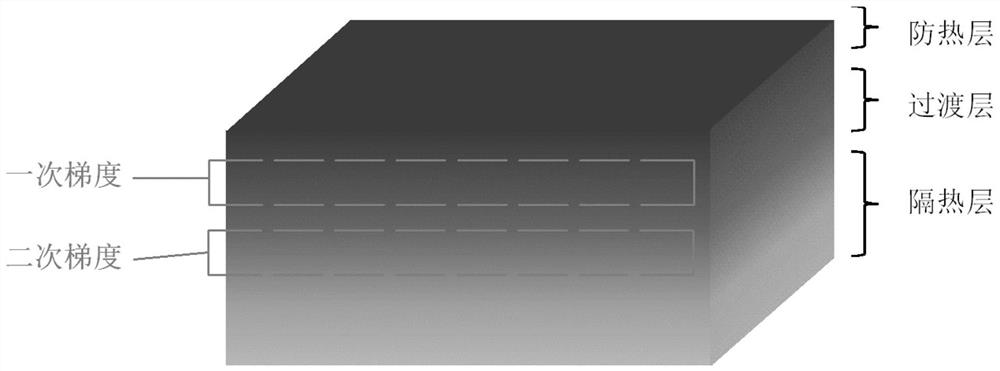

Heat-proof and heat-insulation double-gradient functional composite material and preparation method thereof

A functional composite material and dual-gradient technology, applied in chemical instruments and methods, flat products, and other household appliances, can solve the problems of easy peeling of thermal protection materials, improve interface bonding effect, improve ablation resistance, Efficient heat insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

