Patents

Literature

36results about How to "Solve the problem of easy peeling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ballastless track structure

InactiveCN101798785AImprove integritySolve the problem of easy peelingBallastwayBuilding constructionSelf-consolidating concrete

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

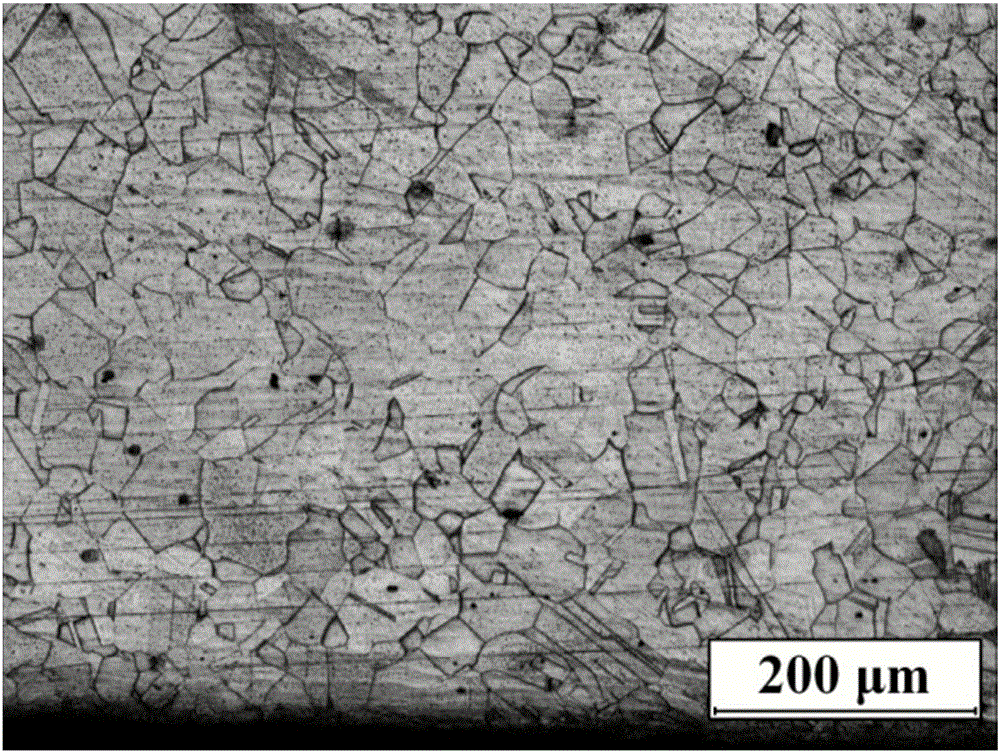

Preparation method of porous stainless steel film

ActiveCN103691329AImprove other performanceSolve the problem of easy peelingSemi-permeable membranesCompression moldingPore diameter

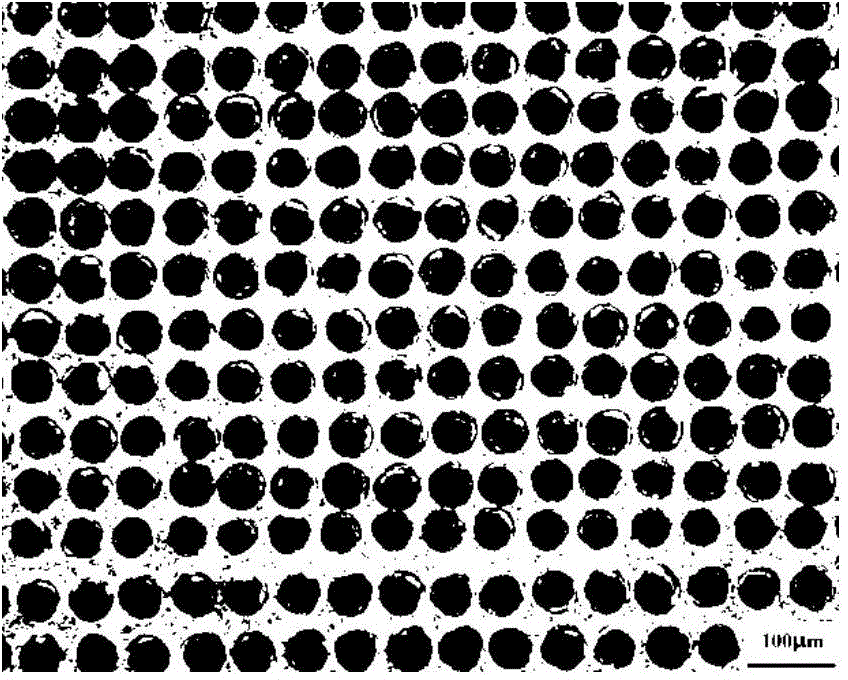

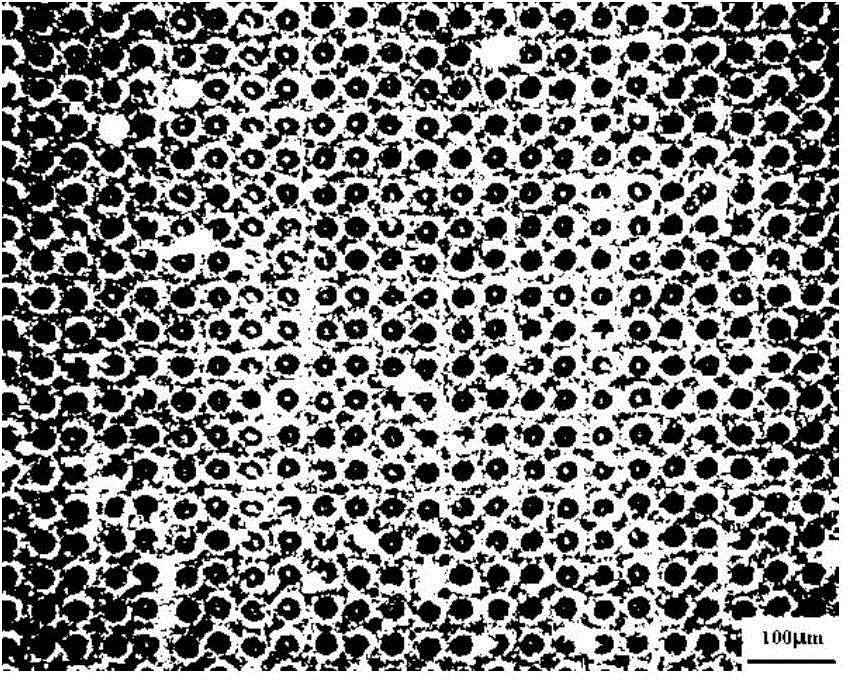

The invention discloses a preparation method of a porous stainless steel film. The preparation method comprises the following steps: firstly, carrying out compression molding on large-grain-size stainless steel powder coated with a low-melting-point metal layer on the surface through a powder compressing machine; secondly, preparing a stainless steel powder film layer on a molded blank body; and finally, sintering to obtain the highly-asymmetrical porous stainless steel film. According to the preparation method provided by the invention, the stainless steel powder surface of the base body for preparation is coated with the low-melting-point metal layer so as to reduce the sintering temperature of stainless steel powder of the base body. Therefore, the base body and the film layer are sintered together; the asymmetrical degree of the prepared porous stainless steel film material is high; the pore diameter distribution of the film layer is narrow; the film layer and the base body are firmly combined; the low-melting-point metal on the surface of the base body powder and the base body powder are alloyed by high temperature sintering; meanwhile, the mechanical intensity of the film material is ensured, and the other metal properties of the porous stainless steel film are improved.

Owner:NANJING UNIV OF TECH

Corundum-mullite composite brick for COREX furnace and preparation method thereof

The invention discloses a corundum-mullite composite brick for a COREX furnace and a preparation method thereof. The raw materials of the corundum-mullite composite brick are composed of a corundum-mullite homogenized material, white corundum, andalusite, a-Al2O3 powder and binding clay, as well as paper pulp liquid waste. The preparation method comprises the steps of firstly, preparing raw materials with various particle sizes according to the ratio; then, using raw materials with particle sizes of 1-3mm and particle sizes smaller than 1mm as aggregate to perform dry mixing, adding a paper pulp liquid waste mixture, finally adding the residual raw materials, and milling to obtain a pug; sequentially performing material trapping, press forming and drying on the obtained pug, and finally roasting to obtain a product. The corundum-mullite composite brick produced in the invention has very low porosity, high compression strength and excellent thermal shock resistance and corrosion resistance, can completely satisfy the harsh application environment of the COREX furnace, and can prolong the service life.

