Zirconium alloy surface nitriding and ion-plating composite coating and preparation method thereof

A technology of surface nitriding and composite coating, which is applied in the field of material science, can solve the problems that zirconium alloy materials cannot meet the requirements of working conditions, and achieve the goal of improving high-temperature oxidation resistance, reducing high-temperature oxidation rate, and improving strength and oxidation resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

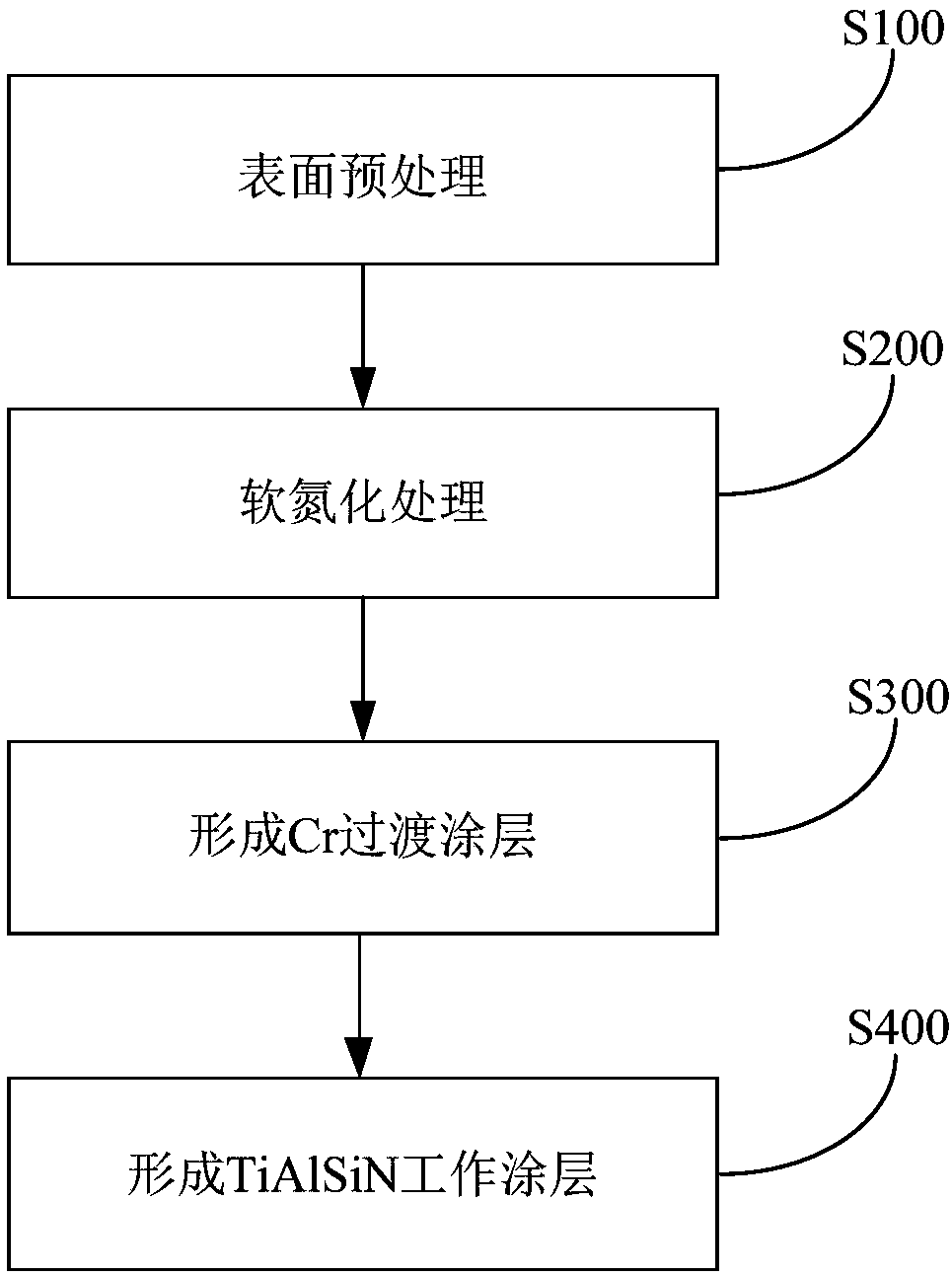

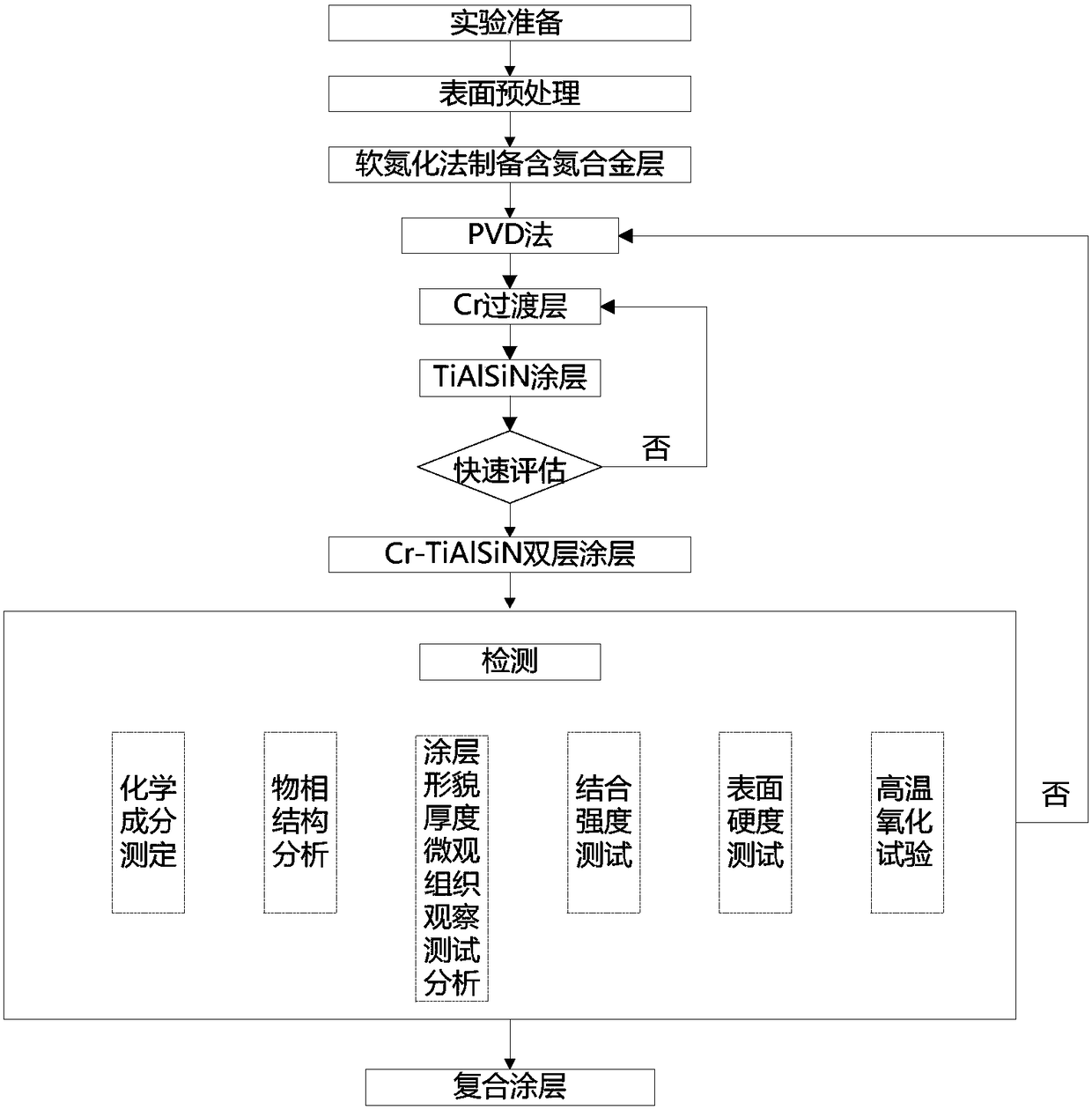

[0053] refer to figure 2 According to the following steps, carry out surface nitriding and ion plating composite coating on the zirconium alloy:

[0054] (1) carry out surface pretreatment with zirconium substrate;

[0055] (2) carrying out nitrocarburizing treatment to the zirconium substrate obtained in step (1);

[0056] Soft nitriding process parameters: nitriding temperature 590±10°C, nitriding time 360min, ammonia gas flow rate 1500-2000L / min, methanol dripping amount 7-8mL / min, cooling medium is anti-rust water;

[0057] (3) forming a Cr transition coating on the surface of the zirconium base material gained in step (2);

