Polyarylether ketone/carbon nanotube composite material with high dielectric property and preparation method thereof

A polyaryletherketone and carbon nanotube technology, which is applied in the field of polyaryletherketone/carbon nanotube composite materials and their preparation, and can solve the problems of limited use environment conditions and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

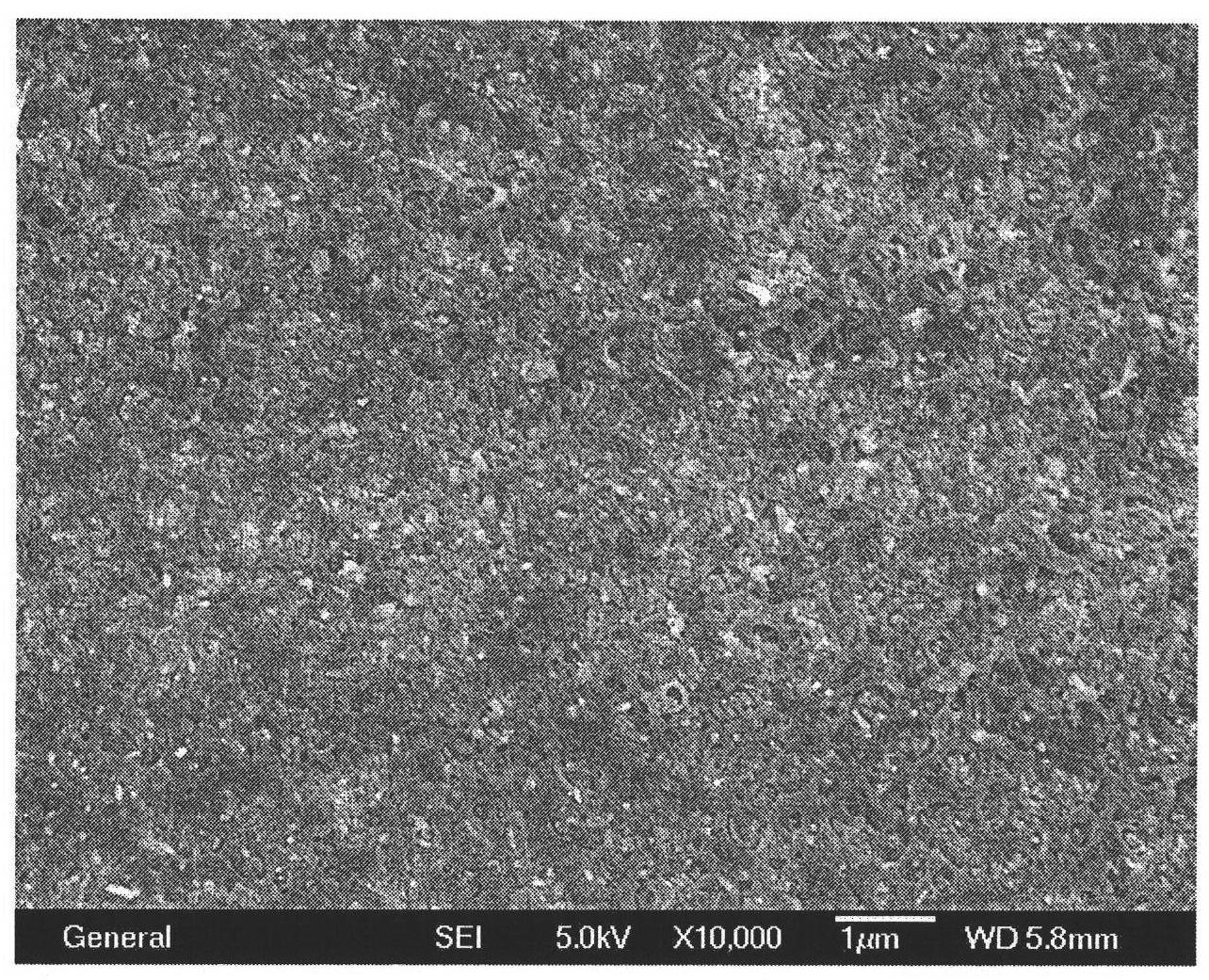

[0034] 1 g of sulfonated polyaryletherketone (x 1 / y 1 =30 / 70) (the density is 1.22g / cm 3 , with a volume of 0.820cm 3 ) was dissolved in 5ml NMP; 0.0173 grams of unmodified carbon nanotubes (density 2.1g / cm 3 , with a volume of 0.0082cm 3 , with a volume fraction of 1%) sonicated for 2 hours to make it evenly dispersed in 1ml NMP; then the two solutions were mixed together and continued to be sonicated for 4 hours, and then cast onto a smooth glass plate, dried at 80°C, and then continued at 120°C The functionalized polyaryletherketone / carbon nanotube composite material is obtained by vacuum drying at high temperature for 24 hours.