Owner:TONGDA REFRACTORY TECH CO LTD +1

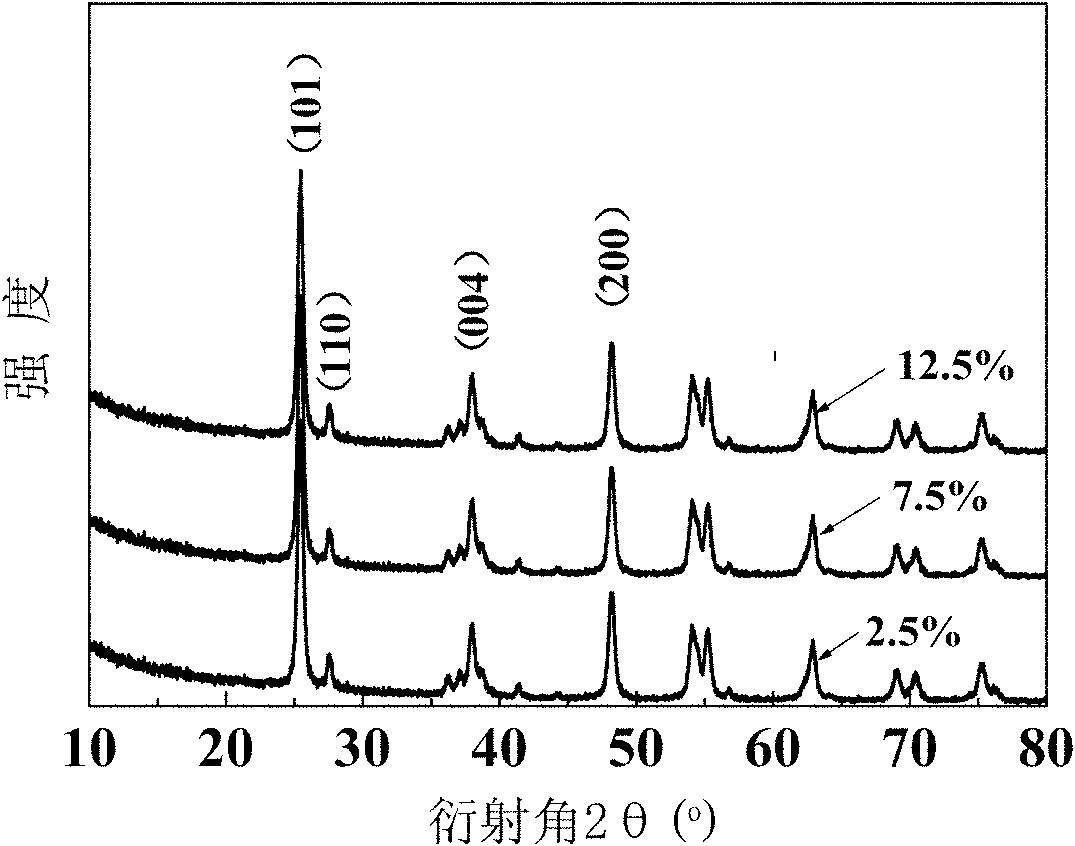

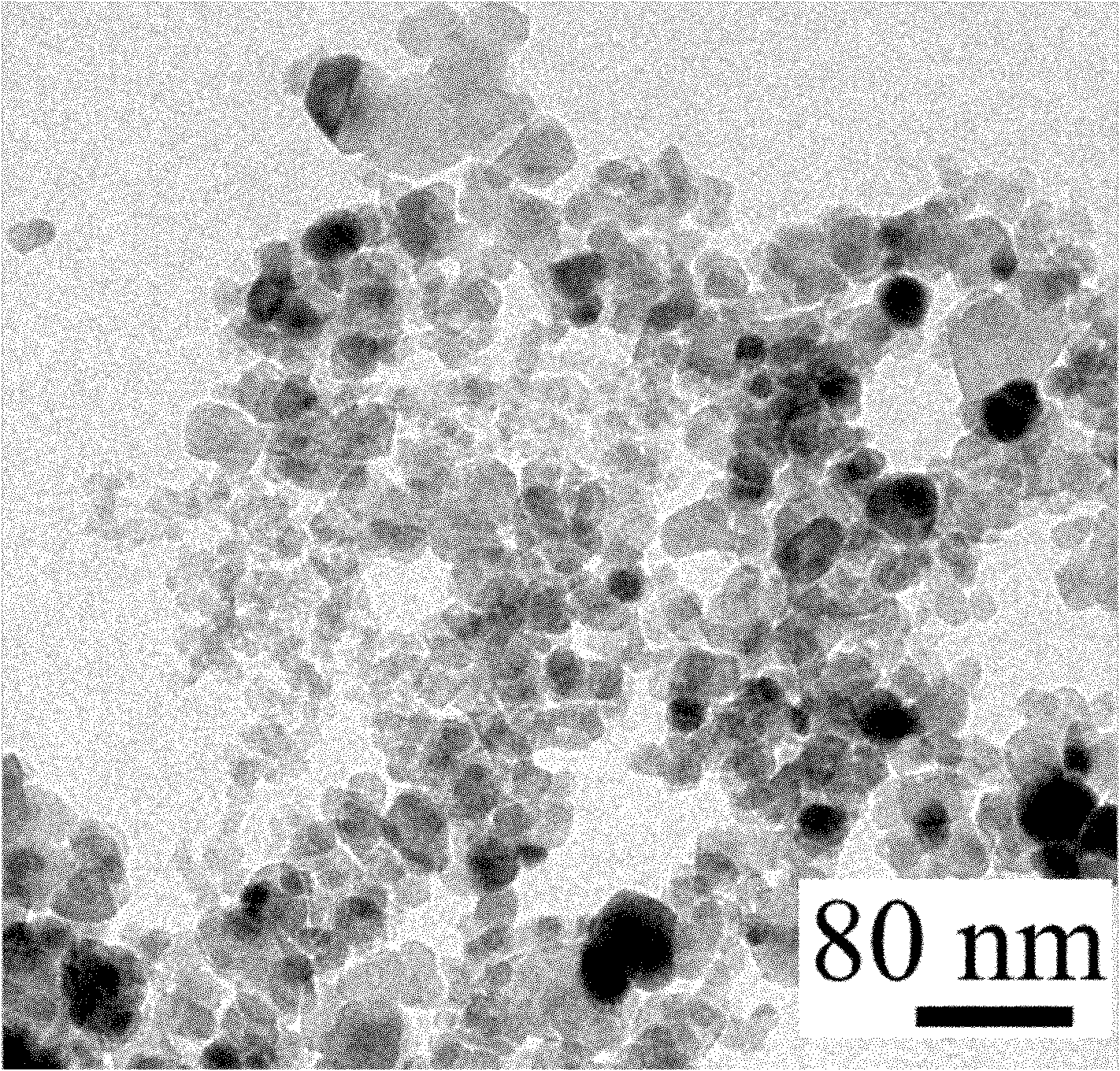

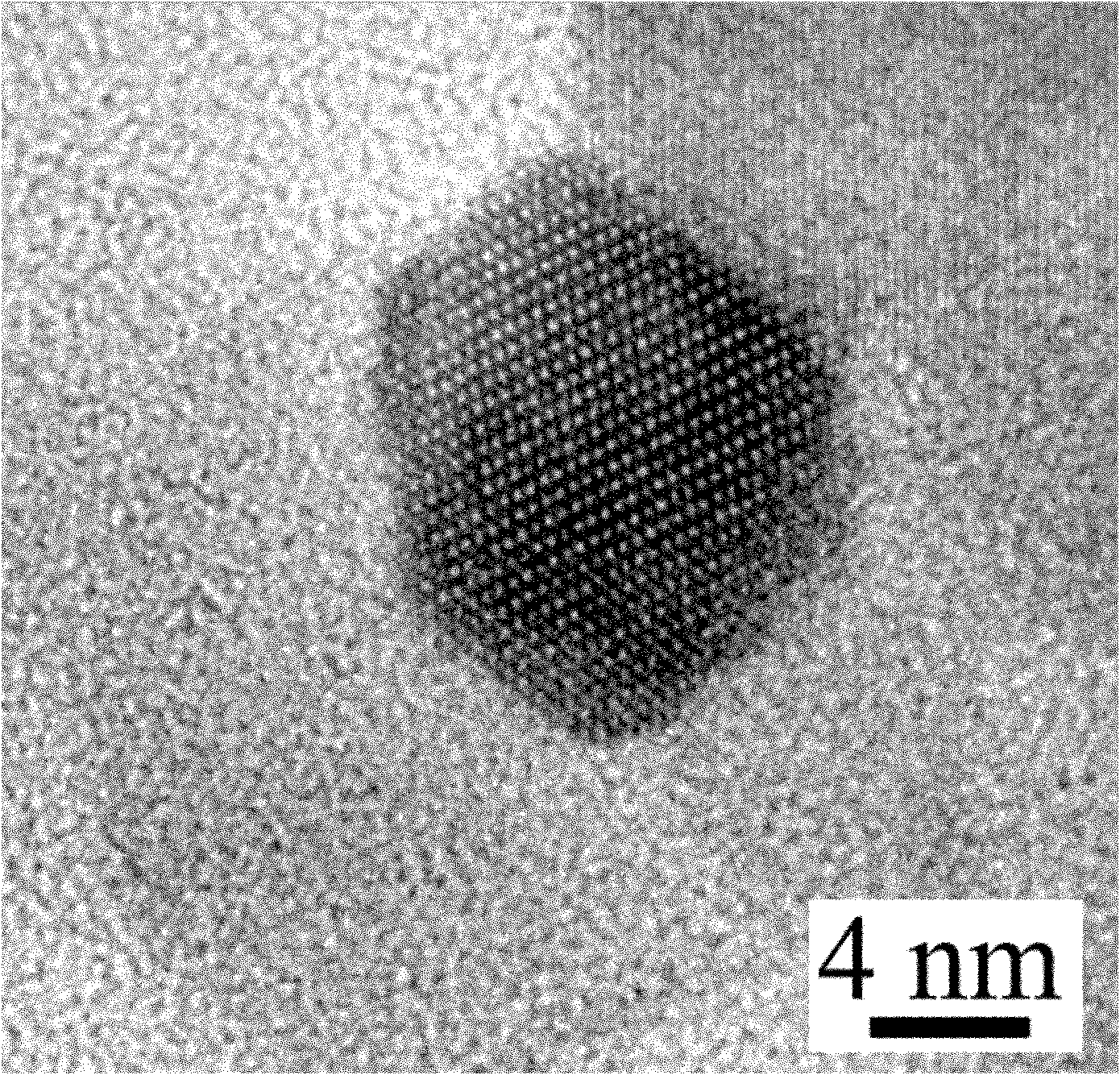

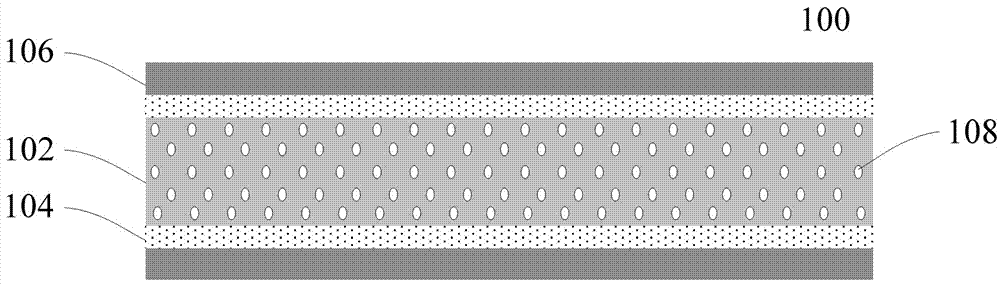

Doping dye sensitized solar cell photo anode, preparation method and application thereof

InactiveCN102074374AGood contactMembrane surface smoothLight-sensitive devicesSolid-state devicesPhotocatalysisNanocrystalline semiconductors

The invention discloses a doping dye sensitized solar cell photo anode, preparation method and application thereof, wherein the doping dye sensitized solar cell photo anode is divided into three layers in structure; the first layer is a common glass; the second layer is a SnO2 transparent conductive film doped with F; the third layer is a nanocrystalline porous composite film formed by doping the nano particle with mesoporous semiconductor at wide band with nanocrystalline semiconductor particles, wherein dyes are attached on the nanocrystalline porous composite film. The doping dye sensitized solar cell photo anode is used in doping dye sensitized solar cells. The doping dye sensitized solar cell photo anode of the invention can improve the photoelectric conversion performance of cells and increase the photoelectric conversion efficiency of solar cells well, and has the advantages of simple preparing technology, good repeatability and low cost; the doping dye sensitized solar cell photo anode not only can be used in dye sensitized solar cell materials, but also can be used in the fields of photocatalysis, gas sensitive material and the like.

Owner:HEFEI UNIV OF TECH

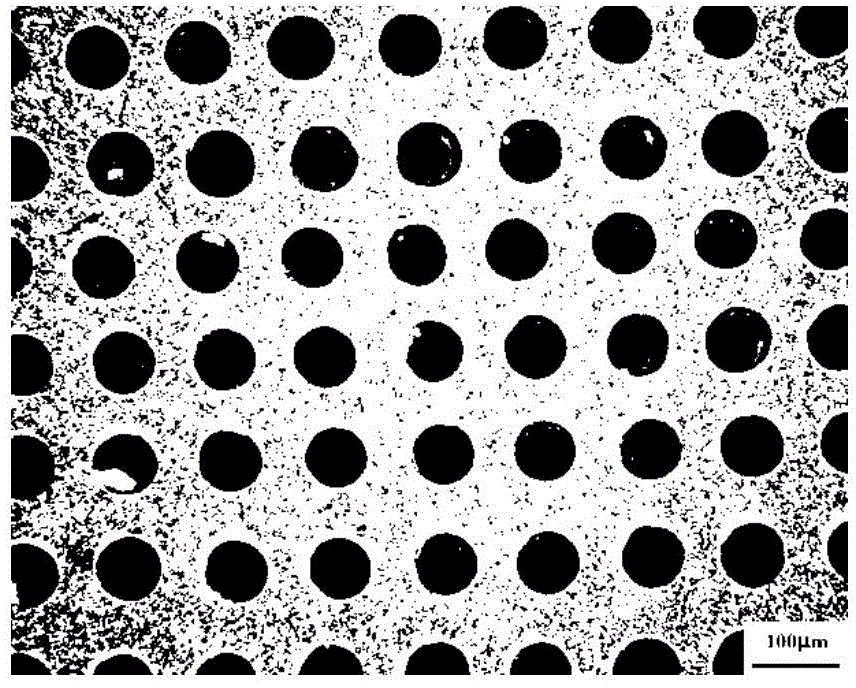

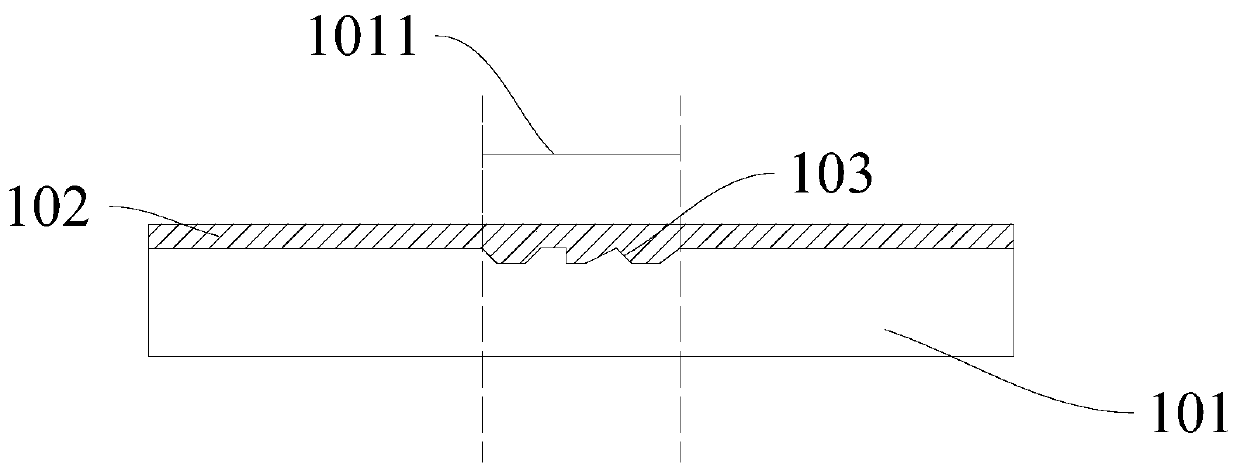

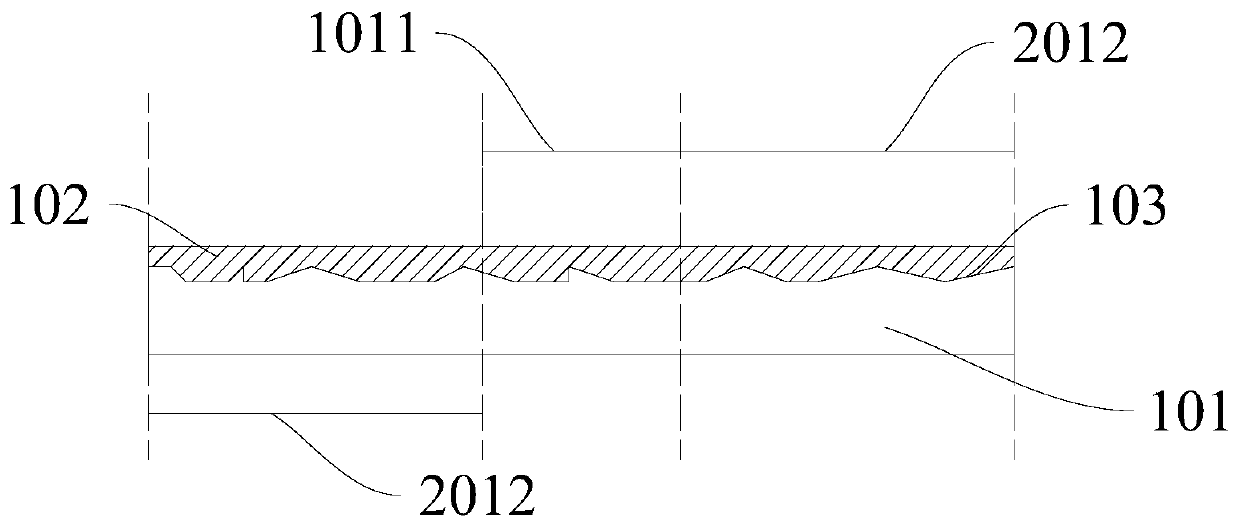

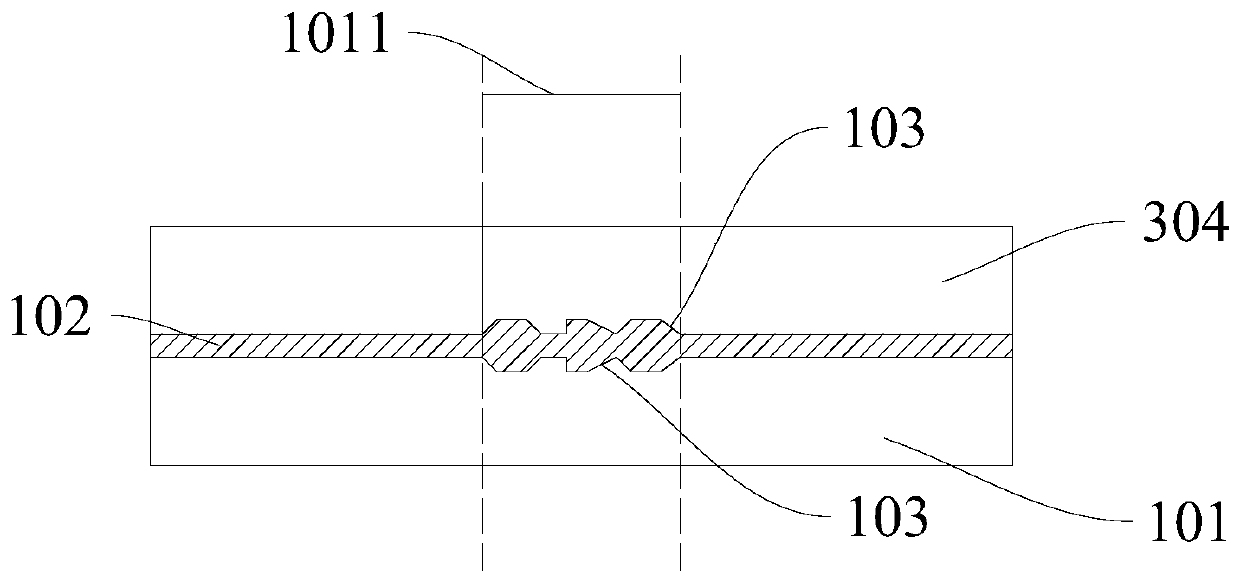

Preparation method of biological composite material using titanium alloy as implant

InactiveCN104127911AHigh bonding strengthSolve the strength problemProsthesisLaser processingMetallurgy

The invention discloses a preparation method of a biological composite material using titanium alloy as an implant. The method comprises the following steps: S1. pretreating a substrate with medical titanium alloy to clean the surface; S2. conducting laser micropore treatment on the surface of the medical titanium alloy substrate obtained in S1, wherein the parameters of laser processing are adjusted so that the medical titanium alloy substrate acquires microporous structures with different diameters, different depths and different hole pitches; S3. conducting post treatment on the microporous medical titanium alloy substrate obtained in S2 to clean the surface; and S4. conducting electrophoretic deposition on the substrate obtained in S3, wherein the electrophoretic deposition is carried out in a solution containing a biological active material. In the method, bioactive material HA and titanium alloy substrate are combined to form a rivet combinations, which firmly embed in the pores and are not easy to fall off, so as to solve the problem of easy peeling of bonded HA layer and titanium alloy.

