High-barrier filing cabinet dust sealing material and preparation method thereof

A file cabinet and high-barrier technology, which is applied in the field of high-barrier file cabinet dust sealing materials and its preparation, can solve the problems of poor oil resistance and high moisture permeability, and achieve improved barrier effect, good air tightness, moisture-proof and environmental protection performance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

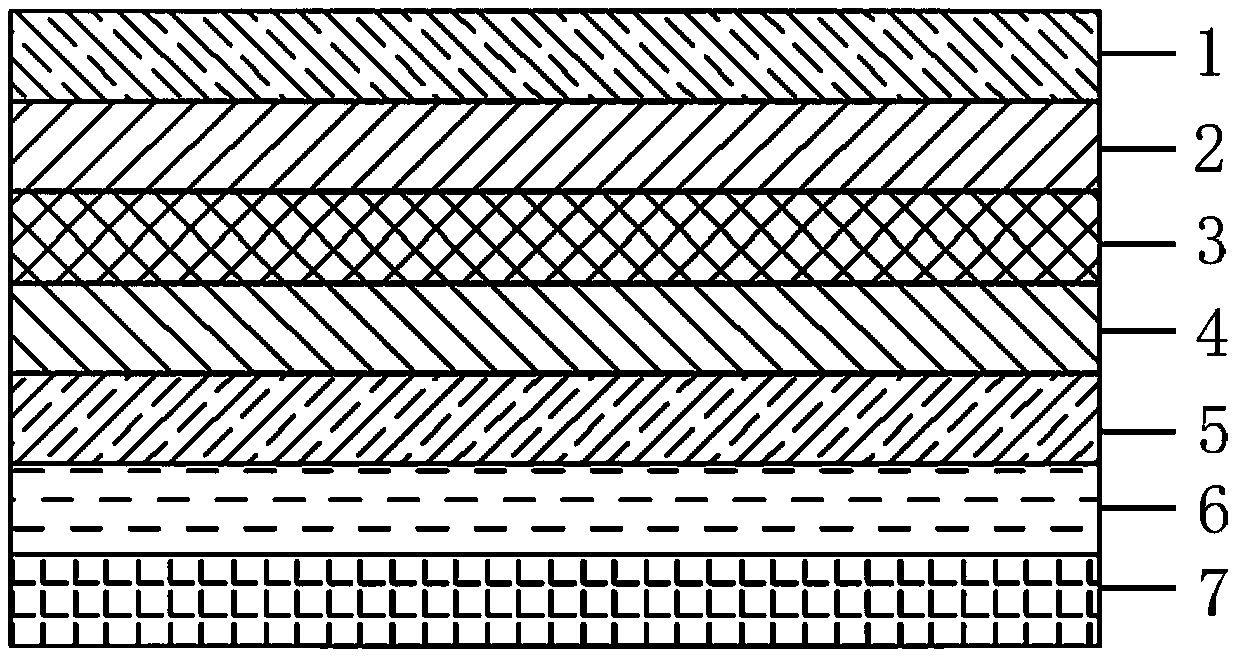

[0029] Embodiment 1: as attached figure 1 As shown, a high-barrier file cabinet dust-sealing material, from top to bottom, includes PVC plastic pulp layer I1, PVC plastic pulp with adhesive I2, high-strength polyester woven fabric 3, and PVC plastic pulp with adhesive Ⅱ4, PVC plastic slurry layer Ⅱ5, PVDC film layer 6 and PVC film layer 7, the PVC plastic slurry layer I1, PVC plastic slurry I2 with adhesive, high-strength polyester woven fabric 3, PVC plastic with adhesive After laminating the slurry II4 and the PVC plastic slurry layer II5, a PVC knife-coated cloth is obtained, and the PVC knife-coated cloth is laminated with the PVDC film layer 6 and the PVC film layer 7 in sequence.

[0030] The PVC plastic layer I1, PVC plastic layer II5 and PVC film layer 7 all include PVC resin, plasticizer, stabilizer, flame retardant and pigment.

[0031] The pigments in the PVC plastic pulp layer I1 and PVC plastic pulp layer II5 are yellow, the flame retardant is a mixture of antimo...

Embodiment 2

[0034] Embodiment 2: A preparation method of a high-barrier filing cabinet dust-sealing material, comprising the following steps,

[0035] a: The PVC film layer 7 is obtained by calendering; after the PVC resin, plasticizer, stabilizer and flame retardant are mixed uniformly, the PVC film layer 7 is formed after being heated and calendered in a calender and cooled; the PVC film layer 7 The thickness is 0.06 mm;

[0036] b: Polyurethane water-based two-component glue is coated on both sides of the PVDC film to obtain the PVDC film layer 6; the temperature for coating the glue is 65°C; the thickness of the PVDC film layer 6 is 0.02 mm;

[0037]c: The front and back sides of the high-strength polyester woven fabric 3 are coated with PVC plastic pulp I2 with adhesive and PVC plastic pulp II4 with adhesive under vertical primer respectively by knife coating method, and the PVC plastic pulp layer is applied again Ⅰ1 and PVC plastic slurry layer Ⅱ5, then dried and plasticized, and c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com