[0035] The dielectric properties of the materials were measured, and the dielectric constants are shown in Table 1 (test temperature 25°C, test frequency 1000 Hz).

Embodiment 2

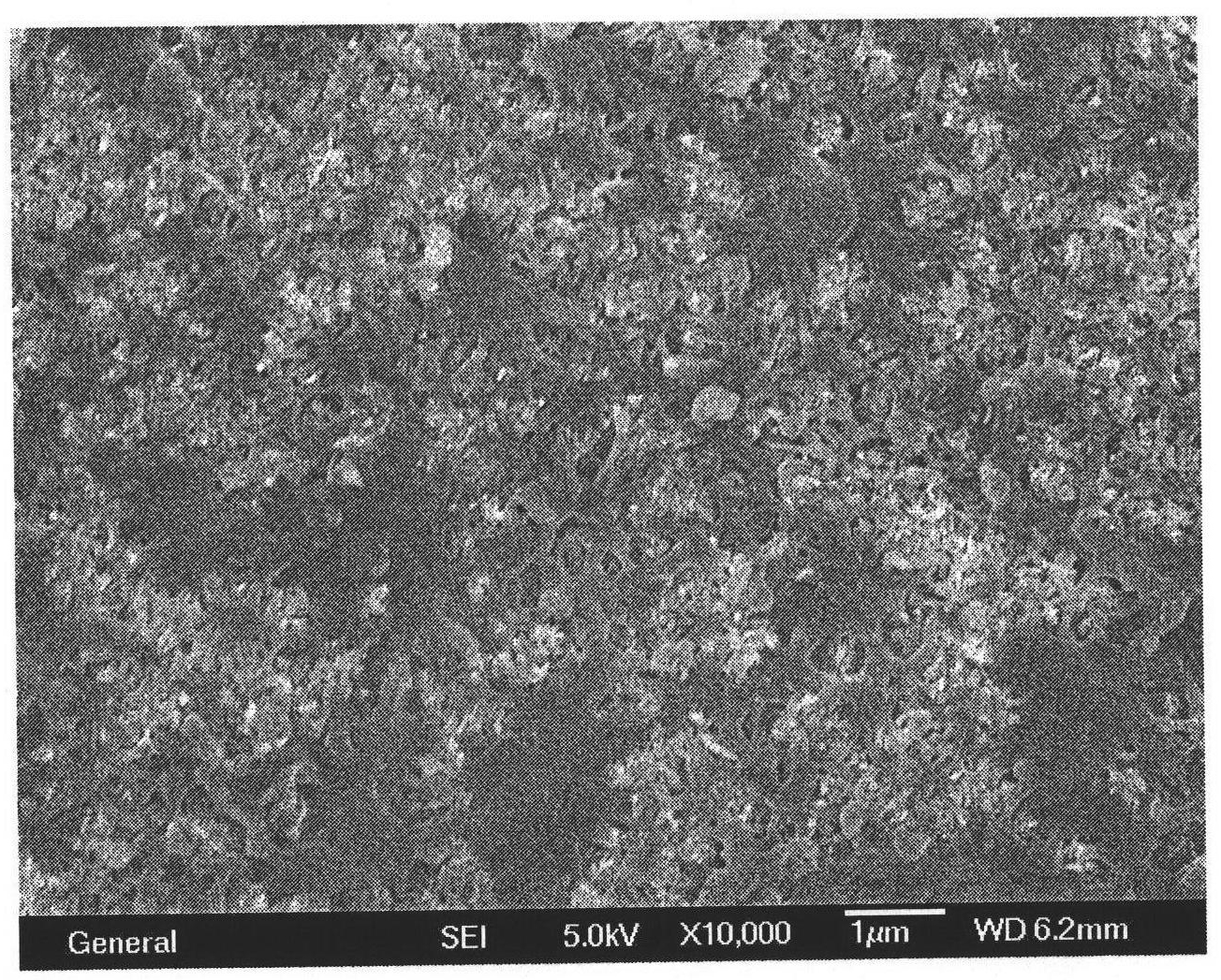

[0037] 1 g of sulfonated polyaryletherketone (x 1 / y 1 =30 / 70) (the density is 1.22g / cm 3 , with a volume of 0.820cm 3 ) was dissolved in 5ml NMP; 0.0173 grams of carboxylic acid-modified carbon nanotubes (density 2.1g / cm 3 , the volume is 0.0082cm, and the volume fraction is 1%) sonication for 2h to make it uniformly dispersed in NMP; mix the two solutions together and continue to sonicate for 4h, then cast onto a smooth glass plate, dry at 80°C, and continue Vacuum dry at 120°C for 24 hours. The dielectric properties of the materials were measured, and the dielectric constants are shown in Table 1 (test temperature 25°C, test frequency 1000 Hz).