Owner:HUAZHONG UNIV OF SCI & TECH

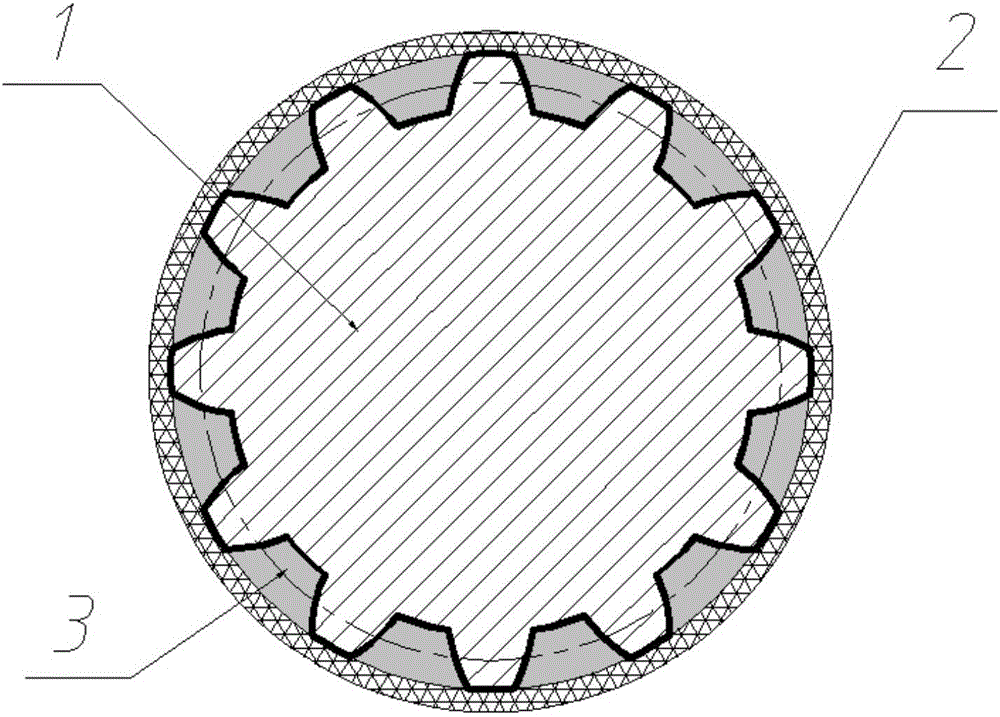

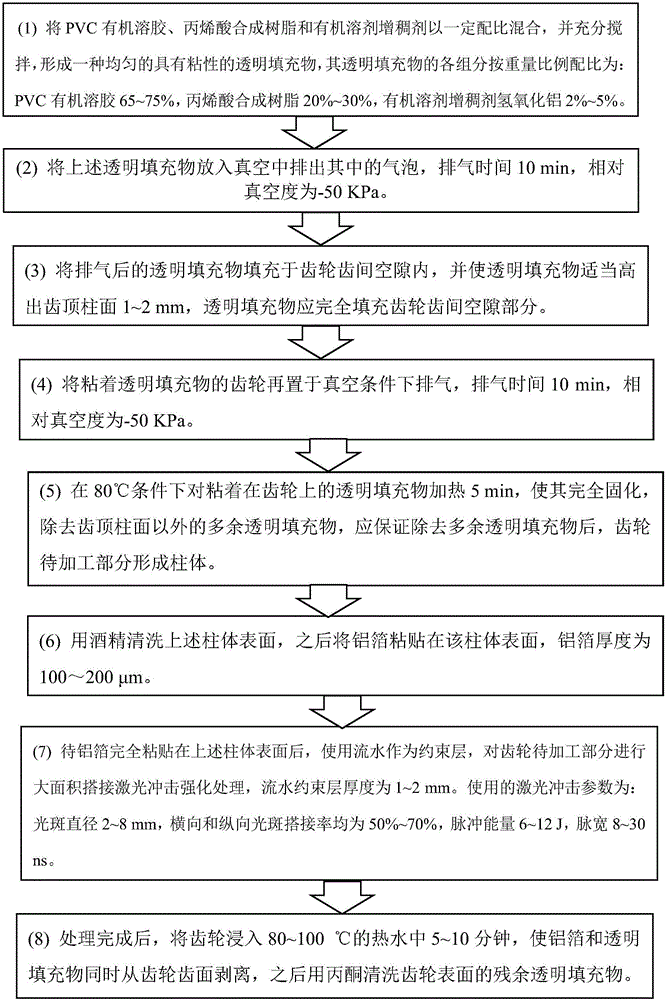

Laser shock strengthening method for small-pitch gear surface

InactiveCN105936974AEasy to cleanFacilitate large-area overlapping laser shock treatmentFurnace typesHeat treatment furnacesShock treatmentsGear tooth

The invention relates to a laser surface shock strengthening technology, and in particular to a laser shock strengthening method for a small-pitch gear surface. The method can be expanded into surface strengthening of a small-pitch spline male die and a fine-pitch thread. The method is characterized in that clearances among teeth of a gear are filled with transparent fillers prepared by mixing materials in ratio, and the clearances are full of the transparent fillers in order to form a column body by the gear and the transparent fillers; then an aluminum foil is adhered to the column surface to be used as an energy absorbing layer; the gear surface can be subjected to large-area overlapping laser shock treatment under the condition that running water is used as a limiting layer. The method has the advantages that the clearances among the teeth of the gear are fully filled with the transparent fillers, and the tops of the teeth of the gear and the transparent fillers can form a smooth column surface, thus the large-area overlapping laser shock treatment can be conveniently carried out for the gear, and as a result, the laser shock strengthening effect can be greatly improved; and after the shock treatment, the transparent fillers in the clearances among the teeth of the gear can be easily removed, so that the demand of mass production can be met.

Owner:JIANGSU UNIV

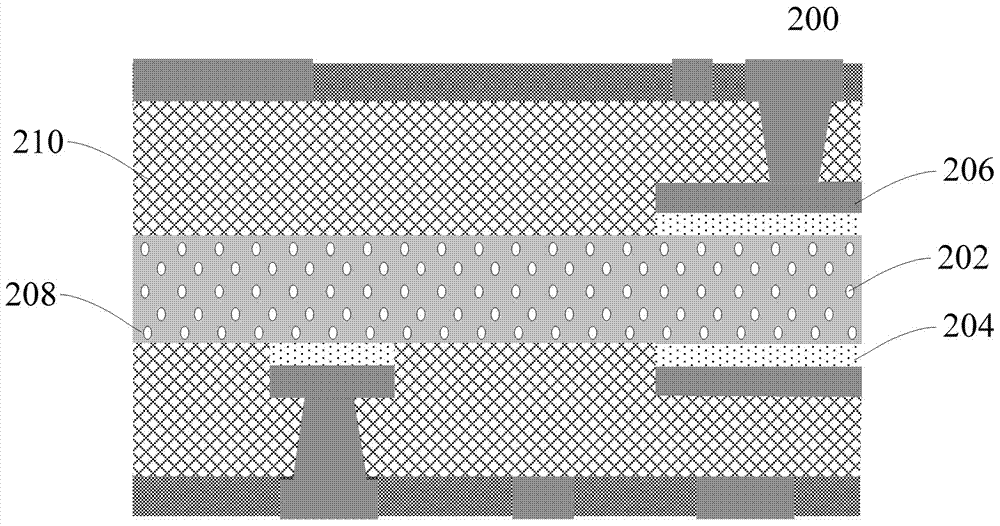

Capacitor, capacitor-burying circuit board and manufacturing method thereof

PendingCN107231747AHigh peel strengthLarge capacityPrinted capacitor incorporationMultilayer circuit manufactureCapacitanceEngineering

The invention relates to a capacitor, a capacitor-burying circuit board and a manufacturing method thereof. The capacitor comprises a high dielectric constant polymer composite material layer; an ion injection layer, wherein the ion injection layer is formed by injecting the conducting material ion into the high dielectric constant polymer composite material layer at high-speed through an ion injection way; and a metal layer formed and covered on the ion injection layer.

Owner:RICHVIEW ELECTRONICS CO LTD

Display panel and manufacturing method thereof

ActiveCN110518118AEasy to prepareThe production process is easy to controlFinal product manufactureDigital data processing detailsEngineeringInterface bond

The invention provides a display panel and a manufacturing method thereof. The display panel comprises a bending area. The display panel comprises a first flexible substrate; a buffer layer which is formed on the surface of one side of the first flexible substrate, wherein in the bending area, the surface, in contact with the buffer layer, of the first flexible substrate is of a rough structure. According to the display panel, an interface bonding force between the flexible substrate and the buffer layer can be enhanced, and the problem that the flexible substrate in the bending area is proneto being stripped from the buffer layer can be solved. Meanwhile, the risk that the flexible substrate in the non-bending area is stripped from the buffer layer can be avoided, the display quality isimproved, and the product yield is increased.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

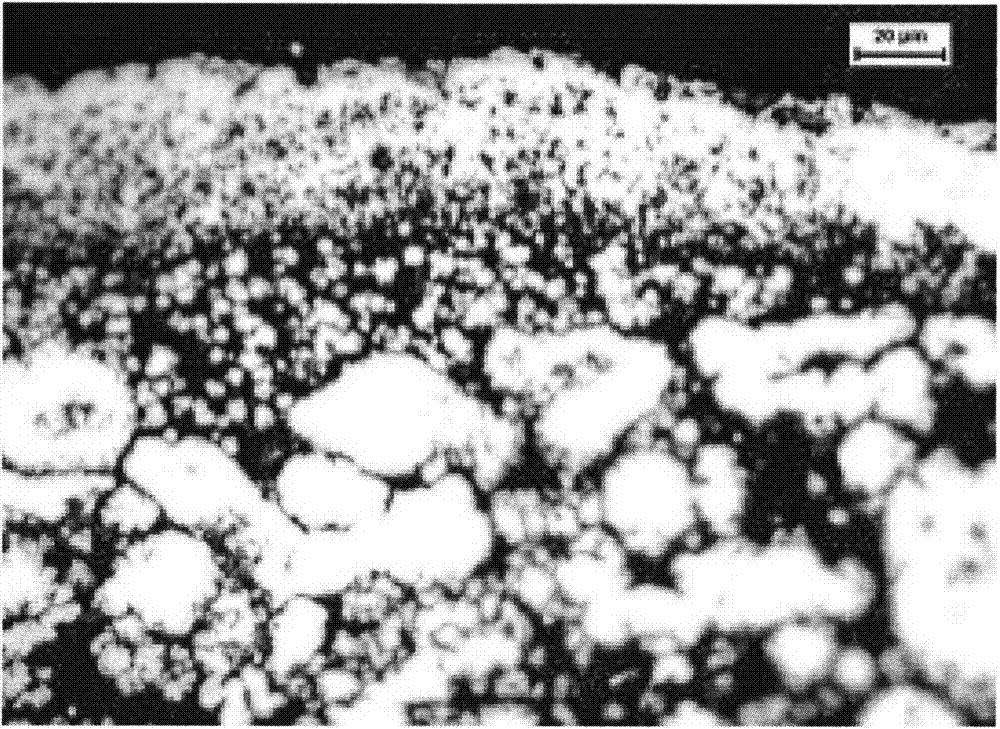

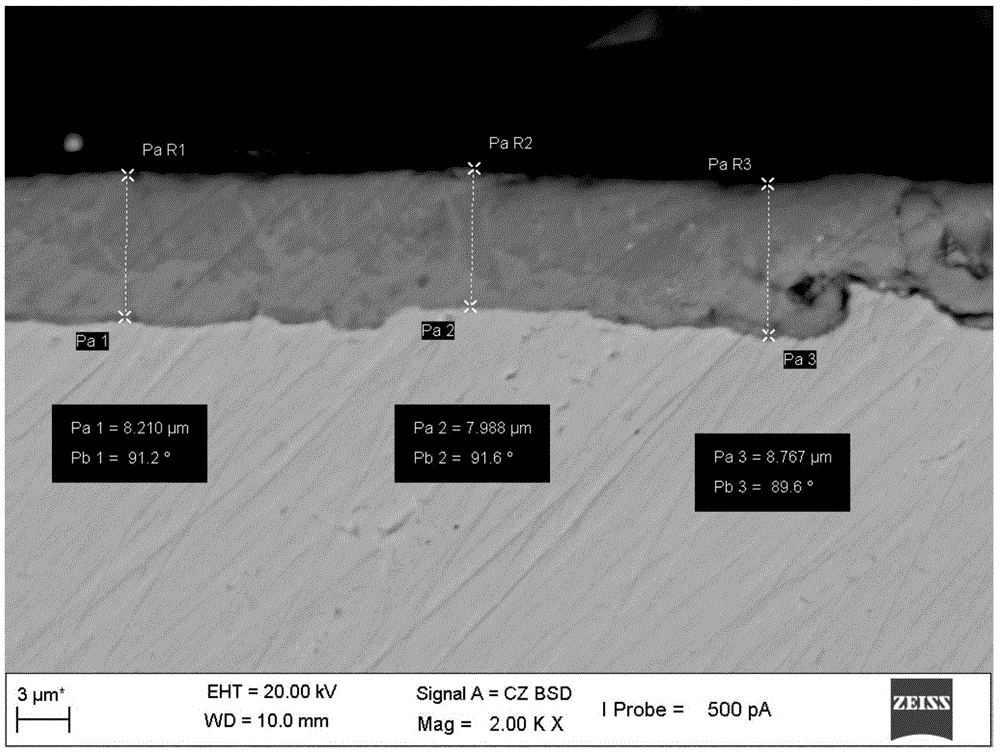

Anti-stripping iron oxide scale structure on surface of hot rolled plate and control process for anti-stripping iron oxide scale structure

InactiveCN105618507ASolve the problem of easy peelingTemperature control deviceWork cooling devicesTemperature controlProportional control

The invention discloses an anti-stripping iron oxide scale structure on the surface of a hot rolled plate, and a control process for the anti-stripping iron oxide scale structure, and belongs to the technical field of steel rolling. The control process is characterized in that a dual-discharge descaling process is adopted, wherein high-pressure water descaling process is controlled to be higher than or equal to 16 MPa; a high-temperature quick rolling mode is adopted; a front-stage sparse cooling mode is adopted after finish rolling; a rolling temperature is controlled to be lower than 650 DEG C; and finally, the thickness of the iron oxide scale structure on the surface of the hot rolled plate with a thickness of 4-14mm is controlled to be smaller than or equal to 10.8 microns, the proportion of Fe3O4 in the iron oxide scale structure is controlled to be 45%-68%, the proportion of FeO is controlled to be 23%-42%, and the proportion of Fe2O3 is controlled to be 8%-15%.

