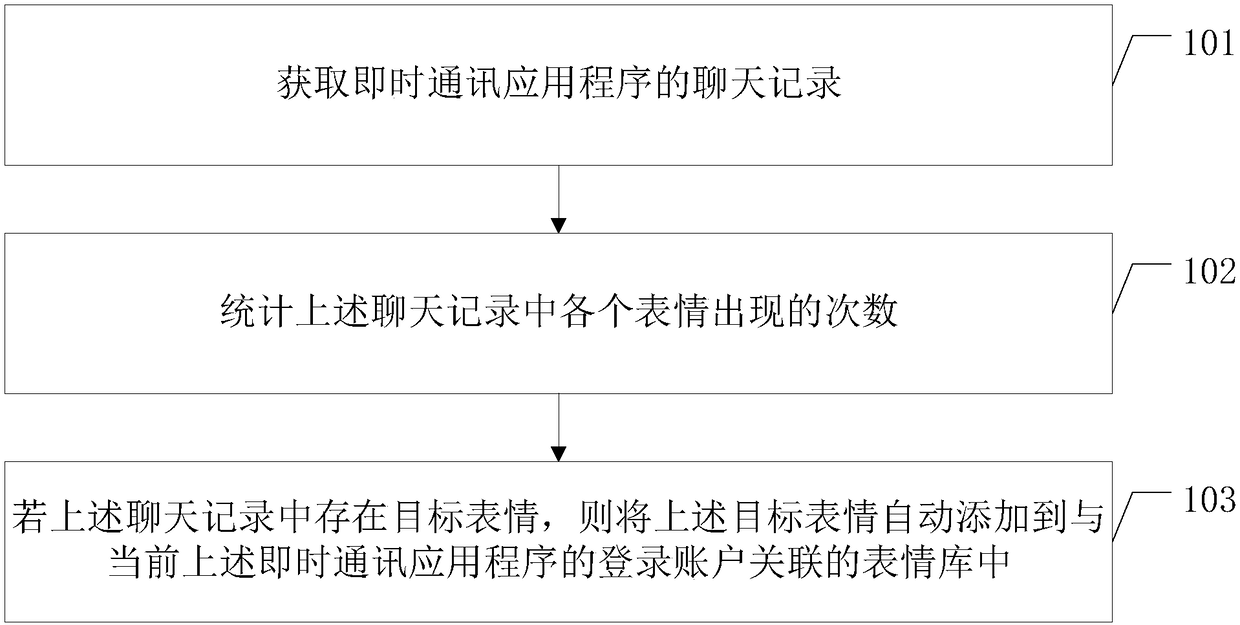

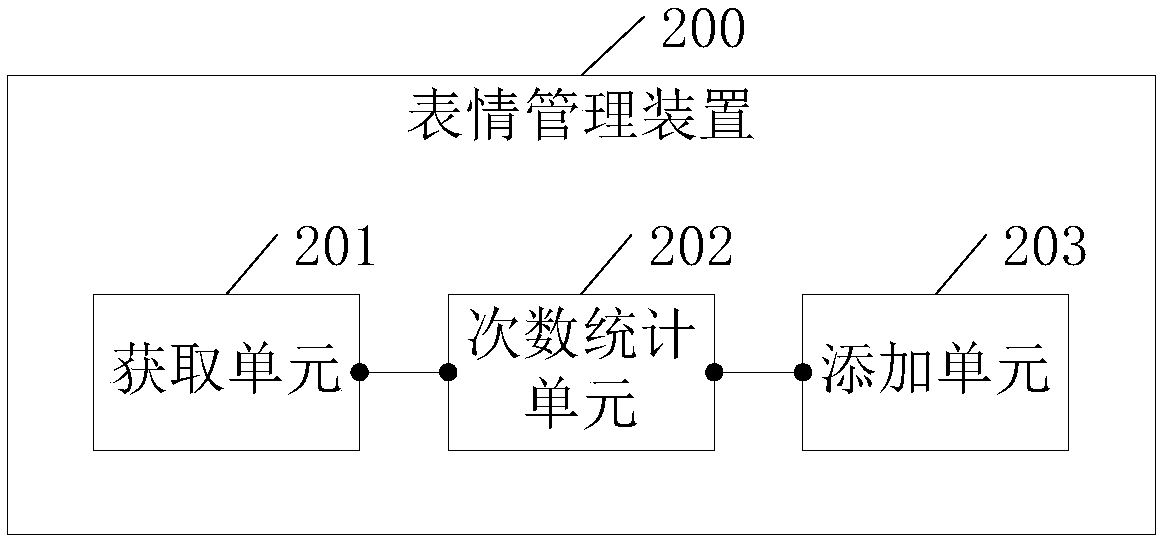

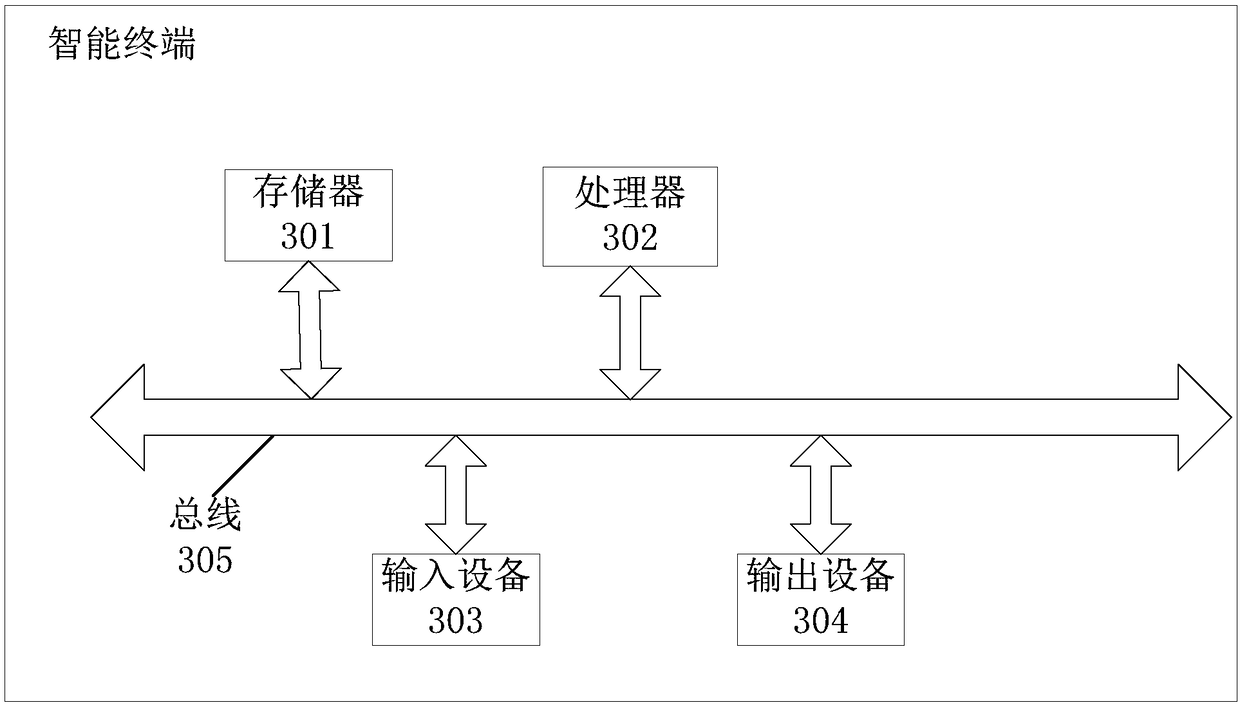

Emoji management method and device, and smart terminal

ActiveCN108234293AImplement automatic additionShort timeSubstation equipmentData switching networksApplication softwareComputer science

The invention provides an emoji management method and device, a smart terminal, and a computer-readable storage medium. The emoji management method comprises the following steps: acquiring chat records of an instant messaging application; acquiring the numbers of appearance times of emojis in the chat records; and if a target emoji exists in the chat records, automatically adding the target emojiinto an emoji library associated with a current logged-in account of the instant messaging application, wherein the target emoji is an emoji of which the number of appearance times exceeds a preset threshold and is not added to the emoji library. The method and device, the smart terminal and the computer-readable storage medium adopting the technical scheme has the advantage that the emojis can beautomatically added.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Automatically-proportioning solid-liquid raw material mixing and proportioning device for chemical production

