Trauma auxiliary material and preparation method thereof

An adjuvant and wound technology, which is applied to the field of wound adjuvant and its preparation, can solve the problems such as the flexibility and mechanical strength of the adjuvant, the short service life of the flexibility and the mechanical strength, the unfavorable drug utilization rate, etc. and protein loss, improve flexibility and mechanical strength, maintain the effect of wound blood supply and oxygen exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0047] The preparation method of wound auxiliary material of the present embodiment comprises the following steps:

[0048] 1) Preparation of spinning solution:

[0049] Configure a mixed solvent of N-N-methylpropylamine, acetone and chloroform, wherein the volume ratio of N-N-methylpropylamine, acetone and chloroform is 3:5:2;

[0050] Weigh 0.1-0.7g of polylactic acid-glycolic acid copolymer (PLGA) and 0.3-0.6g of polyethylene glycol (PEG) particles and add them to 100ml of N-N-methylpropylamine, acetone and chloroform mixed solvent, The sum of the mass concentrations of the polylactic acid-glycolic acid copolymer and polyethylene glycol particles in the mixed solvent is 26% to 30% (w / v), stirred at 37 to 45°C for 1.5 to 2 hours, and left to stand Degassing to prepare PEG / PLGA mixed precursor solution;

[0051] 2) Preparation process of silicone film:

[0052] Mix silicone resin, liquid paraffin, n-hexane and Span-80 uniformly in proportion (13-36 parts of silicone resin,...

