Patents

Literature

65 results about "Membrane adhesion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Membrane adhesion is essential to many vital biological processes. Sites of membrane adhesion are often associated with heterogeneities in the lipid and protein composition of the membrane. These heterogeneities are thought to play functional roles by facilitating interactions between proteins.

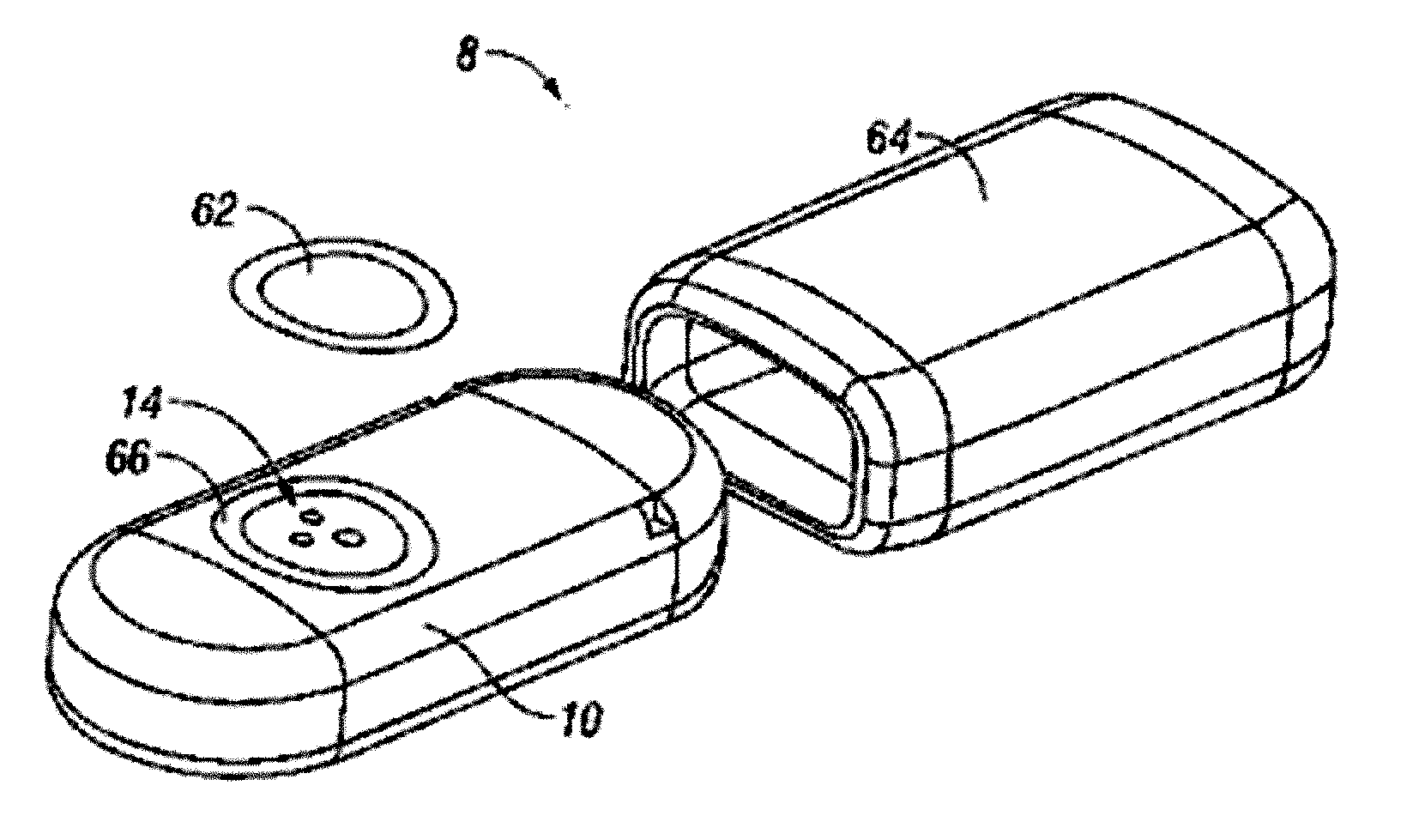

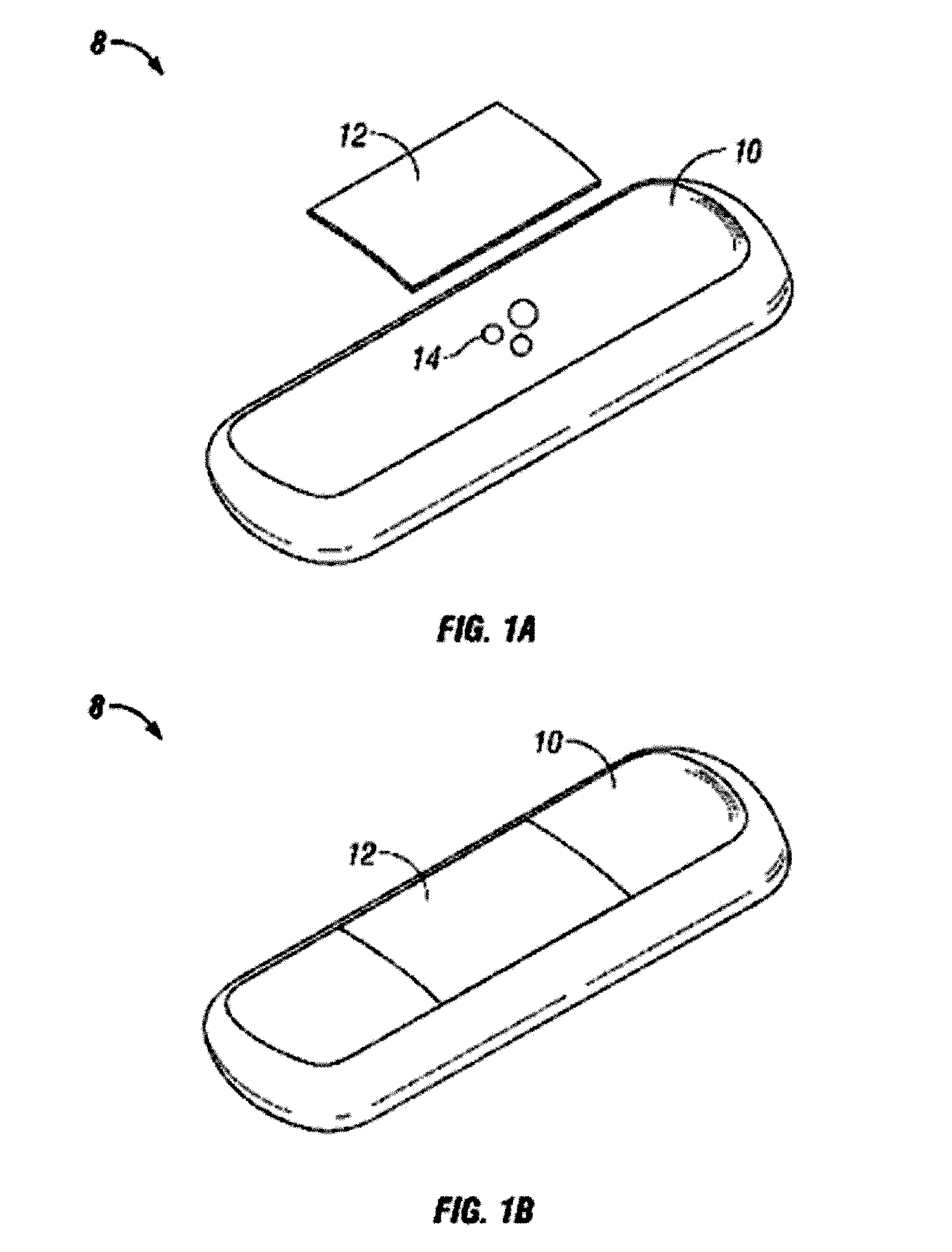

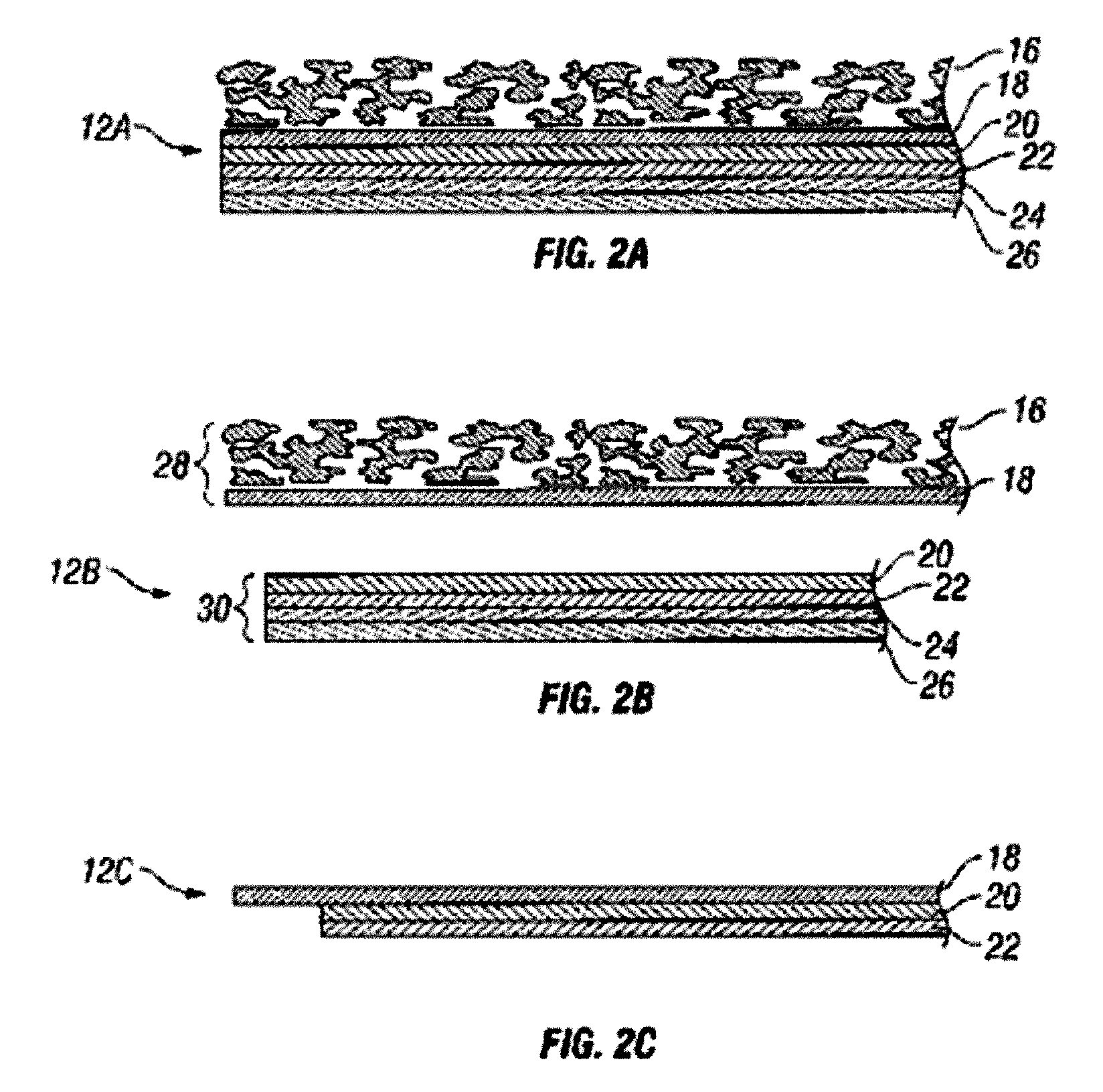

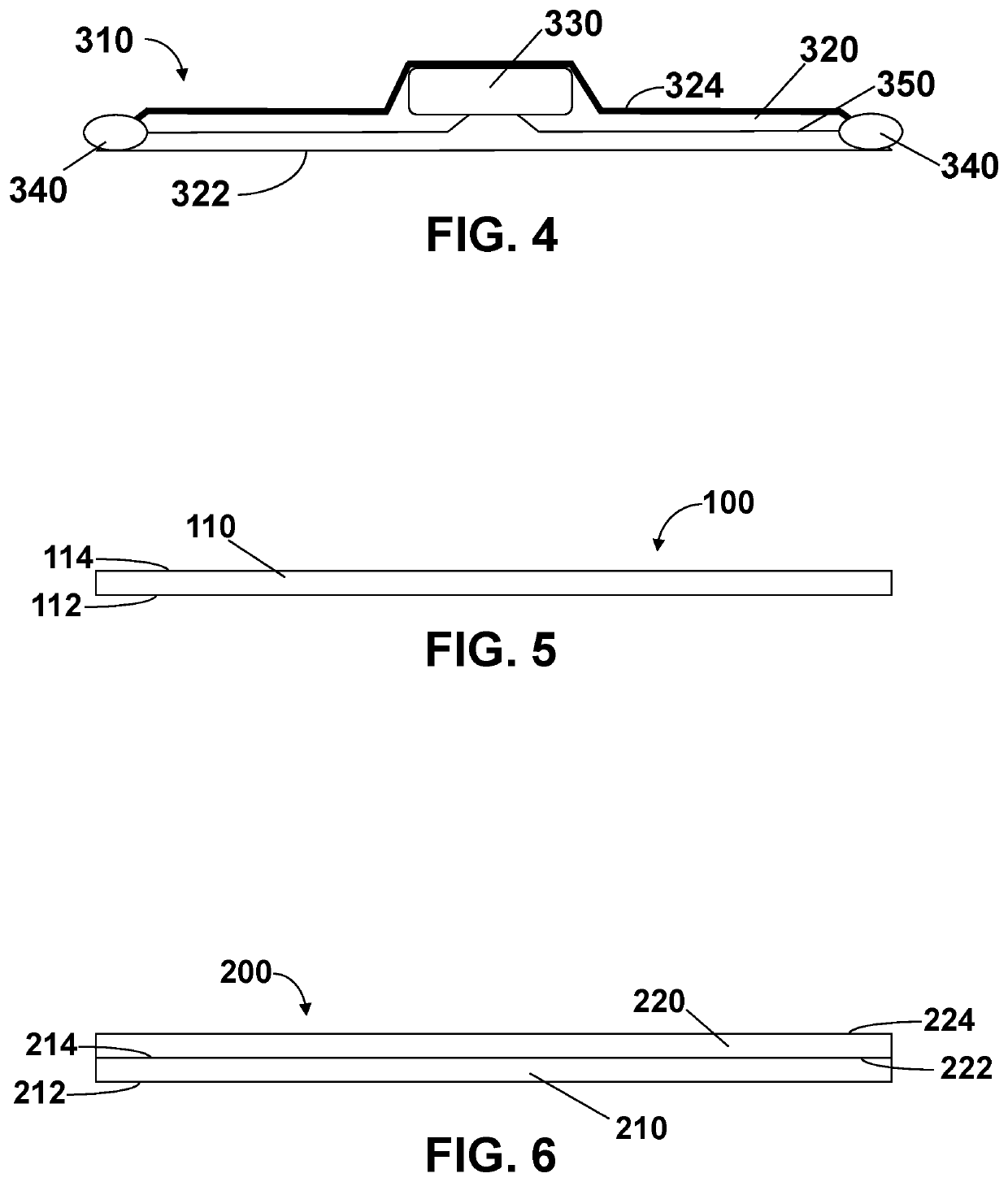

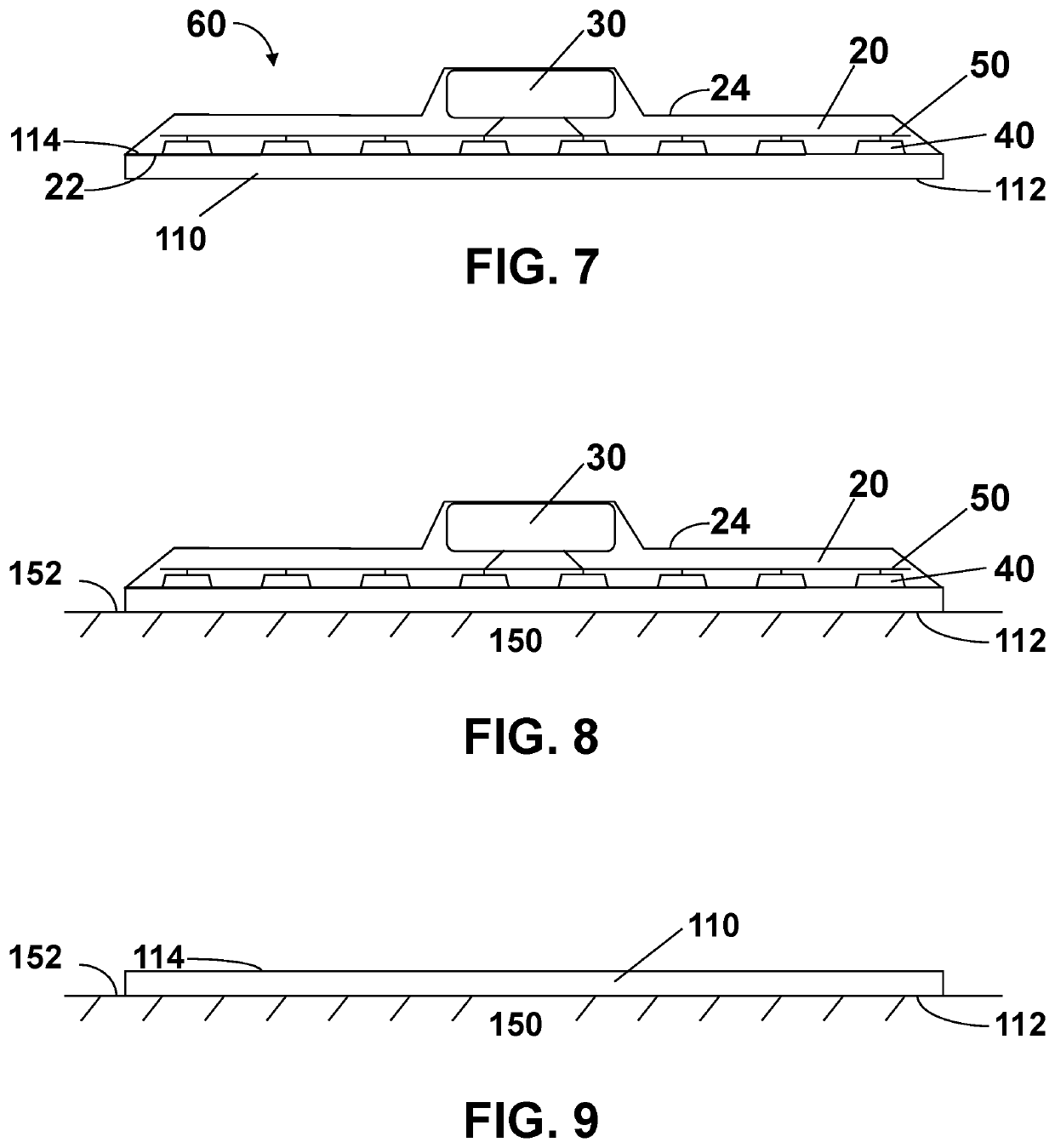

Systems and methods for manufacture of an analyte-measuring device including a membrane system

InactiveUS20060015020A1Minimized in sizeMaximize adhesionLaminationLamination apparatusAnalyteBiomedical engineering

Abstract of the DisclosureSystems and methods for manufacture of an analyte-measuring device, including adhering a membrane system that allows the passage of the analyte therethrough to a sensing mechanism. The implantable analyte-measuring device includes a body formed from a material that is substantially similar to the membrane system so as to enable sufficiently strong adhesion therebetween, which enables a sufficiently strong adhesive joint capable of withstanding in vivo cellular forces. In some embodiments, the device body includes an insert to which the membrane system is adhered, wherein the insert is formed from a material substantially similar to the membrane system to enable strong adhesion therebetween. The analyte-measuring device is designed with optimized device sizing and maximum membrane adhesion and longevity to enable controlled transport of analytes through the membrane system in vivo with improved device performance.