InactiveCN112108055AImplement automatic additionRealize the function of automatic proportioningShaking/oscillating/vibrating mixersTransportation and packagingMixing effectMechanical engineering

The invention discloses an automatically-proportioning solid-liquid raw material mixing and proportioning device for chemical production. The device comprises a shell, a mixing barrel, a movable pipeand a spreading frame, wherein rollers are uniformly connected to the inner wall of the shell through shafts; a vibrating plate is arranged on the inner wall of the mixing barrel; a first return spring is arranged between and connected with a limiting block and the inner wall of a chute; the movable pipe is connected to the lower end of a discharging pipe through a bearing; a stirring rod is welded to the lower end of the spreading frame; a movable column is arranged on the inner side of the stirring rod; a second gear is connected to the interior of the shell through a shaft; and a pull ropeis arranged between and connected with the shaft end of a baffle and the second gear. According to the automatically-proportioning solid-liquid raw material mixing and proportioning device for chemical production, the adding amount of fixed raw materials can be controlled by utilizing the potential energy of injected liquid raw materials, so the solid-liquid raw materials can be simultaneously added, and the function of automatic proportioning is realized; and meanwhile, the solid raw materials can be effectively dispersed and added, so the mixing effect of the device is improved.

Owner:贺智豪

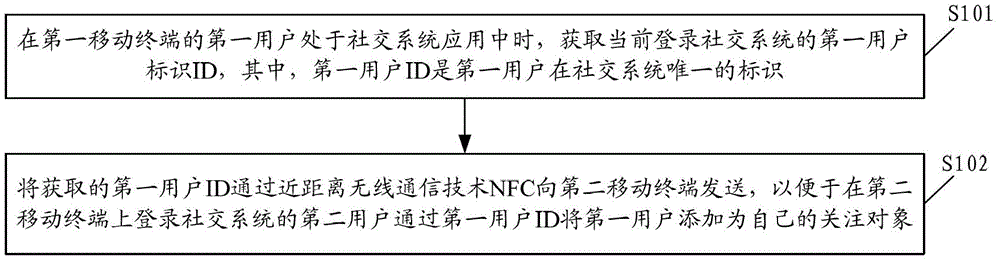

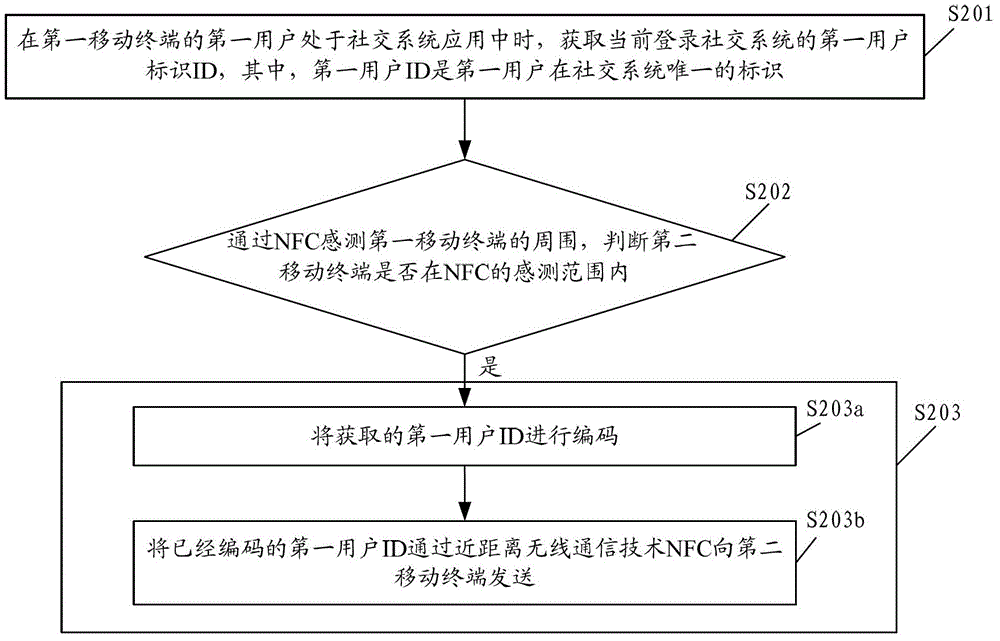

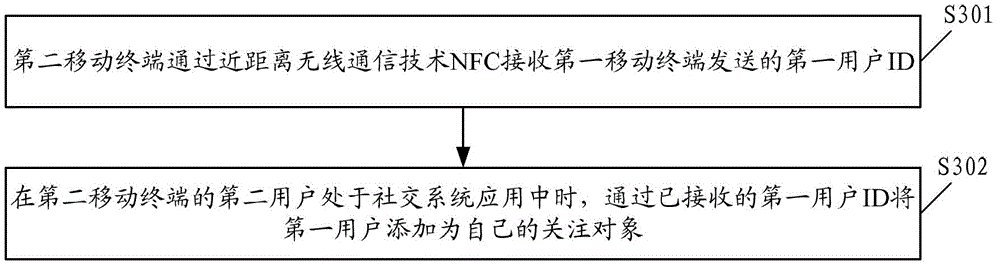

Method and mobile terminal for paying attention in social contact system

InactiveCN103338250AImplement automatic additionImprove communication efficiencyNear-field transmissionSubstation equipmentShortest distanceComputer terminal

