A kind of preparation method of porous stainless steel membrane

A technology of stainless steel membrane and stainless steel, applied in the field of preparation of porous stainless steel membrane, can solve the problems of peeling, shrinkage mismatch, easy peeling off of the membrane layer, etc., to reduce the sintering temperature, optimize the performance of membrane materials, and expand the scope of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

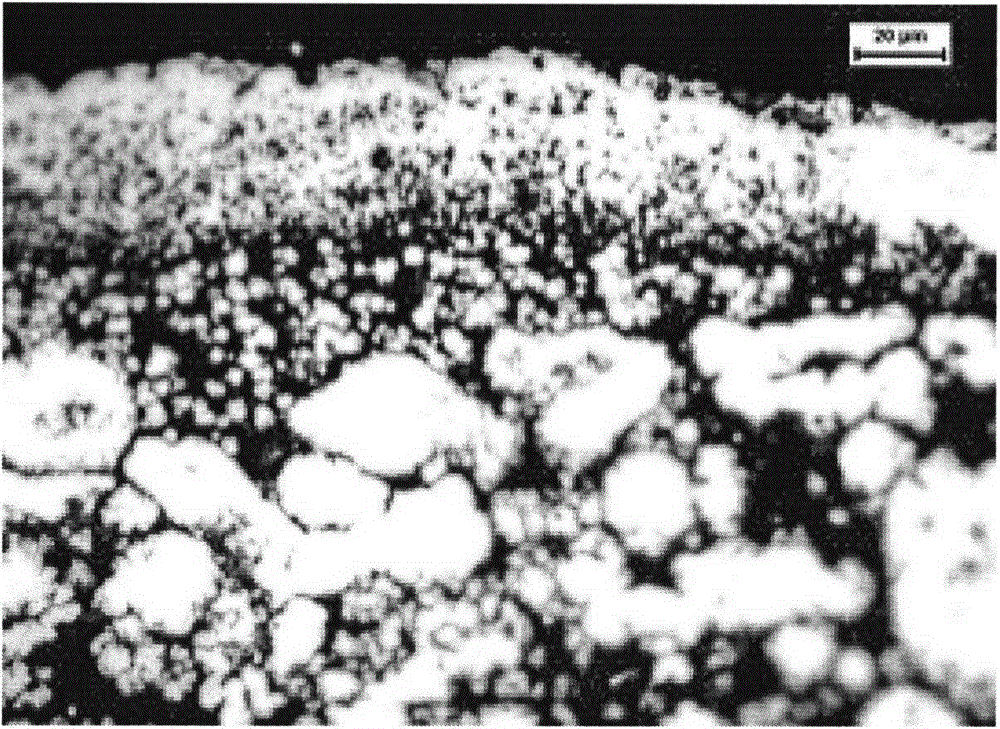

Image

Examples

Embodiment 1

[0023] A kind of preparation steps of porous stainless steel membrane:

[0024] 1. Add stainless steel powder with an average particle size of 100 μm to the saturated nickel sulfate solution, stir and add an appropriate amount of zinc powder. After the zinc powder reacts completely, filter out the stainless steel powder and dry it.

[0025] 2. Use a tablet press to press a porous stainless steel body with a diameter of 30mm, the pressing pressure is 10Mpa, and the holding time is 100s.

[0026] 3. Prepare 100ml of 5wt.% PVA aqueous solution, add 10g of 5μm stainless steel powder, and stir to disperse.

[0027] 4. Prepare a 5 μm stainless steel powder film layer on the porous stainless steel body by spraying.

[0028] 5. Put the asymmetric porous stainless steel body into a high-temperature furnace. The first step is to heat it to 500°C at a heating rate of 2°C / min in an argon atmosphere, and keep it for 1 hour to remove additives; the second step is to heat it in a hydrogen a...

Embodiment 2

[0031] A kind of preparation steps of porous stainless steel membrane:

[0032] 1. Add stainless steel powder with an average particle size of 100 μm to the saturated copper sulfate solution, stir and add an appropriate amount of aluminum powder. After the aluminum powder reacts completely, filter out the stainless steel powder and dry it.

[0033] 2. Use a tablet press to press a porous stainless steel body with a diameter of 20mm, the pressing pressure is 15Mpa, and the holding time is 200s.

[0034] 3. Prepare 100ml of 5wt.% PVB ethanol solution, add 10g of 10μm stainless steel powder, and stir to disperse.

[0035] 4. Prepare a 10 μm stainless steel powder film layer on the porous stainless steel body by brushing.

[0036] 5. Put the asymmetric porous stainless steel body into a high-temperature furnace. The first step is to heat it to 500°C at a heating rate of 2°C / min in an argon atmosphere, and keep it for 1 hour to remove additives; the second step is to heat it in a ...

Embodiment 3

[0038] A kind of preparation steps of porous stainless steel membrane:

[0039] 1. Add stainless steel powder with an average particle size of 100 μm to the saturated silver nitrate solution, stir and add appropriate amount of zinc powder, after the zinc powder reacts completely, filter out the stainless steel powder and dry it.

[0040] 2. Use a tablet press to press a porous stainless steel body with a diameter of 15mm, the pressing pressure is 20Mpa, and the holding time is 300s.

[0041]3. Prepare 100ml of 2wt.% PVP solution, add 10g of 15μm stainless steel powder, and stir to disperse.

[0042] 4. Prepare a 15 μm stainless steel powder film layer on the porous stainless steel body by spraying.

[0043] Put the asymmetric porous stainless steel body into a high-temperature furnace. The first step is to heat it up to 500°C with a heating rate of 2°C / min in an argon atmosphere, and keep it for 1 hour to remove additives; the second step is to use a hydrogen atmosphere. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com