Owner:DEXCOM

Semi-solid mucoadhesive formulations

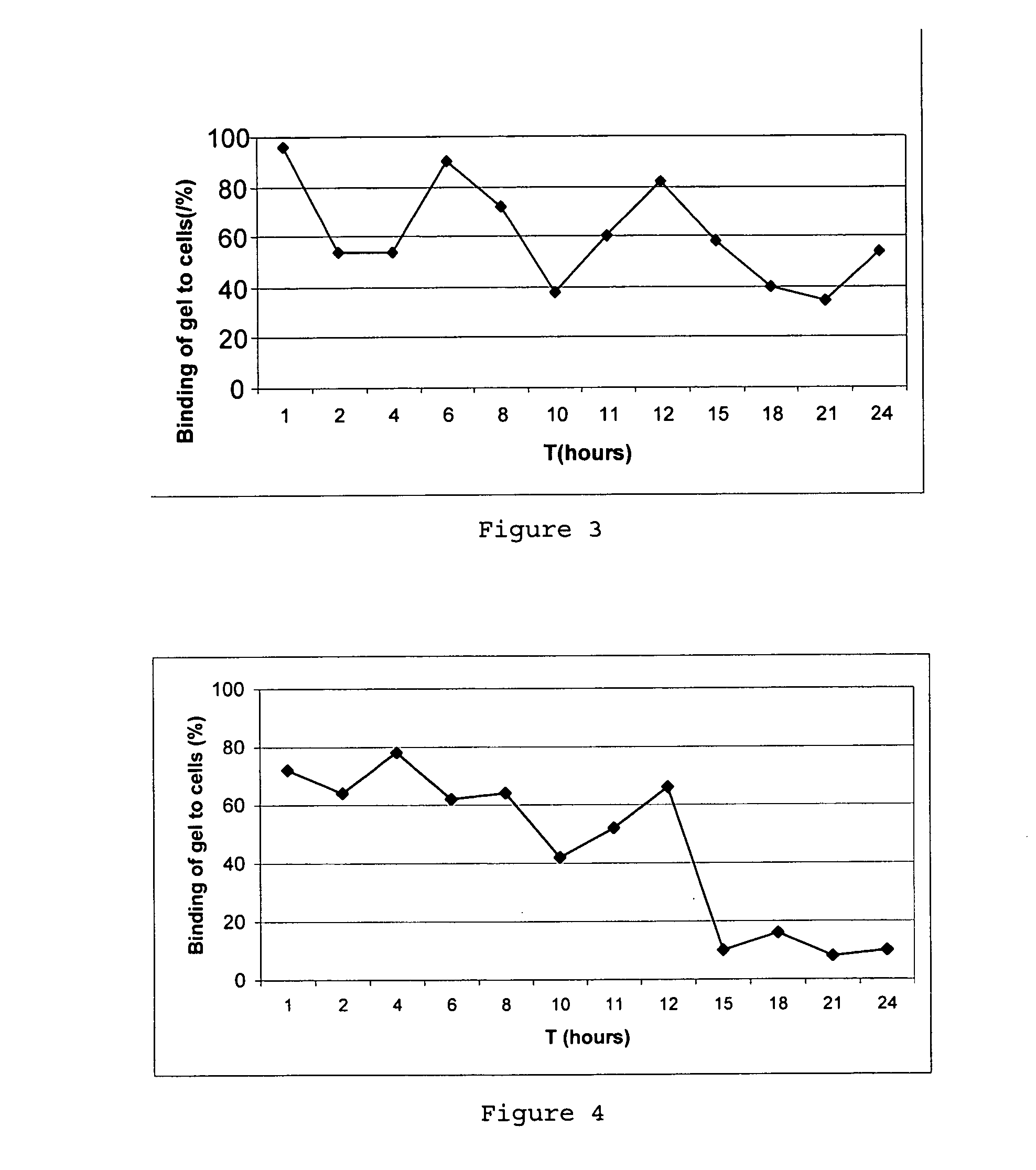

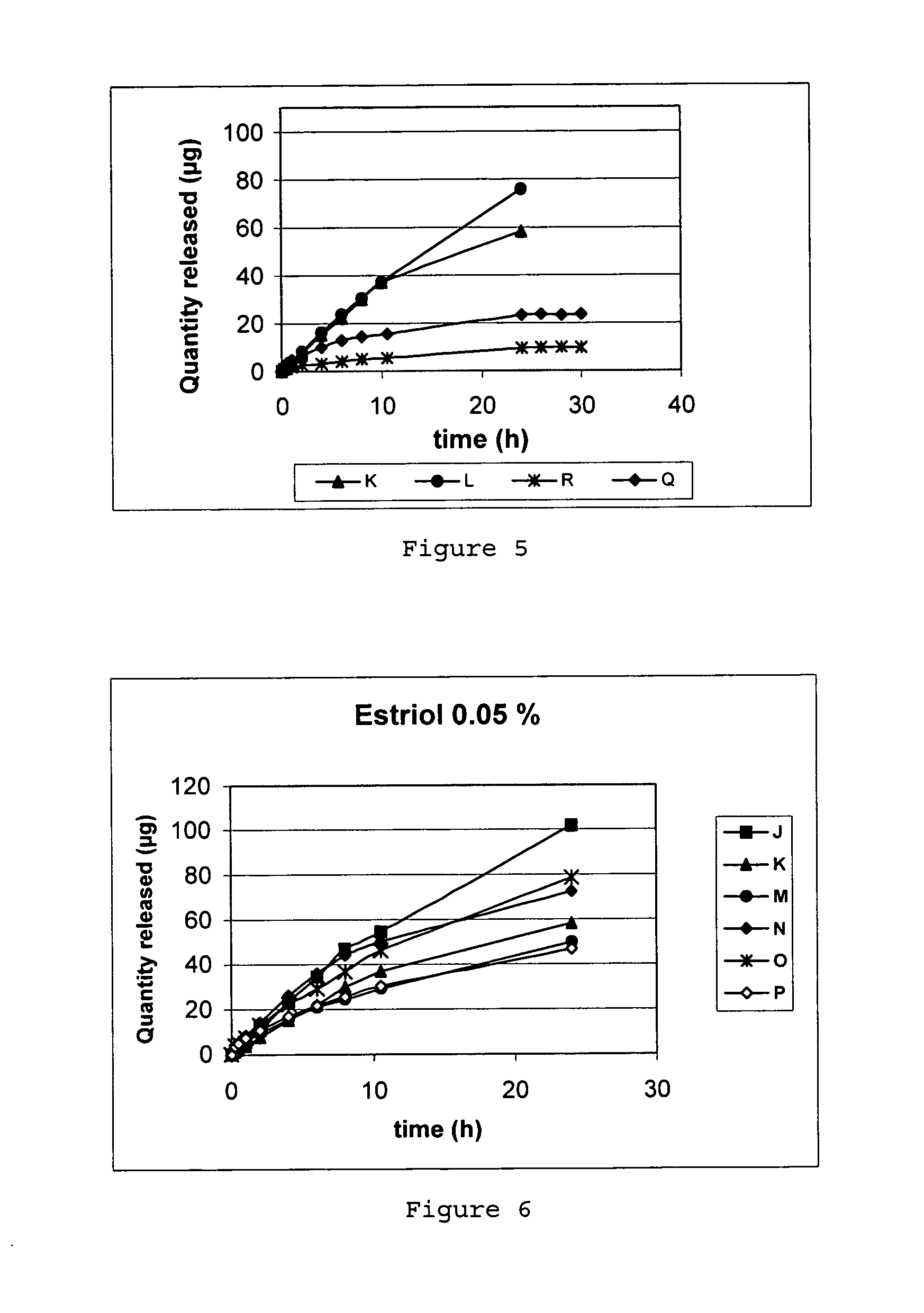

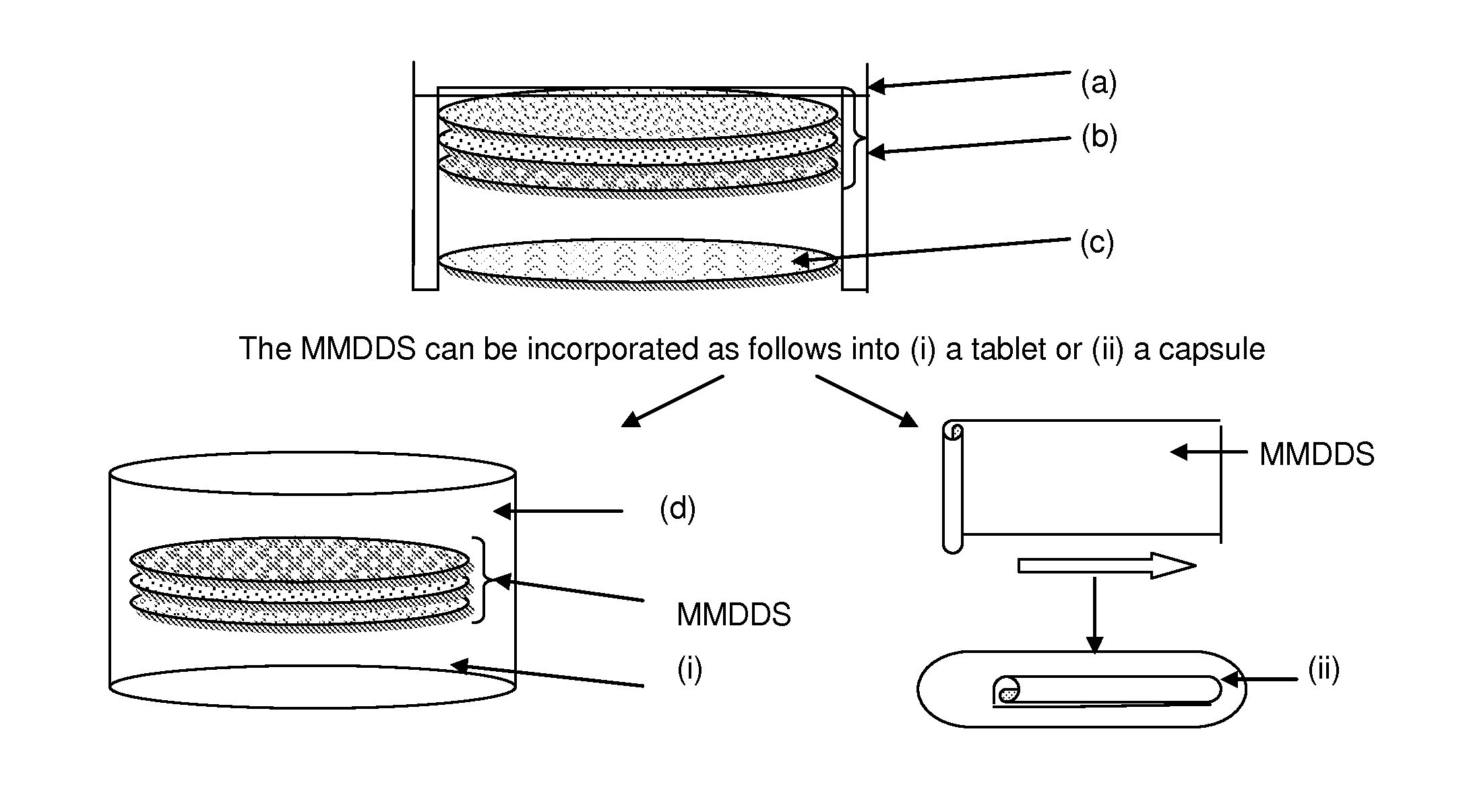

ActiveUS20060240111A1Good bioadhesionEfficient use ofPowder deliveryOintment deliveryDiseaseGynecology

Semisolid mucoadhesive formulations for vaginal application, with improved technical and organoleptic characteristics, which contain at least two bioadhesive gelling polymers and an active ingredient, useful in the prevention and / or treatment of various pathologies and disorders in human beings or animals.

Owner:ITF RISECH FARMA S L U

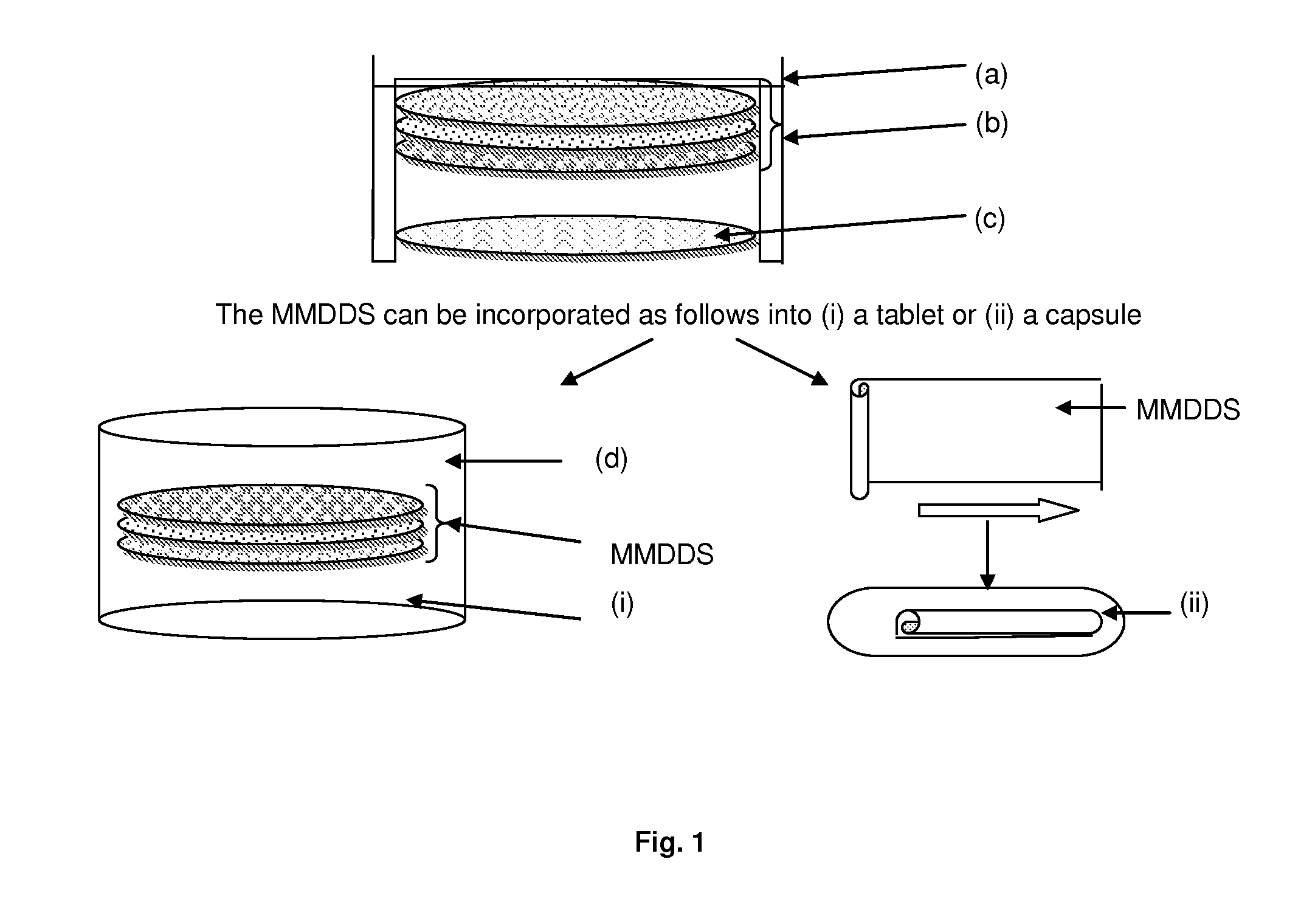

Pharmaceutical dosage form

InactiveUS20130337022A1Reduce releaseReduce deliveryBiocidePeptide/protein ingredientsActive agentMucoadhesion

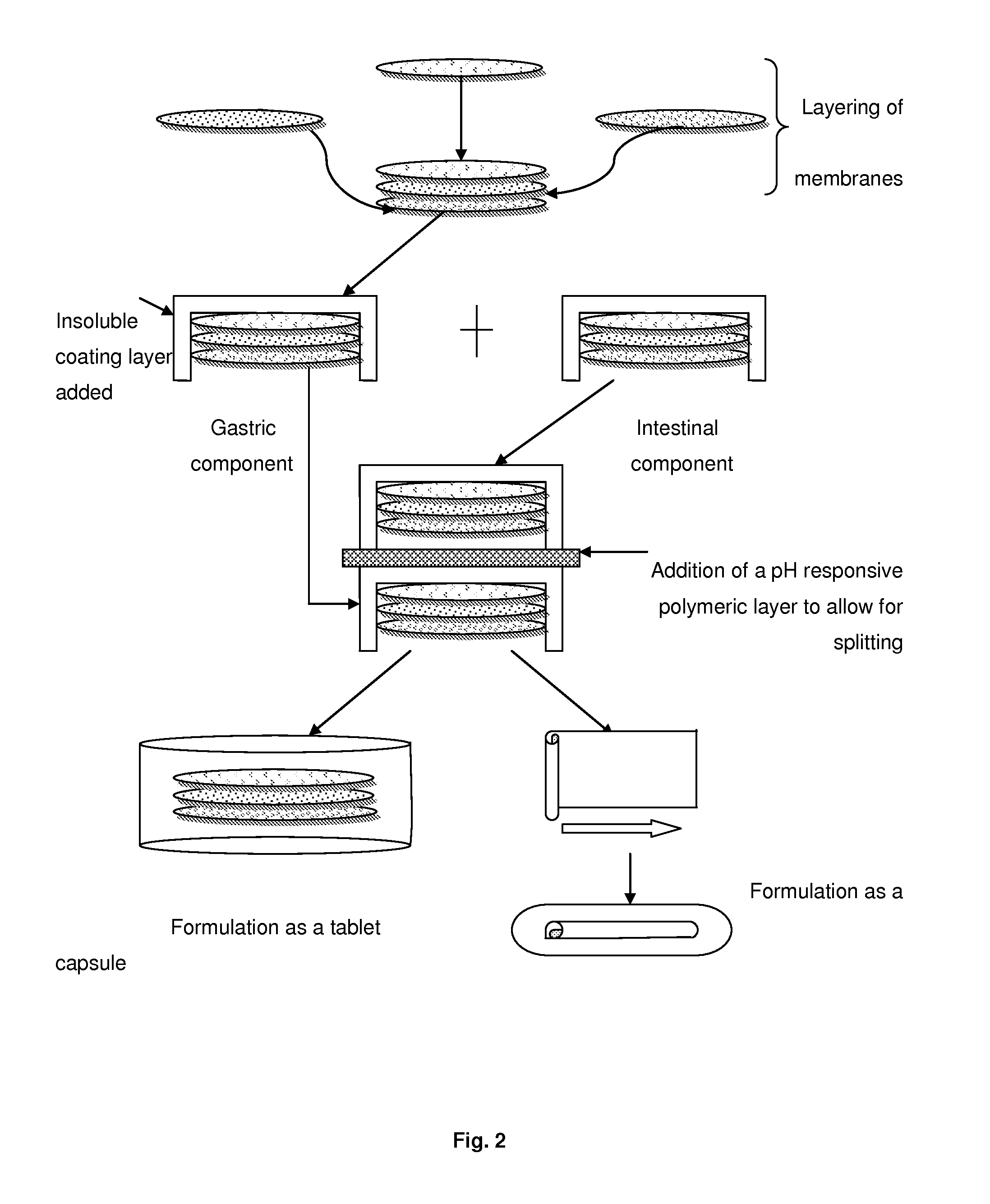

A pH responsive and mucoadhesive pharmaceutical dosage form for the release of a pharmaceutically active agent is described. The dosage form includes a mucoadhesive layer for site-specific mucoadhesion, a water-insoluble outer layer, and an intermediate layer including one or more pharmaceutically active agents for site-specific delivery. The different membranous layers perform different functions in order to create a drug delivery system which is able to deliver a drug to a specific site, for a particular period of time and with a specific drug release pattern. The dosage form can have two or more intermediate layers, each layer comprising an active agent. The mucoadhesive layer can also include an active agents. The dosage form is preferably an oral or buccal delivery form for release of the active agent into the gastro intestinal tract. The intermediate layer can be an electrospun fibrous membrane layer containing the active agent.

Owner:UNIVERSITY OF THE WITWATERSRAND

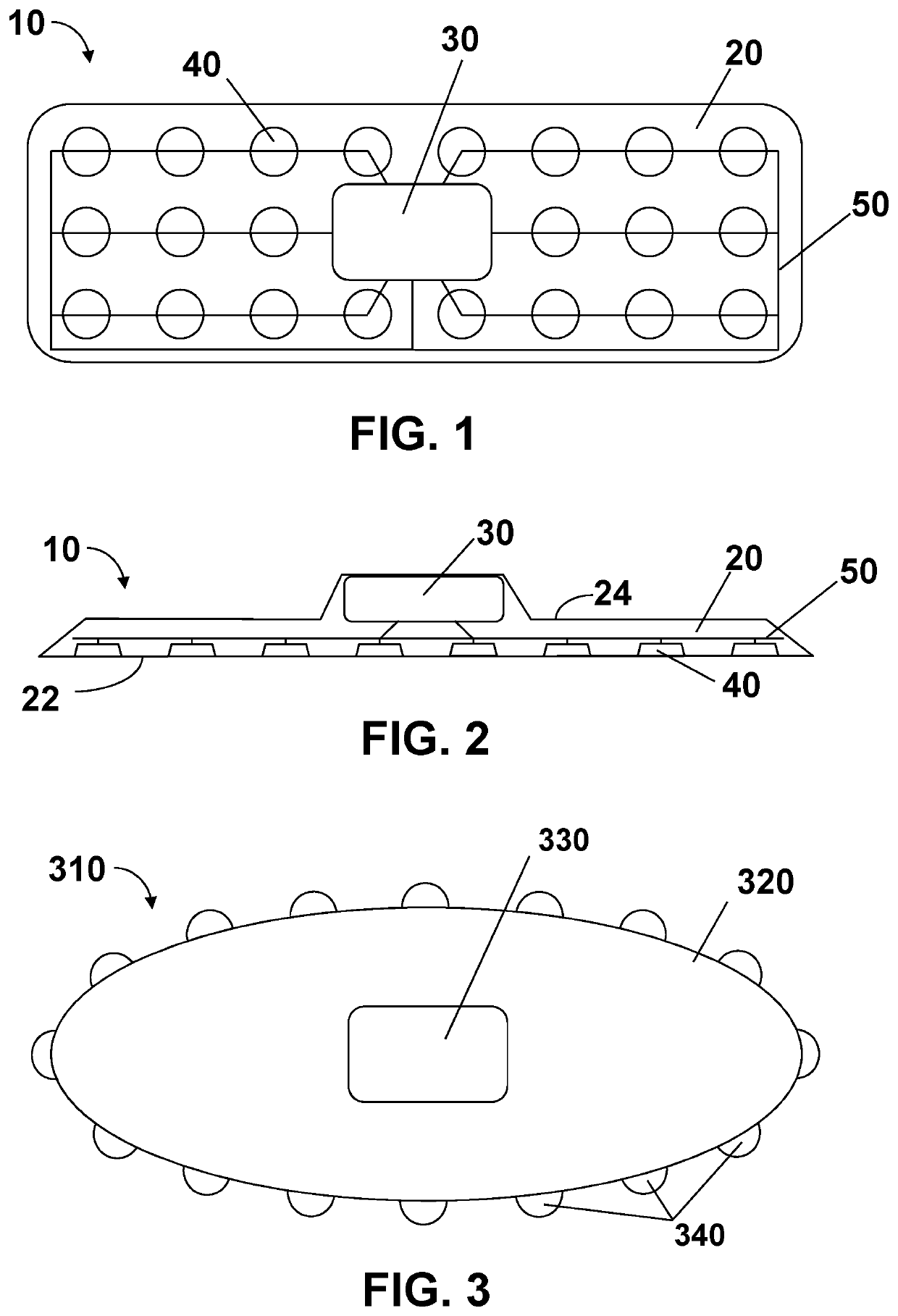

Film dosage form with extended release mucoadhesive particles

ActiveUS20180360736A1Avoid discomfortEasy to controlHydroxy compound active ingredientsPharmaceutical delivery mechanismOral medicationFilm Dosage Form

An orally administered dosage form that facilitates delivery of an agent locally in the buccal cavity for a sustained period of time includes mucoadhesive particles that are made of at least a mucoadhesive material combined with the agent, and which are dispersed in a disintegrating film. The dosage form is capable of delivering an agent to a patient at the desired oral mucosa site over an extended period of time while reducing patient discomfort or annoyance associated with conventional sustained release mucoadhesive films that must reside on the oral mucosa during the period of sustained release.

Owner:INTELGENX CORP

Long-acting slow-release oral ulcer film and preparation method thereof

InactiveCN106109445AHigh biosecurityBiodegradableDigestive systemPharmaceutical non-active ingredientsMembrane adhesionLong acting

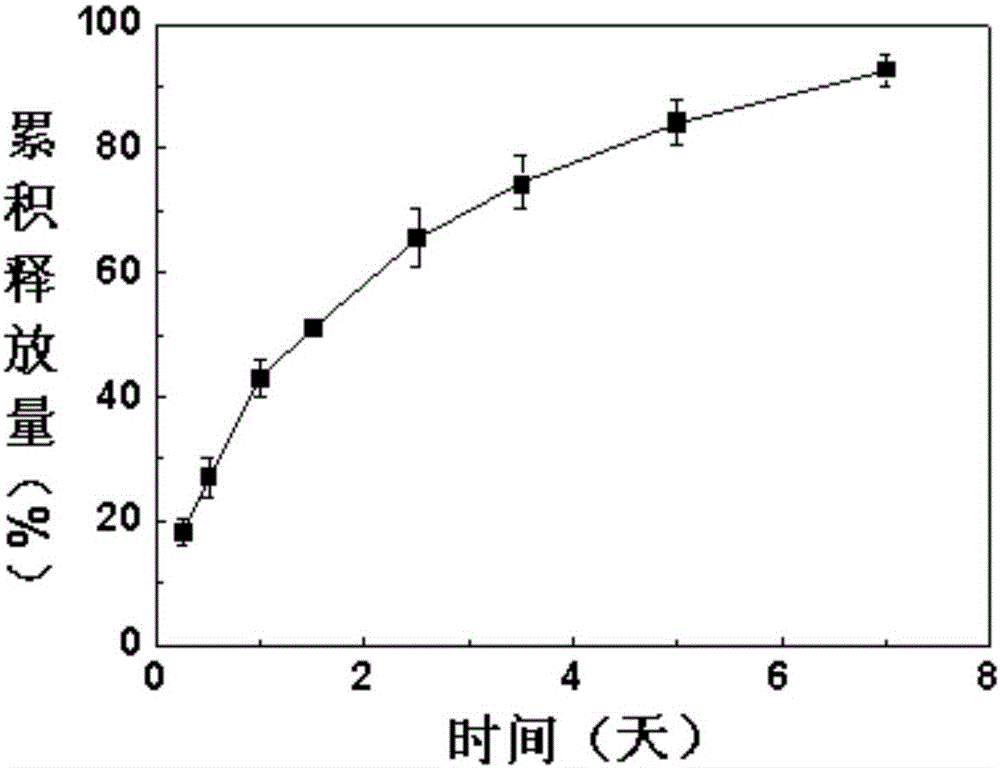

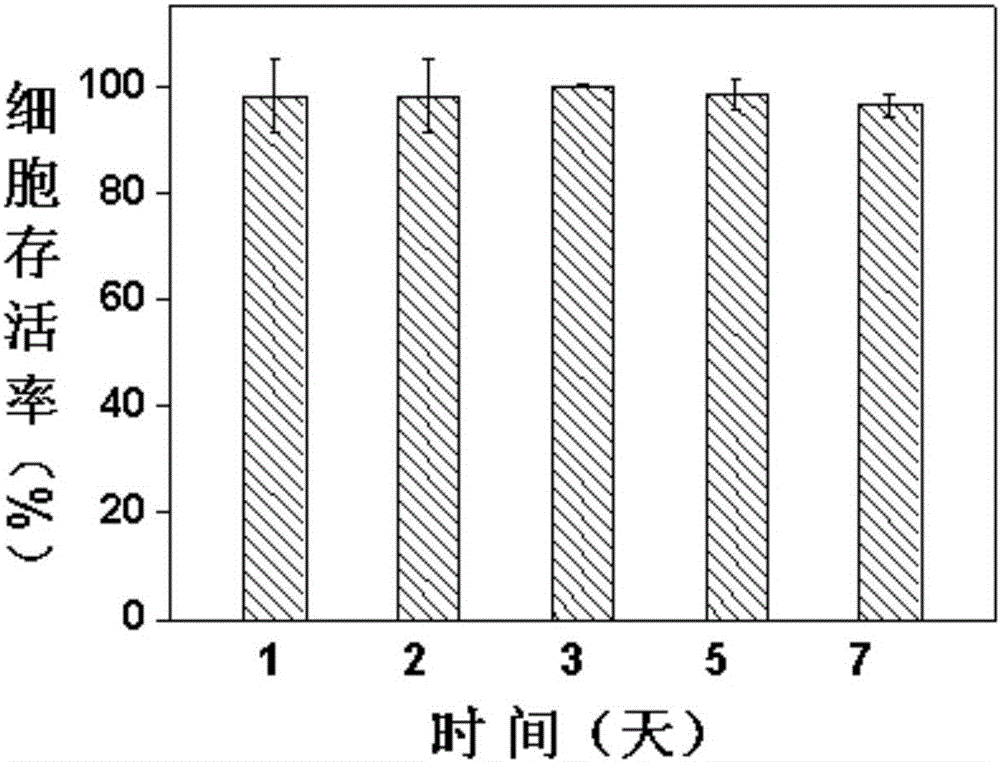

The invention belongs to the technical field of biomedical materials and discloses a long-acting slow-release oral ulcer film and a preparation method thereof. The oral ulcer film is formed by three layers of composite membranes, wherein the innermost layer is of a modified cellulose membrane adhesion layer, the interlayer is of a modified cellulose grafted polycaprolactone copolymer membrane drug-containing layer, and the outermost layer is of a polycaprolactone membrane drainage layer. The oral ulcer film is easy to use, good in biological safety and degradable; the inner layer of material has the advantages of adhesion and waterproof outer layer by design of the three layers of the composite membranes, and the oral ulcer film can be ensured to be applied to the infected part for a long time; the amphiphilic design of the interlayer is fit for embedding of the majority of hydrophilic or hydrophobic drugs, the function that the inner hydrophilic layer and the hydrophobic layer are adhered is achieved, and the oral ulcer film is hopefully and widely applied in the field of oral ulcer treatment.

