Multilayer-color composite material for dental department and preparation method of composite material

A composite material and dental technology, applied in the field of dental multi-layer color composite materials and its preparation, can solve the problem of low color similarity, achieve the effect of improving biological safety and strength, high similarity, and improving aesthetic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

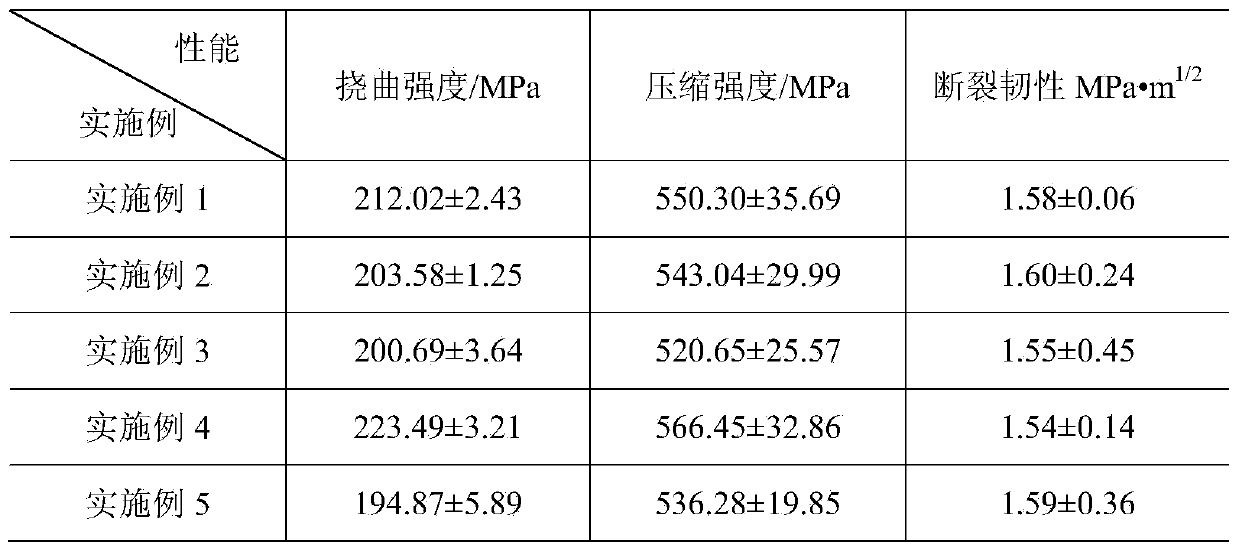

Examples

preparation example Construction

[0023] The present invention provides a kind of preparation method of dental multilayer color composite material, may comprise the following steps:

[0024] a) Preparing N types of monochrome composite precursor powders of different colors, N≥3; wherein, the preparation process of each monochrome composite precursor powder includes:

[0025] Mix the polymer monomer matrix, inorganic fillers, initiators and colorants with grinding aids, grind for 0.5-2 hours, and dry to obtain a monochrome composite material precursor powder; wherein, the weight of the polymer monomer matrix and the inorganic filler The ratio is 10:90-90:10, preferably 15:85-30:70, the weight of the initiator is 0.1%-1%, preferably 0.2%-0.5%, of the total weight of the polymer monomer matrix and the inorganic filler, and the coloring The weight of the agent is 0.01%-0.2%, preferably 0.03%-0.1%, of the total weight of the polymer monomer matrix and the inorganic filler.

[0026] In the present invention, the po...

Embodiment 1

[0045] According to the formulations of powders 1-3 in Table 1 and related process parameters, after the materials are mixed and ball-milled evenly, three kinds of monochromatic composite material precursor powders (ie powders 1-3) with different colors can be prepared; then Add powder 1 to the dry pressing mold first, then add powder 2 after flattening, and then add powder 3 after flattening, wherein, the thickness of powder 1 is 4mm, the thickness of powder 2 is 6mm, and the thickness of powder 2 is 6mm. 3 with a thickness of 4 mm, and then use a dry press to perform dry press preforming under a pressure of 5 MPa to obtain a preformed body of multi-layer color composite material; then pressurize and heat the preform body of multi-layer color composite material , the treatment temperature is 140°C, the pressure is 15 MPa, and the holding time is 1.5 hours, a multi-layer color composite material with three-layer color gradient can be obtained.

Embodiment 2

[0047] According to the formulation of powder 1-3 in Table 1 and related process parameters, three kinds of monochrome composite material precursor powders (i.e. powder 1-3) with different colors were prepared; then using powder 1-3 as raw material, the Powder 1 is added to a dry pressing mold with a thickness of 3mm, and is preformed by dry pressing under a pressure of 7MPa; the same method is used to preform powder 2 with a thickness of 7mm and dry powder 3 with a thickness of 4mm. Press preform. Then put the obtained three single-color preformed bodies into the mold successively and carry out dry pressing preforming under a pressure of 10MPa to obtain a multi-layer color composite material preformed body;

[0048] Then pressurize and heat the preformed body of the multi-layer color composite material. The treatment temperature is 130° C., the pressure is 17 MPa, and the holding time is 2 hours. A multi-layer color composite material with three-layer color gradient can be ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com