Composite condensing/evaporating four-functional hot water heat pump air conditioner device

A heat pump air conditioning and hot water technology, which is applied in air conditioning systems, refrigerators, household heating and other directions, can solve problems such as unfavorable production and processing, thermal pollution, waste of energy, etc., and achieves easy production and processing, less component changes, Overcome the complex effects of retrofits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

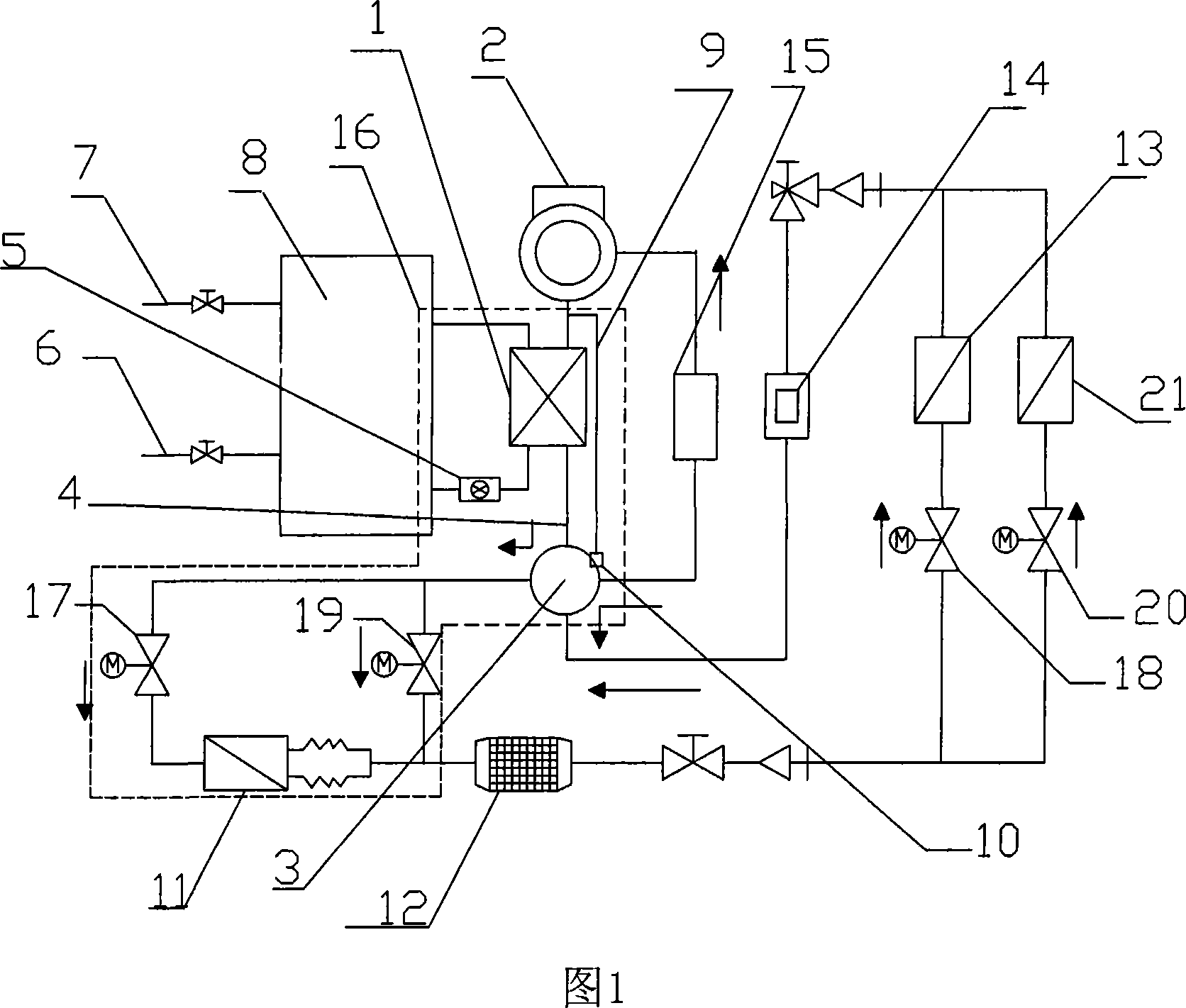

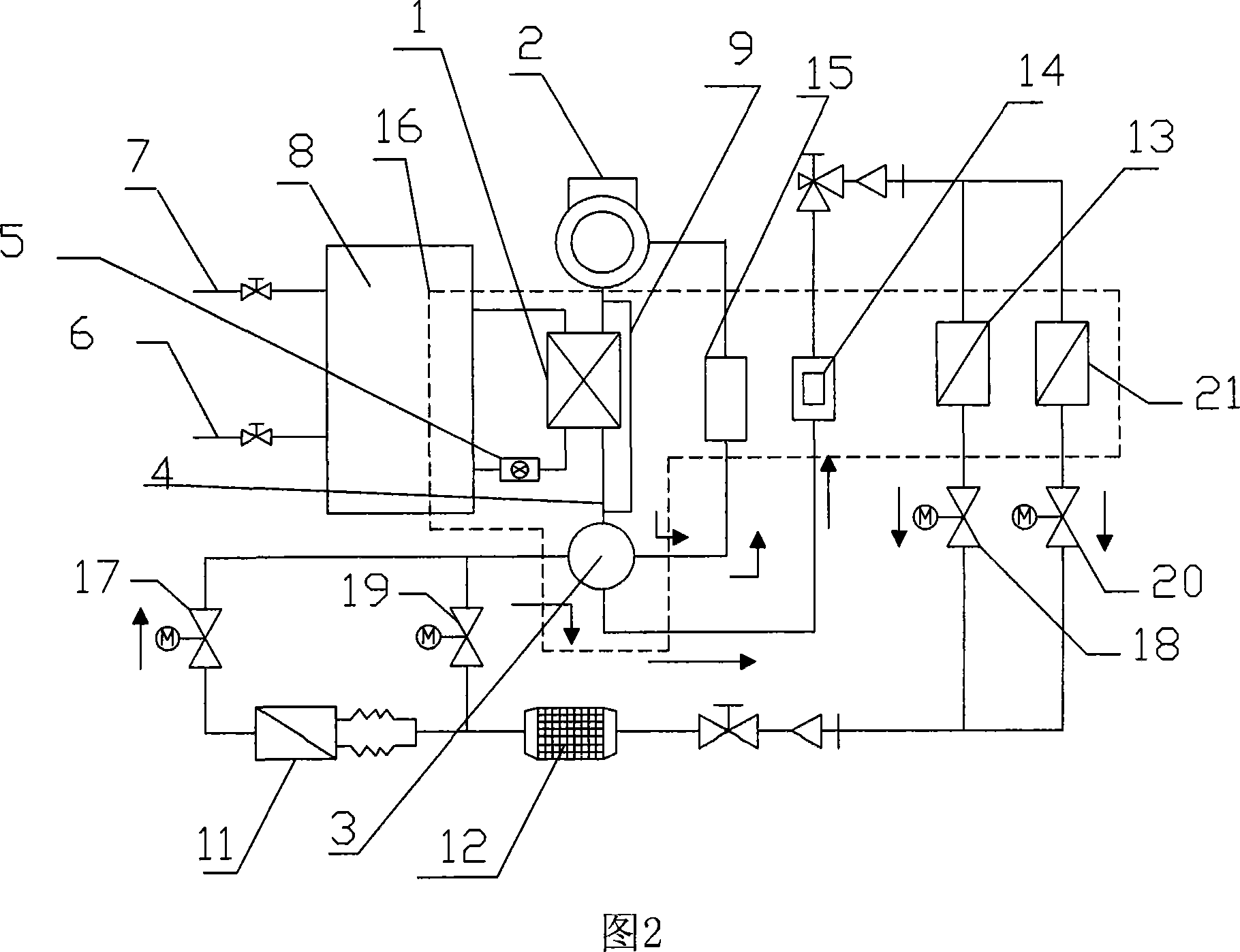

[0013] Referring to Fig. 1, the heat exchanger water storage tank 8 provided with the input pipe 6 and the output pipe 7 is connected in series between the outlet of the compressor 2 and the inlet 4 of the high pressure side of the four-way valve 3 through the water heat recovery device 1 of the delivery pump 5, and the bypass One end of the control pipe 9 communicates with the outlet of the compressor 2, the other end communicates with the inlet of the pilot valve 10 on the pneumatic control pipe of the four-way valve 3, and one end of the condenser 11 communicates with the outlet of the four-way valve 3 through the first control solenoid valve 17 to condense The other end of the device 11 communicates with the outlet of the four-way valve 3 through the second control solenoid valve 19; the air-cooled evaporator 13 and the water-cooled evaporator 21, which are respectively connected in series with the third control solenoid valve 18 and the fourth control solenoid valve 20, are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com