Owner:佛山市高明绿化纳新材料有限公司

Adriamycin-indocyanine green bionic nanoparticles and application thereof

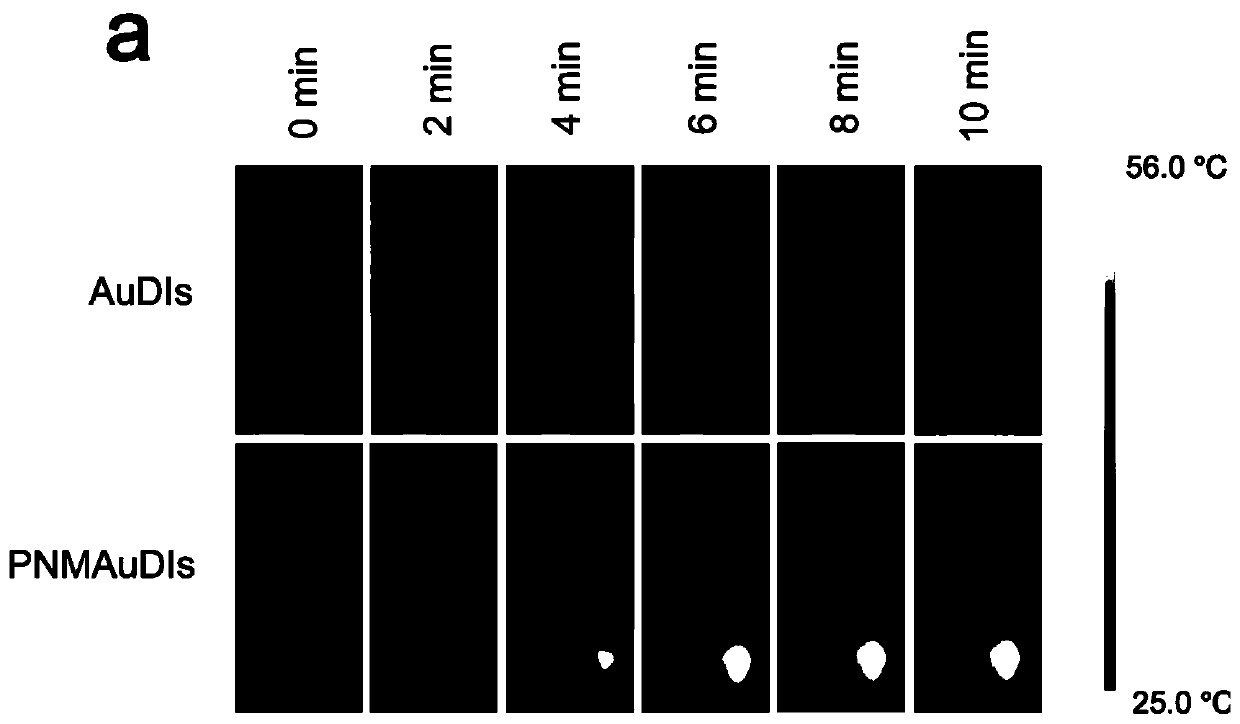

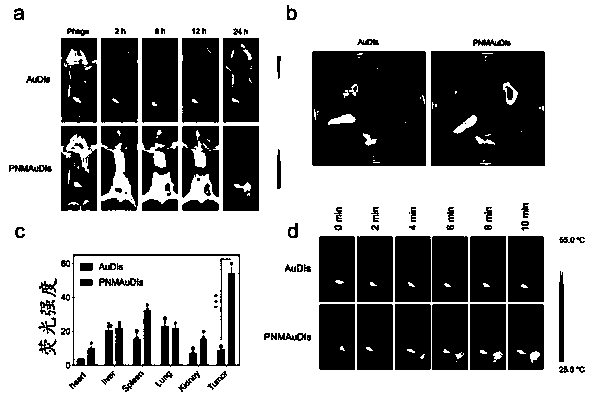

ActiveCN111000822AOrganic active ingredientsEnergy modified materialsDiseaseBreast cancer metastasis

The invention relates to the technical field of medicines, and relates to adriamycin-indocyanine green bionic nanoparticles coated with platelet and neutrophil fusion membranes and an application of the adriamycin-indocyanine green bionic nanoparticles in preparation of medicines for treating tumor metastasis diseases. The bionic nanoparticle coated with the platelet and neutrophil hybrid membranecomprises adriamycin, indocyanine green, a nano carrier material, a platelet membrane and a neutrophil hybrid membrane, which is characterized by comprising the following components in percentage byweight: 8 to 10 percent of doxorubicin, 8 to 10 percent of indocyanine green, 30 to 40 percent of nano carrier material and the balance of platelet and neutrophile granulocyte hybrid membrane. The bionic nanoparticle has the capability of simultaneously capturing and removing circulating tumor cells and tumor-derived exosomes through a high-affinity membrane adhesion receptor, and effectively cutsoff the relationship between the exosomes and immune cells. The primary tumor can be completely ablated, and breast cancer metastasis can be efficiently inhibited in xenograft and in-situ breast tumor models.

Owner:SHENYANG PHARMA UNIVERSITY

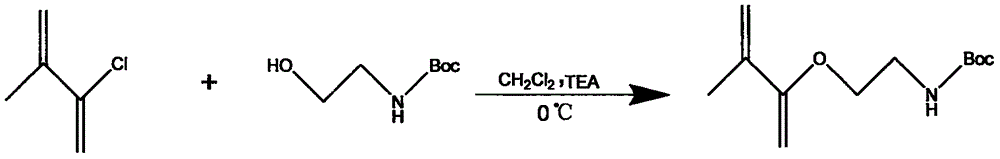

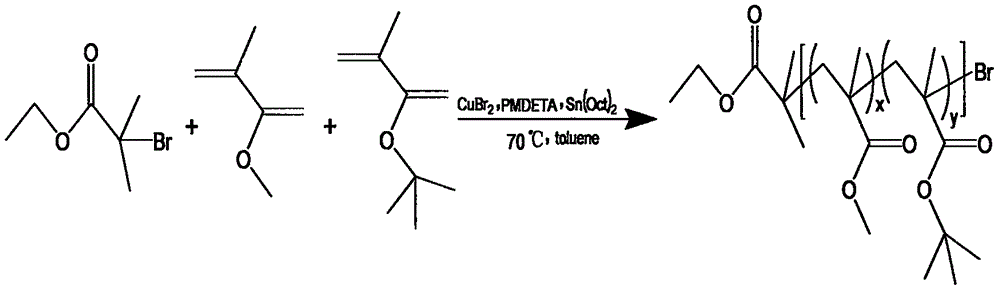

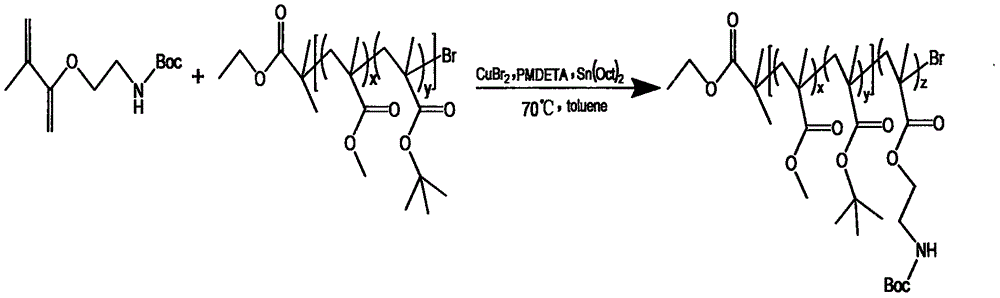

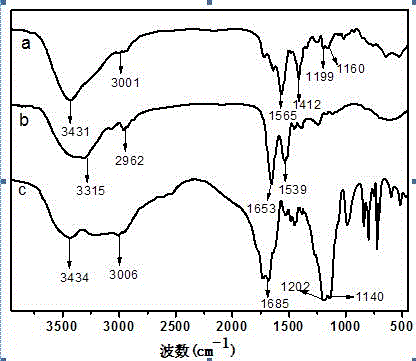

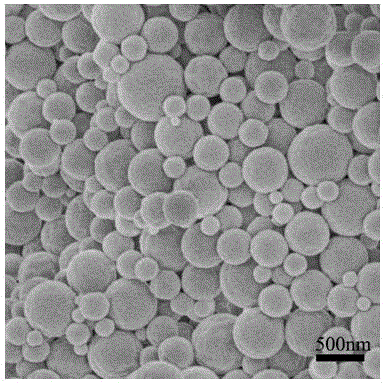

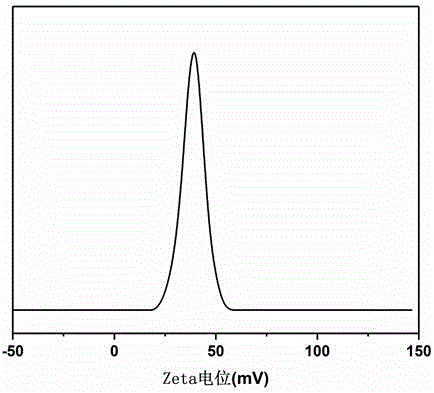

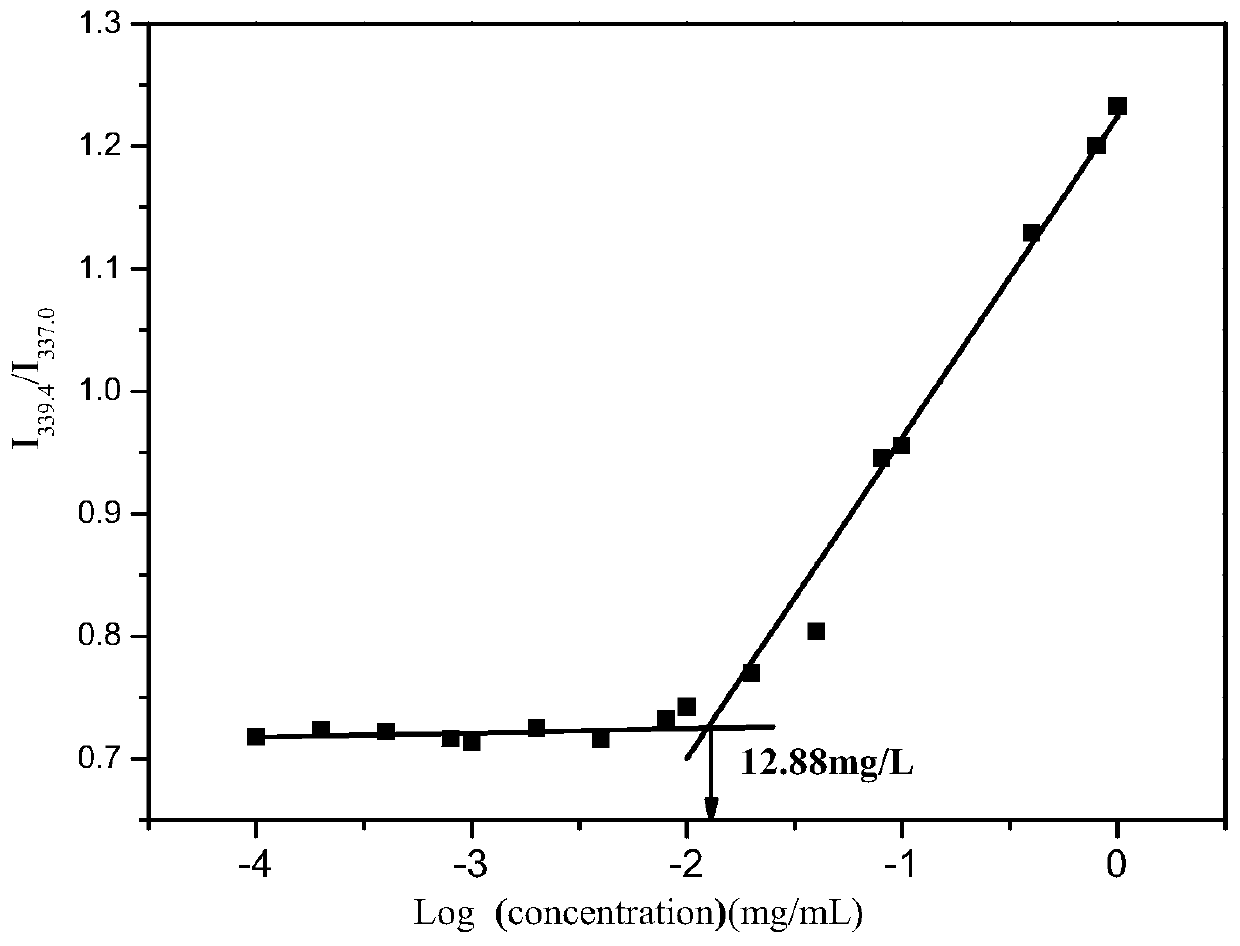

PH response/membrane adhesive amphiphilic block copolymer as well as preparation method and application thereof

ActiveCN106279581AExtended stayPromote absorptionPharmaceutical non-active ingredientsEmulsion deliveryCritical micelle concentrationOral medication

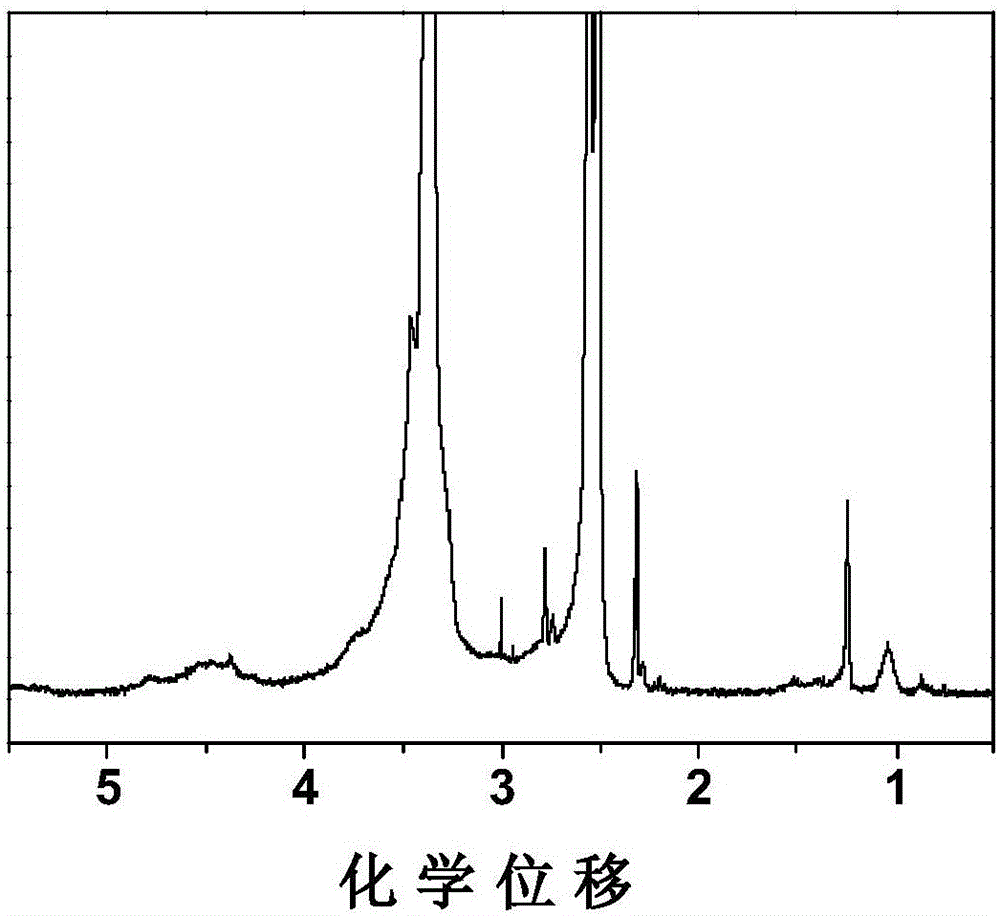

The invention discloses a pH response / membrane adhesive amphiphilic block copolymer as well as a preparation method and application thereof. According to the preparation method, methacrylic acid with an isoelectric point of 5.0-6.5 is utilized as a pH response monomer, methacrylic aminoethyl ester with pH-insensitive hydrophilia is utilized as a membrane-adhesive monomer, an electron transfer activator regeneration-atom transfer free radical active polymerization method is adopted, a pH response monomer and hydrophobic monomer block copolymer is firstly prepared; and by taking the pH response monomer and hydrophobic monomer block copolymer as a macroinitiator, the membrane-adhesive monomer, namely the methacrylic aminoethyl ester is polymerized, and finally acidolysis reaction is performed, so that the pH response / membrane adhesive amphiphilic block copolymer is prepared. The pH response / membrane adhesive amphiphilic block copolymer is capable of being self-assembled to form a core-shell structure micelle in an aqueous solution, has favorable pH sensibility and membrane adhesion property, lower critical micelle concentration and relaively small micelle particle size, and can be used in drug delivery systems for oral medication application of polypeptide or proteinic drugs.

Owner:XIANGTAN UNIV

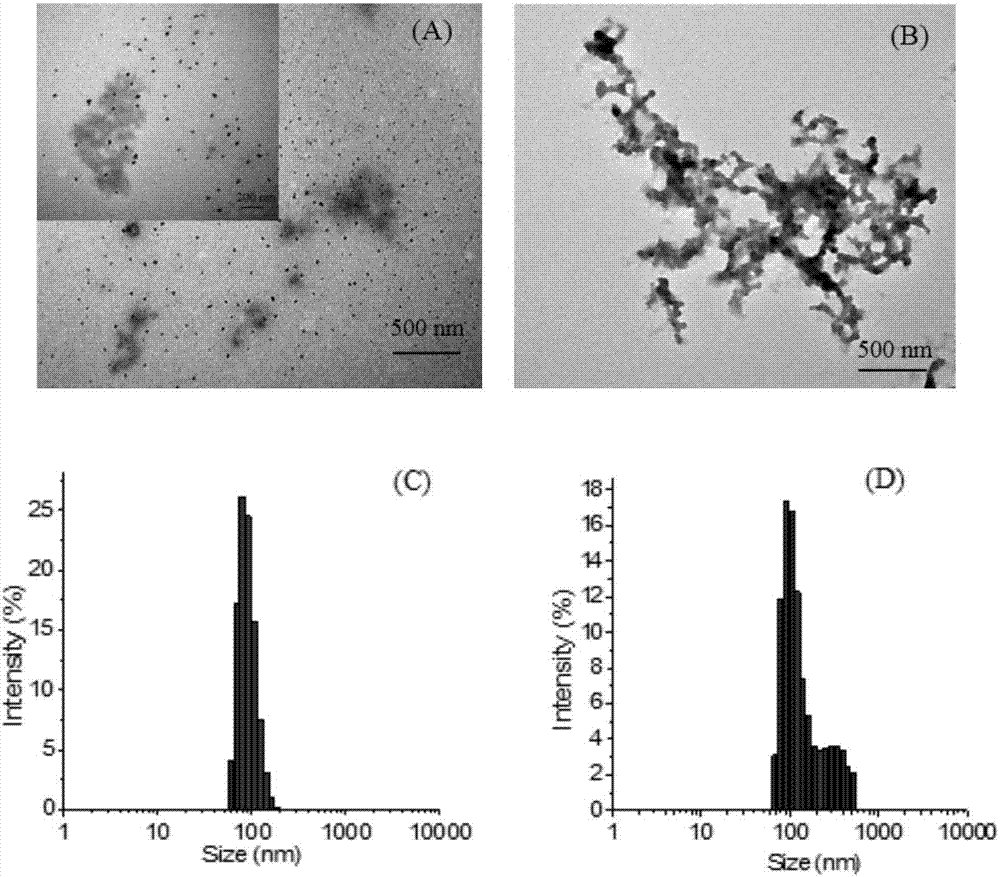

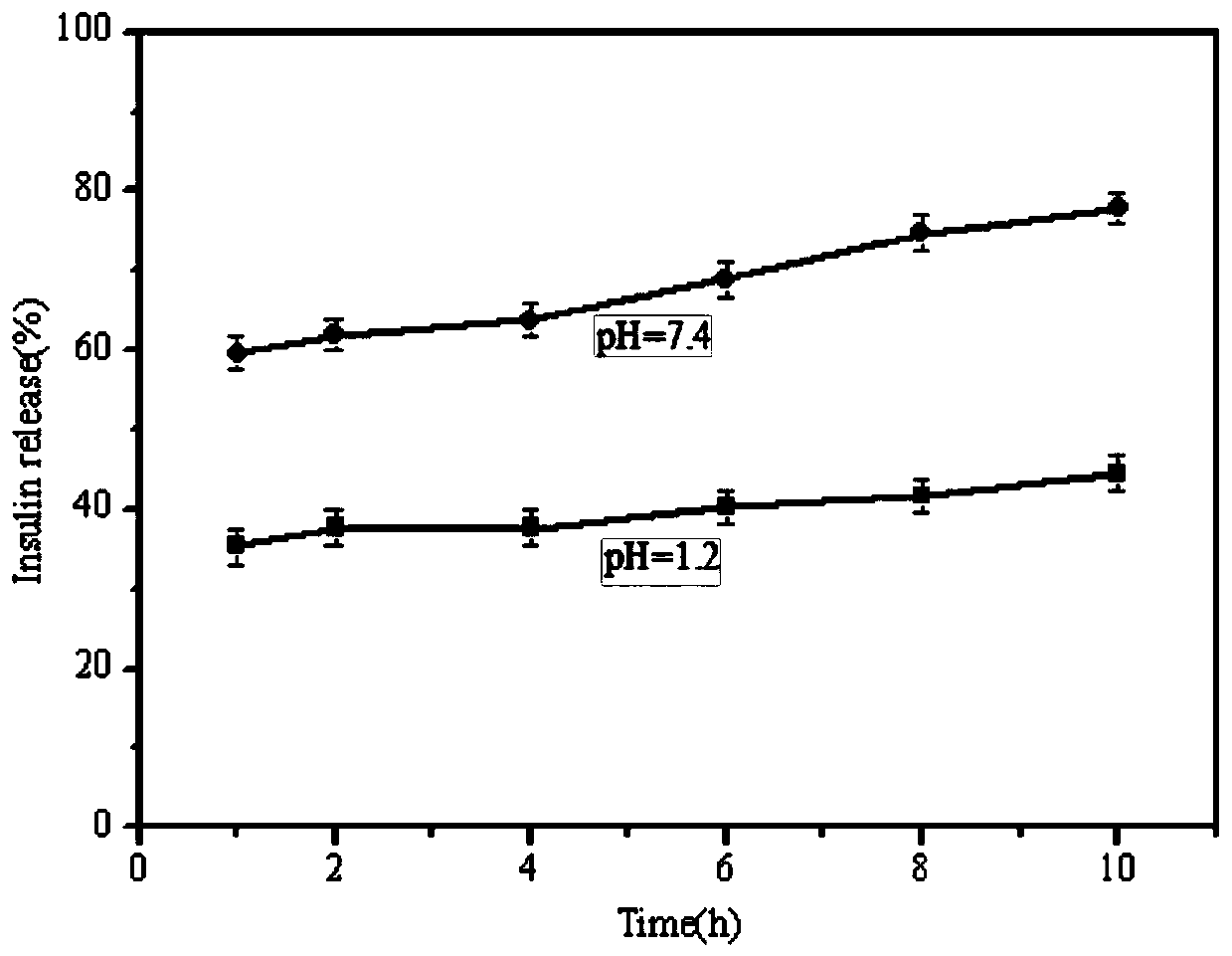

Method for preparing oral insulin-loaded nano-micelles

InactiveCN107519484APH sensitiveAdhesiveOrganic active ingredientsPeptide/protein ingredientsSolventChemistry

The invention discloses a method for preparing insulin-loaded nano-micelles with pH (potential of hydrogen) sensibility and membrane adhesive ability. The method includes dissolving insulin in dilute acid solution to form insulin solution; dissolving poly (methyl methacrylate-co-methacrylic acid)-b-polymethacrylic acid ammonia ethyl ester copolymers P (MMA-co-MAA)-b-PAEMA in organic solvents to form polymer solution; slowly adding the insulin solution into the polymer solution; removing the solvents by means of dialysis in acetic acid-sodium acetate buffer solution with the pH of 5.0-6.0; carrying out centrifuging and freeze drying to obtain the insulin-loaded nano-micelles. The method has the advantages that the prepared insulin-loaded nano-micelles with the pH sensibility and the membrane adhesive ability are suitable for oral administration, have uniform particle sizes and are high in medicine loading capacity and entrapment efficiency.

