Long-acting slow-release oral ulcer film and preparation method thereof

An oral ulcer and film-sticking technology, which is applied in the field of long-acting sustained-release oral ulcer film and its preparation, achieves the effects of convenient access, easy self-operation, and wide drug-carrying range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The preparation method of anhydrous DMSO: add 1 gram of calcium hydride to 500 mL of dimethyl sulfoxide and stir for 12 hours, then filter with a sand core funnel to obtain anhydrous dimethyl sulfoxide.

[0043] The preparation method of dry caprolactone monomer: add 1 gram of calcium hydride to 500 mL of caprolactone monomer and stir for 12 hours, then filter with a sand core funnel to obtain dry caprolactone monomer.

[0044] The drying method of the modified cellulose: place the modified cellulose in a vacuum oven and dry at 70° C. for 16 hours.

Embodiment 1

[0046] (1) Synthesis of hydroxyethyl cellulose grafted polycaprolactone copolymer:

[0047]Weigh 5 grams of dried hydroxyethyl cellulose and dissolve it in 30 mL of anhydrous dimethyl sulfoxide, raise the temperature to 40-60 °C until the hydroxyethyl cellulose dissolves; then add 0.1 gram of stannous octoate and 2 grams of dried The caprolactone monomer is raised to 80°C, filled with nitrogen in the reaction bottle for 15 minutes, then heated to 120°C, and reacted for 12 hours under a nitrogen atmosphere; after the reaction, the product is precipitated twice in 150 mL of n-hexane, and then heated Under the condition of vacuum drying for 24 hours, the hydroxyethyl cellulose grafted polycaprolactone copolymer was obtained.

[0048] (2) Preparation of oral ulcer patch:

[0049] a. Dissolving hydroxyethyl cellulose in 95% ethanol solution with a mass fraction of 4%, forming a film on a horizontally clean glass plate coated with a little liquid paraffin, and drying at 50°C to obt...

Embodiment 2

[0053] (1) Synthesis of hydroxypropyl methylcellulose grafted polycaprolactone copolymer:

[0054] Weigh 5 grams of dried hydroxypropylmethylcellulose and dissolve it in 30mL of anhydrous dimethyl sulfoxide, raise the temperature to 40-60°C until the hydroxypropylmethylcellulose is dissolved; then add 0.1g of stannous octoate and 2g After drying the caprolactone monomer, heat up to 80°C, fill the reaction bottle with nitrogen for 15 minutes, then heat up to 120°C, and react under nitrogen atmosphere for 12 hours; after the reaction, the product is precipitated twice in 150mL of n-hexane, and then in Vacuum drying at 60° C. for 24 hours to obtain a hydroxypropylmethylcellulose grafted polycaprolactone copolymer.

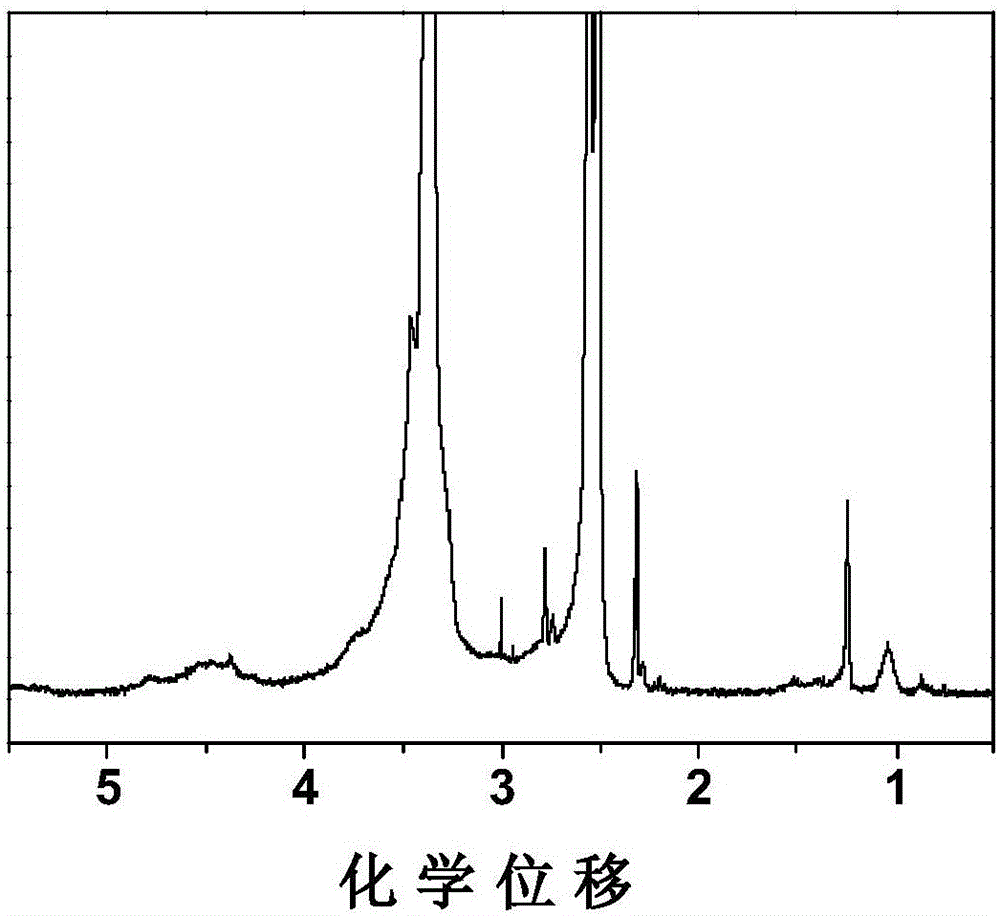

[0055] Weigh 3 mg of the obtained copolymer and dissolve it in 0.5 mL of deuterated dimethyl sulfoxide. The obtained sample was characterized by H NMR, and the results were as follows: figure 1 . figure 1 The peaks corresponding to the chemical shifts at 2.50 and 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com