Two-component microwave ferrite material as well as preparation method and application thereof

A ferrite material and microwave technology, applied in the field of two-component microwave ferrite material and its preparation, can solve problems such as unsuitable for low-field work, low line width, and low saturation magnetic moment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

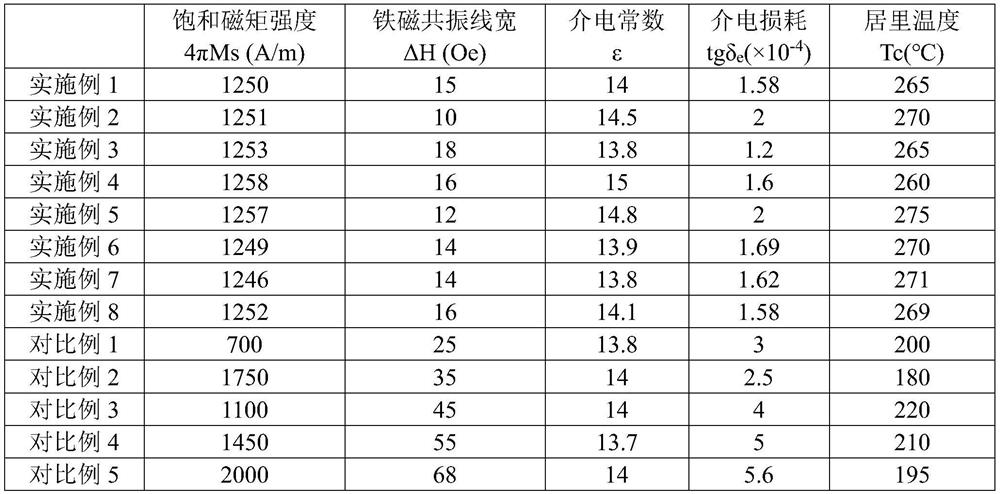

Examples

Embodiment 1

[0118] This embodiment provides a method for preparing a two-component microwave ferrite material. The two-component microwave ferrite material includes a first microwave ferrite material and a second microwave ferrite material.

[0119] The first microwave ferrite material is: Y (3-2a-c-d-e) Ca (2a+c+d+e) Fe (5-a-b-c-d-e) V a Al b Zr c sn d mn e o 12 , where a=0.35, b=0.15, c=0.2, d=0.1, e=0.04;

[0120] The second microwave ferrite material is Gd (3-2A-C-D) Ca (2A+C+D) Fe (5-A-B-C-D-E) V A Al B Ge C In D Ti E o 12 , where A=0.35, B=0.05, C=0.1, D=0.1, E=0.05.

[0121] The preparation method of the two-component microwave ferrite material comprises the following steps:

[0122] (1) Evenly mix the first microwave ferrite material and the second microwave ferrite material according to the mass ratio of 1:1 to obtain the preparation raw material; then prepare the raw material, zirconium ball and deionized water according to the mass ratio of 1:4: 1 mixed, and ...

Embodiment 2

[0133] This embodiment provides a method for preparing a two-component microwave ferrite material. The two-component microwave ferrite material includes a first microwave ferrite material and a second microwave ferrite material.

[0134] The first microwave ferrite material is: Y (3-2a-c-d-e) Ca (2a+c+d+e) Fe (5-a-b-c-d-e) V a Al b Zr c In d mn e o 12 , where a=0.25, b=0.25, c=0.1, d=0.2, e=0.05,;

[0135] The second microwave ferrite material is Gd (3-2A-C-D) Ca (2A+C+D) Fe (5-A-B-C-D-E) V A Al B Ge C In D Ti E o 12 , where A=0.25, B=0.05, C=0.2, D=0.3, E=0.1.

[0136] The preparation method of the two-component microwave ferromagnetic material comprises the following steps:

[0137](1) Uniformly mix the first microwave ferrite material and the second microwave ferrite material according to the mass ratio of 1:3 to obtain the preparation raw material; then prepare the raw material, zirconium ball and acetone according to the mass ratio of 1:7:1.3 Mix, carry...

Embodiment 3

[0148] This embodiment provides a method for preparing a two-component microwave ferrite material. The two-component microwave ferrite material includes a first microwave ferrite material and a second microwave ferrite material.

[0149] The first microwave ferrite material is: Y (3-2a-c-d-e) Ca (2a+c+d+e) Fe (5-a-b-c-d-e) V a Al b Zr c sn d mn e o 12 , where a=0.3, b=0.2, c=0.05, d=0.25, e=0.1;

[0150] The second microwave ferrite material is Gd (3-2A-C-D) Ca (2A+C+D) Fe (5-A-B-C-D-E) V A Al B Ge C In D Ti E o 12 , where A=0.1, B=0.3, C=0.05, D=0.5, E=0.2.

[0151] The preparation method of the two-component microwave ferromagnetic material is as follows:

[0152] (1) Uniformly mix the first microwave ferrite material and the second microwave ferrite material according to the mass ratio of 1:1 to obtain the preparation raw material; then prepare the raw material, zirconium ball and n-propanol according to the mass ratio of 1:6 : 1.4 mixing, carrying out 60...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com