Owner:XIANGTAN UNIV

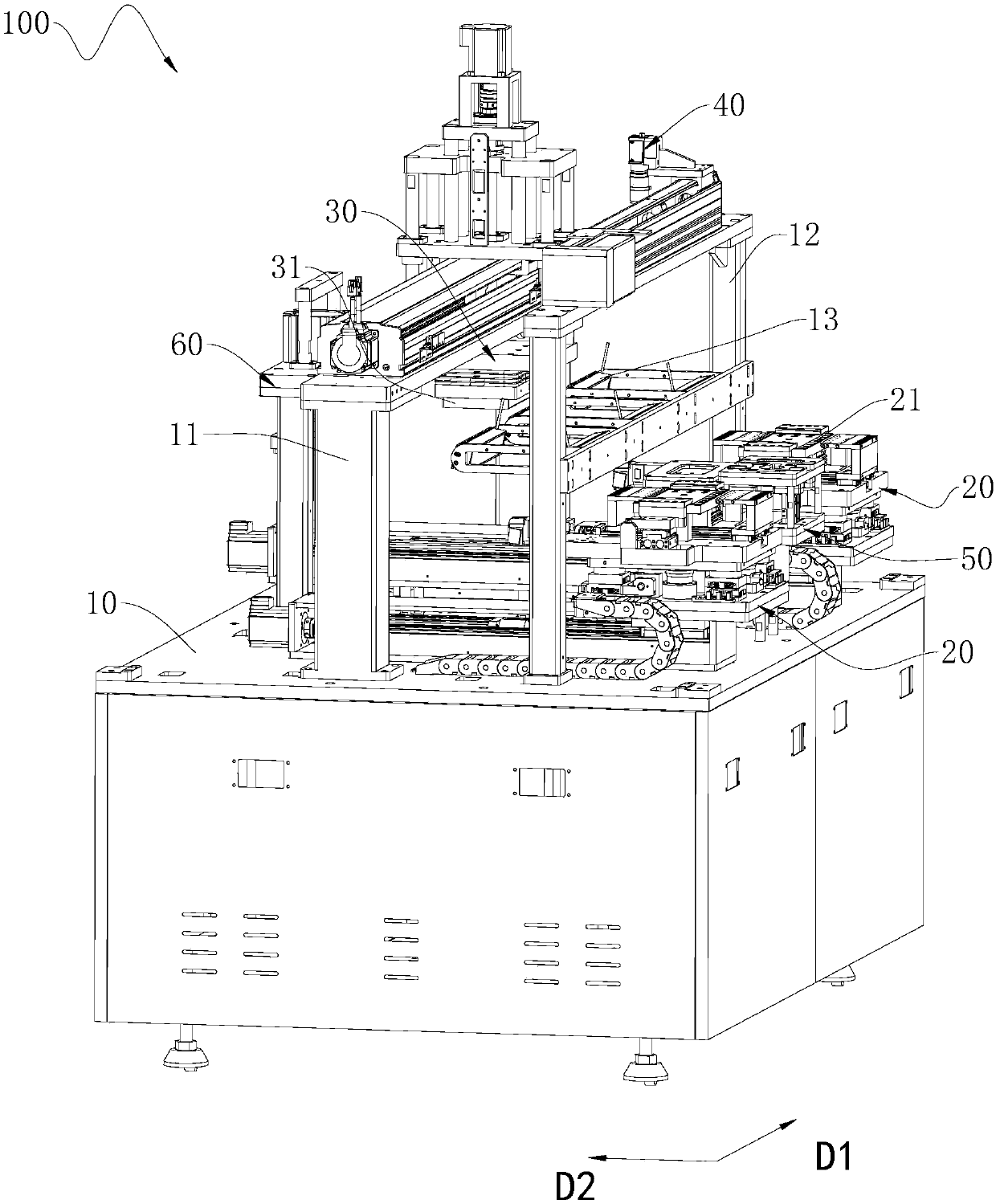

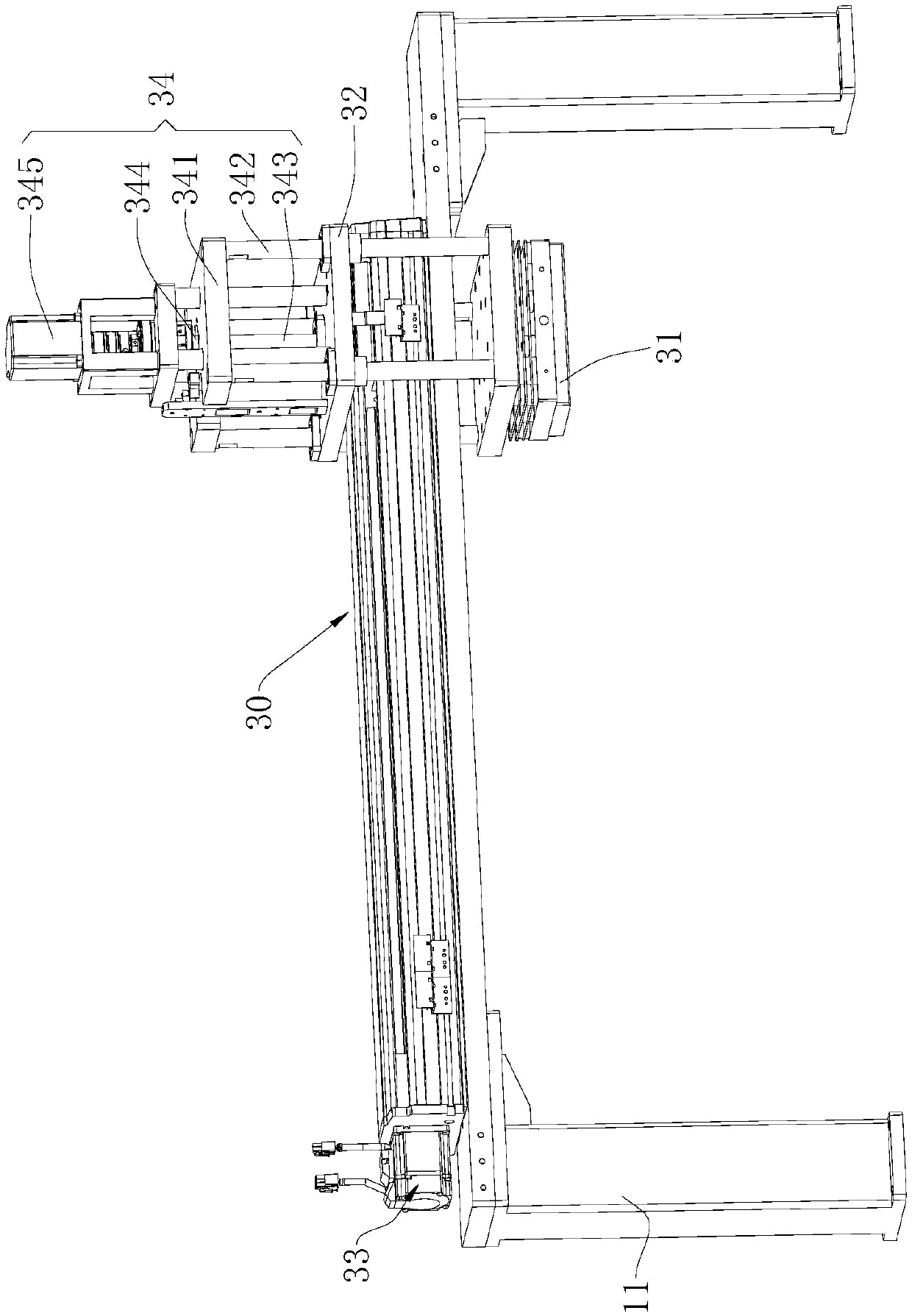

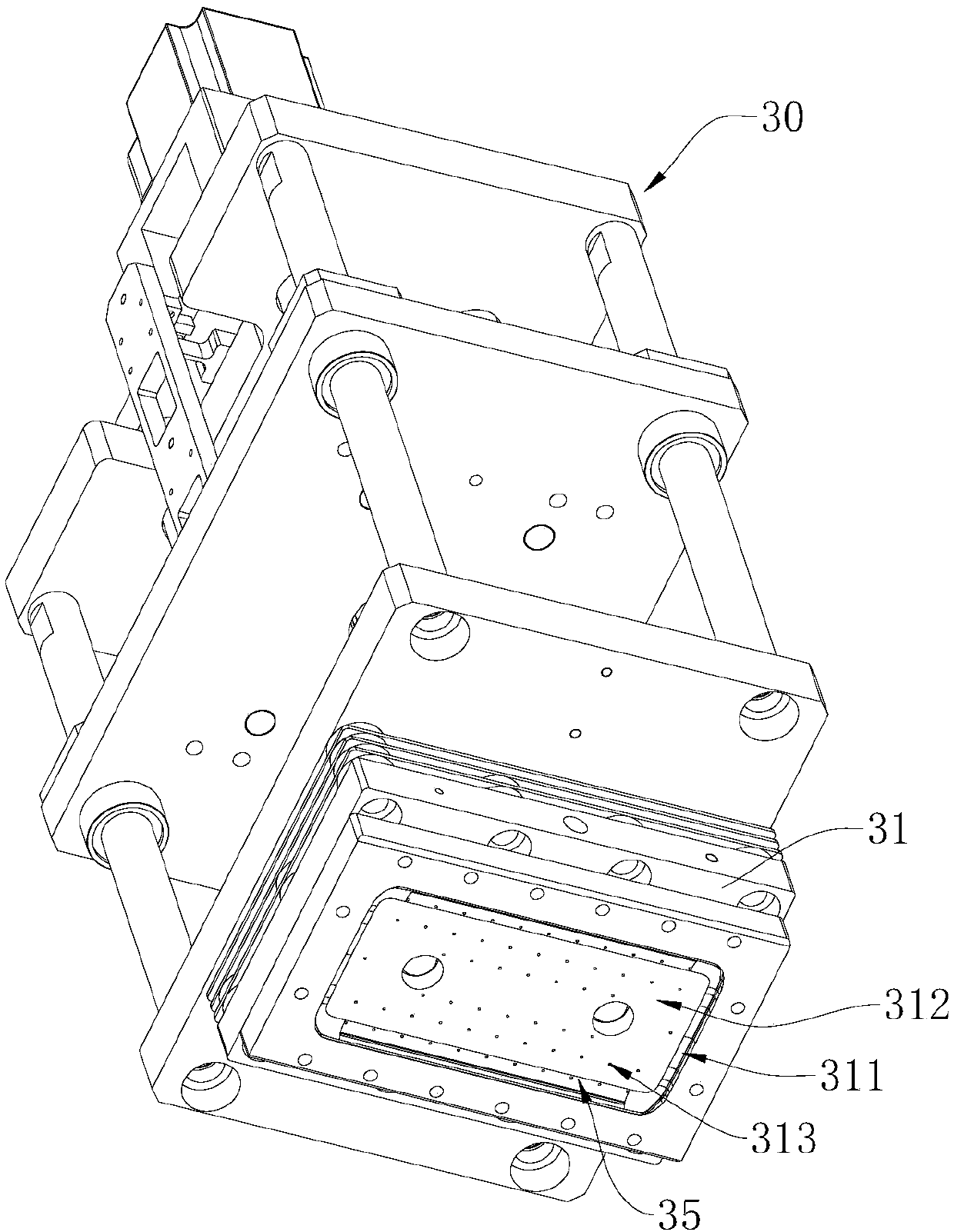

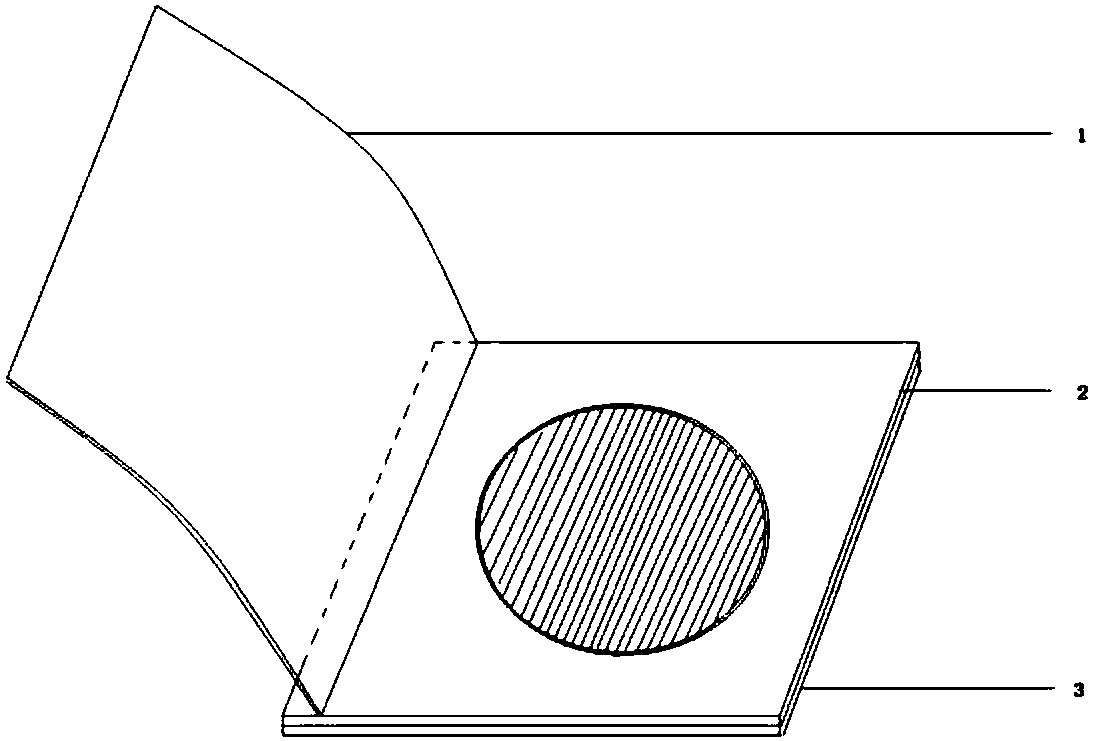

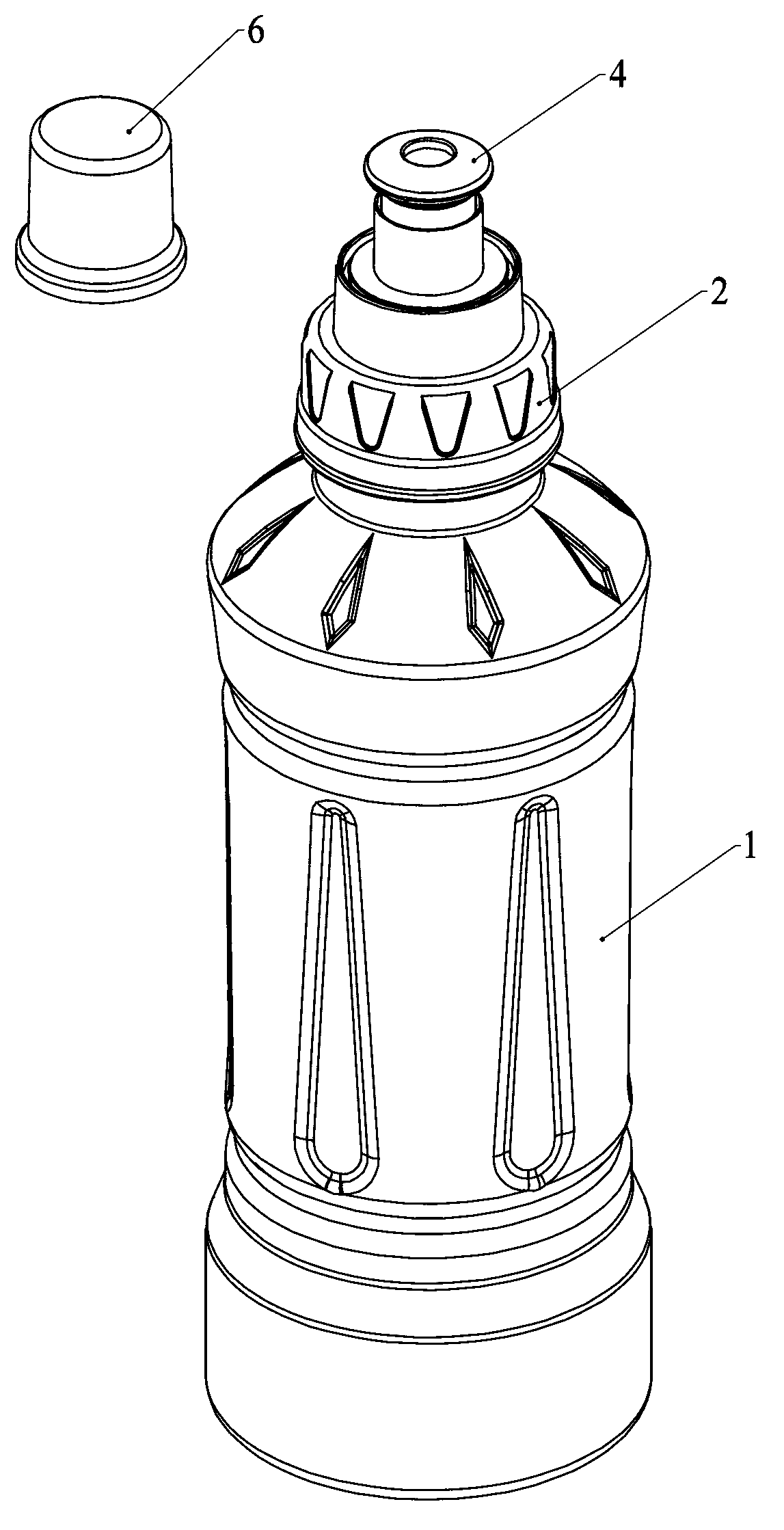

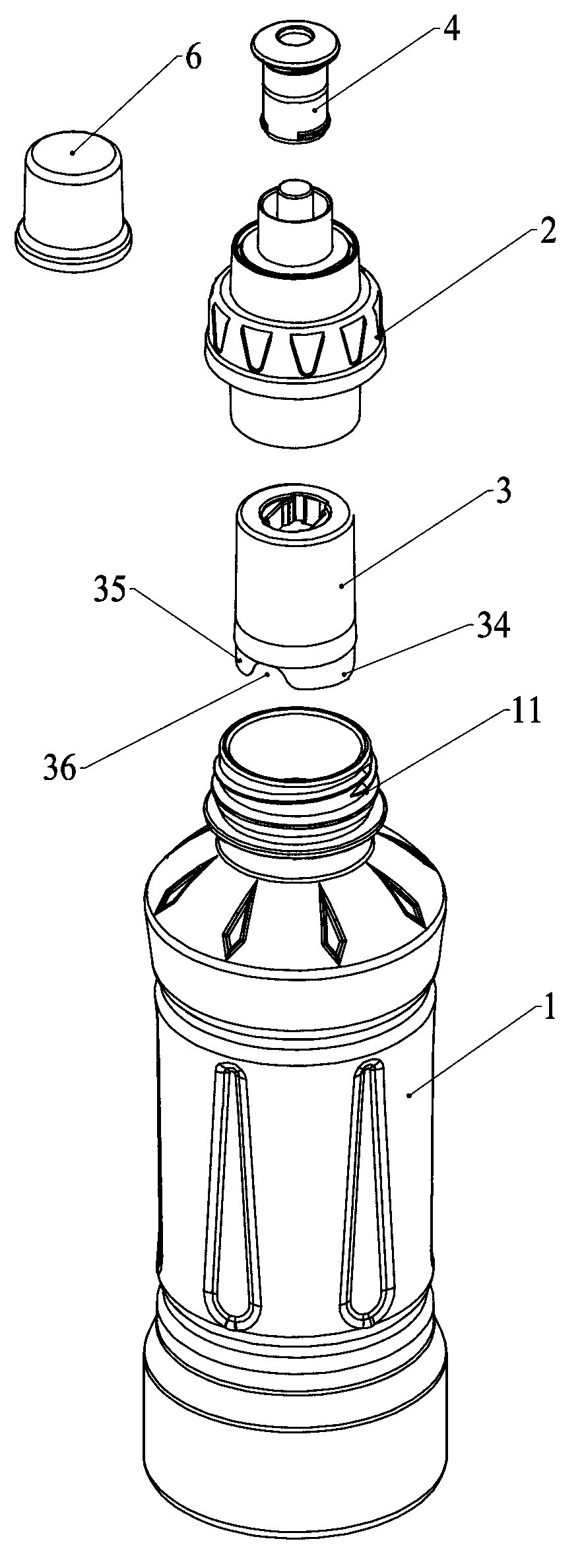

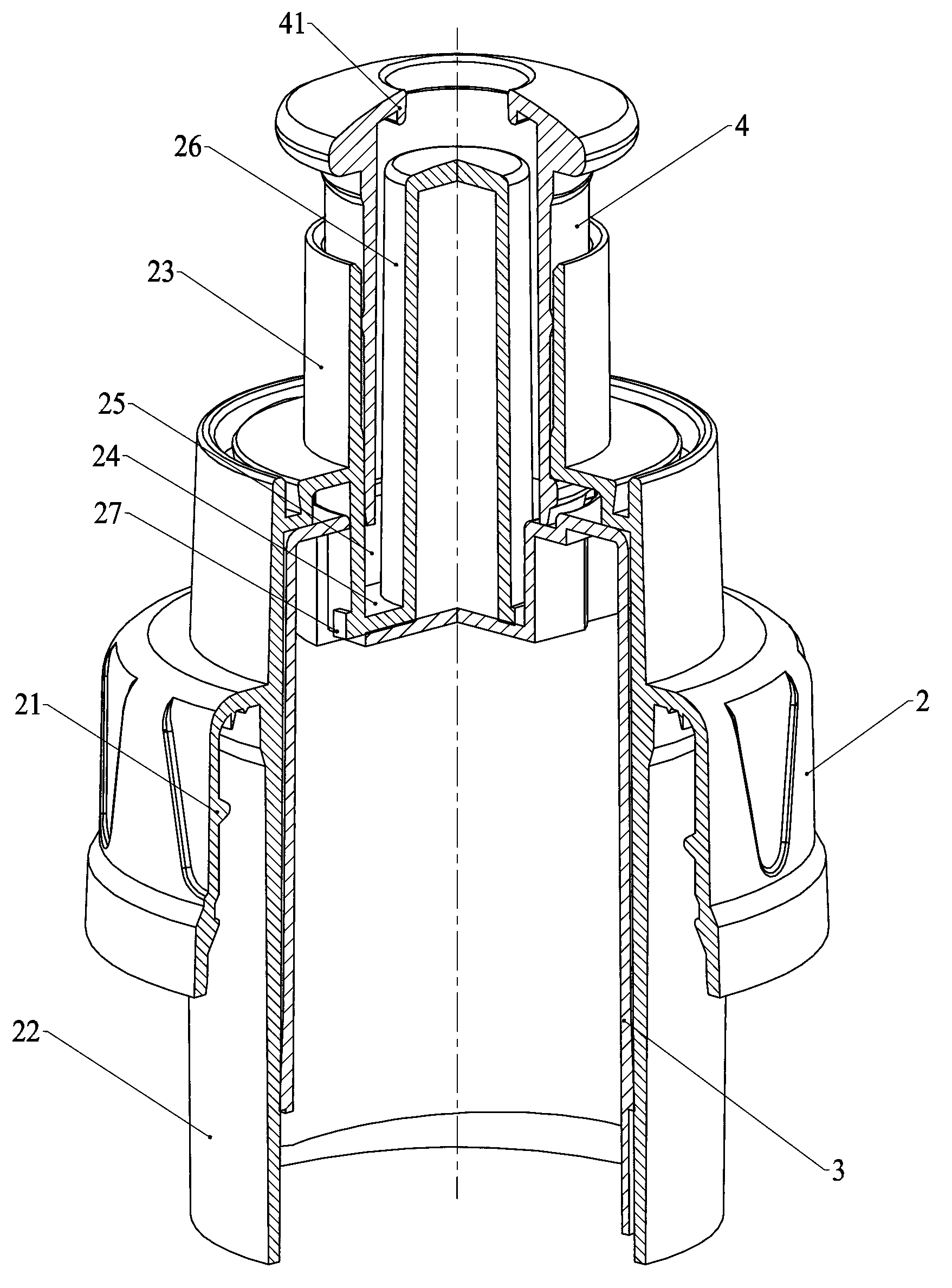

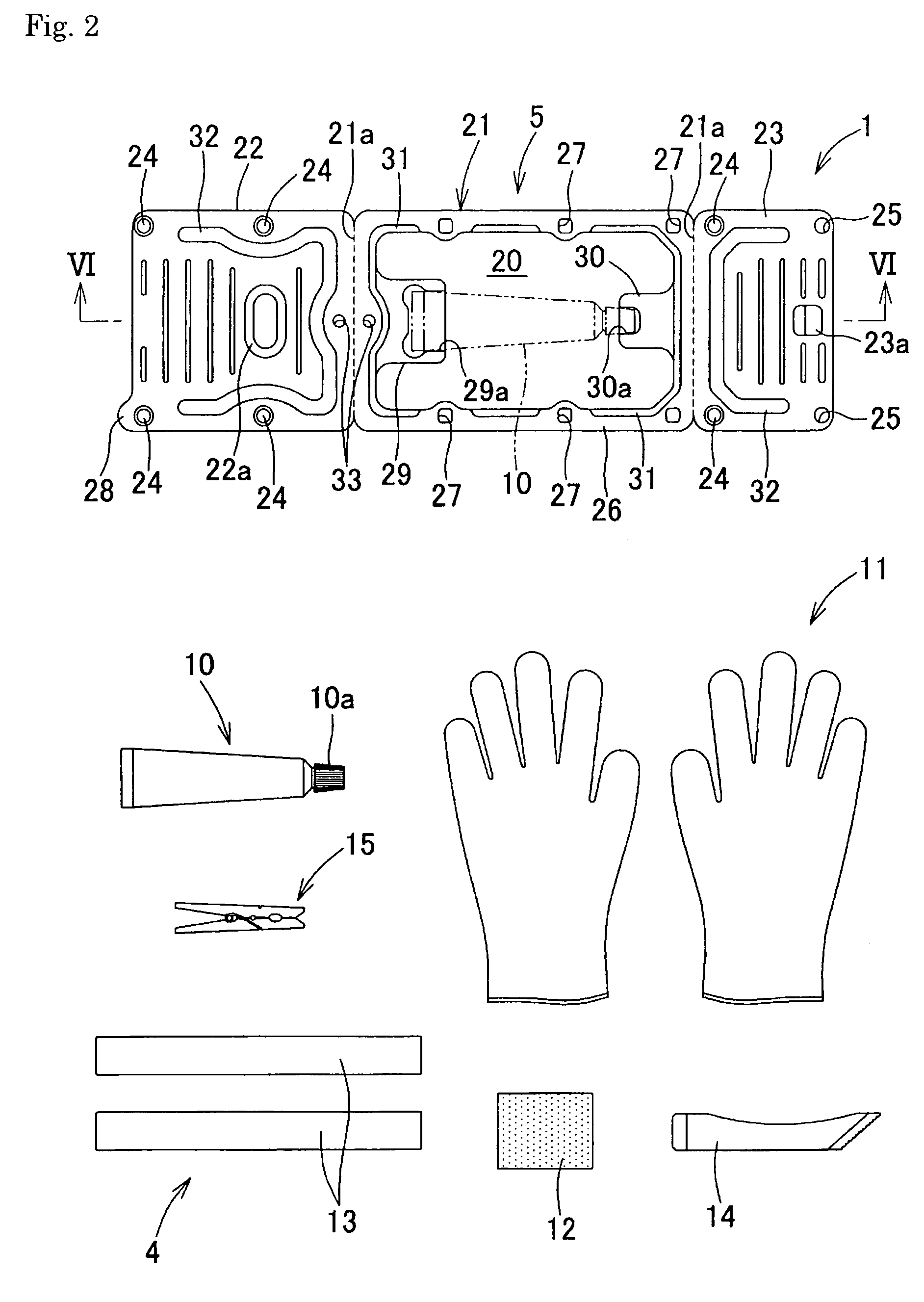

Membrane adhesion facility

ActiveCN107934017AAvoid formingImprove yield ratePackagingMechanical engineeringMembrane configuration