The invention discloses a method and mobile terminals for paying attention in social contact system. The method comprises the following steps: when a first user of a first mobile terminal is in social contact system application, first user identification ID of a current login social contact system is acquired; the acquired first user ID is sent to a second mobile terminal through a short distance wireless communication technology NFC; the first user ID sent by the first mobile terminal is received by the second mobile terminal; the first user is paid attention by oneself through the first user ID received. Through the method, automatically paying attention can be realized.

Owner:HUIZHOU TCL MOBILE COMM CO LTD

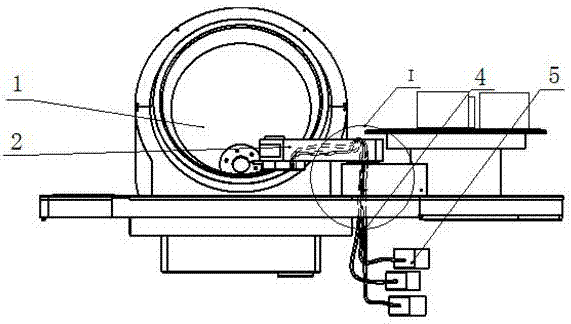

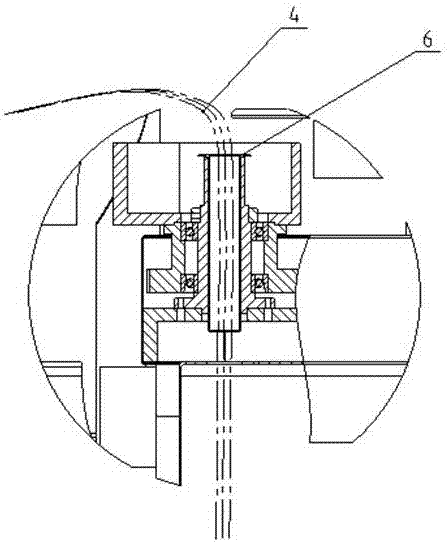

Robot feeding manipulator

InactiveCN107981734AImplement automatic additionSimple structureProgramme-controlled manipulatorCooking vesselsVertical axisRobot manipulator

The invention provides a robot feeding manipulator. The robot feeding manipulator comprises an automatic pan used in sauteing food, a feeding manipulator which transports main materials of dishes, a plurality of liquid nozzles and a plurality of liquid pumping components; the liquid nozzles through a plurality of transmission pipelines are connected with the liquid pumping components in a one-to-one correspondence mode; wherein the feeding manipulator which transports main materials of dishes comprises a first base, a rotating arm and an overturning component; one end of the rotating arm is arranged on the first base, and rotates along a vertical axis under the driving of a driving mechanism, the other end of the rotating arm is provided with a mounting seat, and the mounting seat is provided with the liquid nozzles and the overturning component; the overturning component pours out the materials in the material box by overturning. The robot feeding manipulator has the advantages that the structure is simple, the appearance is concise, the feeding efficiency is high, the occupation of land space is small, and the cost is cheap.

