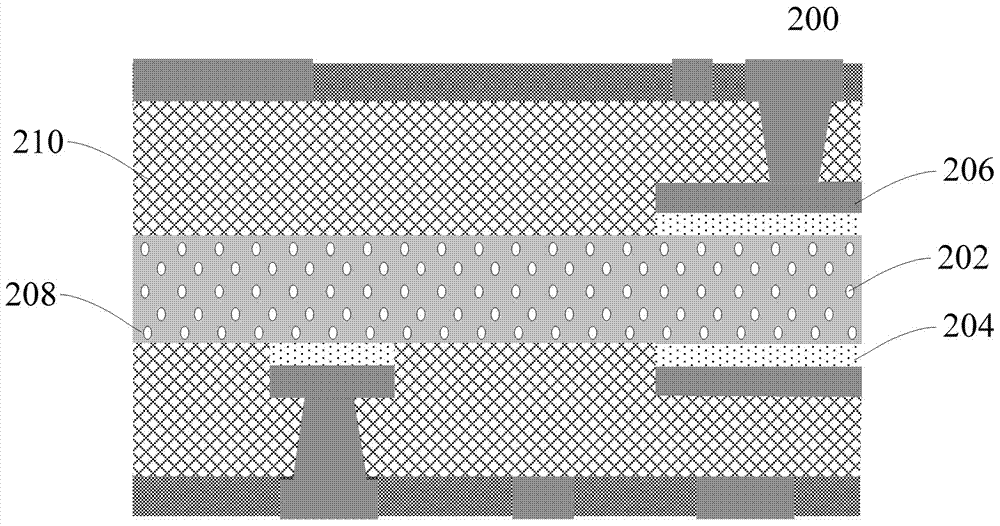

Capacitor, capacitor-burying circuit board and manufacturing method thereof

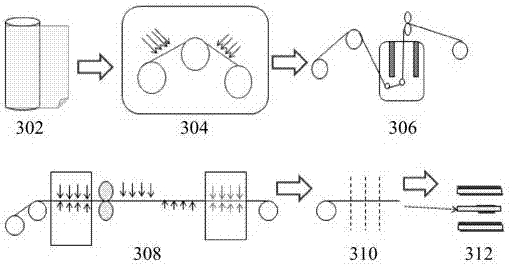

A technology of capacitors and conductive materials, applied in the manufacture of multilayer circuits, including printed capacitors, including printed electrical components, etc., can solve the problem of small peel strength, easy peeling and bending, application limitations in the field of buried capacitors, and copper electrode thickness. Reduce and other problems to achieve the effect of expanding the number of applications, avoiding the peeling of the laminated copper foil, and reducing the number of pinholes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

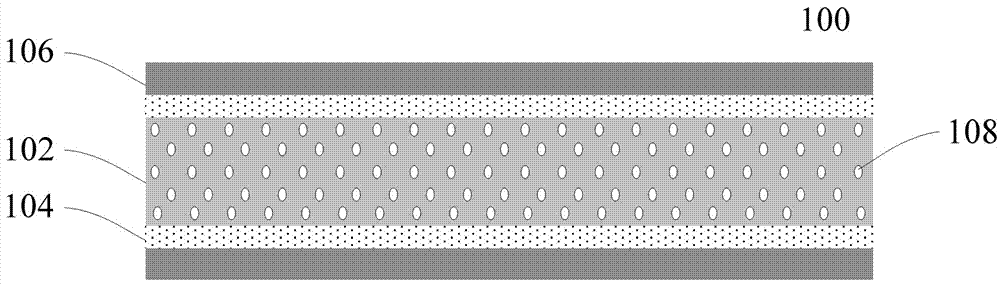

[0100] Substrate components: 20% epoxy resin, BaTiO 3 80%

[0101] Resin thickness: 15 microns

[0102] Dielectric constant: 20, much lower than 35 of similar materials in the prior art

[0103] Dielectric loss factor: 0.009, far lower than 0.014 of similar materials in the prior art.

[0104] First, ion-implant nickel into the substrate, and then conduct plasma deposition of nickel-copper (10-90) alloy to form a metal layer, thereby obtaining a capacitor. The capacitance of the final capacitor is 35, and its performance is more than 50% higher than that of ordinary capacitors.

Embodiment 2

[0106] Substrate components: 15% PI resin, 85% high dielectric constant filler

[0107] Resin thickness: 10 microns

[0108] Dielectric constant: 15, much lower than 40 of similar materials in the prior art

[0109] Dielectric loss factor: 0.010, far lower than 0.029 of similar materials in the prior art.

[0110] Firstly, ion-implanting nickel-chromium alloy into the base material, then depositing nickel by magnetron sputtering, and then depositing copper by magnetron sputtering to prepare a metal layer, thereby obtaining a capacitor. The electrostatic capacitance of the final capacitor is 25, and its performance exceeds that of ordinary capacitors by more than 80%.

Embodiment 3

[0112] Substrate composition: 15% epoxy resin, 85% high dielectric constant filler

[0113] Resin thickness: 20 microns

[0114] Dielectric constant: 15, much lower than 40 of similar materials in the prior art

[0115] Dielectric loss factor: 0.010, far lower than 0.047 of similar materials in the prior art.

[0116] Firstly, ion-implanting nickel-chromium alloy into the base material, then depositing nickel by magnetron sputtering, and then depositing copper by magnetron sputtering to prepare a metal layer, thereby obtaining a capacitor. The electrostatic capacitance of the final capacitor is 30, and its performance exceeds that of ordinary capacitors by more than 90%.

[0117] IX. Conclusion

[0118] The invention can realize metallization on the high dielectric constant polymer substrate with a dielectric constant particle content of more than 80%, and the prepared metal layer and the substrate have high peel strength. Compared with the magnetron sputtering method or p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com