Owner:SHOUGANG CORPORATION

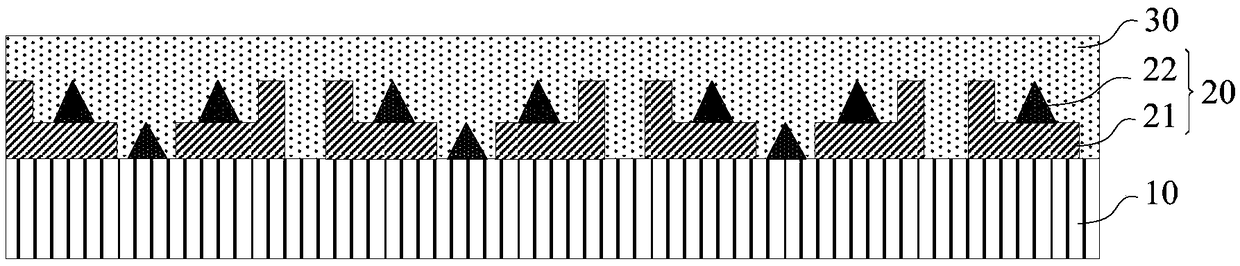

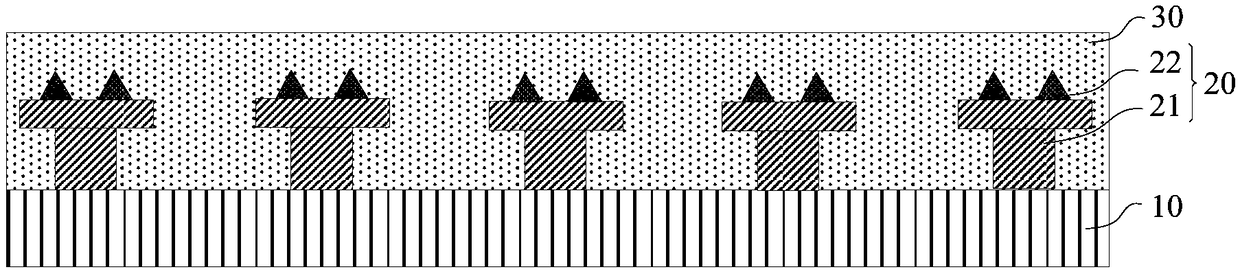

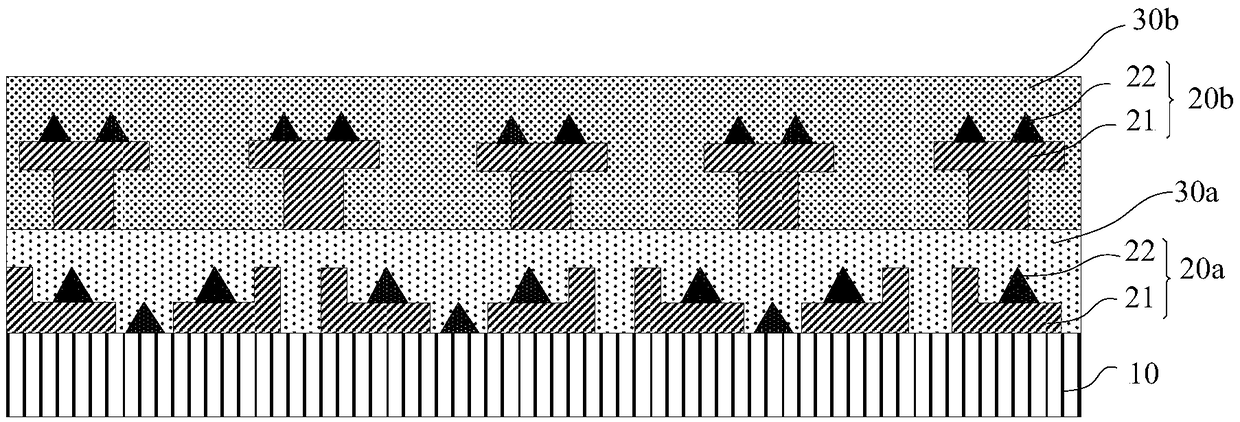

Flexible base plate and manufacturing method thereof, array base plate, display panel and display device

ActiveCN109449290ASolve the adhesionIncrease contact areaFinal product manufactureSolid-state devicesOrganic filmBiochemical engineering

The invention provides a flexible base plate and a manufacturing method thereof, an array base plate, a display panel and a display device. The flexible base plate comprises at least one pattern layerand at least one blocking layer which are arranged on a substrate, and the at least one pattern layer comprises a first pattern layer arranged on the substrate and a second pattern layer in which atleast a part of patterns are positioned on the first pattern layer; the substrate, the first pattern layer and the second pattern layer are covered with the blocking layer, wherein one of the patternlayer and the blocking layer with which the pattern layer is covered is an inorganic film, and the other of the pattern layer and the blocking layer with which the pattern layer is covered is an organic film. The flexible base plate provided by the invention solves the technical problem that the organic film and the inorganic film in an existing flexible display screen are easy to separate.

Owner:GUANGZHOU GOVISIONOX TECH CO LTD

Method for planting high-purity Ni/Cu double-layer target membrane on high borosilicate glass

ActiveCN108456844AImprove uniformityImprove bindingVacuum evaporation coatingSputtering coatingElectrical resistance and conductanceThermal vacuum evaporation

The invention belongs to the technical field of preparation of a nuclear target and discloses a method for planting a high-purity Ni / Cu double-layer target membrane on high borosilicate glass. According to the method, the double-layer target membrane is plated by utilizing metal steam vacuum arc ion source-filtering cathode vacuum arc-resistance heating vacuum evaporation combined equipment. The Ni / Cu double-layer target membrane with high plating layer uniformity, strong binding force and controllable thickness can be prepared successfully by the method provided by the invention, and the problems that the Ni membrane of 1 [mu]m is prepared by the traditional method as well as the thick Cu membrane has bad binding force and is liable to peel off are solved.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Antibacterial aqueous paint used for wood furniture and use method of same

InactiveCN106221523AGood physical and mechanical propertiesImprove water resistanceAntifouling/underwater paintsPaints with biocidesPolyamideSlurry

The invention discloses an antibacterial aqueous paint used for wood furniture and a use method of same. The paint is composed of: modified alkyd resin, phenylated amino resin, 355-3 medium oil alkyd resin, ultrafine zirconium dioxide, calcium lignosulfonate, polyvinyl alcohol, polyamide wax slurry, phenylmethylsulfonyl fluoride, emulsified silicon oil, heavy aromatics, butadiene-vinyl pyridine latex and water. Compared with the prior art, a problem of poor water resistance of aqueous paints is solved by preparing the modified alkyd resin through a novel polymerization process to improve the physical and mechanical performance of the alkyd resin and compounding the alkyd resin with other raw materials. The paint is safe and environment-friendly, can form a stable film structure on the surface of a sheet material, and is significantly improved in the comprehensive physical and mechanical performance than the aqueous paints in the prior art. The paint has long-acting antibacterial effect and is suitable for being promoted.