Owner:四川长虹智能制造技术有限公司

Kitchen garbage recycling treatment device

ActiveCN112222160AHigh recycling rate of resourcesEasy to useTransportation and packagingSolid waste disposalLeavening agentProcess engineering

The invention discloses kitchen garbage recycling treatment device. The kitchen garbage recycling treatment device comprises a box body. An oil collecting tank, a water collecting tank, a processor and a control panel are fixedly arranged in a side frame. A baffle is fixedly arranged at the output end of a second hydraulic cylinder, and a first push rod is fixedly connected to the non-center position of a circular blocking plate. An oil collecting disc is fixedly arranged in an inner cavity of an oil-water separation tank. A smashing box is fixedly arranged in an inner cavity of the box body,an ultraviolet lamp tube is embedded in a transparent cone, and metal cutting knife edges are fixedly arranged on the edges of the transparent cone. A pressing plate is movably arranged in a curing agent box, and a plurality of extrusion holes are formed in the side wall, located in a solidification cavity, of the operation box. The kitchen waste recycling treatment device is provided. Solid-liquid separation can be conducted at first and then oil-water separation is performed, the flotation effect is better, addition of a leavening agent and a curing agent can be achieved in a linkage mannerin the using process, manual operation is omitted, the function is concentrated, the structure is simple and device is very worthy of popularization.

Owner:北京申城生物科技集团有限公司

Lubricating oil guarantee device of automobile engine and control method thereof

ActiveCN105443193AReduce generationImplement automatic additionLubricant filling/drainingLubrication indication devicesEngineeringLubrication

The invention discloses a lubricating oil guarantee device of an automobile engine and a control method thereof. The lubricating oil guarantee device comprises a engine oil bottom shell stored with engine oil. Minimum engine oil amount required for lubrication of the engine is kept without considering engine oil loss within an oil change period when engine oil storage is set for the engine oil bottom shell. The device further comprises an engine oil adding storage tank. The method comprises following steps: detecting storage amount of engine oil in the oil bottom for engine oil; comparing the storage amount with setting storage amount; and adding engine oil to the engine oil bottom shell till the engine oil storage amount is above the set storage amount when the storage amount is less than the set storage amount. The lubricating oil guarantee device of the automobile engine and the control method thereof have following beneficial effects: on the condition that lubrication oil amount for normal operation of the engine is satisfied, lubrication oil is supplemented to the engine when lubrication oil of the engine is constantly consumed in order to ensure that lubrication amount of the engine is the most energy-saving state; efficiency of the engine is given into full play so that a lubrication system is more reasonable; and the engine is oil-saving and generation of carbon deposition is reduced.

Owner:刘新羽

Electrolyte solution charging device

ActiveCN108166022ASolve the problem of deposits on the lower part of the stirring shaftUniform reflowPhotography auxillary processesElectrolysis componentsElectrolysisPhysical chemistry

The invention discloses an electrolyte solution charging device which is used for producing copper foils. The electrolyte solution charging device comprises an electrolyte solution stirring barrel, abuffer storage barrel, an electrolysis slot and a controller, wherein a first pump is used for extracting an electrolyte solution in the electrolyte solution stirring barrel through a pipeline, and feeding the electrolyte solution into the buffer storage barrel through a solution transfer pipeline; the electrolyte solution in the buffer storage barrel is fed into the electrolysis slot through a flow pump; an electrolyte solution sensor is arranged in the electrolysis slot; and the electrolyte solution sensor is mainly used for measuring concentration of copper sulfate in the electrolysis slotin real time. The invention aims to provide the electrolyte solution charging device which can solve the problem about how to automatically charge the electrolyte solution.

Owner:陈治政

Automatic cooker

InactiveCN106618150AImplement automatic additionThe amount of seasoning added is controllableCooking-vessel lids/coversAutomatic controlEngineering

The invention relates to an automatic cooker which comprises a cooking bench, a conveyor belt, multiple pots, a hopper and pot covers. The two sides of the conveyor belt are provided with side plates; openings are formed in the portions, corresponding to the pots, of the side plates, and side wing grooves are formed in the openings; the lower ends of the side wing grooves are connected to the edges of pot openings of the pots in an abutting mode; a push plate and a first electric push rod for pushing the push plate towards the corresponding opening are arranged on the portion, corresponding to each opening, of the corresponding side plate, and stirring shovels are arranged in the centers of the pot covers. The automatic cooker has the advantages that automatic cooking can be achieved, multiple dishes can be independently cooked simultaneously, and not only can the cooking efficiency be improved, but also the single-pot single-dish delicious taste can be guaranteed; the whole process is automated, operation is easy and practical, both the adding quantity and the adding time of seasonings can be automatically controlled through programs, and the taste can be consistent.