The invention relates to the technical field of screen membrane adhesion, and provides a membrane adhesion facility. The membrane adhesion facility comprises a base, membrane bearing devices, a substrate bearing device and an adhesion mechanism, wherein the membrane bearing devices, the substrate bearing device and the adhesion mechanism are arranged on the base. Each membrane bearing device comprises a membrane placement die plate, wherein the membrane placement die plate is used for allowing membranes to be placed. The substrate bearing device comprises a substrate placement die plate, wherein the substrate placement die plate is used for allowing substrates to be placed, and can be combined with the membrane placement die plates in a die assembly mode. The substrate placement die plateand the membrane placement die plates are combined in an encircling mode to form an internal space which is used for holding the substrates and the membranes. The adhesion mechanism comprises a gas bag and a gas inflation and deflation assembly, wherein the gas inflation and deflation assembly enables the gas bag to expand so as to enable the membranes located in the internal space to be pressed on the substrates in a combined mode. Compared with the prior art, the membrane adhesion facility has the advantages that adhesive membranes do not need to be used, the phenomenon that bubbles are formed between the membranes and the substrates can be effectively avoided, and the yield and the production efficiency are improved.

Owner:SHENZHEN WEIHONGKE TECH

Preparation method of short amylase-insulin or short amylase-insulin-procyanidine nanocomposite

ActiveCN107213457AInhibit aggregationSmall particle sizePeptide/protein ingredientsMetabolism disorderAmylaseNanocomposite

The invention discloses a preparation method of short amylase-insulin or short amylase-insulin-procyanidine nanocomposite. The preparation method comprises the steps of mixing short amylase with insulin or mixing short amylase, insulin and procyanidine, and carrying out retrogradation, so as to obtain short amylase-insulin or short amylase-insulin-procyanidine nanocomposite. The short amylase-insulin or short amylase-insulin-procyanidine nanocomposite is relatively small in particle size and can tightly adhere to a membrane adhesion layer of a small intestine, so that the standing time in the stomach and intestine is prolonged, meanwhile, a mucous layer barrier, an enzyme barrier and an epithelial barrier existing in an alimentary system can be overcome, and the bioavailability of oral insulin is increased.

Owner:JIANGNAN UNIV

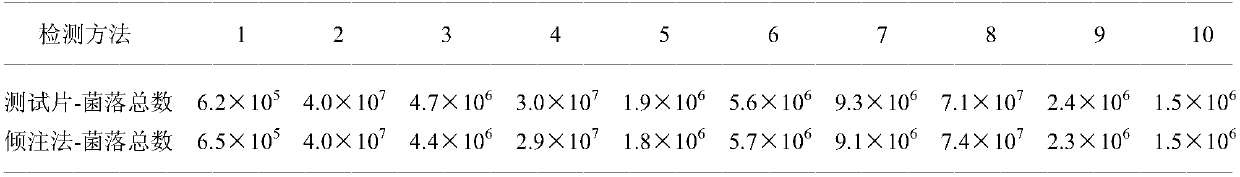

Microbial test strip and application thereof

InactiveCN105950459ASpread evenlyAvoid damageBioreactor/fermenter combinationsBiological substance pretreatmentsBiotechnologyMicroorganism

The invention discloses a microbial test strip and application thereof. The microbial test strip comprises a covering membrane, an adhesive part to which a chromogenic culture system is adhered and an intermediate membrane positioned between the covering membrane and the adhesive part, wherein the adhesive part to which the chromogenic culture system is adhered comprises an adhesive part and the chromogenic culture system adhered thereto; the chromogenic culture system consists of cold-water-soluble gel and a microbial chromogenic culture medium; a through hole is formed in the intermediate membrane; the chromogenic culture system is covered by one surface of the intermediate membrane, and the through hole corresponds to the position of the chromogenic culture system; the other surface of the intermediate membrane is covered by the covering membrane. According to the microbial test strip, work of vessel cleaning, culture medium preparation, waste treatment and the like of an operator is eliminated, and the microbial test strip is convenient to operate, available when needed and high in product repeatability and accuracy.

Owner:孙百莉

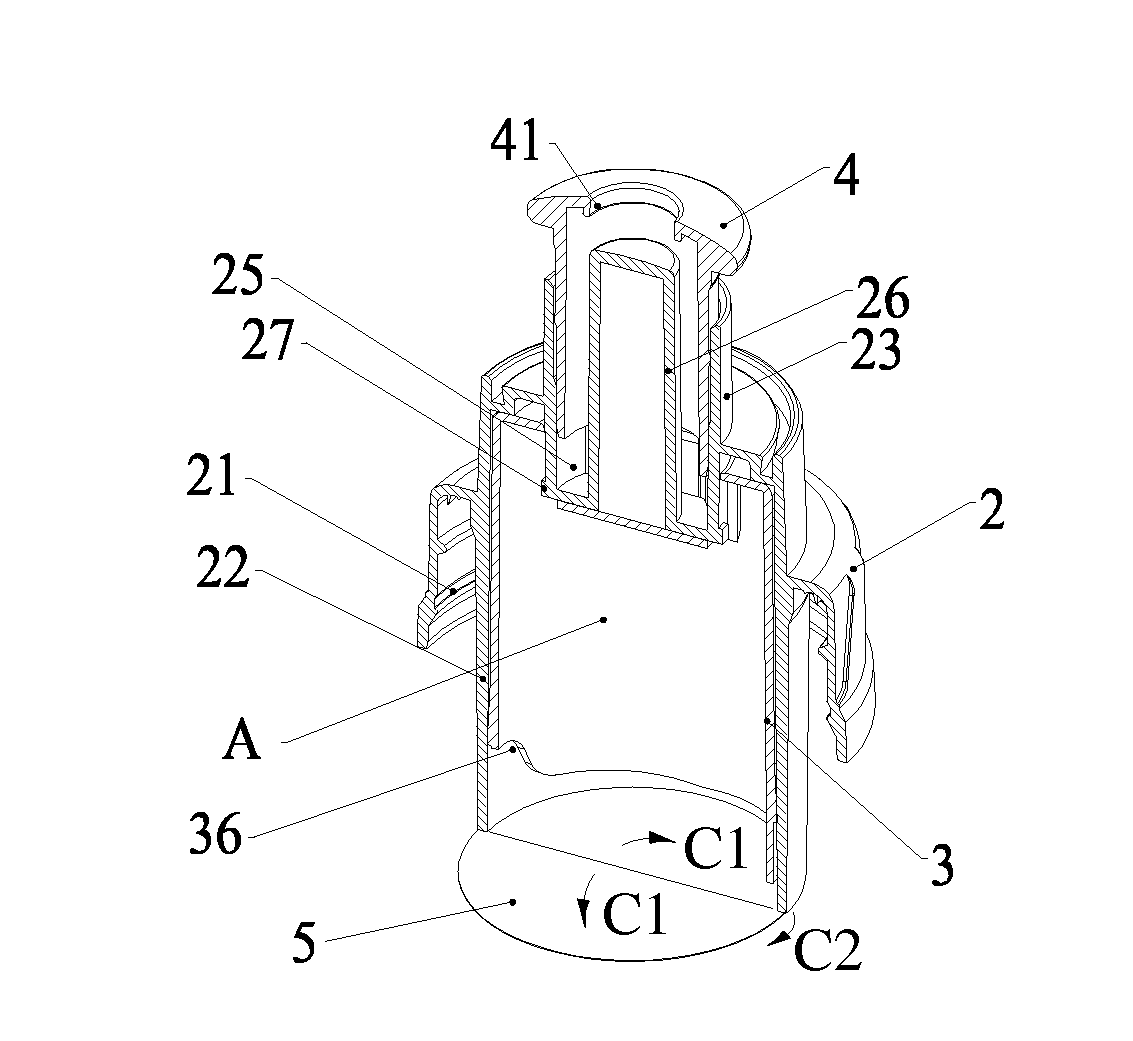

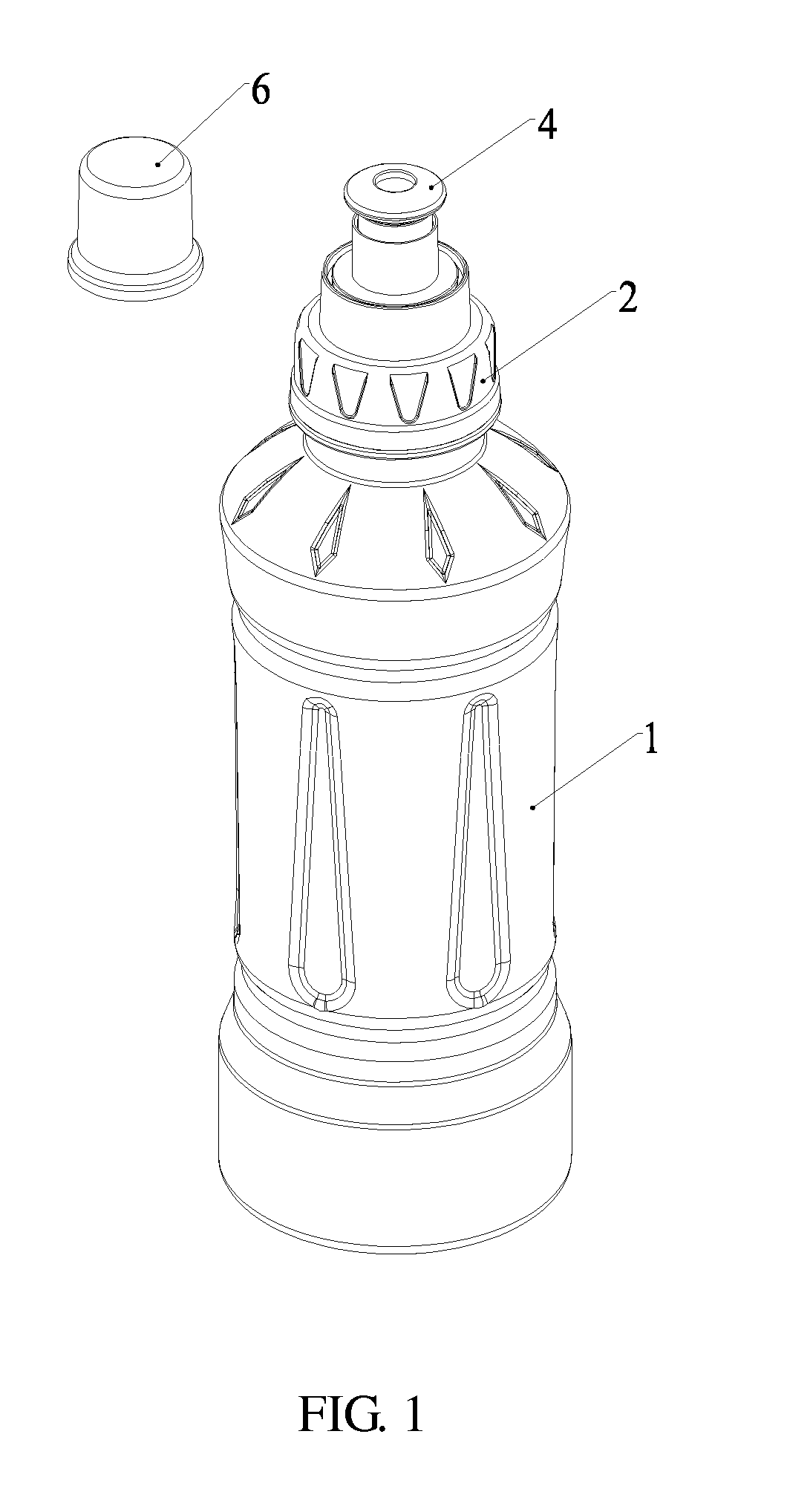

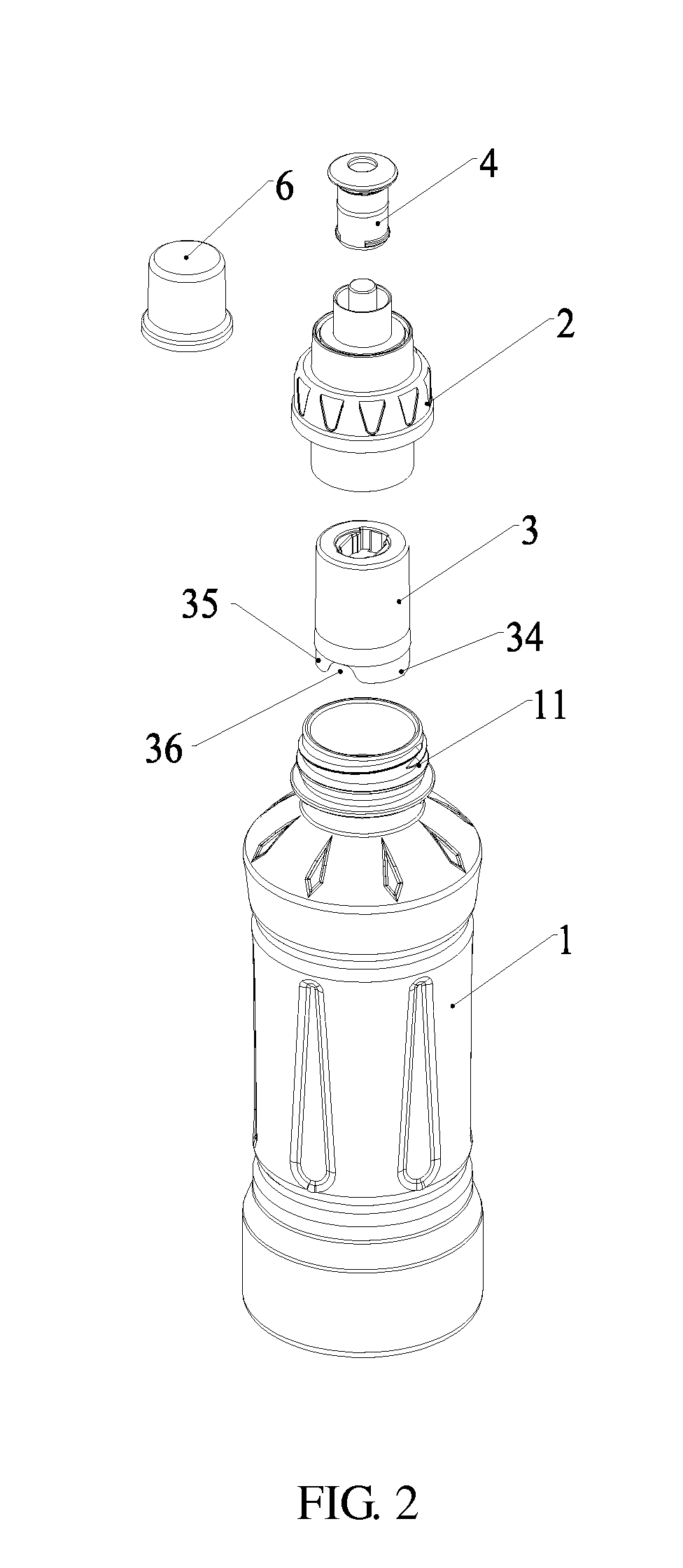

Beverage Bottle with Storage Solutes

InactiveUS20140174966A1Good effectReduce the impactClosure with auxillary devicesRigid containersBottleBiomedical engineering

The present invention relates to a beverage bottle with storage solutes. By means of pressing the drinking pumping cylinder, the cutting membrane inner cylinder being pushed down, two cutting edges of the cutting membrane inner cylinder are provided to cut the membrane; the cutting membrane inner cylinder has a notch to constitute a membrane adhesion structure; the cutting membrane inner cylinder being pushed down, the inner sleeve being separated from the sleeve in longitudinal direction, the water outlet port is connected to the water outlet cylinder portion so as to constitute a water outlet access; the sealed cap cooperates with the central spindle to constitute a switch control structure for the water outlet access. It has the advantages of: its pressing control structure is simple and labor-saving, its cutting membrane effect is good, its solutes are released quickly and completely and it can be provided for drinking directly.

Owner:GUANGDONG HAIXING PLASTIC & RUBBER CO LTD

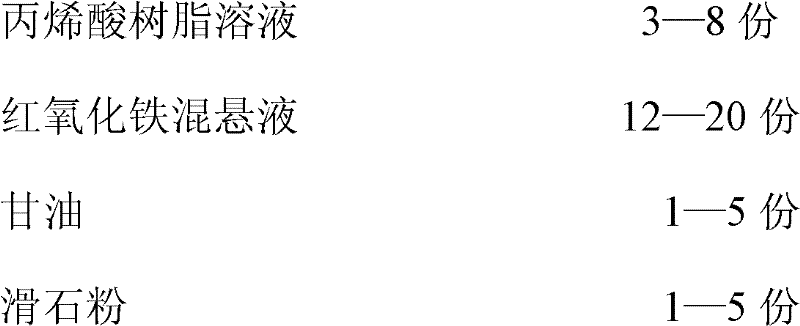

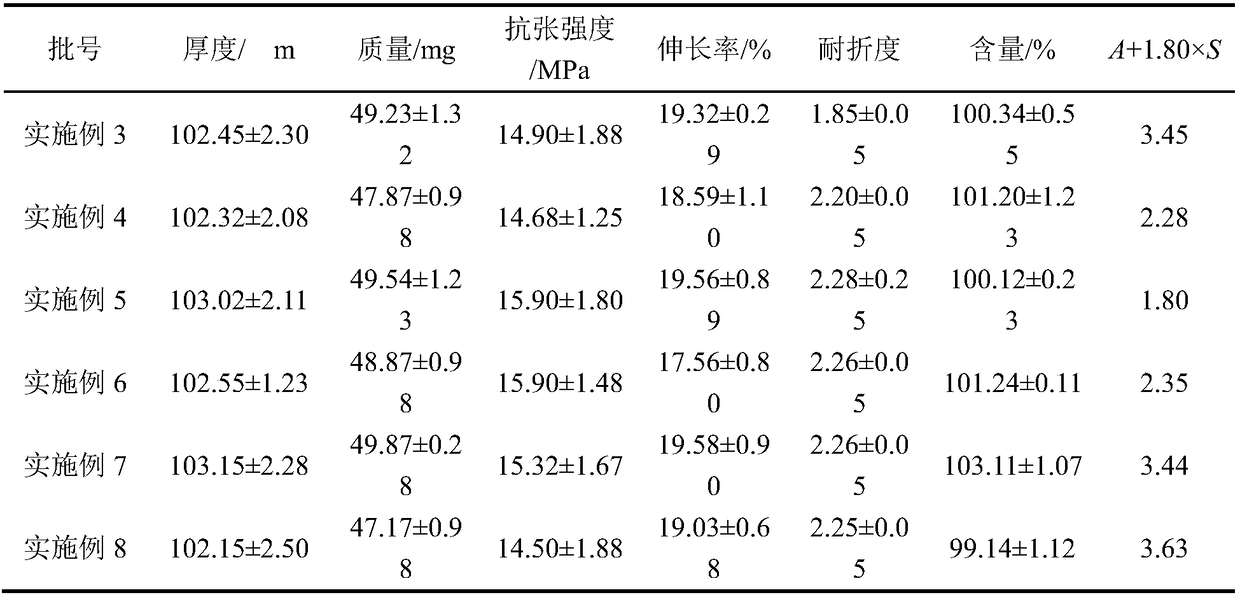

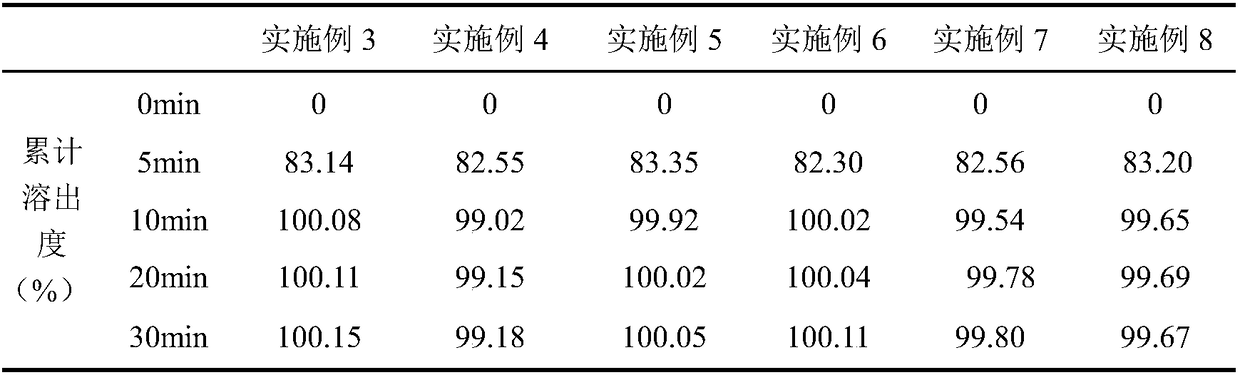

Coating material for complex tablets and preparation method thereof

ActiveCN102526743APrevent precipitationSolving Film Coating ProblemsPharmaceutical delivery mechanismPharmaceutical non-active ingredientsAcrylic resinGlycerol

The invention relates to a coating material for complex tablets and a preparation method thereof. The coating material is composed of following raw materials by weight: 3 parts to 8 parts of acrylic resin solution, 12 parts to 20 parts of red iron oxide injectable suspension, 1 part to 5 parts of glycerol, 1 part to 5 parts of talcum powder and 60 parts to 80 parts of purified water. The complex tablet thin membrane coated tablet made of the coating material is even in tablet surface color and strong in coating membrane adhesion. Accelerated tests and long term experiments show that the coating material is good in humidity resistance, can effectively prevent volatile element borneol from sublimating and dissolving out, and guarantees quality stability of products in an efficacy period.