Embodiment 3

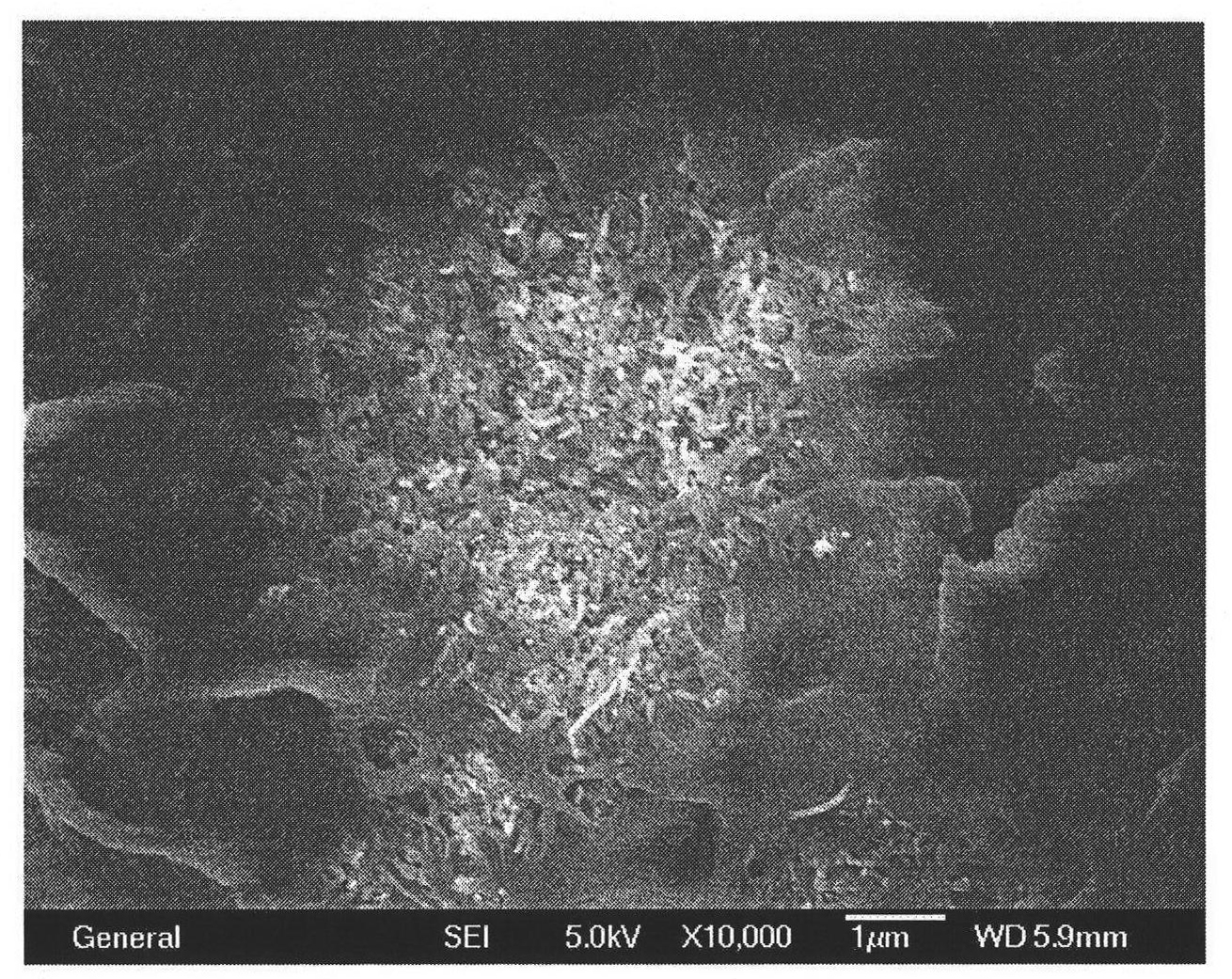

[0039] 1 g of sulfonated polyaryletherketone (x 1 / y 1 =30 / 70) was dissolved in 5ml NMP; 0.0533 grams (3% by volume) of carboxylic acid-modified carbon nanotubes were sonicated for 4h to make them evenly dispersed in NMP; the two solutions were mixed together and continued to be sonicated for 4h, and then cast On a smooth glass plate, after drying at 70°C, continue vacuum drying at 130°C for 16 hours. material appearance see figure 1 , The dielectric constant is shown in Table 1 (test temperature 25°C, test frequency 1000Hz).

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com