One-step production process for ultra-coarse denier polyester industrial fibers

A production process and technology for industrial fibers, applied in the field of polyester industrial fibers, can solve problems such as inability to meet requirements, and achieve the effects of good physical and mechanical properties and excellent physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

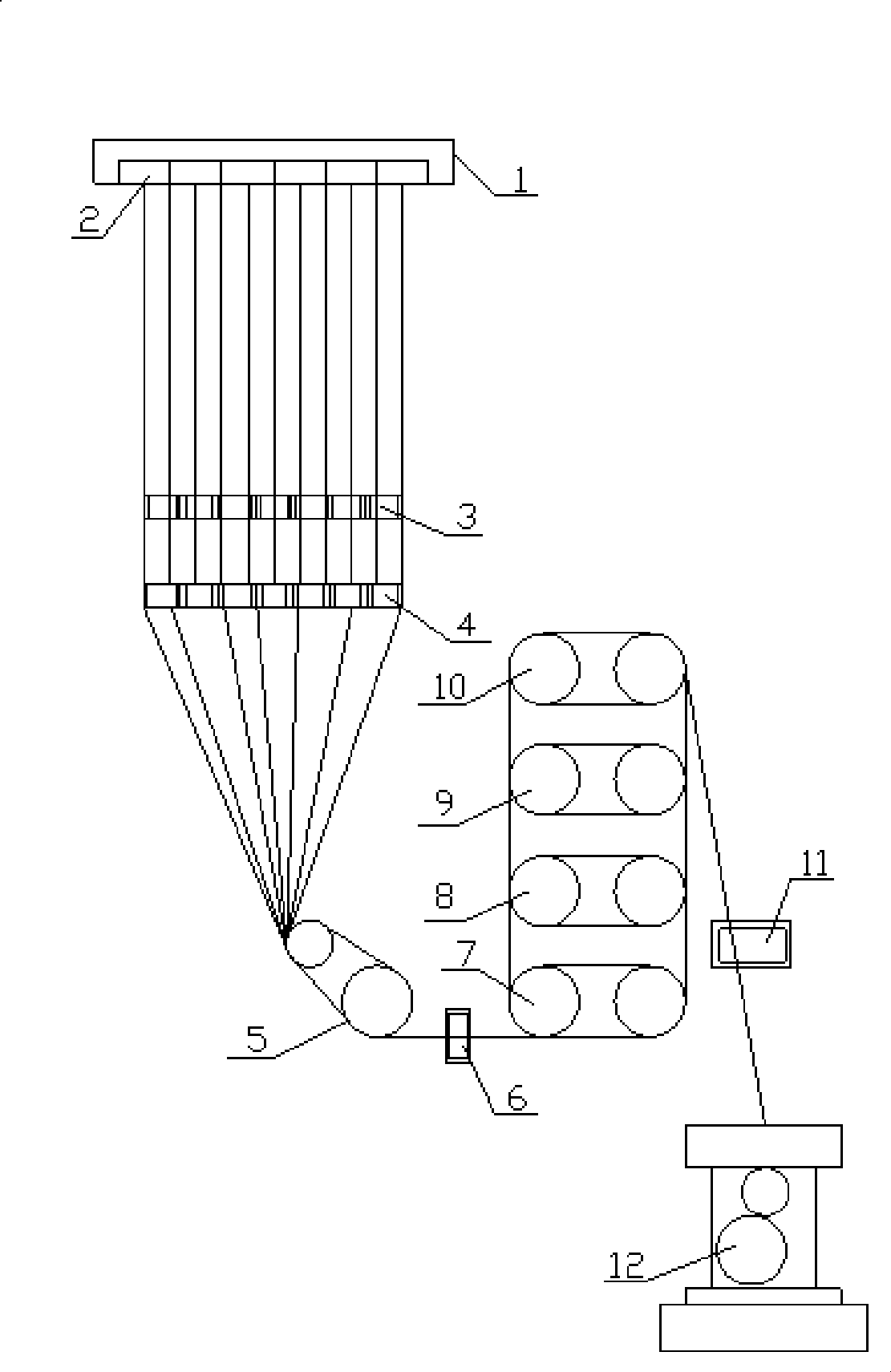

[0018] Specific embodiment 1 of the present invention: the one-step production process of this ultra-coarse denier polyester industrial fiber, comprises the following steps:

[0019] A. Spinning and oiling: After the polyester chip is melted, it is slowly cooled by a slow cooler with a temperature of 300-400 ° C, and the side blowing is cooled in the spinning box 1 through 8-12 ends of the spinning assembly 2, and then Use spinning oil to oil through two sets of oiling components in sequence. Each set of oiling components is equipped with an oil pump. The specification of the oil pump for the first set of oiling components is 0.05-0.10CC, and the speed is 3353rpm; The specification of the oil pump for the oil component is 0.05-0.10CC, and the rotation speed is 12-32rpm. Among them, the melted polyester chips are metered by the metering pump. The specification of the metering pump is 50CC, and the rotation speed is 14.95±0.2-16.5±0.2rpm;

[0020] B. Drawing heat setting: the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com