Owner:ZHENGZHOU RUILONG PHARMA

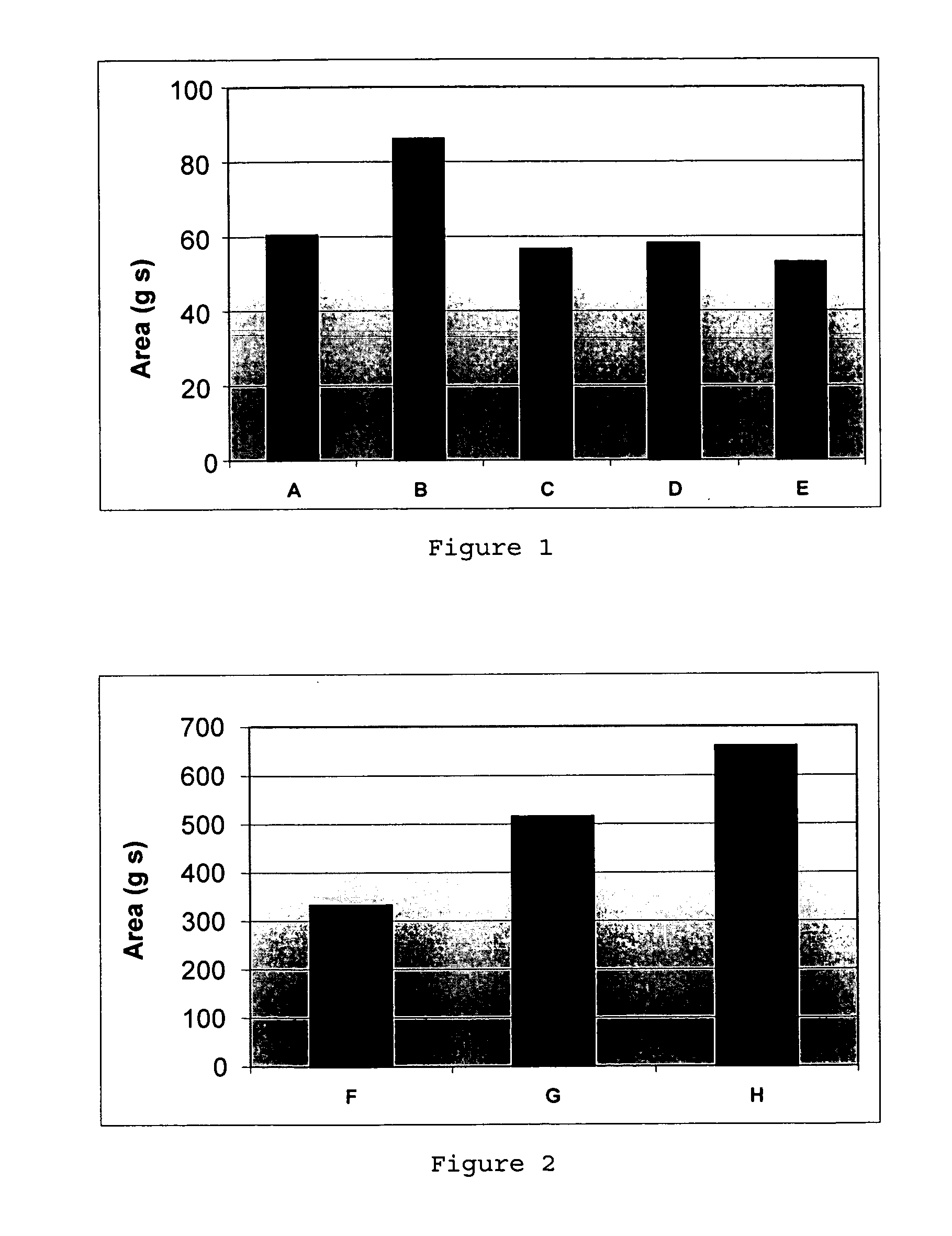

Film dosage form with extended release mucoadhesive particles

ActiveUS10272038B2Avoid discomfortEasy to controlPharmaceutical delivery mechanismPharmaceutical non-active ingredientsOral medicationFilm Dosage Form

An orally administered dosage form that facilitates delivery of an agent locally in the buccal cavity for a sustained period of time includes mucoadhesive particles that are made of at least a mucoadhesive material combined with the agent, and which are dispersed in a disintegrating film. The dosage form is capable of delivering an agent to a patient at the desired oral mucosa site over an extended period of time while reducing patient discomfort or annoyance associated with conventional sustained release mucoadhesive films that must reside on the oral mucosa during the period of sustained release.

Owner:INTELGENX CORP

Special shot blast cleaning machine for concrete mixing cylinder

InactiveCN103009255AImprove fatigue resistanceImprove paint film adhesionAbrasive blasting machinesGrinding/polishing apparatusEngineeringInternal stress

The invention discloses a special shot blast cleaning machine for a concrete mixing cylinder with a cleaning effect. The special shot blast cleaning machine for the concrete mixing cylinder comprises a rack arranged on the ground surface, and the rack is provided with a dedusting device, a shot blast device, a lifter, a separator, a longitudinal spiral conveyer and a trolley. The special shot blast cleaning machine for the concrete mixing cylinder has the advantages that surfaces of workpieces are in natural metal color; the internal stress of workpieces is eliminated; the workpiece anti-fatigue performance is improved; paint membrane adhesion force in painting the workpieces is increased; and finally the aim that the surface and internal quality of the workpieces is improved is achieved.

Owner:JIANGSU JIUCHANG MACHINERY CO LTD

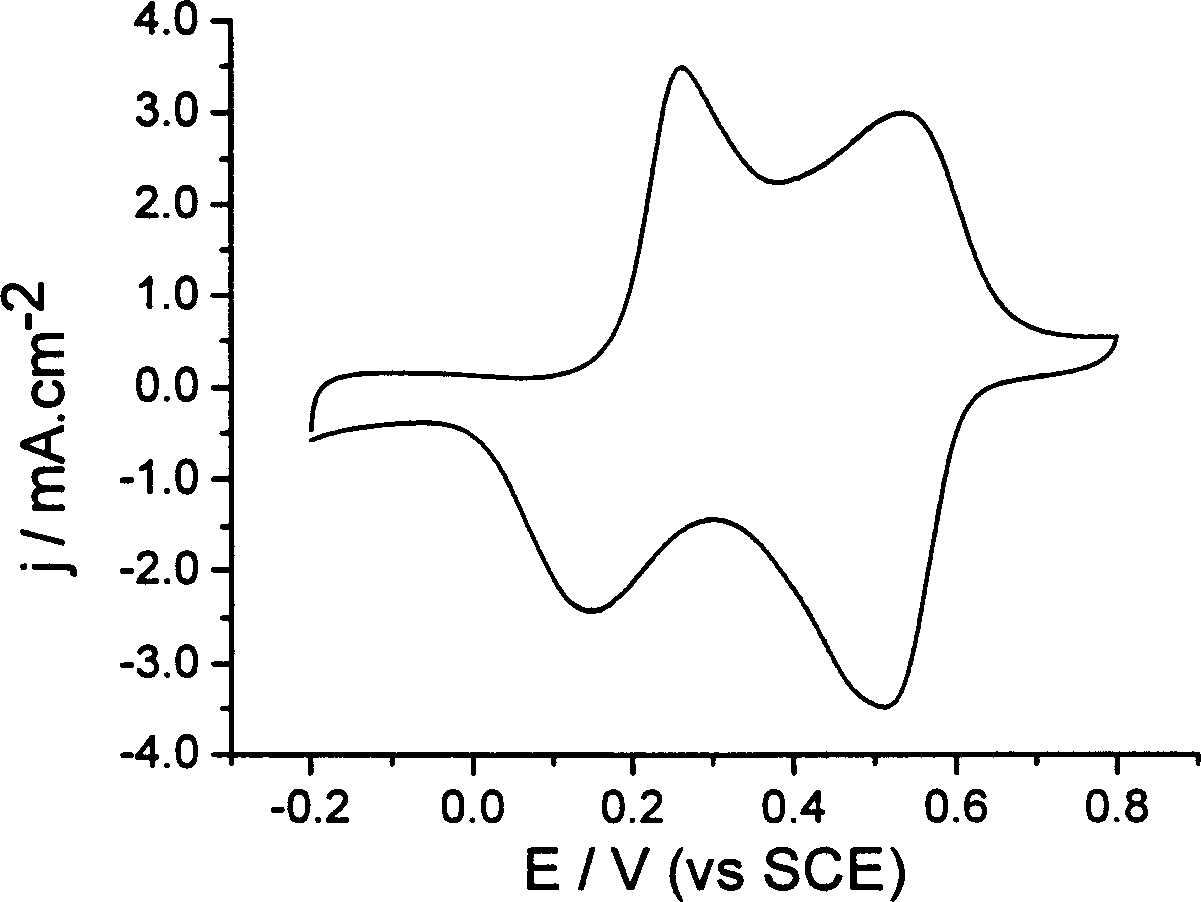

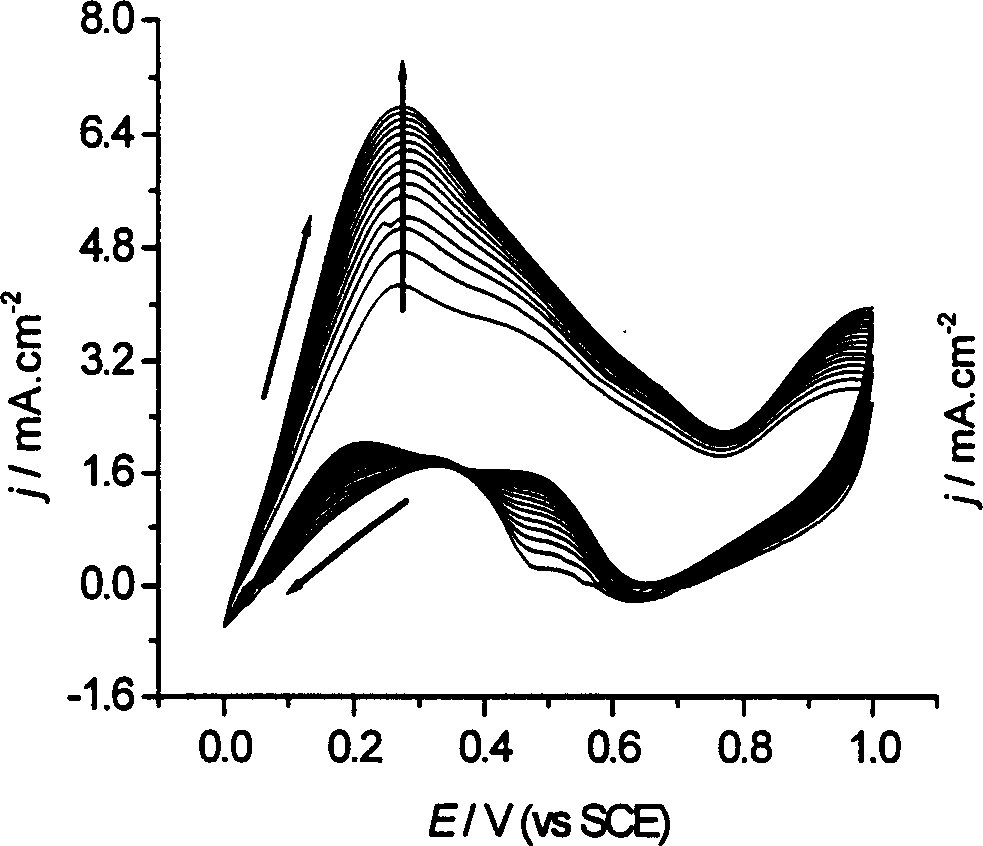

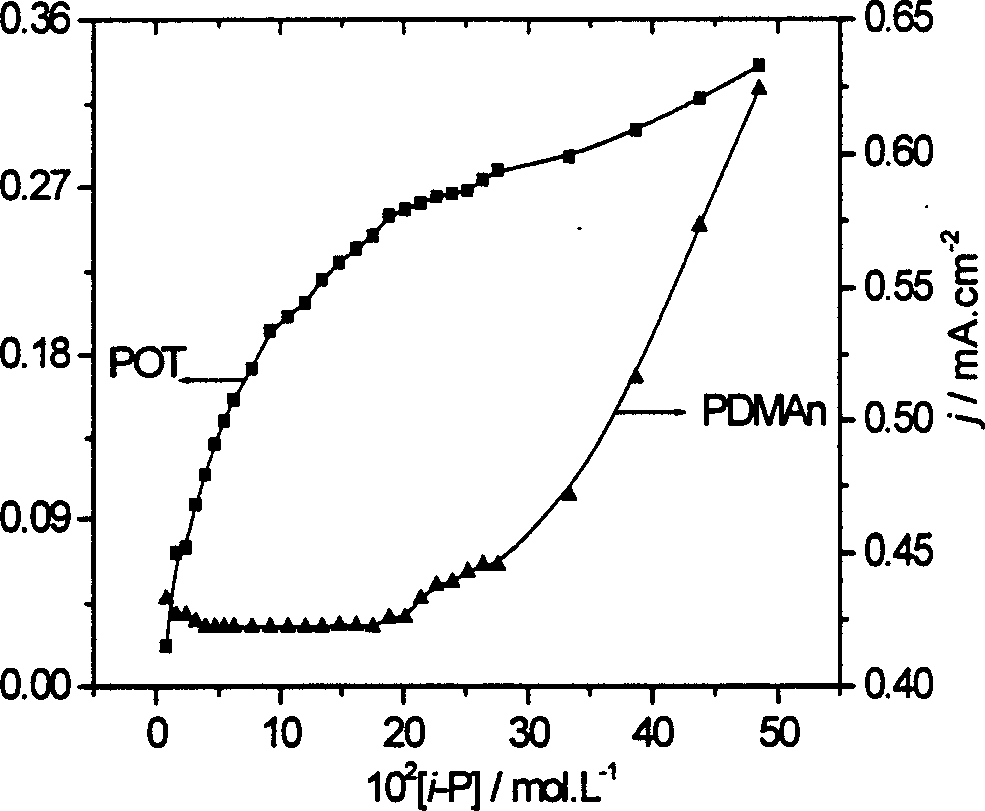

Polymer film modified electrode and preparation method and application thereof

InactiveCN1667404AImproved resistance to CO poisoningHigh yieldMaterial electrochemical variablesPolymer scienceConductive polymer

The invention discloses a polymer membrane modification electrode, its process method and application, wherein, the electrode relates to a conductive polymer metal membrane modification electrode and is mainly used to detect water pollutant isopropanol.Its process method supplies a polymer membrane modification electrode and uses it to process isopropanol detection sensor comprising inert electrode base, conducting polymer membrane and catalyser, wherein, conductive polymer membrane is eigen state orthotoluidine and polymer membrane adhesion in nert electrode base electrode surface is 0.3-1.0mgíñcm-2. Its steps are as follows: processing polymer membrane modification electrode in coating method and metallising polymer membrane.

Owner:XIAMEN UNIV

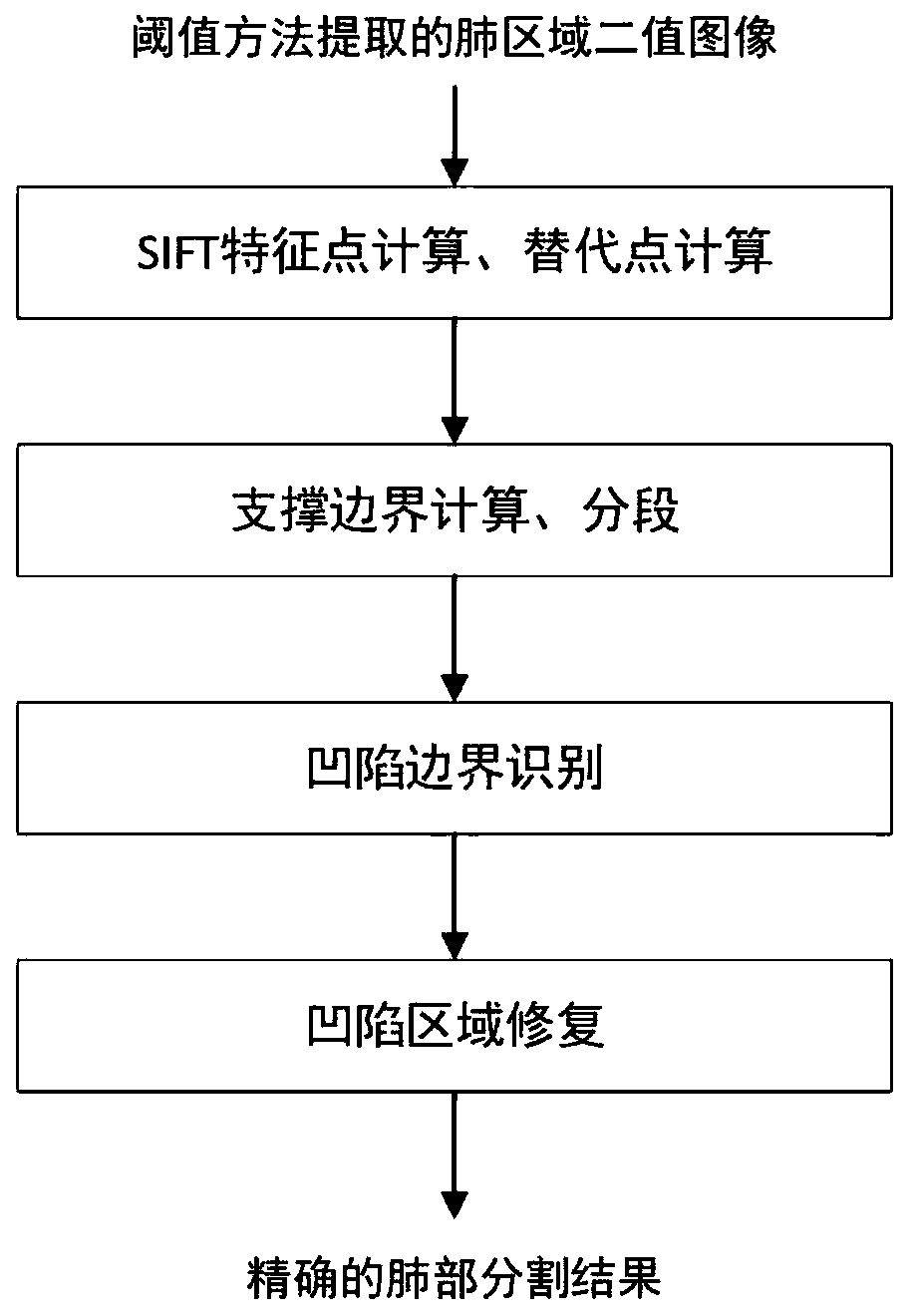

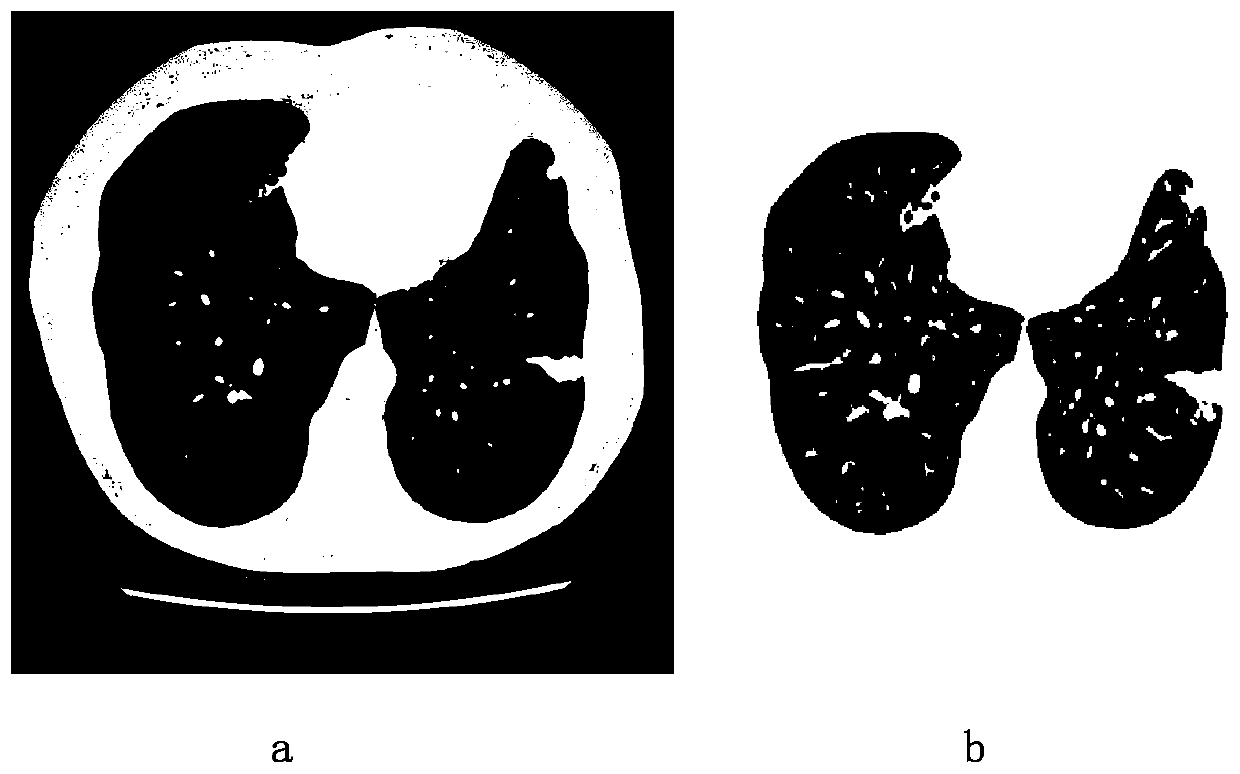

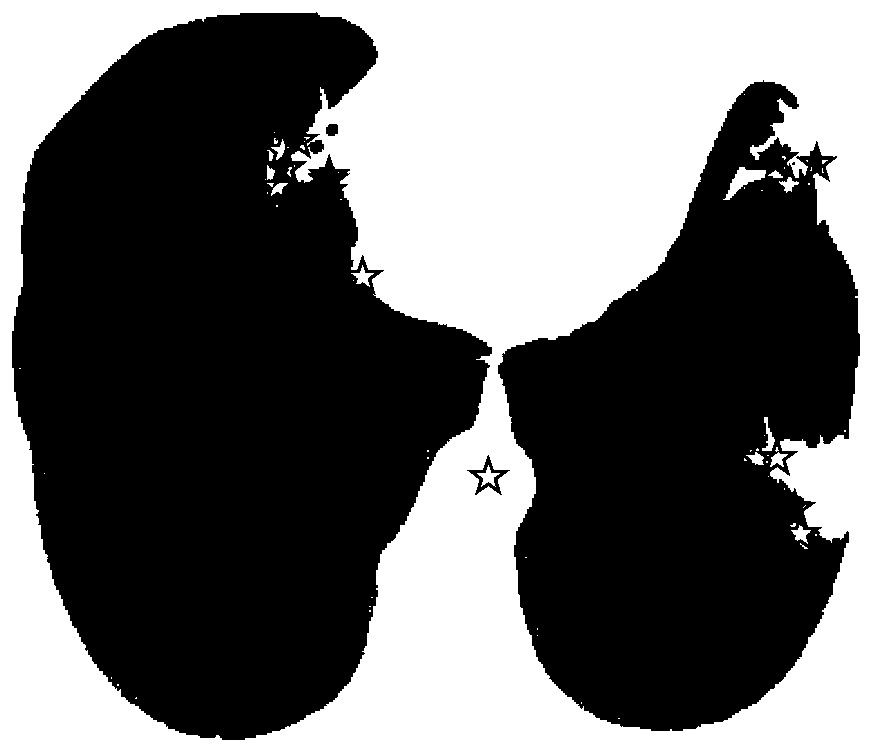

Pulmonary membrane adhesion nodule region accurate repairing method for pulmonary CT image threshold segmentation result

ActiveCN110047085AImprove computing efficiencyReduce the number of processing targetsImage analysisMedical imagesNear neighborBoundary segment

The invention discloses a pulmonary membrane adhesion nodule region repairing method for a pulmonary CT image threshold segmentation result. The method comprises the steps of carrying out the SIFT feature detection on the lung binary image to obtain the feature points in the image, calculating the nearest neighbor substitution points of the obtained non-boundary feature points, and after the calculated substitution points are used for replacing original non-boundary feature points, obtaining a corresponding boundary feature point set; for each boundary feature point in the boundary feature point set, extracting a support boundary based on a specific rule; segmenting the support boundaries according to the calculated connectivity of the support boundaries in the support boundary image to obtain the mutually independent support boundaries in the image; for each support boundary segment, identifying a to-be-repaired boundary by using the curvature code; using a GVF-based method to drive the smooth profile curve for the identified portion to repair the recessed region and boundary. By applying the method provided by the invention, the omissive pulmonary membrane bonding joint region inthe threshold segmentation result can be accurately repaired, and the pulmonary membrane nodule region is re-incorporated into the pulmonary parenchyma region, so that the accuracy of the pulmonary CT image lesion tissue analysis algorithm is ensured.

