High-performance anti-freezing concrete and preparation method thereof

A concrete and high-performance technology, which is applied in the field of high-performance frost-resistant concrete and its preparation, can solve the problems of limited frost resistance of concrete, and achieve the effects of light specific gravity, improved impermeability, and reduced water-cement ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

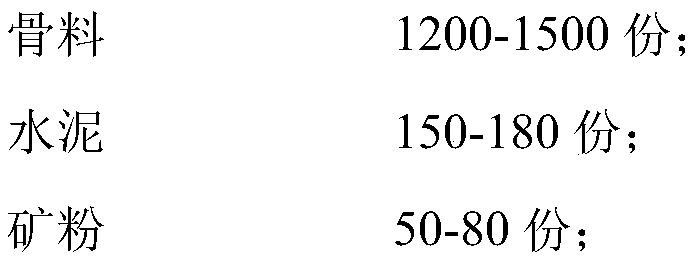

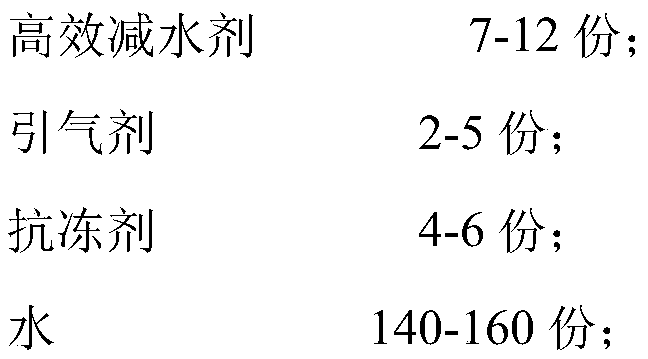

Method used

Image

Examples

Embodiment 1

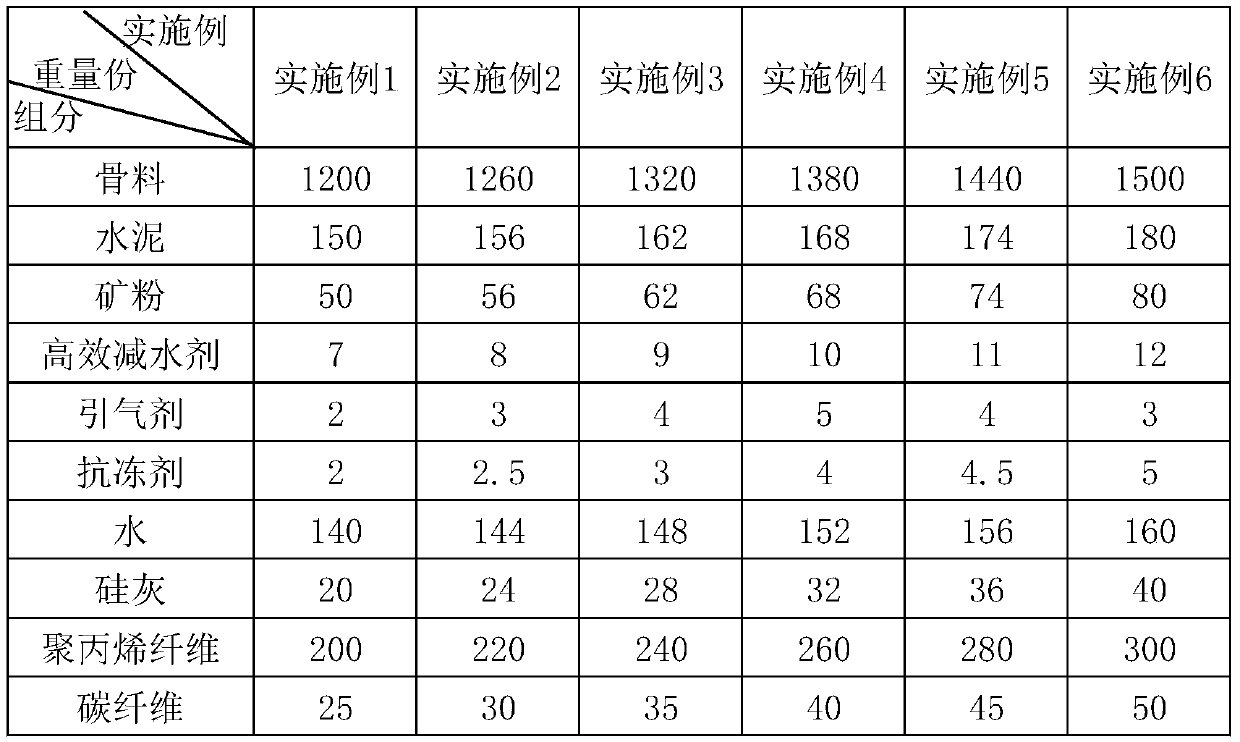

[0039] A high-performance frost-resistant concrete, the content of each component is shown in Table 1.

[0040] Among them, the aggregate is composed of stone, medium sand and fine sand with a mass ratio of 4:2:1.

[0041] Antifreeze is methanol.

[0042] The air-entraining agent is rosin thermal polymer PC-2 air-entraining agent.

[0043] The preparation method of the high-performance frost-resistant concrete comprises the following steps:

[0044] S1. Aggregate pre-dispersion: Mix the stones, medium sand and fine sand in the aggregate and stir at a constant speed of 30r / min for 20min until the stones, medium sand and fine sand are evenly dispersed;

[0045] S2. Powder dispersion: Add cement, mineral powder, and silica fume to the aggregate in step S1, and stir at a constant speed of 120r / min for 1h until the stirring and dispersion are uniform;

[0046] S3. Water agent dispersion: add water, high-efficiency water reducer, air-entraining agent and antifreeze to the mixture...

Embodiment 2

[0051] A high-performance frost-resistant concrete, the content of each component is shown in Table 1.

[0052] Among them, the aggregate is composed of stone, medium sand and fine sand with a mass ratio of 4:3:1.

