Fast, low-overhead and full-automatic digital integrated circuit single-particle fault injection system

A fault injection and integrated circuit technology, applied in the direction of measuring electricity, measuring electrical variables, measuring devices, etc., can solve the problems of poor versatility of commercial simulation software, low connection level, and affecting the test process, etc., to solve memory explosion, The effect of reducing performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Considering that the level of intelligence is not enough for large-scale integrated circuit single event fault injection, and the requirements for large memory and high performance of the computer for fault injection, a fast, low-cost, fully automatic digital integrated circuit single event fault injection system is provided. Based on the flexible analysis of the hardware programming language, the system can realize fully automatic fault injection for all unit types in the library unit, and process the process files generated during the fault injection process in real time, reducing the computer used for fault injection The load realizes fully automatic single event fault injection.

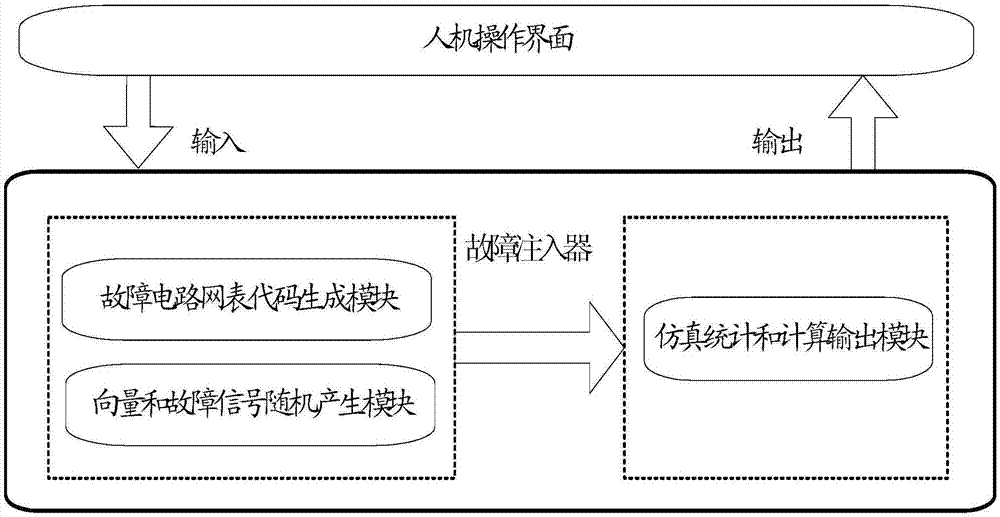

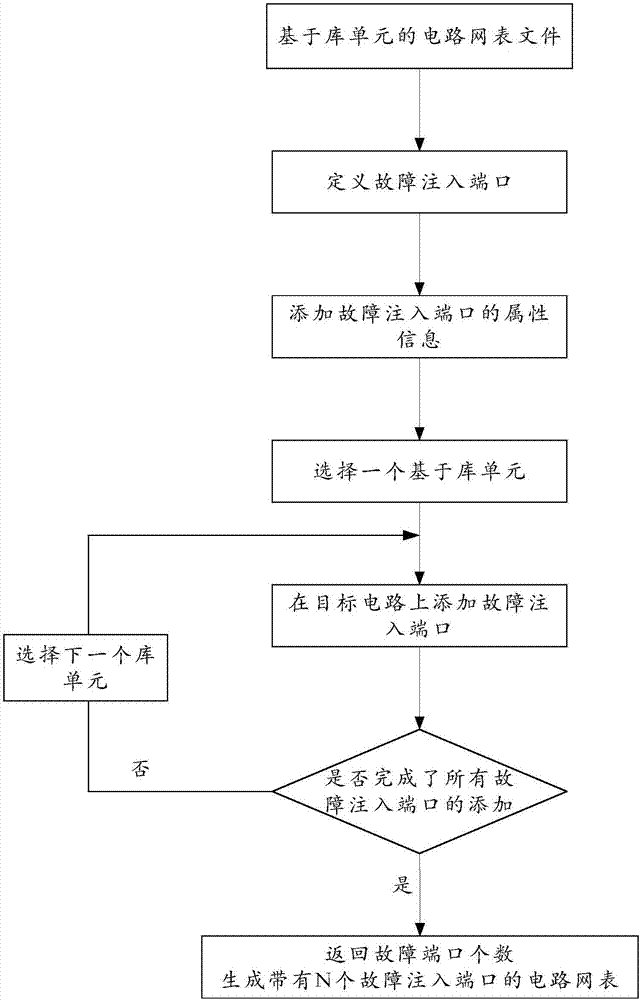

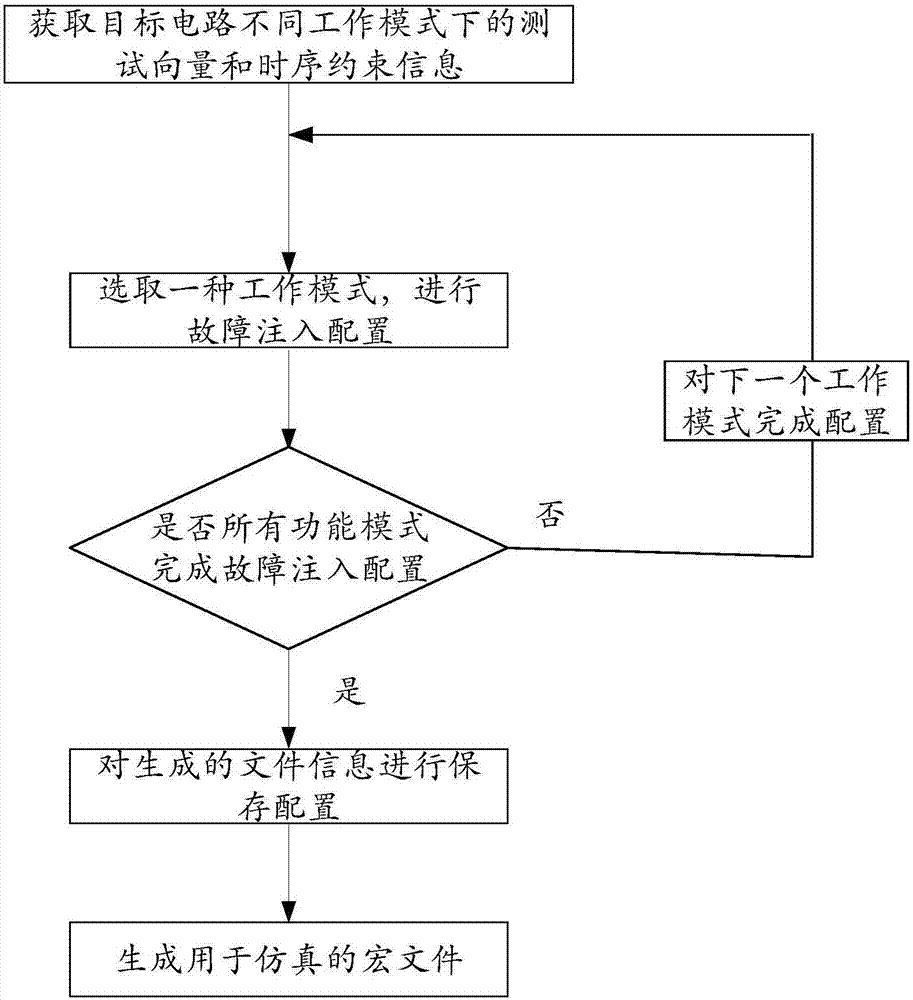

[0037] figure 1 It is a schematic diagram of the structure of the present invention. The device of the present invention includes a man-machine interface, a fault injector, a TCL interface protocol module and a commercial software module; wherein the fault injector includes a fault circui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com