Owner:吴佳涵

Nickel core coating braze coating material

InactiveCN110711972AOvercoming processabilityOvercoming bar problemsWelding/cutting media/materialsSoldering mediaSlurryFiller metal

The invention provides a nickel core coating braze coating material. The nickel core coating braze coating material is of a double-layer structure, is in a wire shape or a strip shape and comprises aninner core material and a coating layer wrapping the outer part of the inner core material, wherein the inner core material is a pure nickel wire or a pure nickel strip with a plurality of grooves inthe surface; and the coating layer comprises, by weight, 5 parts of organic binding agents, 15-45 parts of WC particles, 6 parts of brazing flux and the balance brazing filler metal powder. A preparing method of the nickel core coating braze coating material comprises the steps that the brazing filler metal powder, the WC particles, the brazing flux and the organic binding agents are prepared into suspension slurry to be added into a powder coating cylinder of a press coating device, the pure nickel wire or the pure nickel strip is fed into the powder coating cylinder through a wire feeding mechanism, the surface of the pure nickel wire or the pure nickel strip is evenly coated with the suspension slurry through the press coating device, the coating layer is formed, drying is conducted through a tunnel drying oven, and the nickel core coating braze coating material is obtained through a winding device. The bonding strength of a coating of the nickel core coating braze coating materialis high, the problem that nickel base brazing filler metal is difficult to machine into wires or strips is solved, and automatic production can be achieved in the braze coating process.

