Special shot blast cleaning machine for concrete mixing cylinder

A mixing drum and cleaning technology, applied in abrasive jet machine tools, grinding/polishing equipment, abrasives, etc., can solve the problems of substandard surface quality, no adhesion, poor fatigue resistance, etc., to increase the adhesion of paint film, The effect of eliminating internal stress and improving fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

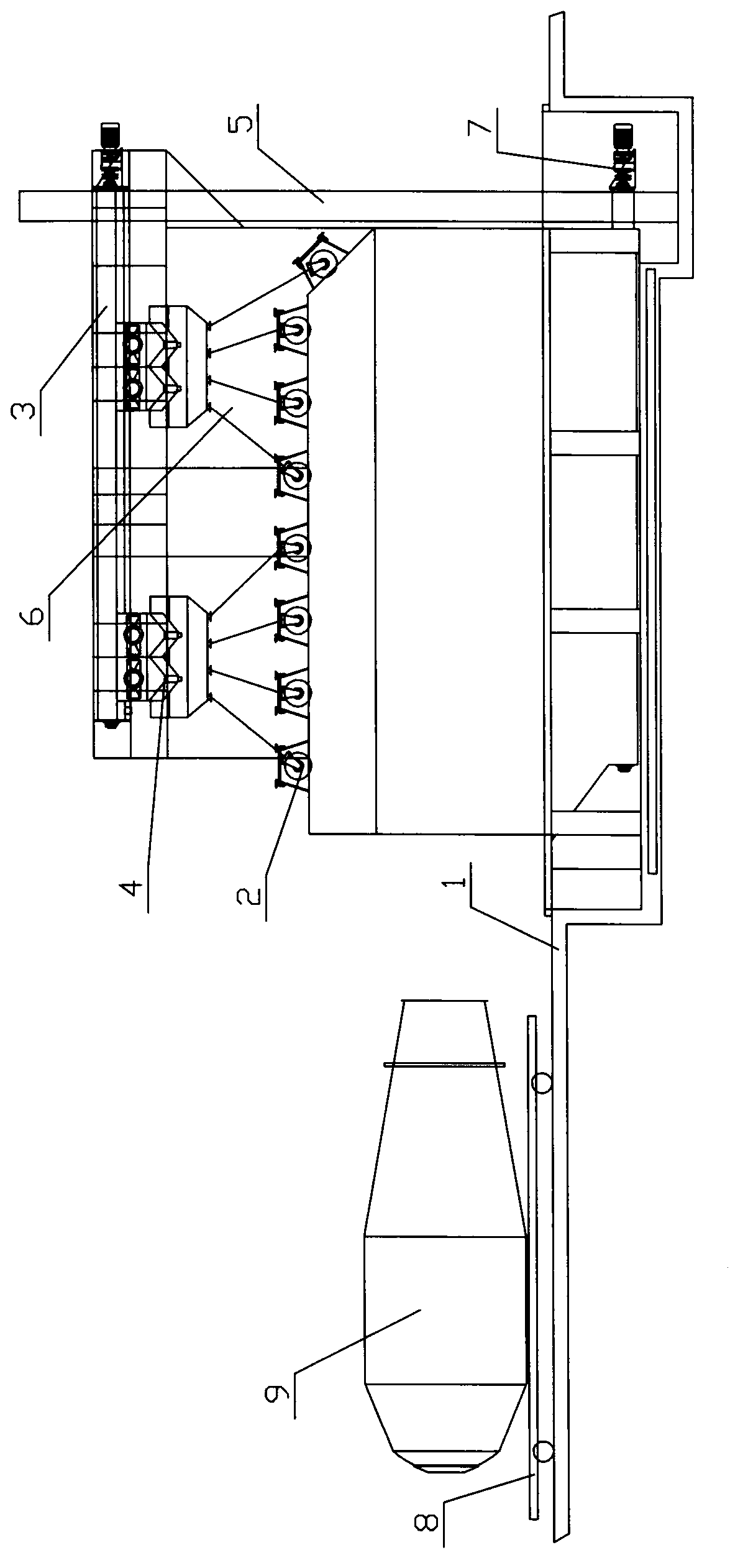

[0009] Such as figure 1 As shown, the special shot blasting machine for concrete mixing drum includes: a frame 2 arranged on the ground 1, and a dust removal device 3, a shot blaster 4, a hoist 5, a separator 6, and a longitudinal spiral are arranged on the frame 2. Conveyor 7 and trolley 8.

[0010] Lift the tank body 9 to the top of the trolley 8, and after the trolley 8 walks to the predetermined position, open the longitudinal screw conveyor 7, hoist, shot blaster 4 and separator 6, close it after the shot blasting is completed, and unload the tank body 9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com