Embodiment 2

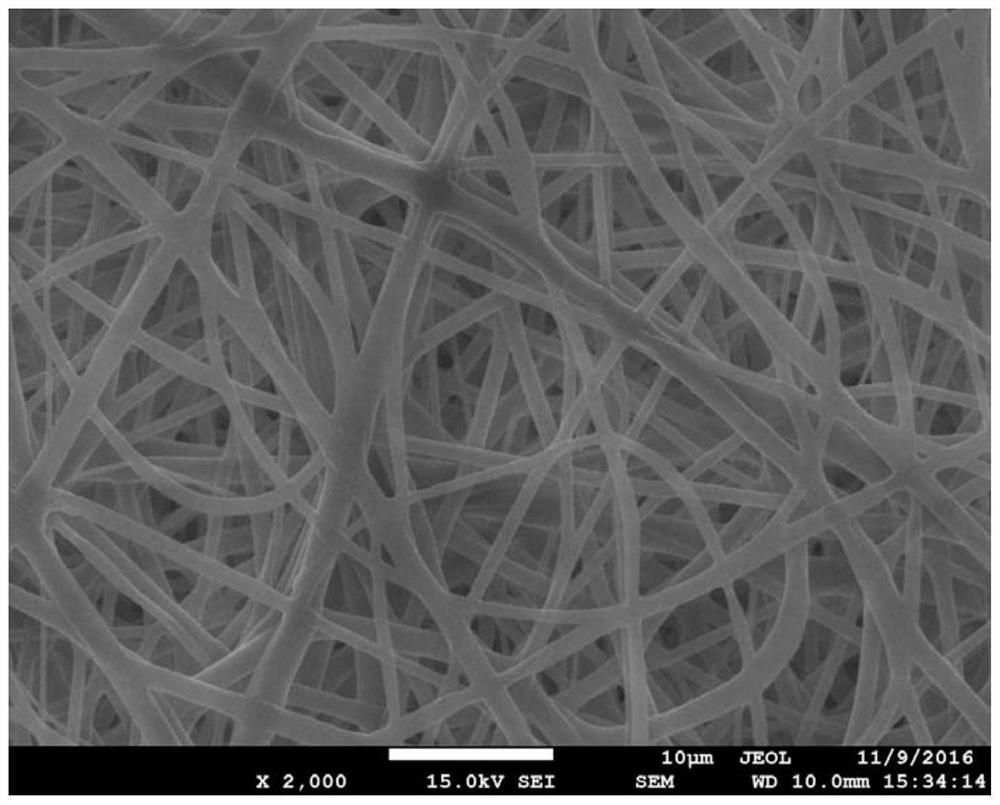

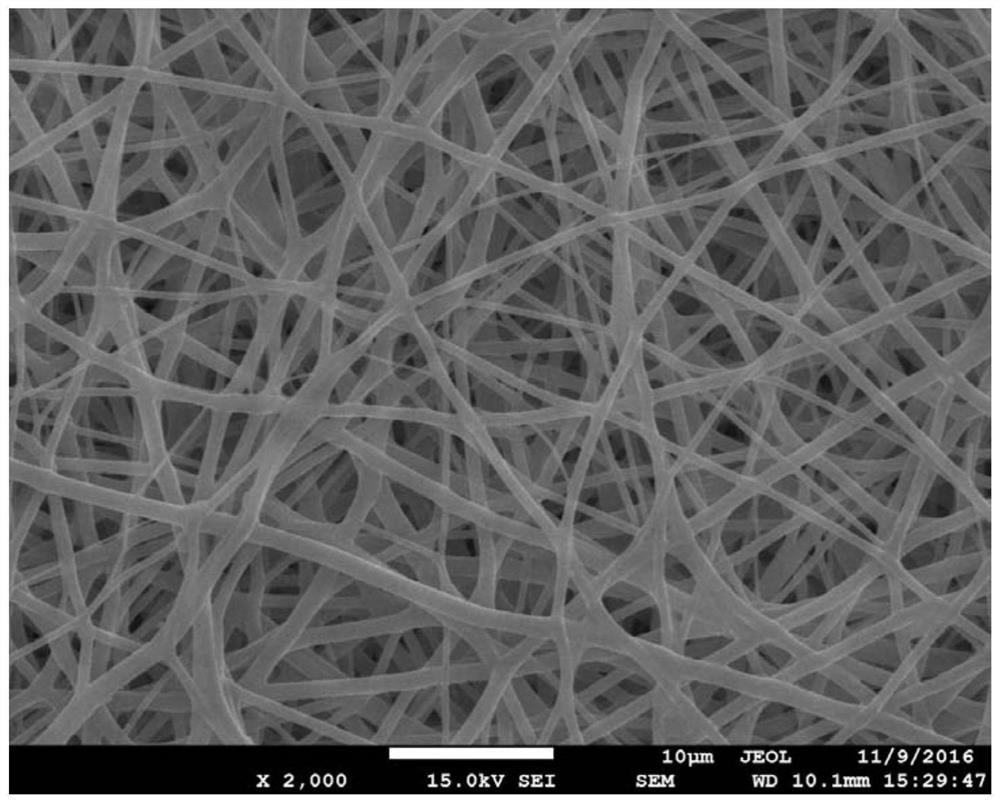

[0072] In order to prove the high porosity and pore connectivity of the nanofiber membrane in the lower layer, the nanofiber membrane and the drug-loaded nanofiber membrane were characterized respectively.

[0073] The non-drug-loaded fibrous membrane was prepared as follows:

[0074] 1) Preparation of spinning solution:

[0075] Configure a mixed solvent of N-N-methylpropylamine, acetone and chloroform, wherein the volume ratio of N-N-methylpropylamine, acetone and chloroform is 3:5:2;

[0076] Weigh 0.1-0.7g of polylactic acid-glycolic acid copolymer and 0.3-0.6g of polyethylene glycol particles into 100ml of N-N-methylpropylamine, acetone and chloroform mixed solvent, the polylactic acid- The sum of the mass concentration of glycolic acid copolymer and polyethylene glycol particles in the mixed solvent is 26% to 30% w / v, stirred at 37-45°C for 1.5-2h, and left to defoam to obtain PEG / PLGA mixed precursor solution;

[0077] 2) Electrospinning the spinning solution in step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com