Owner:ANHUI CHANGFA IND

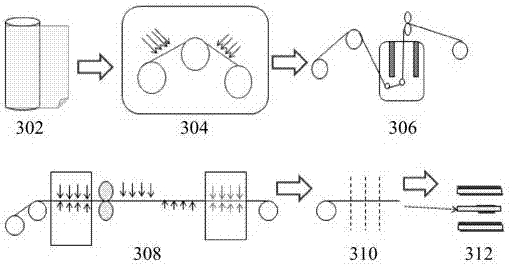

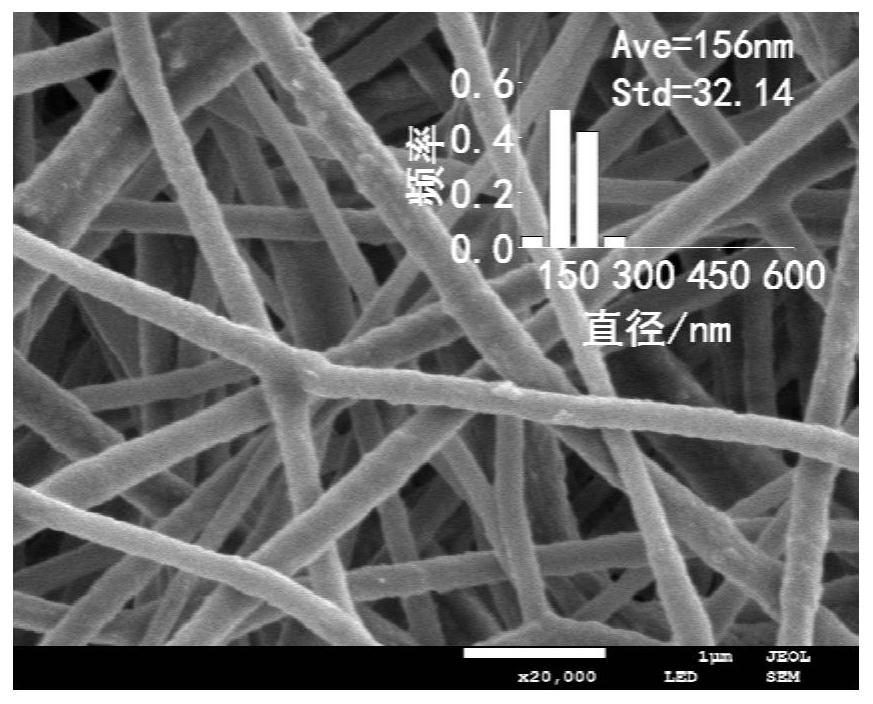

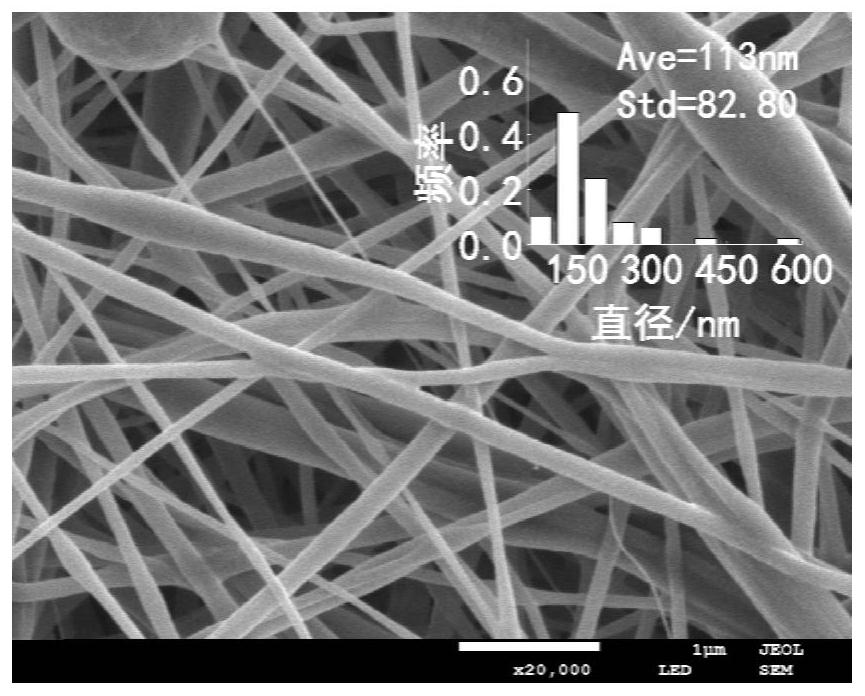

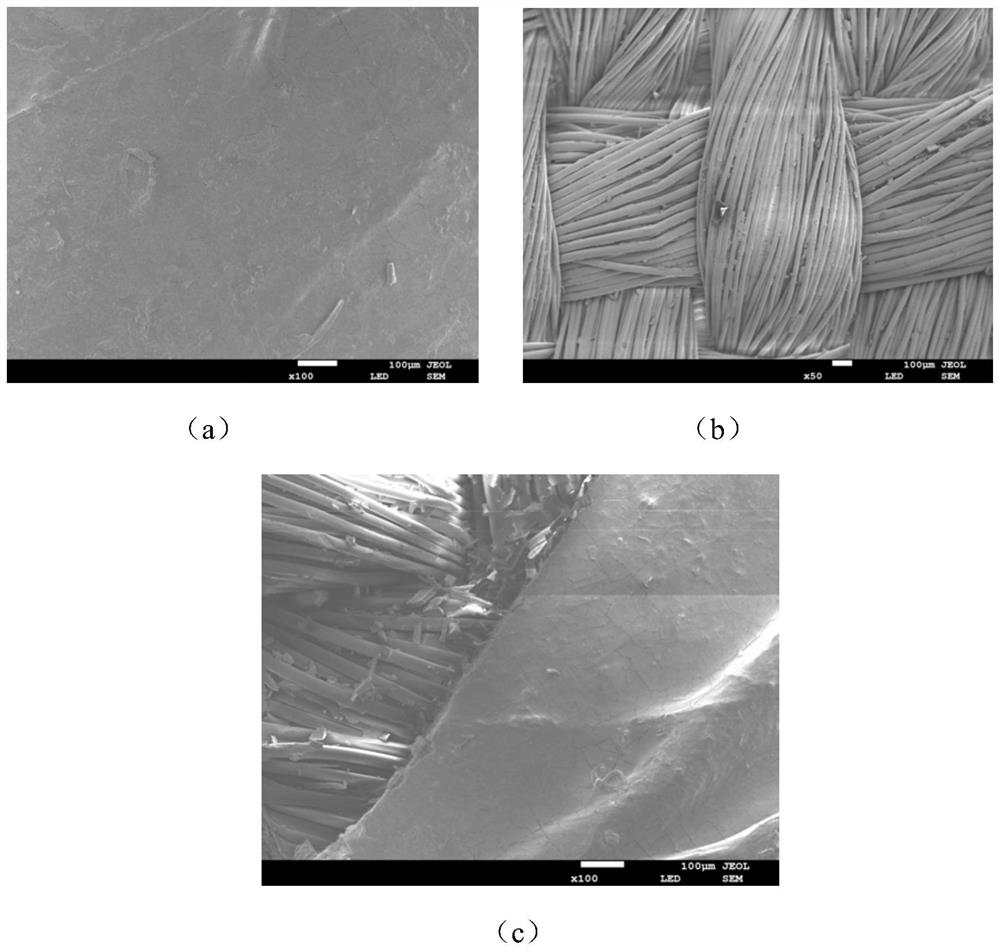

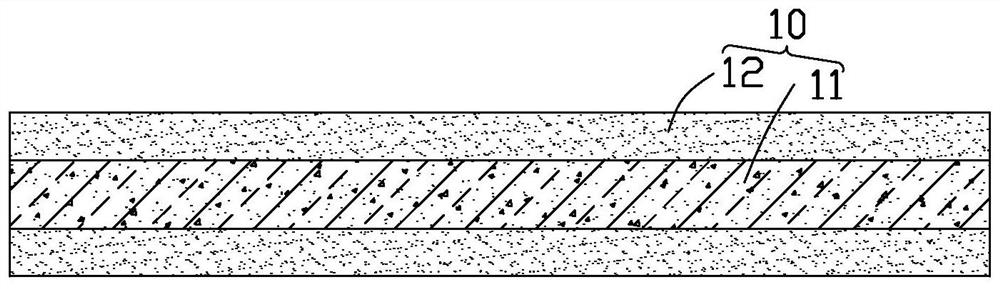

Washable mask core fiber filter material and preparation method thereof

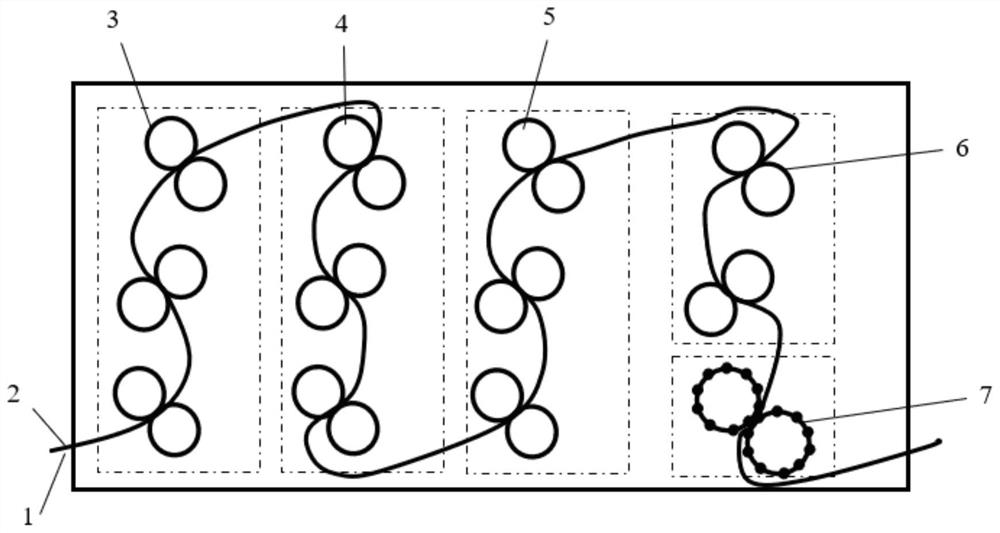

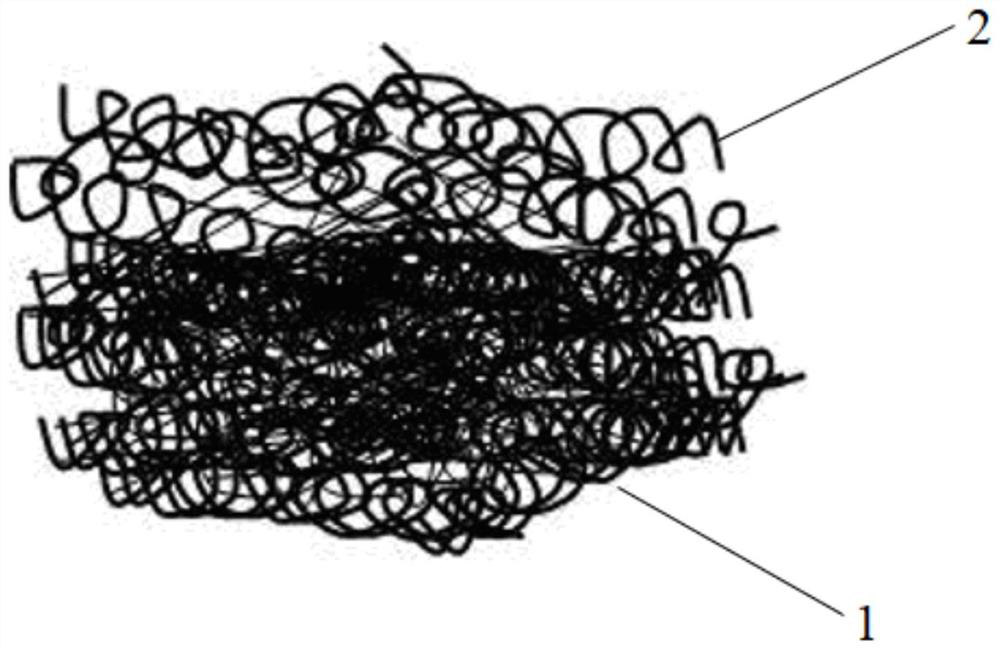

ActiveCN112981719ASolve wasteSolve the problem of easy peelingElectro-spinningNon-woven fabricsFiberSpinning

The invention discloses a washable mask core fiber filter material and a preparation method thereof. The preparation method comprises the following steps: a nanofiber compact layer and a nanofiber fluffy layer are prepared by respectively regulating and controlling solvent / moisture double diffusion speeds of different spinning solutions under the action of a high-voltage electrostatic field, and the nanofiber compact layer and the nanofiber fluffy layer are sequentially deposited on a receiving base material to obtain a composite layer; and after the composite layer is subjected to step-by-step heat treatment and dotted ultrasonic compounding by a sectional type high-temperature / ultrasonic compounding device, a functional group type cross-linking agent in the compact layer fiber forms an inner cross-linked network structure in the fiber, meanwhile, a haplotype cross-linking agent in the fluffy layer fiber forms a semi-interpenetrating cross-linked network in the fiber, then the fibers with the lower glass transition temperature are molten, heat bonding points are generated among the fibers, so that the fiber filter material with a multi-stage cross-linked structure is obtained in one step. The invention provides the preparation method of the washable mask core filter material which is not prone to peeling between layers and can be repeatedly used.

Owner:DONGHUA UNIV

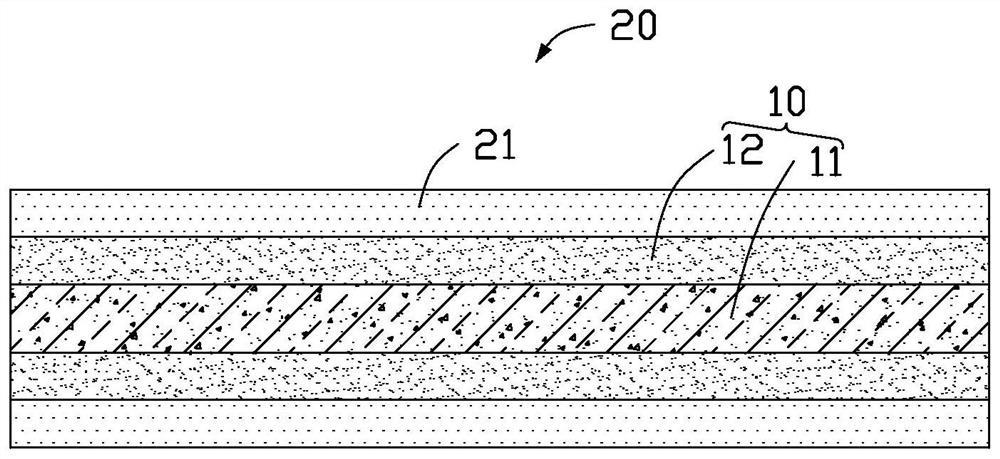

Production technology of waterproof and heat-insulated integrated board

ActiveCN102806745AHigh bonding strengthAvoid chemical reactionsLaminationLamination apparatusChemical reactionPlasticizer

The invention discloses a production technology of a waterproof and heat-insulated integrated board. The production technology comprises the following steps of: firstly, compositing an enhanced isolating material at one side of a waterproof roll; pre-heating the waterproof roll composited with the enhanced isolating material by a pre-heating device; compositing an heat-insulated material at one side of the waterproof roll composited with the enhanced isolating material after pre-heating; and finally, covering another pre-heated waterproof roll on the surface of the heat-insulated material. By providing the enhanced isolating material at one side of the waterproof roll, not only can the bonding strength between the enhanced isolating material and the waterproof roll be enhanced, but also the waterproof roll and the heat-insulated material can be effectively isolated; the condition that the waterproof roll is contacted with the heat-insulated material for a long time to cause chemical reaction can be avoided; a plasticizer inside the roll is prevented from migrating; the quality of the product is ensured; a procedure of pre-heating the waterproof roll is added before the waterproof roll and the heat-insulated material are composited; and the phenomenon that a waterproof layer and an insulating layer are stripped after the board is molded can be avoided, and the performance and quality of the board are further improved.

Owner:SHENZHEN ZHUOBAO TECH

A production process of waterproof and thermal insulation integrated board

ActiveCN102806745BHigh bonding strengthAvoid chemical reactionsLaminationLamination apparatusChemical reactionPlasticizer

Owner:SHENZHEN ZHUOBAO TECH

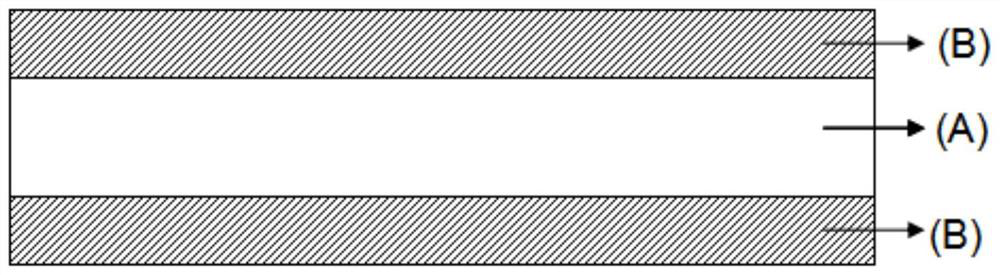

Specific near-infrared-absorption polyester thin membrane capable of achieving mass production and preparation method of polyester thin membrane

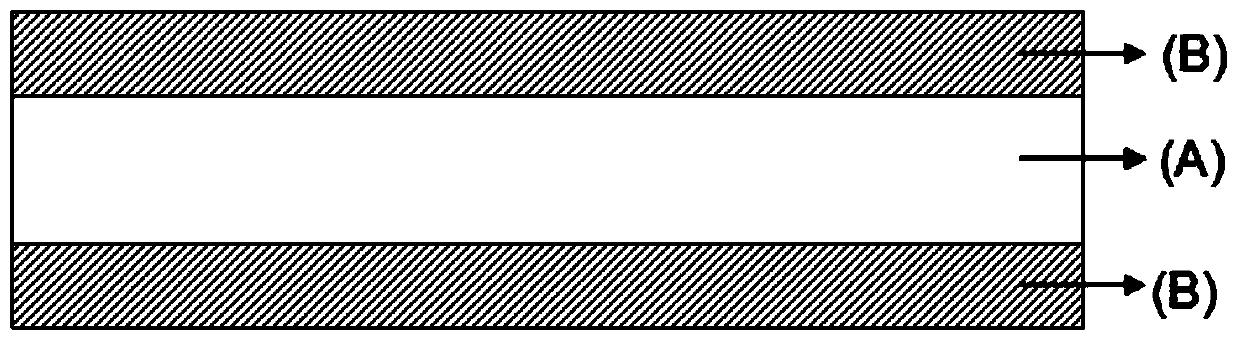

ActiveCN110202896AThickness is easy to controlIncreasing the thicknessSynthetic resin layered productsFlat articlesPolyesterHeat resistance

The invention provides a specific near-infrared-absorption polyester thin membrane capable of achieving mass production and a preparation method of the polyester thin membrane. The thin membrane is aBAB-type three-layer-structure thin membrane, wherein an A layer is a specific near-infrared-absorption layer, a B layer is a surface modification layer, and the total thickness of the thin membrane is 30-100 microns; the A layer is prepared from, by weight, 50%-99.9% of optical-grade high-transmittance PET chips, 0%-50% of optical-grade high-transmittance PCT chips and 0.1%-1% a near-infrared adsorbent; a B layer is prepared from, by weight, 5%-35% of PET master batches containing silicone and 65%-95% of optical-grade high-transmittance PET chips. The prepared near-infrared-absorption polyester thin membrane has the advantages of being good in heat resistance and low in transmittance of light within the near-infrared band of 700-900 nanometers.