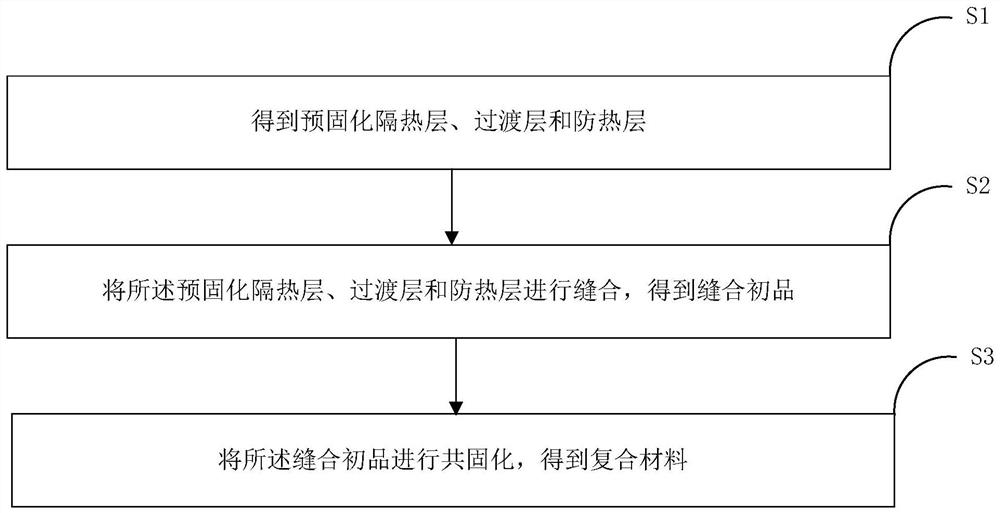

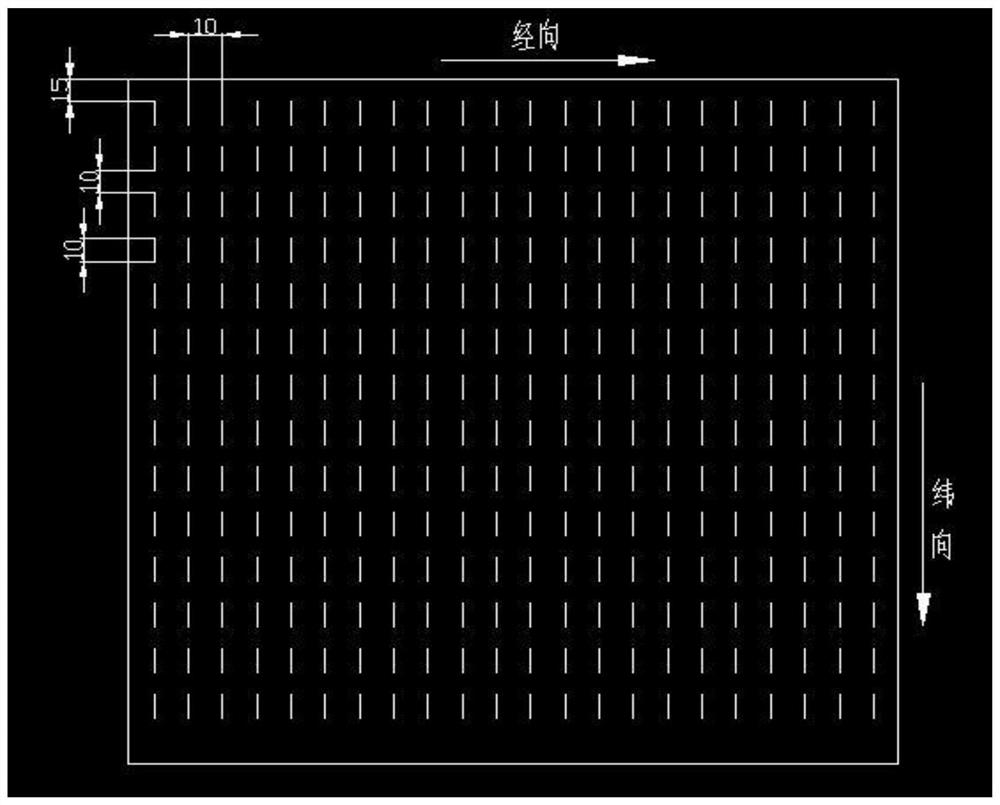

[0057] According to another typical embodiment of the present invention, a method for preparing the heat-resistant and heat-insulating dual-gradient functional composite material as described above is provided, the method comprising:

[0058] S1. Obtain pre-cured heat insulation layer, transition layer and heat protection layer;

[0059] In some embodiments, the preparation method of the pre-cured insulation layer includes:

[0060] S1.1. The modified phenolic resin and quartz fiber felt are mixed to obtain a mixture,

[0061] S1.2. Curing and molding the mixture to obtain a shaped product;

[0062] In this embodiment, the curing molding adopts a low-pressure RTM glue injection process, the glue injection temperature of the low-pressure RTM glue injection process can be 10°C-70°C, and the glue injection time of the low-pressure RTM glue injection process can be 2h- 10h, the injection pressure of the low-pressure RTM injection process can be 0.05MPa-0.3Mpa;

[0063] When the...

Embodiment 1

[0081] A method for preparing a heat-resistant and heat-insulating dual-gradient functional composite material, the method comprising:

[0082] S1.1. The modified phenolic resin and quartz fiber felt are mixed to obtain a mixture,

[0083] In the present embodiment, the natural state density of quartz fiber felt is 0.1g / cm 3 ;

[0084] S1.2. Curing and molding the mixture to obtain a shaped product;

[0085] In this embodiment, the low-pressure RTM glue injection process is used for curing and molding. The glue injection temperature of the low-pressure RTM glue injection process is 30°C, and the glue injection time of the low-pressure RTM glue injection process is 6 hours. The low-pressure RTM glue injection process The glue injection pressure is 0.05Mpa;

[0086] S1.3. Pre-curing the molded product to obtain a pre-cured heat insulation layer;

[0087] In this embodiment, the curing temperature of the pre-curing is 90° C., and the curing time of the pre-curing is 8 hours; ...

Embodiment 2

[0098] A method for preparing a heat-resistant and heat-insulating dual-gradient functional composite material, the method comprising:

[0099] S1.1. The modified phenolic resin and quartz fiber felt are mixed to obtain a mixture,

[0100] In the present embodiment, the natural state density of quartz fiber felt is 0.3g / cm 3 ;

[0101] S1.2. Curing and molding the mixture to obtain a shaped product;

[0102] In this embodiment, the low-pressure RTM glue injection process is used for curing and molding. The glue injection temperature of the low-pressure RTM glue injection process is 70°C, and the glue injection time of the low-pressure RTM glue injection process is 4 hours. The low-pressure RTM glue injection process The glue injection pressure is 0.3MPa;

[0103] S1.3. Pre-curing the molded product to obtain a pre-cured heat insulation layer;

[0104] In this embodiment, the curing temperature of the pre-curing is 80°C, and the curing time of the pre-curing is 10h;

[010...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com