Owner:TAISHAN UNIV

PH sensitive/membrane adhesive bifunctional insulin-loaded mixed micelle nanoparticle and preparation method thereof

InactiveCN110522739AExtended stayPromote absorptionPeptide/protein ingredientsMetabolism disorderMonomethoxypolyethylene glycolFreeze-drying

The invention discloses a preparation method of a pH sensitive / membrane adhesive bifunctional insulin-loaded mixed micelle nanoparticle. The preparation method comprises the following steps: dissolving a polymer poly(methyl methacrylate-co-methacrylic acid)-b-polymethyl methacrylate monomethoxypolyethylene glycol ester P(MMA-co-MAA)-b-PPEGMA and a polymer poly(methyl methacrylate-co-methacrylic acid)-b-polyaminoethyl methacrylate P(MMA-co-MAA)-b-PAEAMA into a polymer solution in an organic solvent, dissolving insulin in an acid solution with a pH value of 2-3, after fully dissolving, mixing the insulin solution and the polymer solution evenly, and then transferring the mixed solution into a dialysis bag, dialyzing the mixed solution in an environment of pH = 5 to 5.5 to form a polymer drug-loaded micelle, removing the organic solvent, and freeze-drying the polymer drug-loaded micelle to obtain the insulin-loaded mixed micelle nanoparticles with obvious pH sensitivity and excellent membrane adhesion.

Owner:XIANGTAN UNIV

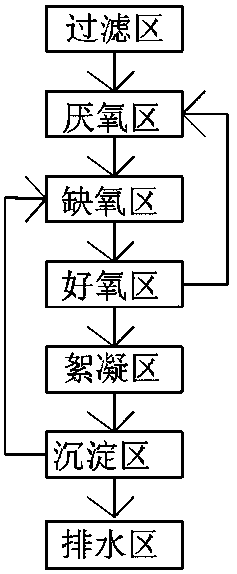

Sewage treatment upgrading reconstruction system based on MBBR functional carrier materials

InactiveCN110143729AAvoid competitionA large amount of attached biofilmTreatment using aerobic processesTreatment involving filtrationFiltrationCharge carrier

The invention belongs to the technical field of sewage treatment, and especially relates to a sewage treatment upgrading reconstruction system based on MBBR functional carrier materials. The three MBBR functional carrier materials have positive charges with different intensities, and are respectively used for attracting anaerobic bacteria, anoxic bacteria and aerobic bacteria with different numerical negative charges, and water filtration, carrier interception and bio-membrane adhesion reduction of positively charged carrier filter screens are adopted to achieve the targeted sewage treatment effect of bio-membranes on the carriers in three tanks of AAO. The three carriers are specifically used for the three different bacteria, so competition among the bacteria is avoided, the dominant bacterium attached biomasses in different treatment tanks are large, the charge attraction and adhesion effect mode is good, and the AAO process sewage indicator reduction effect is good.

Owner:浙江国阡环境与节能工程研究院 +1

Dextrorotatory oxiracetam oral membrane and preparation method thereof

InactiveCN108785282ASolve the problem of poor film formationSolve the appearanceOrganic active ingredientsNervous disorderPlasticizerIndustrial equipment

The invention provides a dextrorotatory oxiracetam oral membrane which is prepared from a membrane forming material containing acrylate together with a plasticizer, a filler, a corrigent and dextrorotatory oxiracetam by a coating method. Since the membrane forming material containing acrylate is mixed with a particular quantity of raw materials such as dextrorotatory oxiracetam, the filler and theplasticizer to achieve an synergistic effect, the stripping performance is improved while problems such as membrane adhesion and soft texture are solved, and thus, quality of the product is improved.The dextrorotatory oxiracetam oral membrane has uniform and complete appearance, uniform color, and consistent thickness, stable physical and chemical properties, short time for disintegration, quickdissolving and quick action; the preparation method is simple, can be implemented without any large-size industrial equipment, and is suitable for industrial production.

Owner:CHONGQING RUNZE PHARM CO LTD

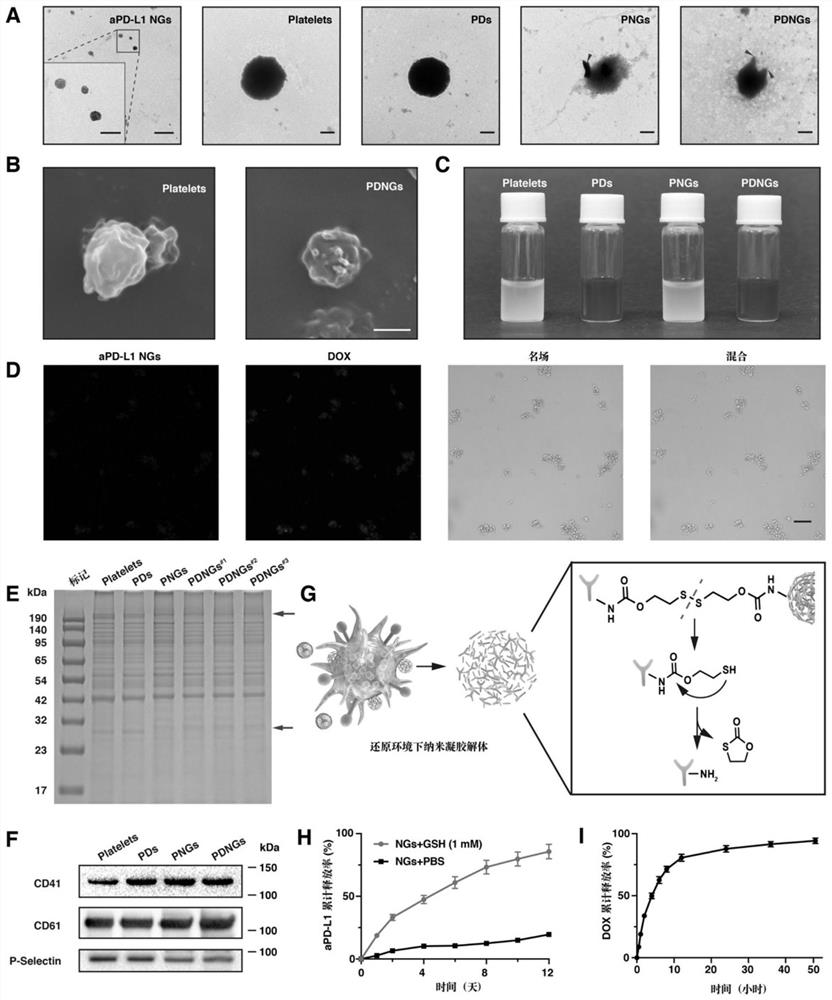

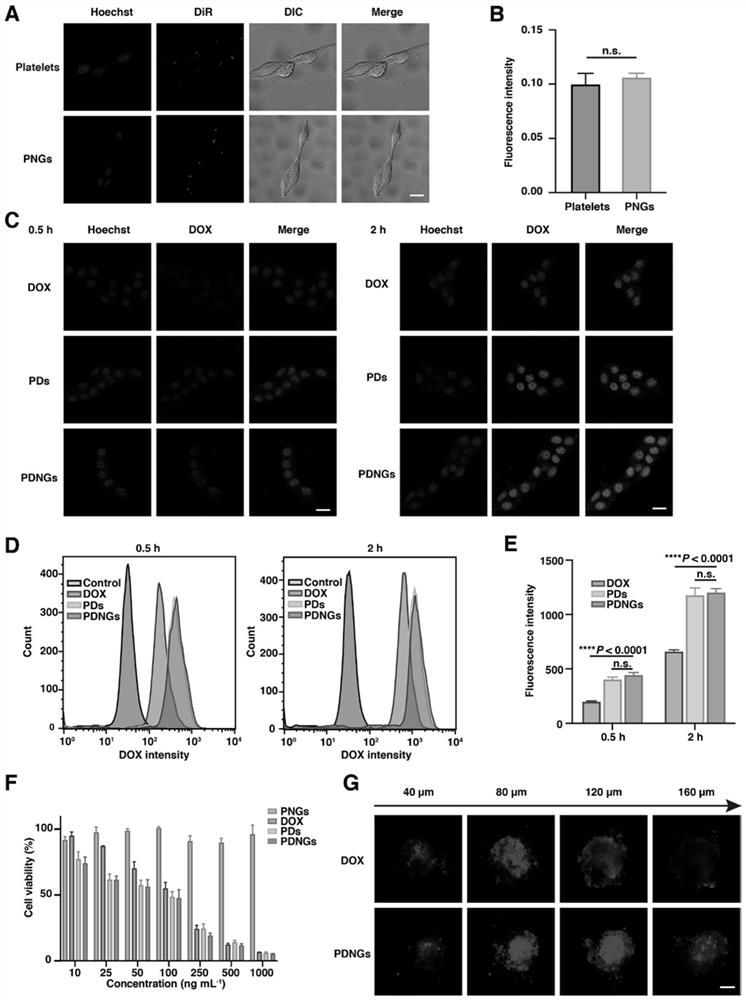

Engineered platelets of nanogel internally loaded with chemotherapeutic drugs and externally carried with immune checkpoint inhibitors as well as preparation method and application of engineered platelets

PendingCN113750244AImprove loading efficiencyImprove securityOrganic active ingredientsAerosol deliveryVascular endotheliumReceptor

The invention discloses engineered platelets of nanogel internally loaded with chemotherapeutic drugs and externally carried with immune checkpoint inhibitors as well as a preparation method and application of engineered platelets, and belongs to the technical field of drugs. The preparation method of the engineered platelets includes the following steps: crosslinking the nanogel carried with an immune checkpoint inhibitor, to extract and purified the platelets, and loading a chemotherapeutic drug and the nanogel onto the platelets, and the like. The engineered platelets deliver the chemotherapeutic drug and the immune checkpoint inhibitor to postoperative tumor remaining parts by efficiently targeting damaged vascular endothelium, circulating tumor cells are captured and cleared through a high-affinity membrane adhesion receptor, and the engineered platelets are activated in situ on the surfaces of the tumor cells, and the chemotherapeutic drug and the immune checkpoint inhibitor are released to trigger the T-cell-mediated anti-tumor immune response, so that the tumor is ablated, and the postoperative tumor recurrence and metastasis are effectively avoided.

Owner:SHENYANG PHARMA UNIVERSITY

Membrane-adherent self-assembled systems for treatment of ocular disorders

ActiveUS20170049697A1Increase concentrationAntibacterial agentsOrganic active ingredientsDiseaseLiquid crystalline

A liquid crystalline drug delivery system for ocular administration. The drug delivery system, which is mucoadhesive, biocompatible, non-irritating, and tissue permeable, contains nanoparticles stably dispersed in an aqueous solution and can be formulated for sustained release. Also provided are methods for producing the drug delivery system and methods for treating ocular disorders by administering it to a subject.

Owner:INTEGRAL BIOSYST

Sodium hyaluronate irrigation solution for nonbacterial cystitis treatment

InactiveCN105030656AOrganic active ingredientsPharmaceutical delivery mechanismEpitheliumBacterial cystitis

The invention belongs to the field of biological medicines, and relates to a bladder irrigation solution which is used for treating the effective concentration of nonbacterial cystitis, is in contact with the internal surface epithelium and relevant structures of the bladder of a patient suffering from the nonbacterial cystitis to prevent and treat the nonbacterial cystitis and contains sodium hyaluronate. The bladder irrigation solution comprises a water-soluble mucous membrane adhesive material, an active component and a medically acceptable carrier and / or an additive. The water-soluble mucous membrane adhesive material is prepared from hyaluronic acid-cysteine and salt thereof, and the molecular weight is not less than 50,000 Dalton, and the use amount is smaller than 1 percent; the active component comprises glycosaminoglycan and / or amino monosaccharide; glycosaminoglycan is one or a combination of several of salt, chondroitin sulfate and dermatan sulfate of any proportion; amino monosaccharide is a combination of one or two of glucosamine and acetylglucosamine of any proportion. The irrigation solution contains the medically acceptable carrier and / or an additive which comprises an osmotic pressure adjusting agent, a pH adjusting agent, a preservative and water.

Owner:SUZHOU JIOU BIOTECH CO LTD

Beverage bottle with stored solute

ActiveCN103010593ASimple control structureAvoid splashbackClosure with auxillary devicesContainers with multiple articlesBottle capBiomedical engineering

The invention relates to a beverage bottle with a stored solute. A screwed part of a bottle cap main body is connected with a bottle mouth of a bottle body in a screwing way. A membrane cutting internal cylinder is driven to move downwards by pressing a drinking water draw tube, and dual side membrane cutting blades of the membrane cutting internal cylinder cut a membrane to form a dual-side membrane cutting structure. Nicks are formed in the membrane cutting internal cylinder to form a cut membrane adhesion structure for the membrane. The membrane cutting internal cylinder is driven by the drinking water draw tube to move downwards, an inner sleeve of the membrane cutting internal cylinder is separated from a sleeve of the bottle cap main body in upward and downward directions, and a water outlet in the inner sleeve is communicated with a water outlet tube part of the bottle cap main body to form a water outlet channel. A sealing cover of the drinking water draw tube is matched with a middle mandrel of the bottle cover main body to form an opening / closing control structure for the water outlet channel. The beverage bottle has the advantages that a pressing control structure is simple and labor-saving, a membrane cutting effect is good, the solute can be released quickly and completely, and beverage can be directly drunk.

Owner:GUANGDONG HAIXING PLASTIC & RUBBER CO LTD

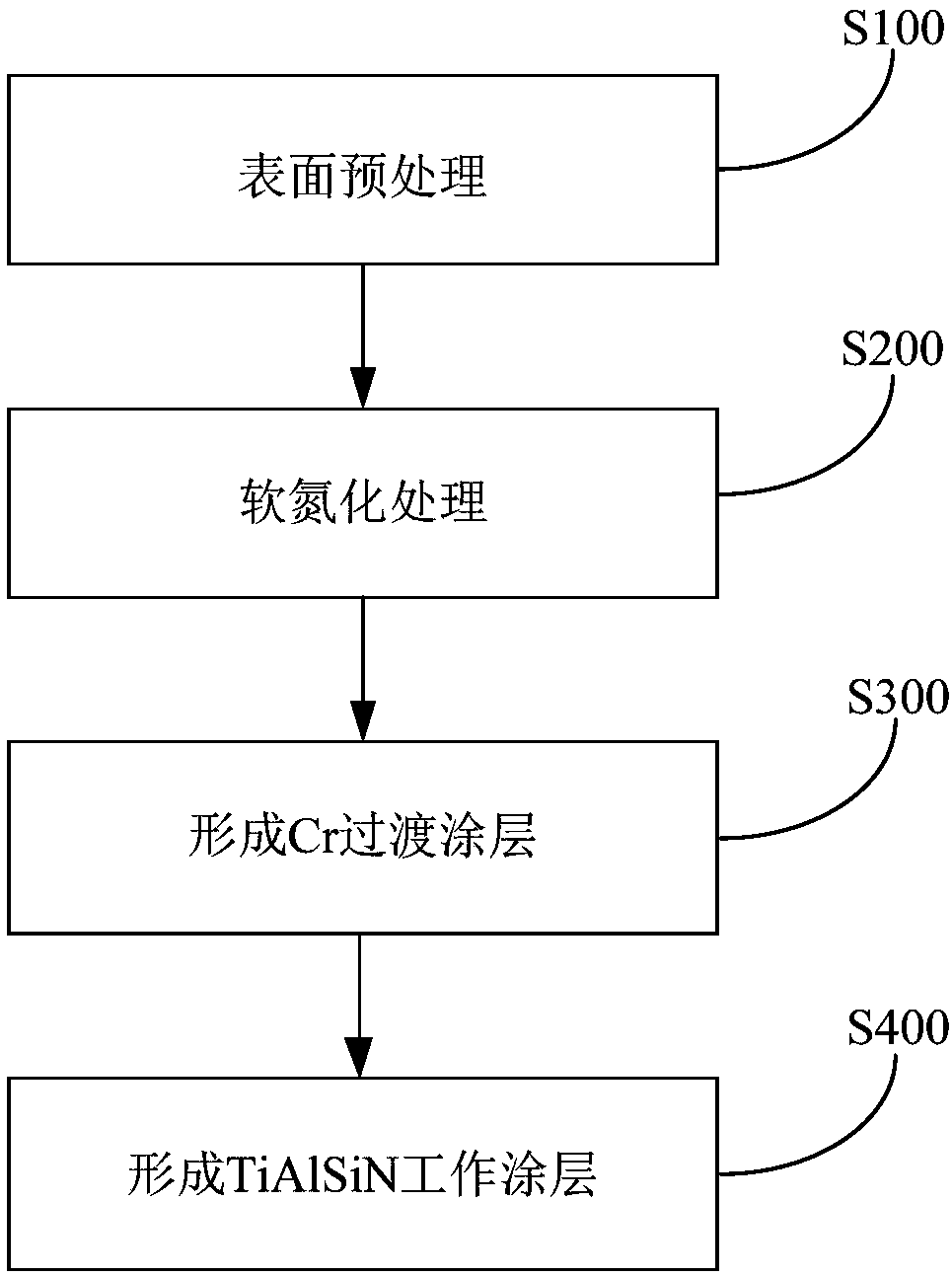

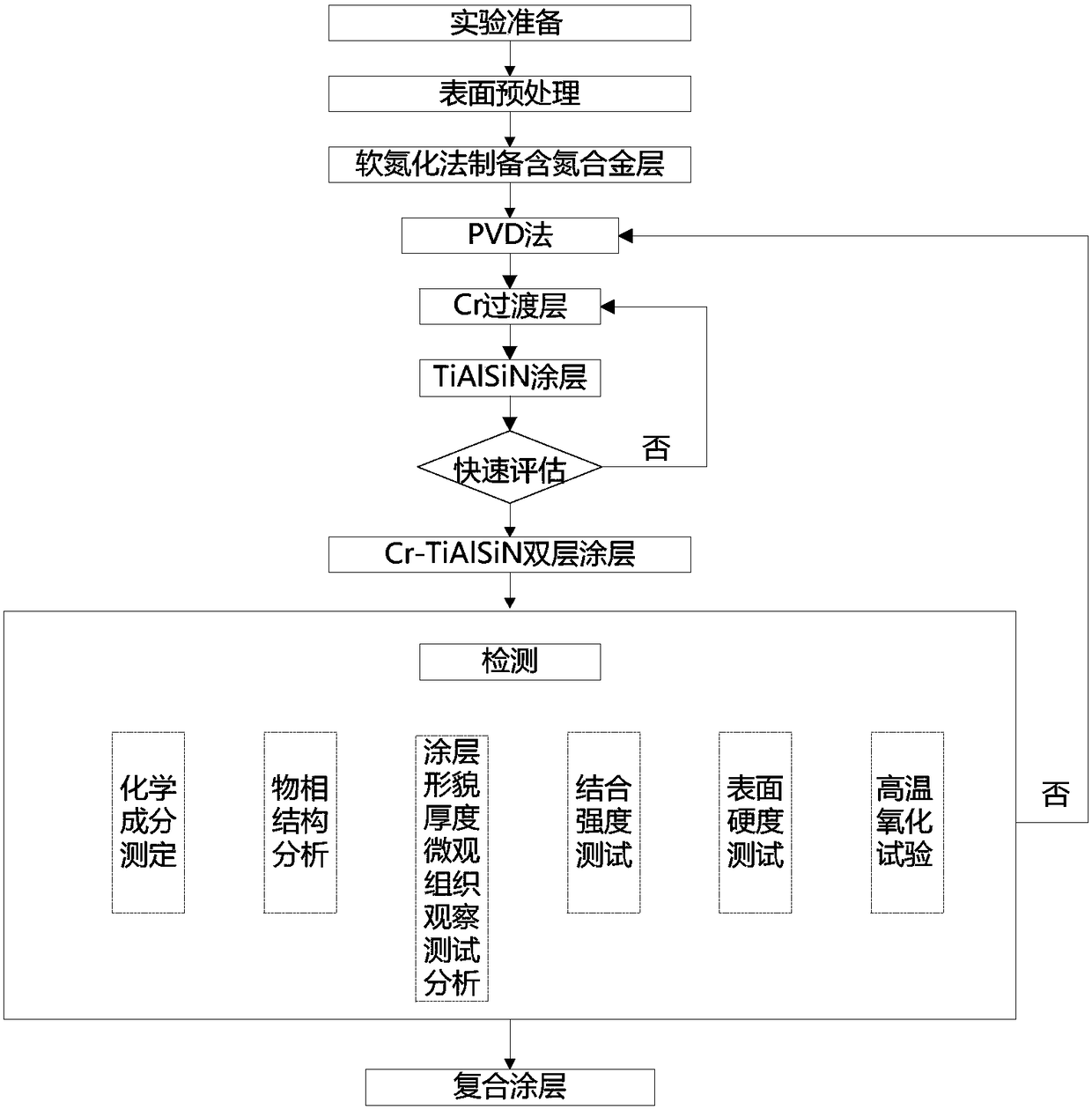

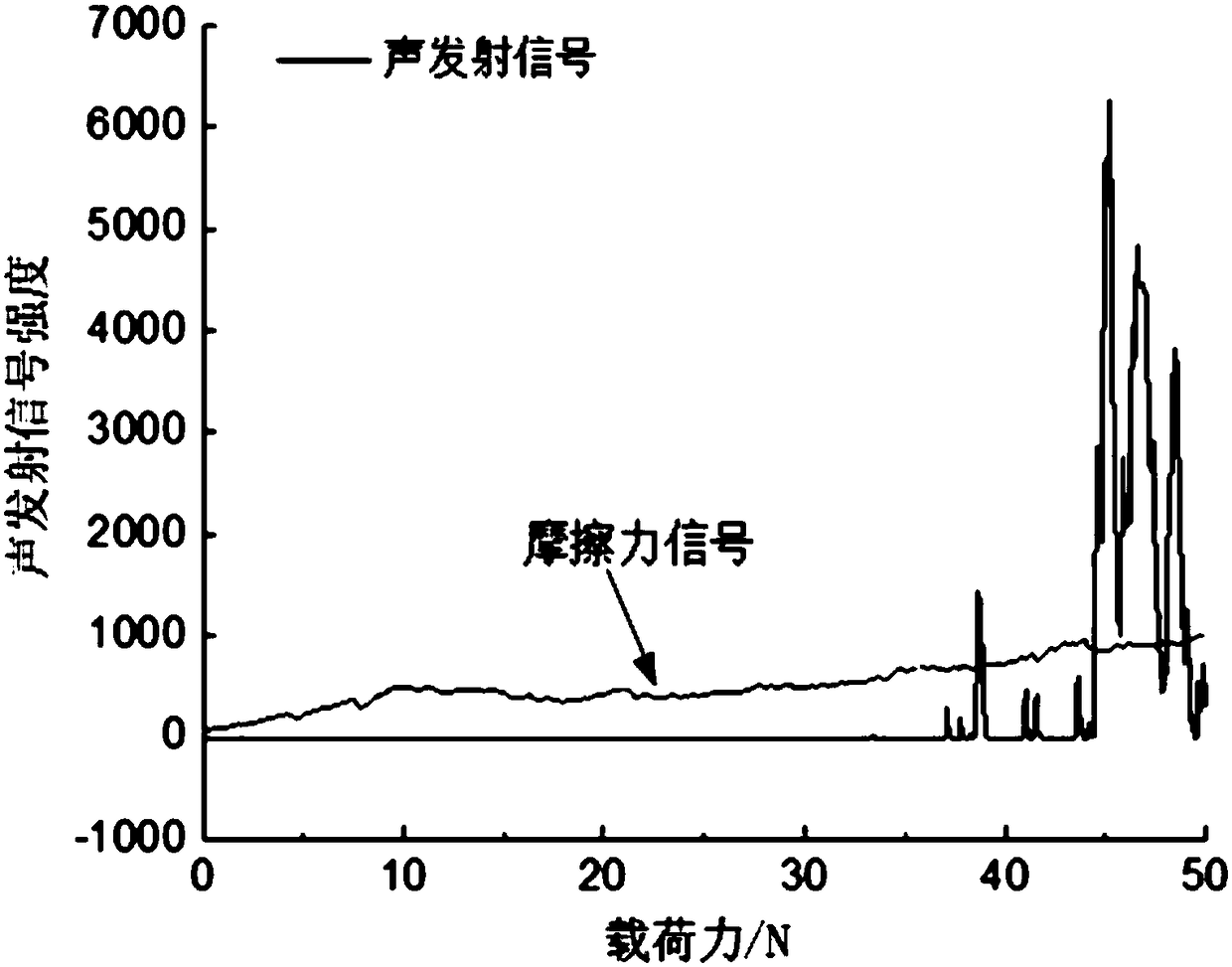

Zirconium alloy surface nitriding and ion-plating composite coating and preparation method thereof

InactiveCN109207936AHigh hardnessImprove bindingVacuum evaporation coatingSputtering coatingOxidation resistantZirconium alloy

The invention discloses a zirconium alloy surface nitriding and ion-plating composite coating preparation technology. A method for preparing a zirconium alloy surface nitriding and ion-plating composite coating comprises the steps that (1), surface pretreatment is performed on a zirconium base material; (2), soft nitriding treatment is performed on the zirconium base material obtained in the step(1); (3), a Cr transition coating is formed on the surface of the zirconium base material obtained in the step(2); and (4), a TiAlSiN working coating is formed on the surface of the Cr transition coating to conveniently obtain the composite coating. According to the zirconium alloy surface nitriding and ion-plating composite coating preparation method, by means of the manners that the soft nitriding treatment is performed on the zirconium alloy surface and the composite coating of the Cr transition coating and the TiAlSiN working coating is formed on the zirconium alloy surface, the high-temperature oxidation resistance and the membrane adhesion of zirconium alloy can be significantly improved.