Owner:HANGZHOU HESHUN TECH CO LTD

Fluororesin primer containing poly(ether-ketone-ketone) resin and laminating body using same

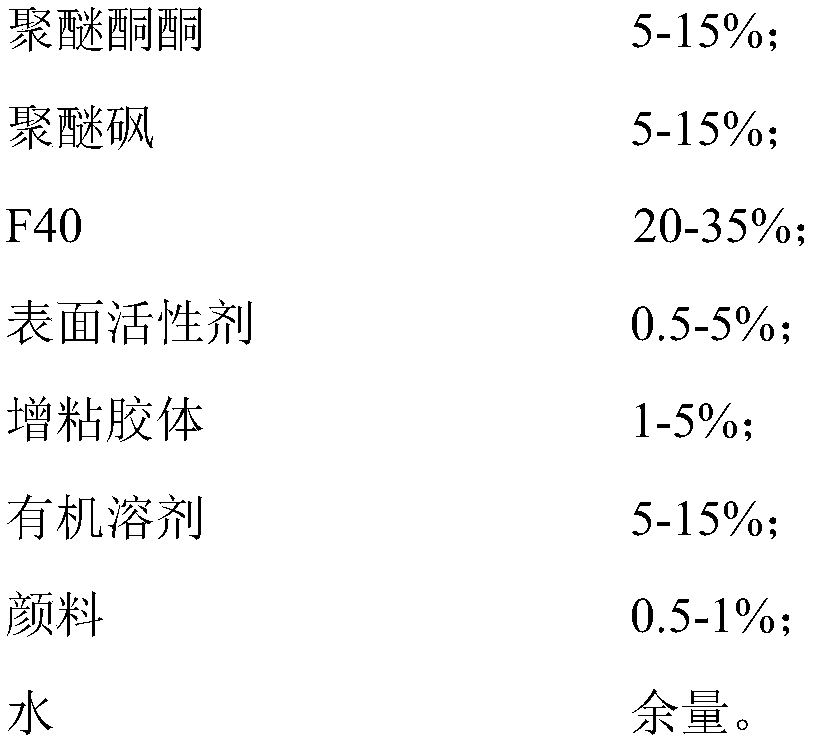

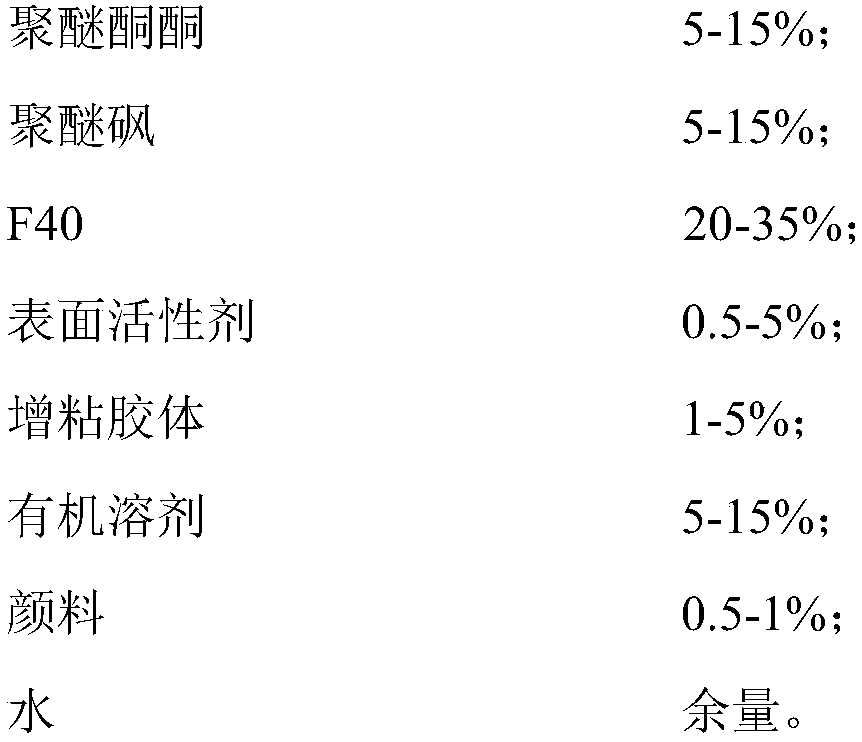

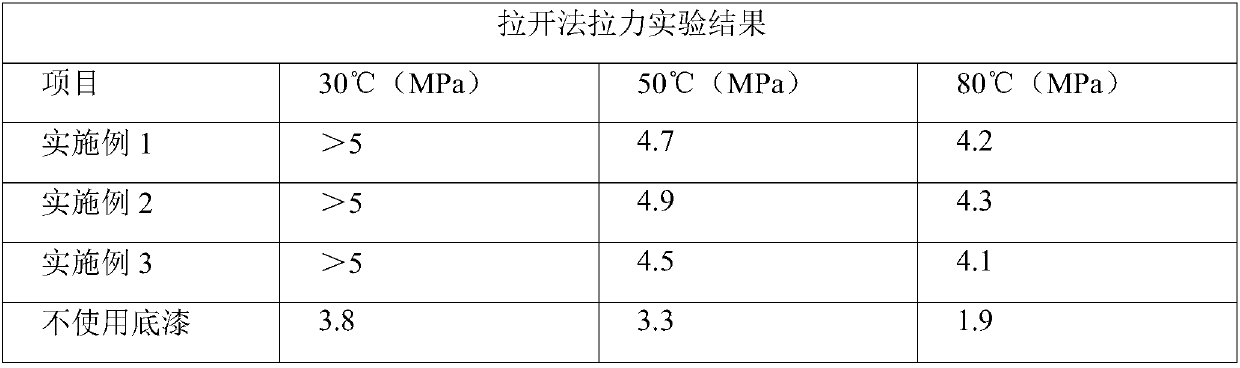

ActiveCN109608951ASolve the problems of poor bonding force and poor vacuum resistanceImprove bindingLiquid surface applicatorsAnti-corrosive paintsKetonePolymer

The present invention relates to a fluororesin primer containing poly(ether-ketone-ketone) resin and a laminating body using the same, and belongs to the technical field of polymers. The fluororesin primer containing poly(ether-ketone-ketone) resin of the present invention is composed of the following substances in percentage by mass: 5-15% of poly(ether-ketone-ketone); 5-15% of polyethersulfone;20-35% of F40; 0.5-5% of surfactant; 1-5% of viscosity-increasing colloid; 5-15% of organic solvent; 0.5-1% of pigment; and the balance of water. The fluororesin primer containing poly(ether-ketone-ketone) resin has the characteristics of strong adhesion, good heat resistance and excellent chemical resistance. At the same time, the present invention also provides the laminating body using the same, and solves the problem that a conventional fluororesin anticorrosive coating has poor adhesion to a metal substrate and poor vacuum resistance.

Owner:SHANDONG KAISHENG NEW MATERIALS +1

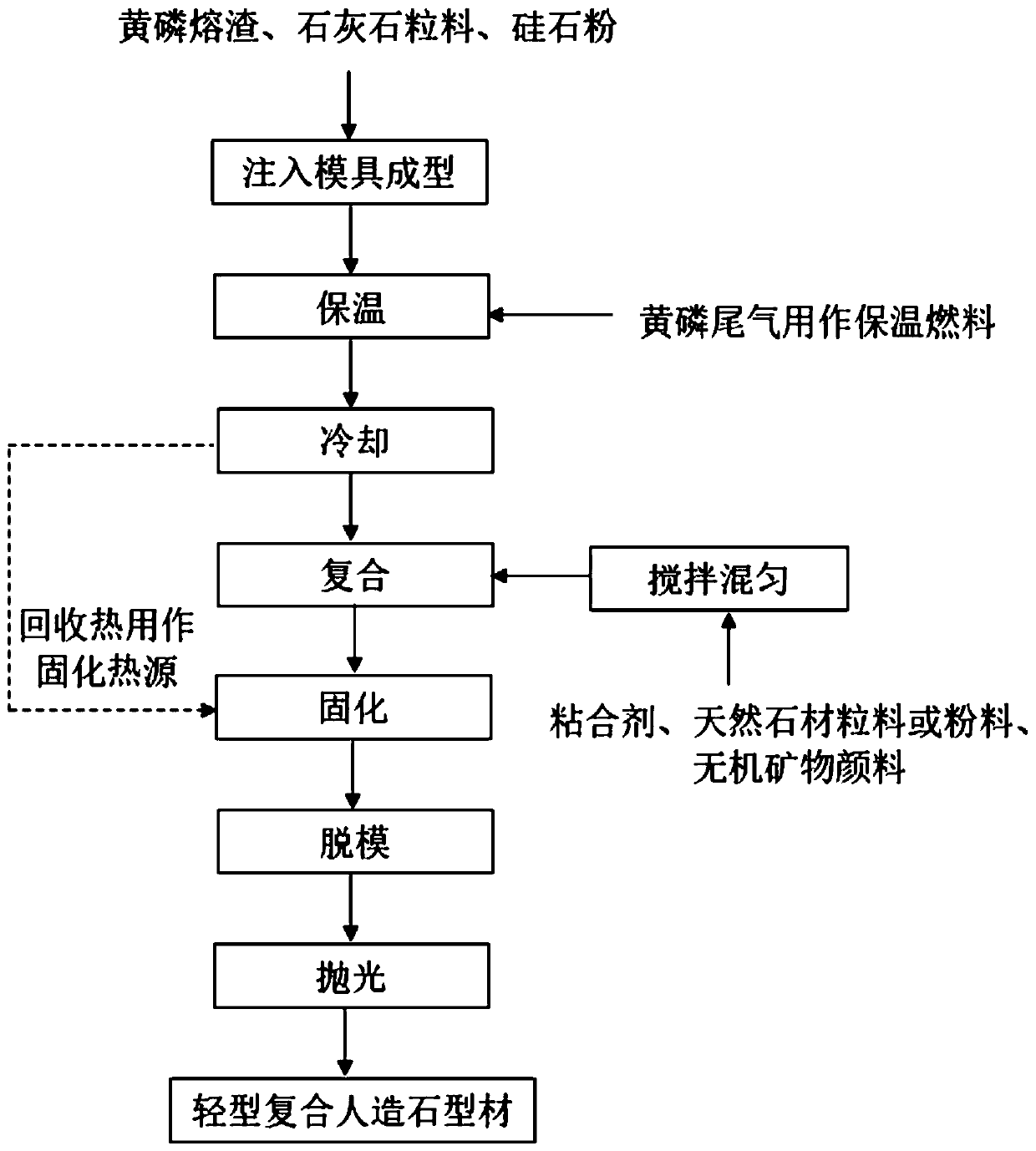

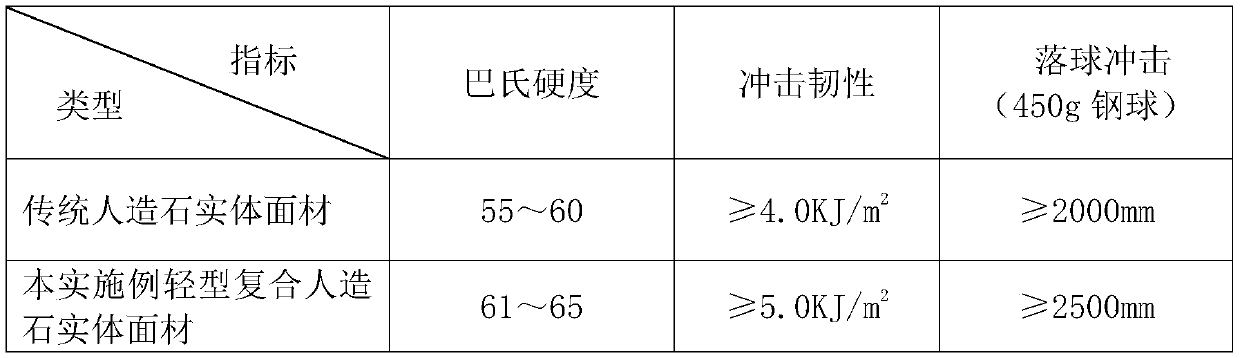

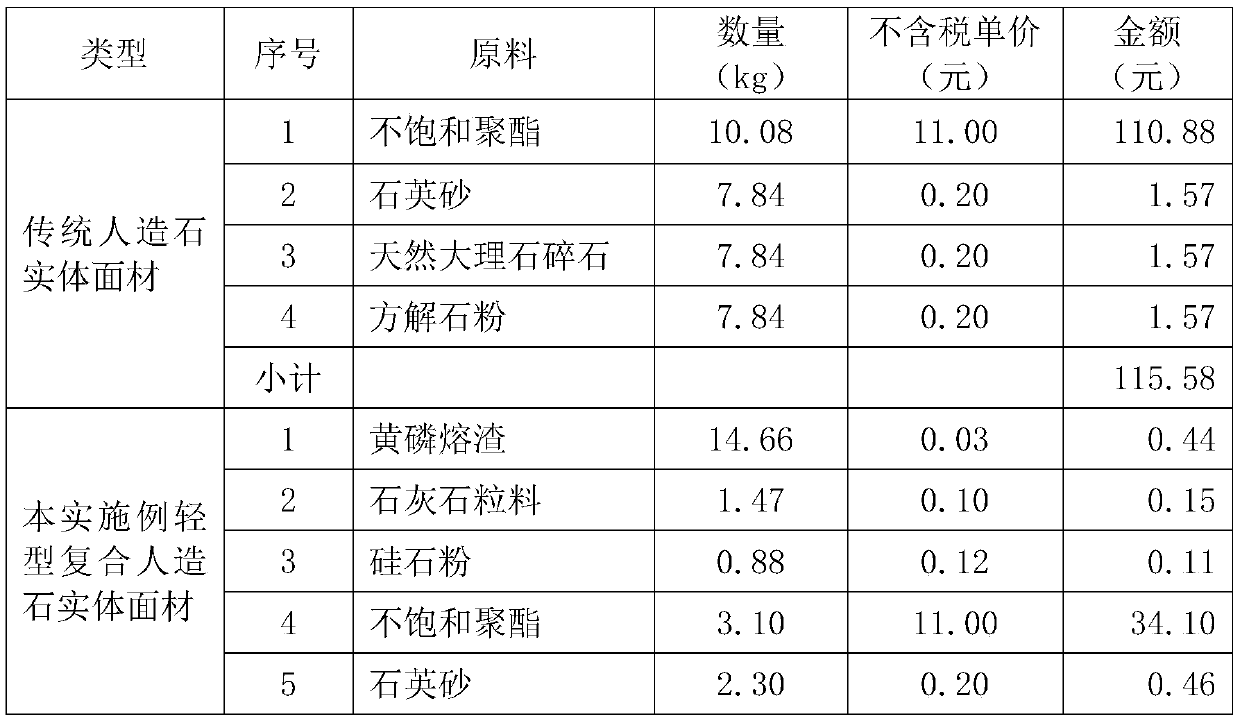

Method for preparing light composite artificial stone profile by using yellow phosphorus slags

The invention provides a method for preparing a light composite artificial stone profile by using yellow phosphorus slags, which comprises the following steps of: S1. preparing a pore base layer, uniformly mixing silica powder and limestone granules, uniformly arranging the silica powder and the limestone granules at the bottom of a base layer forming die, pouring the yellow phosphorus slags intothe base layer forming die, and carrying out heat preservation, cooling and cutting processes to obtain a pore base layerprofile;S2. preparing a surface layer and forming thelight composite artificialstone profile, mixing and stirring an adhesive, natural stone granules or powder materials and inorganic mineral pigments to obtain a mixture, placing the pore base layer profile at the bottom of anartificial stone forming die, injecting the mixture into the artificial stone forming die, and uniformly coatingon the surface of the pore base layer profilewith the mixture through a composite process to form the surface layer;finally, preparing the light composite artificial stone profile through the working procedures of curing, demoulding and polishing.The method for preparing the light composite artificial stone profile by using the yellow phosphorus slags has the beneficial effects that the specific gravity of the pore base layer profile is reduced, the content of residual free calcium oxide and magnesium oxide in the yellow phosphorus slags is reduced, and the yellow phosphorus slagsarechanged into valuable.