[0058] Cr transition coating coating process parameters are: bias voltage -200V, current 65A, air pressure 1.2Pa, temperature 380°C;

[0059] (4) Form a TiAlSiN working coating on the surface of the Cr transition coating;

[0060] Coating process parameters of TiAlSiN working coating: bias voltage -100V, current 60A, air pressure 2.2Pa, temperatu...

Embodiment 2

[0062] refer to figure 2 According to the following steps, carry out surface nitriding and ion plating composite coating on the zirconium alloy:

[0063] (1) carry out surface pretreatment with zirconium substrate;

[0064] (2) carrying out nitrocarburizing treatment to the zirconium substrate obtained in step (1);

[0065] Soft nitriding process parameters: nitriding temperature 590±10°C, nitriding time 360min, ammonia gas flow rate 1500-2000L / min, methanol dripping amount 7-8mL / min, cooling medium is anti-rust water;

[0066] (3) forming a Cr transition coating on the surface of the zirconium base material gained in step (2);

[0067] Cr transition coating coating process parameters are: bias voltage -200v, current 65A, air pressure 1.2Pa, temperature 400°C;

[0068] (4) Form a TiAlSiN working coating on the surface of the Cr transition coating;

[0069] Coating process parameters of TiAlSiN working coating: bias voltage -100v, voltage 60A, air pressure 2.2Pa, temperatu...