[0053]Antifreeze is ethylene glycol.

[0054] The air-entraining agent is sodium dodecylbenzenesulfonate.

[0055] The preparation method of the high-performance frost-resistant concrete comprises the following steps:

[0056] S1. Aggregate pre-dispersion: Mix the stones, medium sand and fine sand in the aggregate and stir at a constant speed of 30r / min for 25 minutes until the stones, medium sand and fine sand are evenly dispersed;

[0057] S2. Powder dispersion: Add cement, mineral powder, and silica fume to the aggregate in step S1, and stir at a constant speed of 125r / min for 1.1h until the stirring and dispersion are uniform;

[0058] S3. Water agent dispersion: add water, high-efficiency water reducer, air-entraining agent and antifreeze to the mixture in ...

Embodiment 3

[0061] A high-performance frost-resistant concrete, the content of each component is shown in Table 1.

[0062] Among them, the aggregate is composed of stone, medium sand and fine sand with a mass ratio of 5:2:1.

[0063] Antifreeze is a mixture of methanol and ethylene glycol in a weight ratio of 1:1.

[0064] The air-entraining agent is sodium lauryl fatty alcohol sulfate.

[0065] The preparation method of the high-performance frost-resistant concrete comprises the following steps:

[0066] S1. Aggregate pre-dispersion: Mix the stones, medium sand and fine sand in the aggregate and stir at a constant speed of 30r / min for 30min until the stones, medium sand and fine sand are evenly dispersed;

[0067] S2. Powder dispersion: Add cement, mineral powder, and silica fume to the aggregate in step S1, and stir at a constant speed of 130r / min for 1.2h until the stirring and dispersion are uniform;

[0068] S3. Water agent dispersion: add water, high-efficiency water reducer, ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com