Owner:四川新磷环保技术有限公司

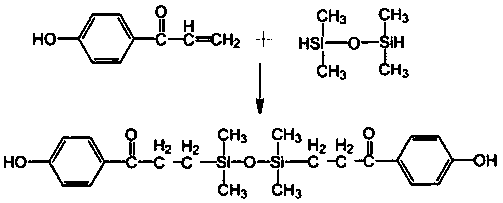

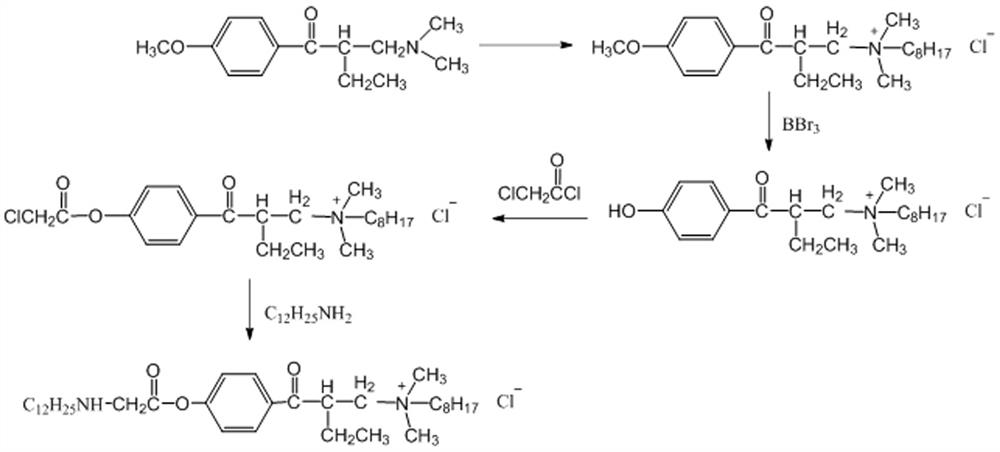

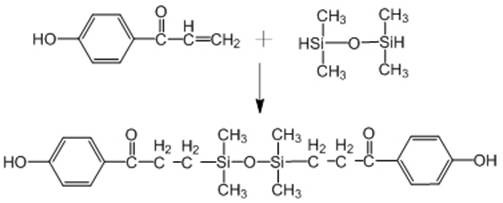

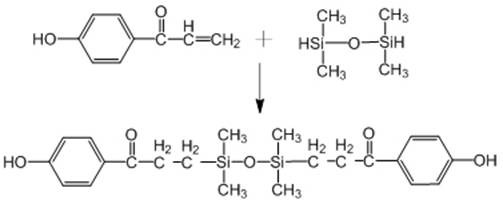

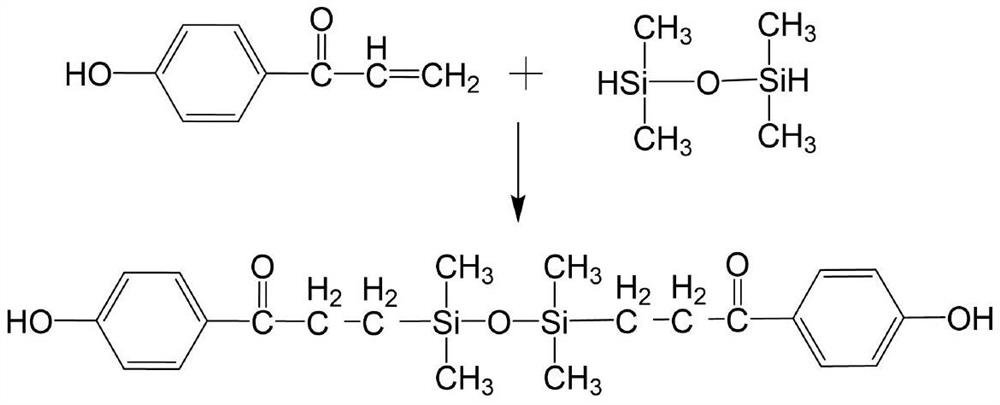

Adhesive for building decorative plates and preparation method of adhesive

ActiveCN111234754ASolve the problem of easy peelingImprove hydrophobicityEpoxy resin adhesivesPolymer scienceAdhesive

The invention discloses an adhesive for building decorative plates, which comprises a component A and a component B. The component A and the component B are mixed according to a mass ratio of 5.2-5.5:1. The adhesive prepared by the invention is prepared by curing and crosslinking a silanized epoxy resin through a weather-resistant curing agent; according to the silanized epoxy resin, tetramethyldisiloxane is taken as a center; two phenolic hydroxyl groups are connected; the middle part of each chain link in the epoxy resin which is generated after polymerization contains a siloxane bond; further, a prepared polymer uniformly contains a large number of siloxane bonds; meanwhile, according to theused weather-resistant curing agent, tetramethyldisiloxane is taken as a center, andpiperidylamine is connected to the two sidesrespectively, a polymer chain generated after cross-linking and curing uniformly contains oxysilane bonds, then the prepared product has uniform high-temperature resistance and hydrophobicity, the shear strength of the adhesive is not changed at a high temperature, and colloid is not prone to stripping in a humid environment.

Owner:佛山市同高新材料有限公司

High-barrier filing cabinet dust sealing material and preparation method thereof

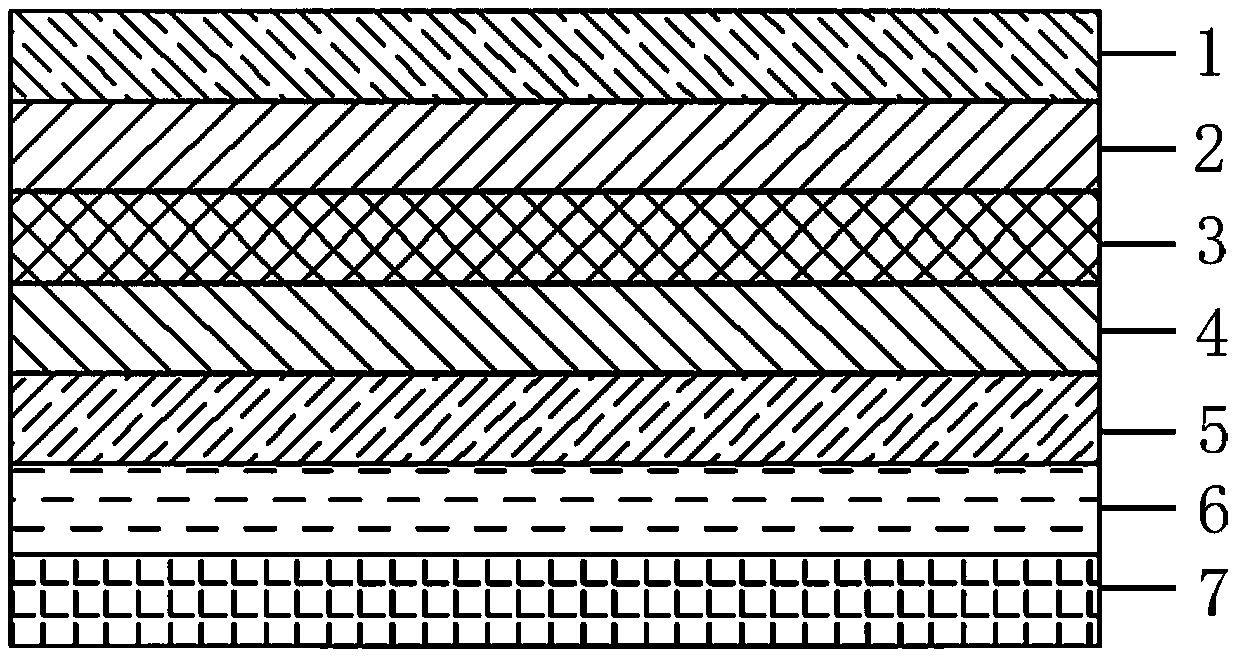

InactiveCN110356076ASolve the problem of easy peelingImprove barrier propertiesSynthetic resin layered productsPolyesterAdhesive

The invention discloses a high-barrier filing cabinet dust sealing material which sequentially comprises a PVC plastic paste layer I, a PVC plastic paste layer I with an adhesive, a high-strength polyester woven fabric, a PVC plastic paste layer II with an adhesive, a PVC plastic paste layer II, a PVDC film layer and a PVC film layer from top to bottom, wherein the PVC plastic paste layer I, the PVC plastic paste layer I with the adhesive, the high-strength polyester woven fabric, the PVC plastic paste layer II with the adhesive and the PVC plastic paste layer II are bonded to obtain PVC knifescraping coating cloth, and the PVC knife scraping coating cloth is sequentially bonded to the PVDC film layer and the PVC film layer. The high-barrier filing cabinet dust sealing material has the advantages of high strength, high barrier, good air tightness, excellent peeling strength and good moisture-proof and environment-friendly performance.

Owner:ZHEJIANG SHANGCHENG SCI&TECH

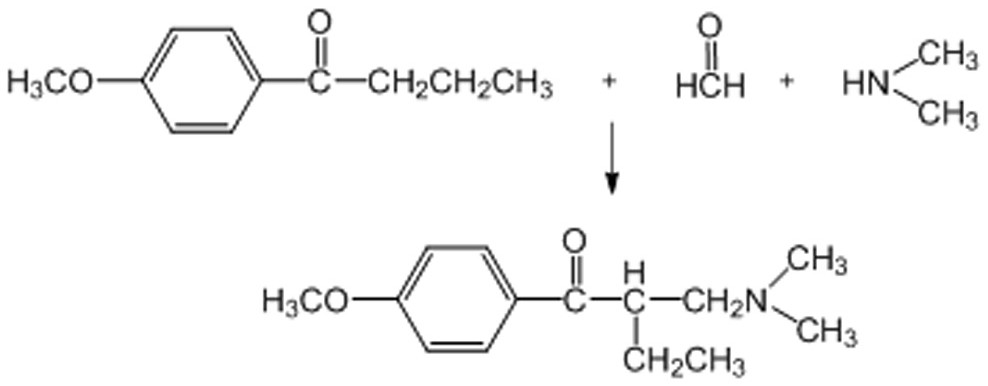

Preparation method of phase-change temperature-adjusting heating fibers

InactiveCN113445146AImprove adhesion stabilitySolve the problem of easy peelingMonocomponent synthetic polymer artificial filamentMicroballoon preparationPhase-change materialPolyacrylonitrile

The invention discloses a preparation method of phase-change temperature-adjusting heating fibers. The preparation method comprises the steps that functional microcapsules are prepared firstly and then are added into polyacrylonitrile to prepare the phase-change temperature-adjusting heating fibers, wherein the prepared functional microcapsules are of a three-layer structure, the inner layer is a phase-change material, the middle layer is polyurethane, the outer layer is the far-infrared ceramic powder, and have dual functions of phase-change temperature regulation and far-infrared heat storage; and the polyurethane and the far-infrared ceramic powder are connected through chemical bonds, so that the adhesion stability of the far-infrared ceramic powder is good, and the problem of easy stripping existing in conventional physical addition is solved.

Owner:吉祥三宝高科纺织有限公司

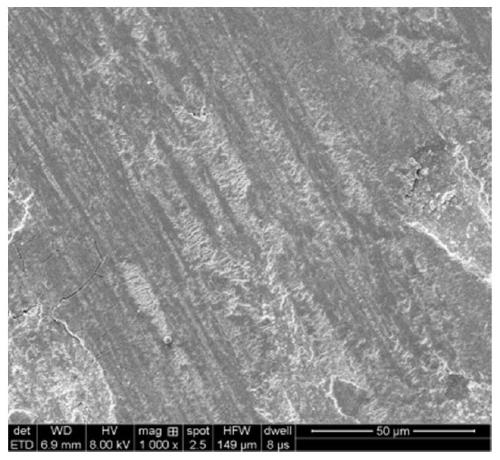

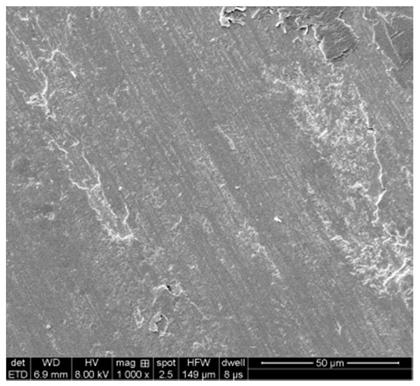

Wear-resistant and corrosion-resistant gradient coatings of middle trough of scraper conveyor

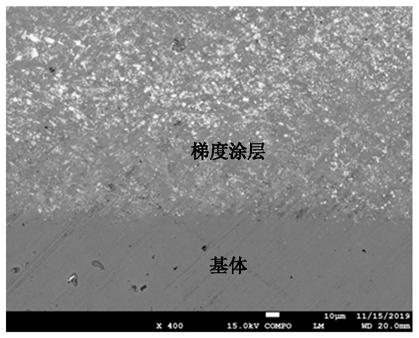

InactiveCN111498387AImprove bindingNot easy to fall offConveyorsMetallic material coating processesWear corrosionWear resistance

The invention relates to wear-resistant and corrosion-resistant gradient coatings of a middle trough of a scraper conveyor. The wear-resistant and corrosion-resistant gradient coatings can effectivelysolve the problems of uneven wear, serious corrosion and easy falling of coatings of an existing middle plate to a certain extent. According to the technical solution, the components of the coatingsare in gradient change, three parts are involved in total, the gradient coatings comprise the following components of, in percentage by weight, 43%-48% of Ni50, 47%-52% of Ni60, 1%-3% of TiC and 2%-4%of WC of a gradient coating-1, 38%-43% of Ni50, 42%-47% of Ni60, 6%-8% of TiC and 7%-9% of WC of a gradient coating-2, and 33%-38% of Ni50, 37%-42% of Ni60, 11%-13% of TiC and 12%-14% of WC of a gradient coating-3. According to the wear-resistant and corrosion-resistant gradient coatings of the middle trough of the scraper conveyor, the wear-resistant and corrosion-resistant gradient coatings have the characteristics of low water absorption rate, good toughness, light weight and the like, and have the main characteristics of wear resistance and corrosion resistance, meanwhile, by controllinggradient change of the components of the coatings, sudden change of structures and the performances among a base body and the coatings is avoided, the bonding condition among interfaces of the coatings are improved, the bearing capacity and the abrasion resistance of the coatings can be further improved, the overall service life of the middle trough can be effectively prolonged, and safe and efficient operation of the scraper conveyor is guaranteed.

