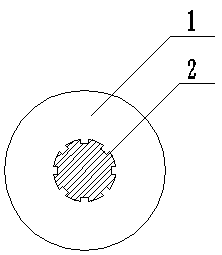

Nickel core coating braze coating material

A brazing and coating technology, applied in welding/cutting media/materials, welding media, metal processing equipment, etc., can solve the problems of low work efficiency, poor workability, waste of flux, etc., to achieve automatic production, promote lubrication Wet spreading, the effect of ensuring the quality of the brazing coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Choose BNi-2 solder alloy (BNi85.4Cr7Si4.5B3.1Fe3), take a pure nickel wire with a diameter of 1.0mm and a surface of 11 meters long with grooves, and weigh the quality of the nickel wire to be 70 grams. Since the percentage of Ni is 85.4%, then the total mass of the solder alloy is 82 grams, and the other elements Cr, Si, B, Fe in the solder alloy are calculated according to the mass fraction percentage of each element of the solder alloy, a total of 12 grams, if the WC mass percentage is 15%, The mass percentage of brazing flux is 6%, and the binder is 5%, so the mass percentage of solder alloy in the whole coating material is (100-15-6-5)%=74%. The mass of the entire coating layer is calculated from the total mass of the solder alloy and the mass percentage of the solder alloy, thereby calculating the quality of WC, the quality of the flux, and the quality of the binder. WC particles are selected from 20-30 mesh cast tungsten carbide powder, flux Use borax: calcium f...

Embodiment 2

[0033] Choose BNi-2 solder alloy (BNi85.4Cr7Si4.5B3.1Fe3), take a pure nickel wire with a diameter of 2.0mm and a surface of 103 meters long with grooves, and weigh the mass of the nickel wire to be about 2796 grams. Due to the percentage of Ni is 85.4%, then the total mass of solder is 3274 grams. The other elements of the solder, Cr, Si, B, and Fe, are calculated according to the mass fraction percentage of each element of the solder, which is about 478 grams in total. If the mass percentage of WC is 20%, the mass percentage of flux is 6%, and the binder is 5%, then the mass percentage of brazing material in the entire coating material is (100-20-6-5)%=69% . From the total mass of brazing material and the mass percentage of brazing material, the mass of the entire sheathed brazing coating material is calculated, so as to calculate the quality of WC, flux, and binder. WC particles choose cast tungsten carbide powder of 20-30 meshes, and the brazing flux is borax:calcium flu...

Embodiment 3

[0037]Choose BNi-2 solder alloy (BNi85.4Cr7Si4.5B3.1Fe3), take a pure nickel wire with a diameter of 3.0mm and a surface of 105 meters long with grooves, and weigh the nickel wire to be about 6291 grams. The mass fraction percentage of each element calculates the remaining solder metal powder Cr, Si, B, Fe, which is about 1075.5 grams in total, and the total mass of the solder is 7366.5 grams. If the mass percentage of WC is 25%, the mass percentage of flux is 6%, and the binder is 5%, then the mass percentage of brazing material in the entire coating material is (100-25-6-5)%=64% . From the total mass of brazing material and the mass percentage of brazing material, the mass of the entire sheathed brazing coating material is calculated, so as to calculate the quality of WC, flux, and binder. WC particles choose 20-30 mesh cast tungsten carbide powder, and the brazing flux uses borax: calcium fluoride = 90:10 hard brazing flux.

[0038] First, the above-mentioned solder metal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com