Embodiment 3

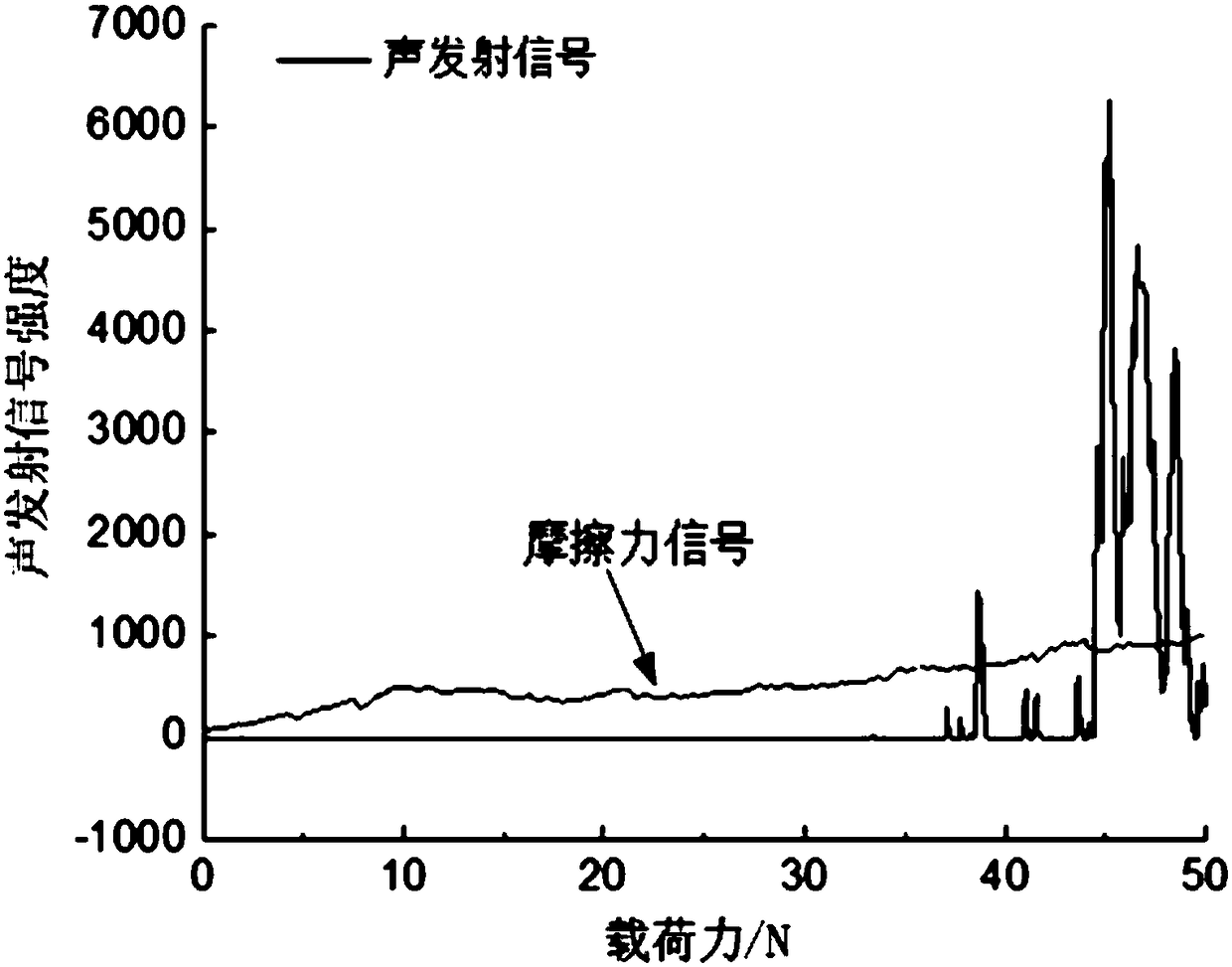

[0071] Investigate the application of zirconium alloy surface nitriding and ion plating composite coating (base material / nitridation / chromium / TiAlSiN composite coating) and existing base material / TiAlSiN coating, base material / nitridation / TiAlSiN coating Film-base adhesion performance, the instrument uses WS-2005 coating adhesion automatic scratch tester. the result shows:

[0072] (1) if image 3 As shown, the friction acoustic signal diagram of the zirconium alloy surface nitriding and ion plating composite coating scratch test of the present application, the friction force at the first peak position of the acoustic signal is the coating bonding force, which is 38N;

[0073] (2) if Figure 4~5 As shown, the substrate / TiAlSiN coating prepared under different process conditions has a coating-film-substrate bonding force of 23-32N;

[0074] (3) if Figure 6~7 As shown, the substrate / nitridation / TiAlSiN coating prepared under different process conditions has a film-base bond...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com