Owner:UNIV OF JINAN

Electrospinning nanofiber membrane-fabric composite coating material and preparation method

ActiveCN110253984BImprove interface strengthSolve the problem of easy peelingNon-adhesive dressingsSynthetic fibresPolyvinylidene fluoridePhenols

The invention discloses an electrospun nanofiber membrane-fabric composite coating material and a preparation method thereof. The composite coating material consists of three layers. The surface layer is cross-linked PVPP obtained by free radical polymerization of PVP persulfate; the middle layer is polyvinylidene fluoride-hexafluoropropylene (PVDF-HFP) / polyvinylpyrrolidone (PVP) needle-free electrospun nanofiber membrane; the bottom layer is fabric. The surface layer is the functional layer, and the middle layer and the bottom layer are composited together through the self-crosslinking of PVP and the intercrosslinking with PVDF‑HFP during the PVP crosslinking process to form the supporting layer of the composite coating material. The composite material prepared by the invention can be used for functional medical dressings and beer stabilizers, and has the double-layer functions of polyphenol adsorption and filtration.

Owner:DALIAN POLYTECHNIC UNIVERSITY

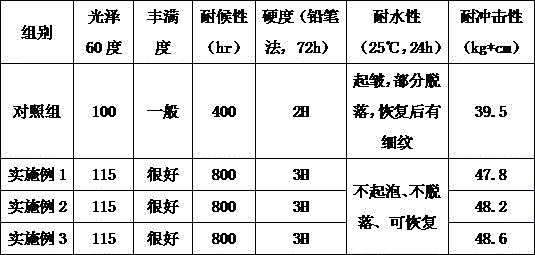

A color pre-coated sheet with high gloss

ActiveCN109731759BPrevent peelingSolve the problem of easy peelingLiquid surface applicatorsCoatingsParaffin waxPolymer science

The invention discloses a high-gloss colored pre-coated plate, which comprises a hot-dip galvanized steel plate, a layer of protective primer is sprayed on the surface of the hot-dip galvanized steel plate, and a layer of wear-resistant bright topcoat is sprayed on the surface of the protective primer. In the present invention, a layer of primer layer is compounded on the cladding surface of the hot-dip galvanized steel sheet, and a porous primer layer is compounded on the surface of the primer layer, and the primer layer and the porous primer layer are formed on the surface of the hot-dip galvanized steel sheet. Form the protective primer layer; because the composite primer is mixed with paraffin wax, when the composite primer adheres to the surface of the base primer layer, the mixed paraffin wax melts at high temperature, and the occupied sites of the paraffin wax are vacated. The surface of the paint layer is covered with voids vacated by paraffin, which makes the surface of the primer layer rough, which is convenient to realize the combination with the topcoat when spraying the topcoat in the later stage, and prevents the peeling of the topcoat layer. The surface of the layer is coated with topcoat, which causes the problem that the topcoat layer is easy to peel off.

Owner:JIANGSU LIBA ENTERPRISE JOINT STOCK

Adhesive for building decorative panels and preparation method thereof

ActiveCN111234754BSolve the problem of easy peelingImprove hydrophobicityEpoxy resin adhesivesPolymer scienceAdhesive

Owner:佛山市同高新材料有限公司

Artificial leather for automotive trim and preparation method thereof

PendingCN114713480AImprove wear resistanceGood flexibilityCoatingsSpecial surfacesEngineeringHigh wear resistance

The invention discloses artificial leather for automotive trim and a preparation method thereof, belongs to the field of artificial leather manufacturing, and solves the problems that artificial leather for automotive trim in the prior art is poor in wear resistance and a coating is easy to fall off. The artificial leather is base-cloth-free artificial leather, the artificial leather sequentially comprises the PVC foaming layer, the resin layer and the surface treatment layer from bottom to top, the problem that the base cloth layer and the leather layer are easy to peel off is solved, the artificial leather sequentially comprises the PVC foaming layer, the resin layer and the surface treatment layer from bottom to top, the wear resistance of the artificial leather is improved, and the service life of the artificial leather is prolonged. However, due to the fact that the wear resistance needs to be improved, the film forming hardness of the PVC artificial leather is large, the problem that after the hardness of the artificial leather is increased, the buckling resistance is reduced at the low temperature is solved, the softness and comfort of the artificial leather are kept, and the experience feeling of the artificial leather applied to automobile interiors can be improved.

Owner:WUXI MANYOULI NEW COMPOSITE MATERIALS

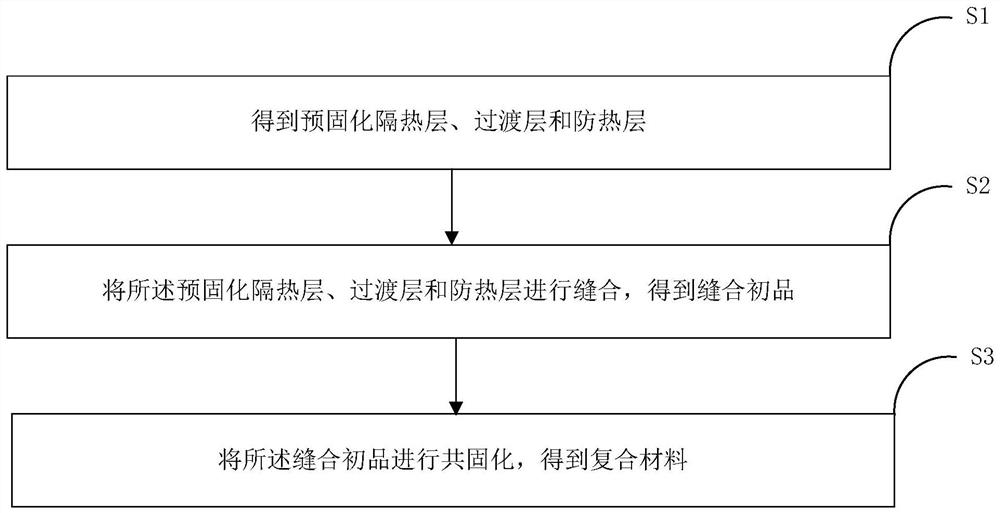

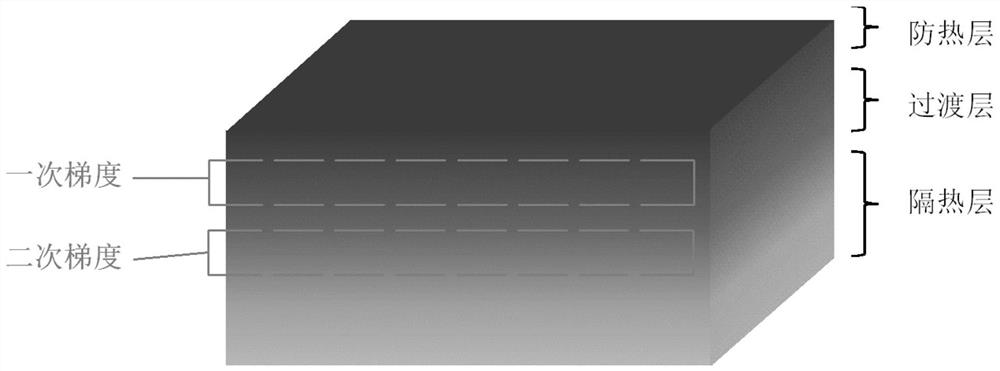

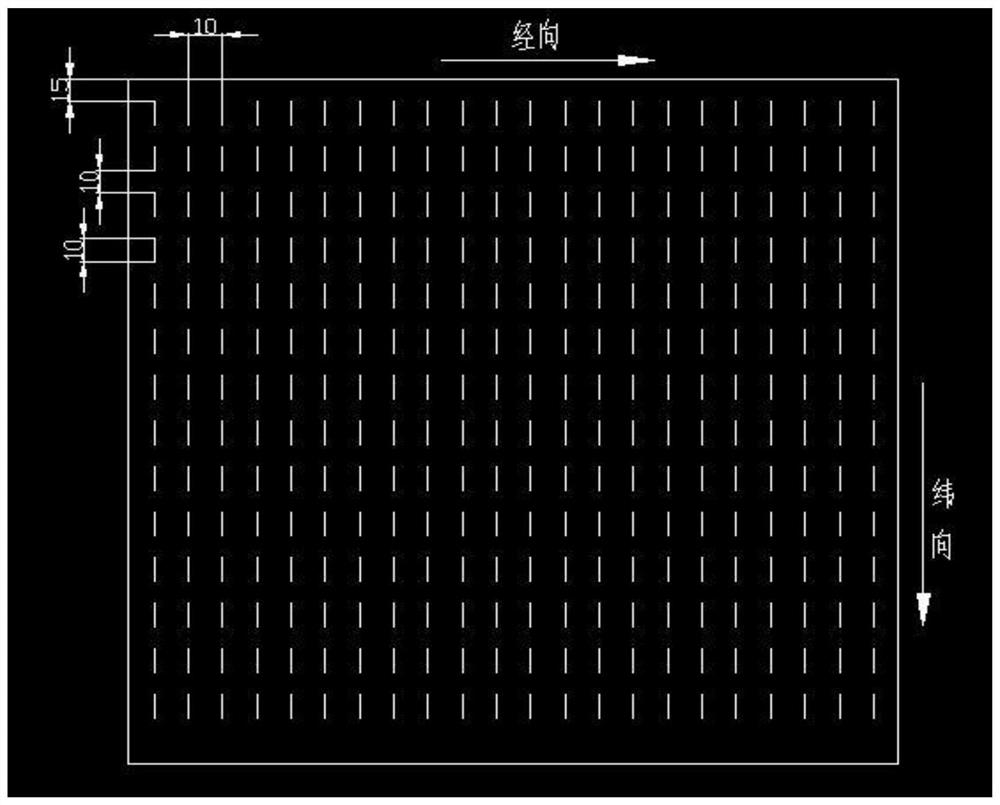

Heat-proof and heat-insulation double-gradient functional composite material and preparation method thereof

ActiveCN114311870AEliminate interfaceImproves ablation resistanceSynthetic resin layered productsWeight reductionInsulation layerFunctional composite

The invention particularly relates to a heat-proof and heat-insulation double-gradient functional composite material and a preparation method thereof, and belongs to the technical field of heat-insulation materials, the composite material comprises a heat-insulation layer, a transition layer and a heat-proof layer, and the transition layer is arranged between the heat-insulation layer and the heat-proof layer; the heat insulation layer is prepared from the following raw materials: modified phenolic resin and quartz fiber felt; raw materials of the transition layer comprise mixed multifunctional resin and first quartz fiber cloth; the heat-proof layer is prepared from phenolic resin, ablation-resistant filler and second quartz fiber cloth; the base materials of the heat insulation layer, the transition layer and the heat protection layer are all selected from phenolic resin material systems with good ablation performance, good bonding performance and compatibility are achieved, obvious material interfaces can be eliminated, and the interface bonding effect is improved. And phenolic mixed resin is adopted as a transition layer between the heat-proof layer and the heat-insulating layer, so that the purpose of gradient gradual change of the material performance is achieved, and the problem that various layers of the existing heat protection material are easy to peel off is solved.

Owner:HUBEI SANJIANG AEROSPACE GRP HONGYANG ELECTROMECHANICAL

Circuit board, preparation method thereof and backlight board

PendingCN113630958AHigh light reflectivityHigh bonding strengthCircuit optical detailsCircuit susbtrate materialsAdhesive cementComposite substrate

The invention discloses a preparation method of a circuit board, which comprises the steps of providing a glass fabric, impregnating the glass fabric in a first adhesive, and curing to obtain a bonding sheet; coating the surface of the bonding sheet with a second adhesive, wherein the light reflectivity of the second adhesive is less than that of the first adhesive, and a composite base material is obtained after curing; forming a first conductive circuit layer on the surface of the composite base material; and forming a first protection layer on the surface of the first conductive circuit layer, wherein part of the first conductive circuit layer is exposed to the first protection layer to form a first welding pad and a second welding pad. The invention further provides a circuit board and a backlight board. According to the invention, the peeling strength of the conductive circuit layer is not reduced while the light reflectivity is high.

Owner:AVARY HLDG (SHENZHEN) CO LTD +1

A kind of special near-infrared absorbing polyester film capable of batch production and its preparation method

ActiveCN110202896BThickness is easy to controlIncreasing the thicknessSynthetic resin layered productsFlat articlesPolyesterMasterbatch

The invention provides a special near-infrared absorbing polyester film that can be mass-produced and a preparation method thereof. The film is a BAB type three-layer structure film, wherein layer A is a special near-infrared absorbing layer, layer B is a surface modification layer, and the total film The thickness is 30-100 μm; the raw materials of the A layer are 50%-99.9% optical-grade high-transmittance PET slices, 0%-50% optical-grade high-transmittance PCT slices and 0.1%-1% near-infrared Absorbent composition: The raw materials of the B layer are composed of 5%-35% silicon-containing PET masterbatch and 65%-95% optical-grade high-transparency PET slices by weight. The near-infrared absorbing polyester film prepared by the present application has the characteristics of good heat resistance and low light transmittance in the 700-900nm near-infrared band.

Owner:HANGZHOU HESHUN TECH CO LTD

A kind of preparation method of porous stainless steel membrane

ActiveCN103691329BImprove other performanceSolve the problem of easy peelingSemi-permeable membranesCompression moldingPore diameter

The invention discloses a preparation method of a porous stainless steel film. The preparation method comprises the following steps: firstly, carrying out compression molding on large-grain-size stainless steel powder coated with a low-melting-point metal layer on the surface through a powder compressing machine; secondly, preparing a stainless steel powder film layer on a molded blank body; and finally, sintering to obtain the highly-asymmetrical porous stainless steel film. According to the preparation method provided by the invention, the stainless steel powder surface of the base body for preparation is coated with the low-melting-point metal layer so as to reduce the sintering temperature of stainless steel powder of the base body. Therefore, the base body and the film layer are sintered together; the asymmetrical degree of the prepared porous stainless steel film material is high; the pore diameter distribution of the film layer is narrow; the film layer and the base body are firmly combined; the low-melting-point metal on the surface of the base body powder and the base body powder are alloyed by high temperature sintering; meanwhile, the mechanical intensity of the film material is ensured, and the other metal properties of the porous stainless steel film are improved.

Owner:NANJING TECH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com