Owner:STATE POWER INVESTMENT CORP RES INST +1

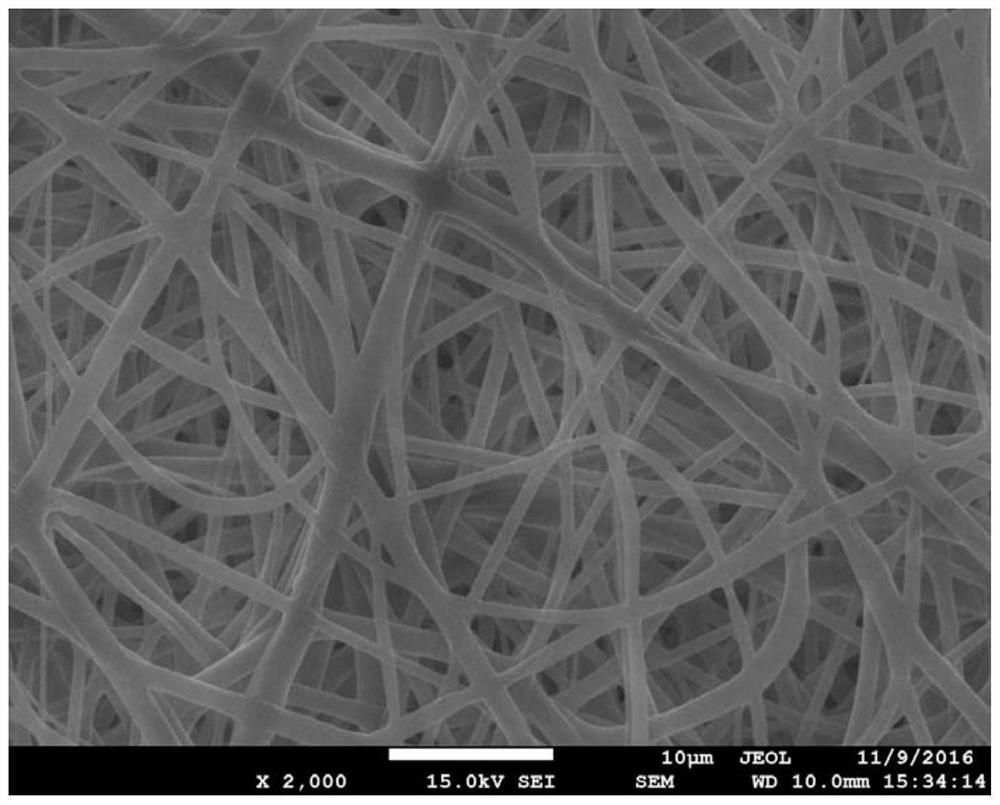

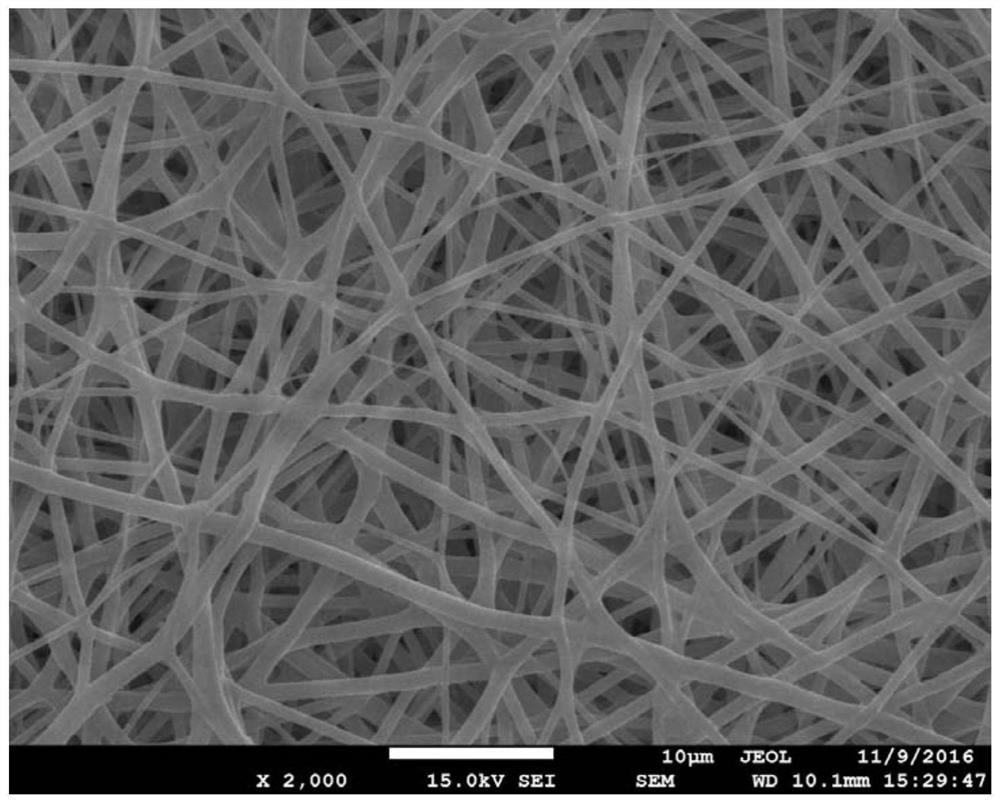

Trauma auxiliary material and preparation method thereof

InactiveCN111701069AMoisturizingHas antibacterial propertiesSpinning head liquid feederPharmaceutical delivery mechanismFiberSilicone membrane

The invention discloses a preparation method of a trauma auxiliary material, and belongs to the technical field of medical trauma auxiliary materials. The trauma auxiliary material is composed of twolayers, wherein the upper layer is a silicone membrane, and the lower layer is a PEG / PLGA composite nanofiber membrane. The preparation method of the PEG / PLGA composite nanofiber membrane comprises the following steps: 1) preparing a PEG / PLGA mixed spinning solution; 2) preparing a silicone membrane; 3) adhering the silicone membrane to an aluminum foil, fixing the aluminum foil on a roller receiver of an electric spinning machine, and performing electrostatic spinning on the mixed spinning solution obtained in the step 1); and 4) drying samples for a certain time after spinning. Through preparation of the double-layer membrane auxiliary material formed by combining the silicone membrane and the PEG / PLGA composite nanofiber membrane, the auxiliary material has moisturizing and antibacterial properties, the flexibility and mechanical properties of the auxiliary material can be remarkably improved, and the action time of drug properties of the auxiliary material is prolonged.

Owner:中国科学院大学深圳医院

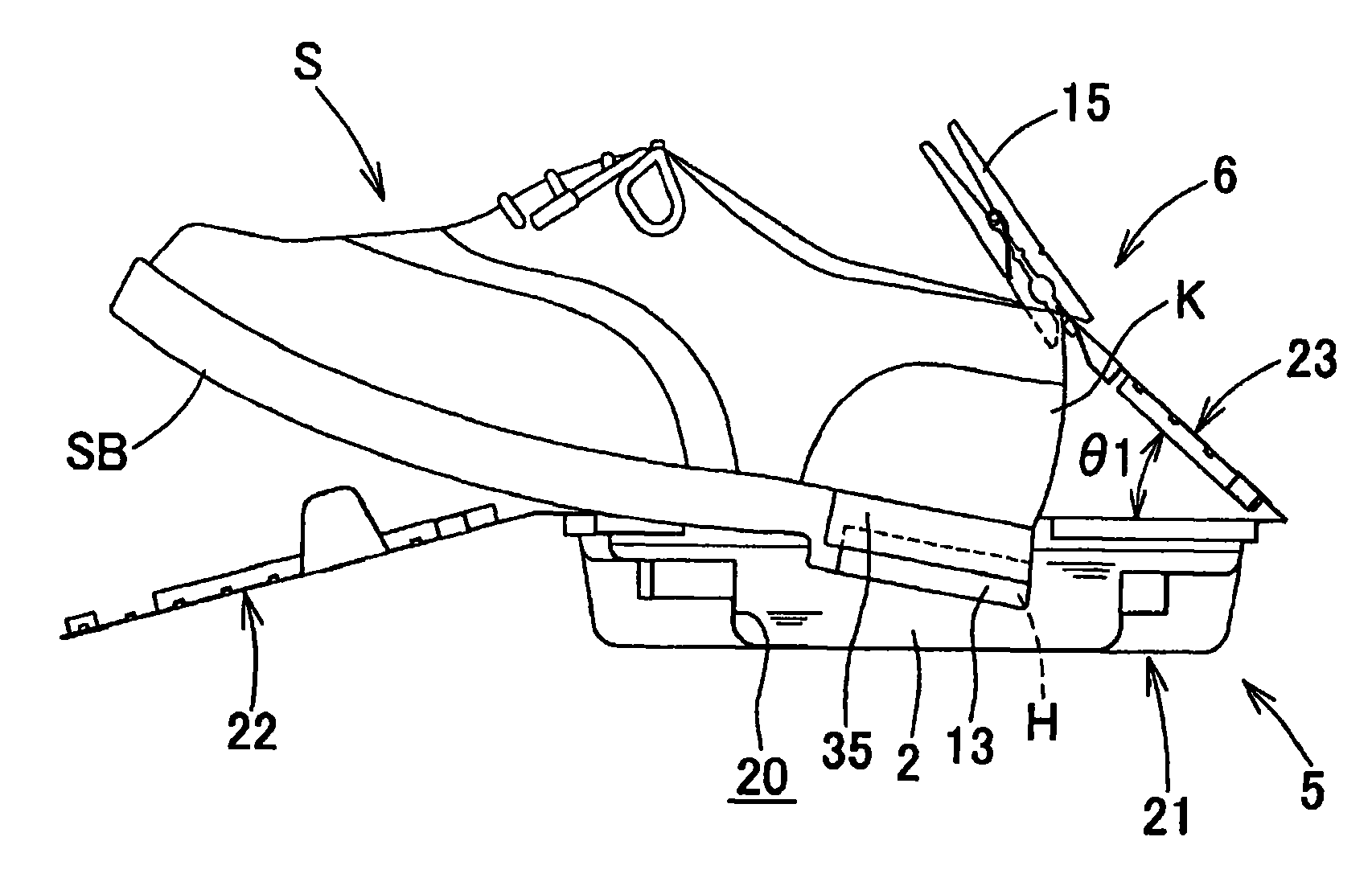

Shoe bottom repair agent and shoe bottom repair set utilizing the same

ActiveUS8082616B2Reduce wall thicknessShort timeLastingShoemaking devicesCarbamateAdditive ingredient

There is provided a shoe bottom repair agent consisting of one-component thermosetting composition comprising as main ingredients a terminal isocyanate having urethane prepolymer and / or a polyisocyanate compound and a latent curing agent. This shoe bottom repair agent is free from, experienced in use of solvent base shoe bottom repair agents, safety and sanitation problems such as odor and inflammation by solvent evaporated at the time of curing as well as cured matter thickness reduction of a mended part caused by solvent evaporation. With use of this shoe bottom repair agent, damaged shoe bottom portion can be mended to a desired shape through one-time repair work. Short-time curing can be effected by heating. Further, before heating, there is substantially no viscosity increase and no surface film is formed to avoid adhesion of a film resulting from surface drying to a spatula. Therefore, the repair surface can be finished smoothly and neatly.

Owner:SUNSTAR GIKEN KK

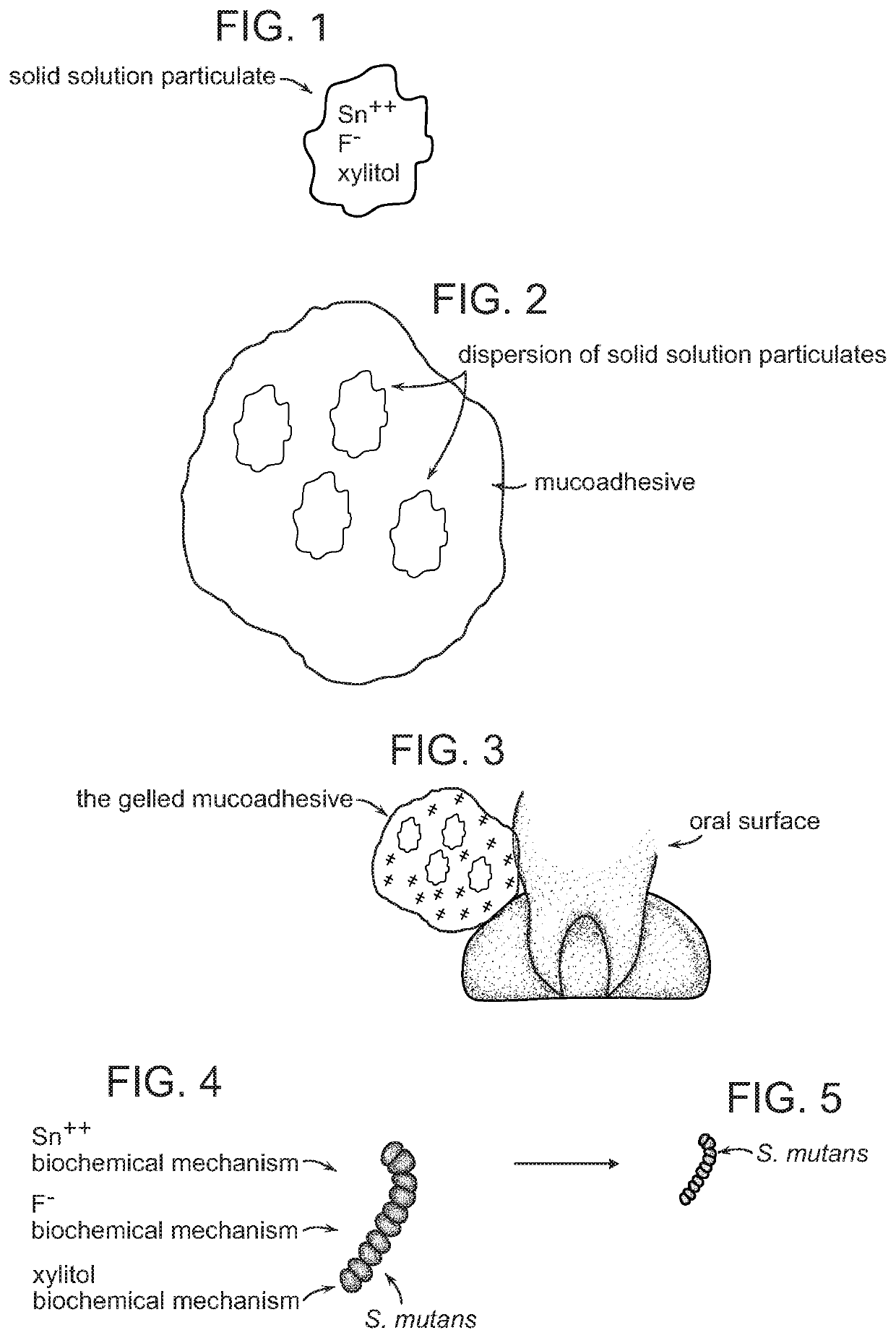

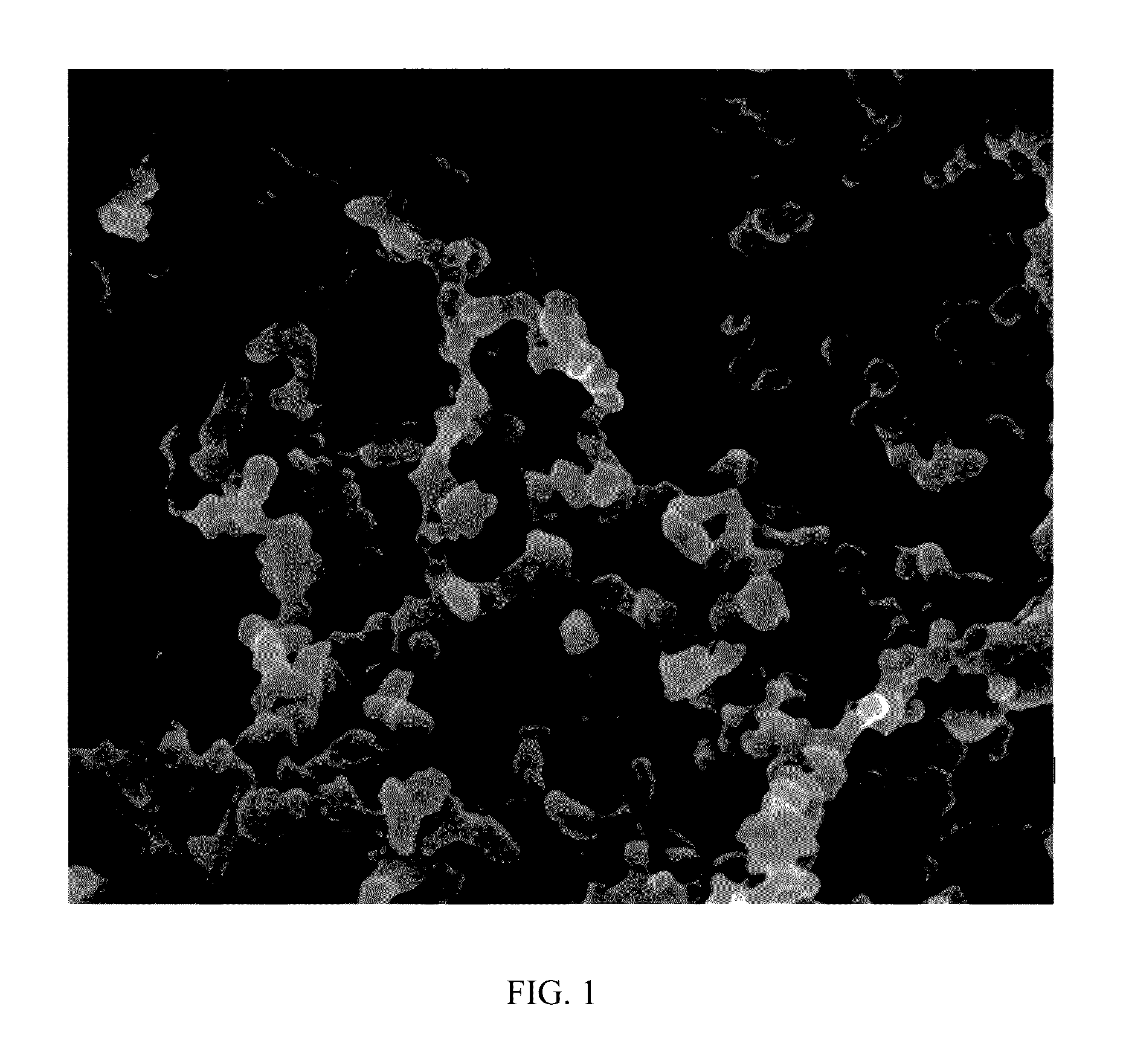

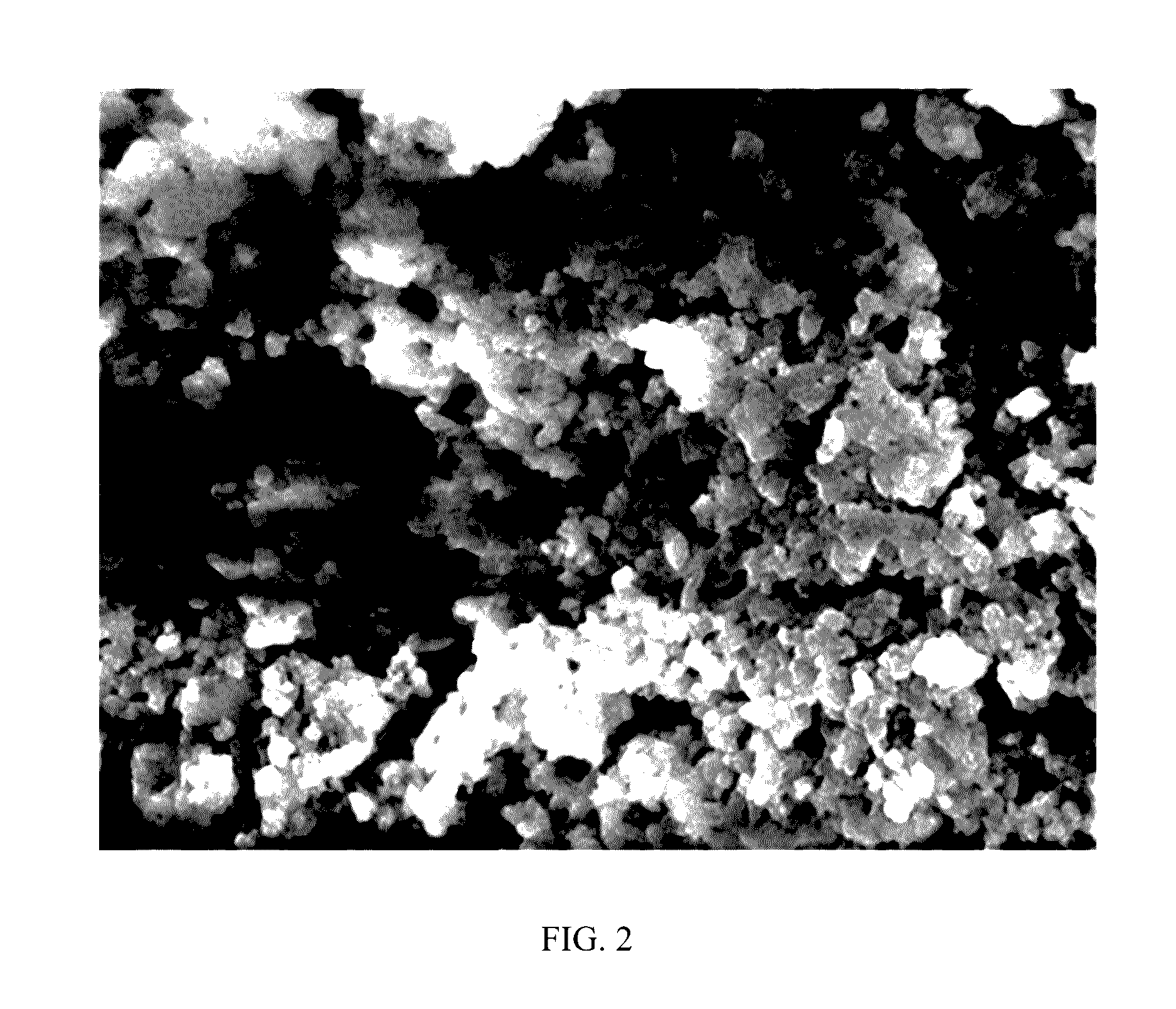

Stannous Fluoride Sugar Alcohol Solid Solutions

Stannous fluoride polyol solid solutions combine three complimentary, biochemical mechanisms attributed to Sn++, F− and Polyol, respectively to reduce growth and metabolism of Streptococcus mutans while effecting superior Bioactivity Quotients. The stannous fluoride polyol solid solution particulate compositions of the present invention comprise:(a) stannous fluoride at between about 0.01 and about 0.8% by weight;(b) a polyol at between about 0.1 and about 30% by weight;(c) an astringency neutralizer at between about 0.01 and about 0.4% by weight, where the ratio of astringency neutralizer to stannous fluoride is from between about 0.01 and about 0.2;(d) a mucoadhesive at between about 1.5 and about 70% by weight, wherein the ratio of mucoadhesive to stannous fluoride polyol is from between about 7 to 1 and about 25 to 1;(e) a pH stabilizer, selected from the group consisting of malic, fumaric, citric acid and combinations thereof, wherein the ratio of pH stabilizer to stannous fluoride polyol is from between about 0.03 and 5 and preferably from between about 0.1 and about 3; and(f) optional flavorants, stabilizers, preservatives, conditioners, and oral care adjuncts.

Owner:WHITEHILL LIFE SCI LLC

Kit and method for topical delivery of benefits

ActiveUS10821297B2Reduce intensityOvercome failureCosmetic preparationsToilet preparationsBiologyBiomedical engineering

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

Lactobacillus rhamnosus rht-3201 conjugated to polysaccharide polymer binder, and use thereof for prevention or treatment of atopic diseases

ActiveUS20170051247A1Convenient treatmentPreventing, alleviating, or treating atopic dermatitisBacteriaBacteria material medical ingredientsLactobacillus rhamnosusMedicine

The present invention relates to heat-killed Lactobacillus rhamnosus conjugated to a polysaccharide polymer binder, a preparation method therefor and a use thereof. The heat-killed Lactobacillus rhamnosus conjugated to a polysaccharide polymer binder of the present invention has an excellent therapeutic effect for atopic diseases, and particularly has high industrial applicability because membrane adhesion competitiveness, which is an advantage of existing lactic acid bacteria, is significantly improved, thereby exhibiting dermatitis preventing, alleviating and treating effects of the same level as steroid-based drugs.

Owner:ILDONG BIOSCIENCE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com