A kind of special near-infrared absorbing polyester film capable of batch production and its preparation method

A near-infrared absorbing agent and polyester film technology, applied in the field of polyester film, can solve the problems of poor heat resistance, easy peeling of the near-infrared absorbing film coating, etc., and achieves good heat resistance, good market application prospects, and light transmission. low rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

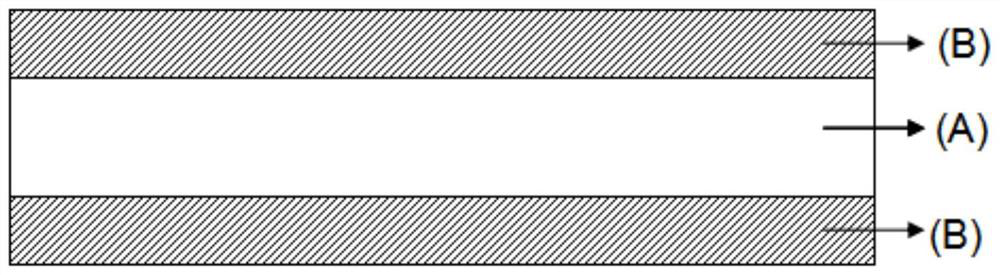

[0100] Such as figure 1 As shown, a special near-infrared absorbing polyester film that can be mass-produced, the film is a BAB type three-layer structure film, A is a special near-infrared absorbing layer, and B is a surface modification layer. The raw materials of layer A are composed of 50%-99.9% optical grade high-transparency PET slices, 0%-50% optical grade high-transparency PCT slices and 0.1%-1% near-infrared absorber by weight percentage; the raw materials of B layer The composition is composed of 5%-35% of silicon-containing PET masterbatch and 65%-95% of optical-grade high-transparency PET slices by weight percentage.

[0101] Specifically, in this embodiment, the preparation method of a special near-infrared absorbing polyester film that can be mass-produced comprises the following steps:

[0102] (1) The polyester film is prepared by three-layer co-extrusion biaxial stretching equipment, and the A-layer raw material (using o-phenylenediamine nickel complex dye, t...

Embodiment 2

[0113] (1) The polyester film is prepared by three-layer co-extrusion biaxial stretching equipment, and the A-layer raw material (using indole iodine polymethine cyanine dye, adding a mass fraction of 0.4%, optical grade high-transparency PET slices) The added mass fraction is 89.6%, and the added mass fraction of optical-grade high-transparency PCT chips is 10%) is sent to the corresponding feed bin of the main extruder through the suction system, and the main extrusion volume is 1250kg / h, controlled by a metering pump The ratio of raw materials is fed into the main extruder, melted and extruded at 273°C, vacuumed at 2.5mbar, and filtered through a 15μm butterfly filter to remove moisture, oligomers and impurities in the raw material melt as the main extruder. extrusion melt;

[0114] (2) Send the B-layer raw materials (the mass fraction of silicon-containing masterbatch is 10%, and the mass fraction of optical-grade high-transparency PET slices is 90%) to the corresponding h...

Embodiment 3

[0123] (1) The polyester film is prepared by three-layer co-extrusion biaxial stretching equipment, and the A-layer raw material (using thiodiene cobalt complex dye, the added mass fraction is 0.1%, the added mass of optical grade high-transparency PET slices The fraction is 79.9%, and the added mass fraction of optical-grade high-transparency PCT slices is 20%) is sent to the corresponding feed bin of the main extruder through the suction system, and the main extrusion volume is set at 1200kg / h, controlled by a metering pump The ratio of raw materials is fed into the main extruder, melted and extruded at 275 ° C, vacuumed at 2.1 mbar, and filtered through a 15 μm butterfly filter to remove moisture, oligomers and impurities in the raw material melt as the main extrusion melt;

[0124] (2) Send the B-layer raw materials (the mass fraction of silicon-containing masterbatch is 15%, and the mass fraction of optical-grade high-transparency PET slices is 85%) to the corresponding h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com