Owner:CHINA INNOVATION ACADEMY OF INTELLIGENT EQUIP CO LTD +1

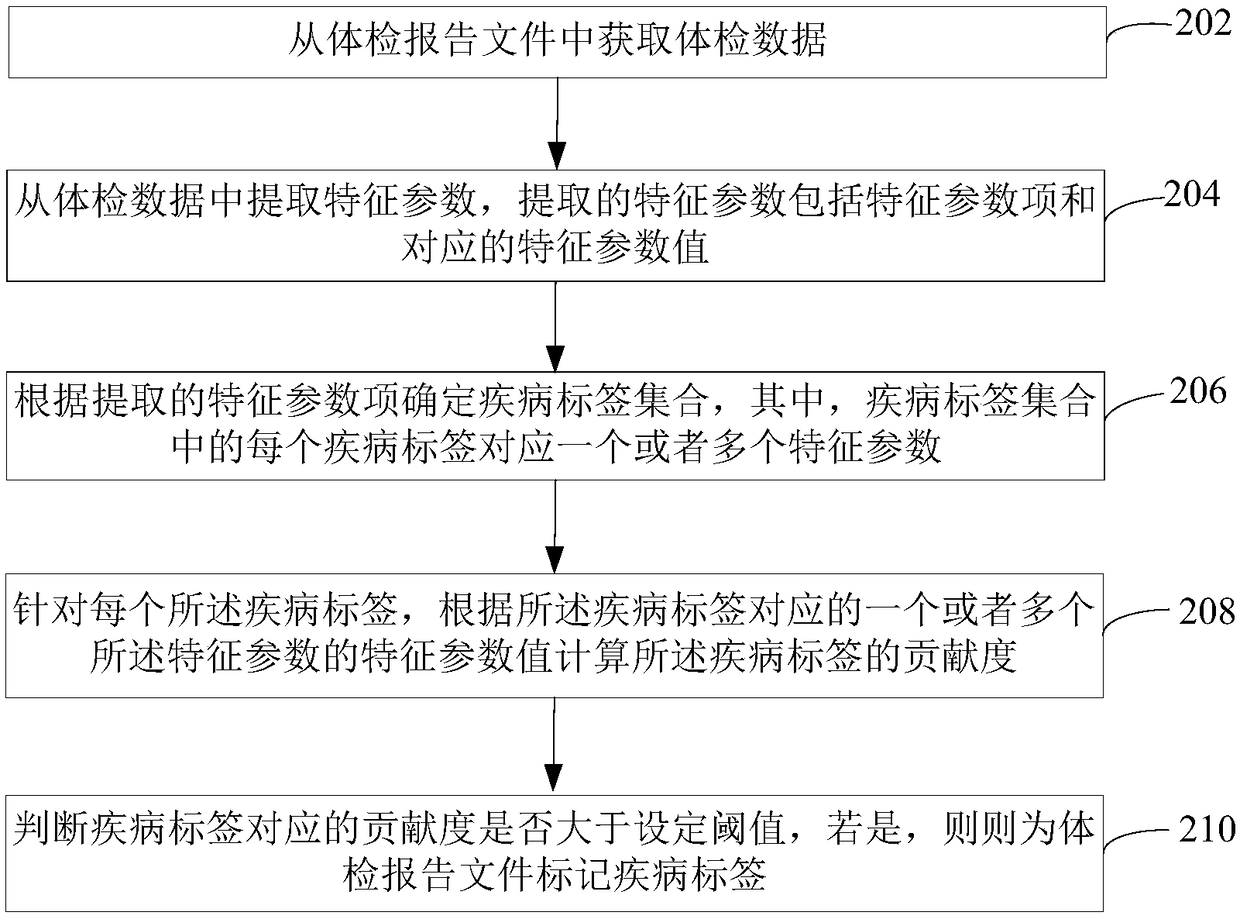

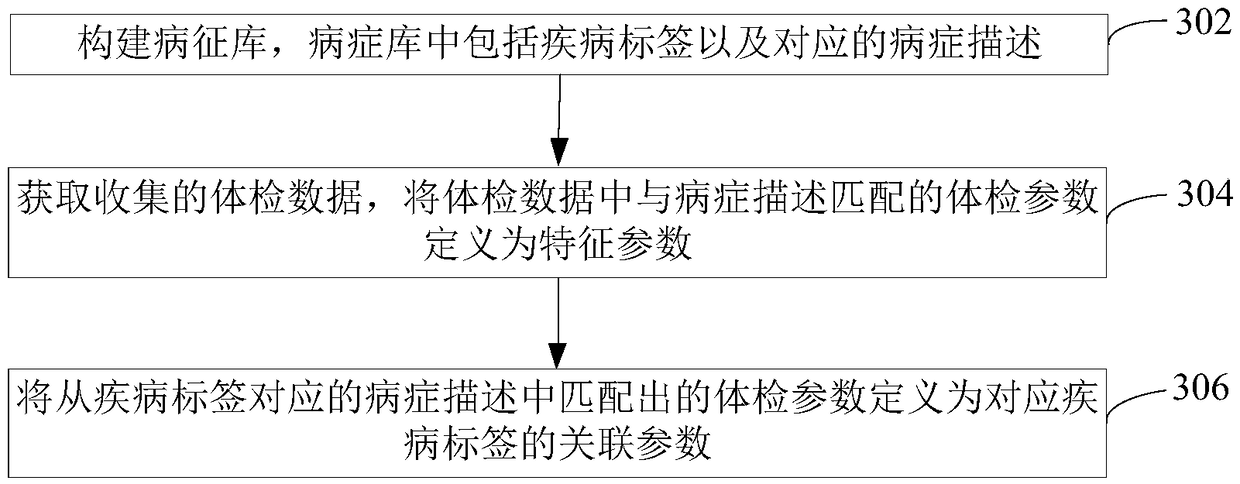

Physical examination data processing method and apparatus, computer apparatus and storage medium

ActiveCN108899063ARealize automatic judgmentImplement automatic additionPatient-specific dataDiseaseComputer science

The application relates to a physical examination data processing method and apparatus, a computer apparatus and a storage medium. The method comprises: physical examination data are obtained from a physical examination report file; characteristic parameters are extracted from the physical examination data, wherein the extracted characteristic parameters include characteristic parameter items andcorresponding characteristic parameter values; a disease tag set is determined based on the extracted characteristic parameter items, wherein each disease tag in the disease tag set corresponds to oneor more characteristic parameters; according to characteristic parameter values of corresponding one or more characteristic parameters, contribution degrees of the disease tags in the disease tag setare calculated; and whether the contribution degrees of the disease tags are larger than a set threshold is determined; if so, the physical examination report file is marked with the disease tag. Therefore, the health tag of the physical examination report is determined automatically.

Owner:KANG JIAN INFORMATION TECH (SHENZHEN) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com