Wear-resistant and corrosion-resistant gradient coatings of middle trough of scraper conveyor

A scraper conveyor and gradient coating technology, applied in the field of corrosion-resistant gradient coating and wear-resistant middle groove of scraper conveyor, can solve the problems of uneven wear of the middle plate, easy to fall off, corrosion coating, etc. load-carrying capacity, improved anti-wear properties, low oxide content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

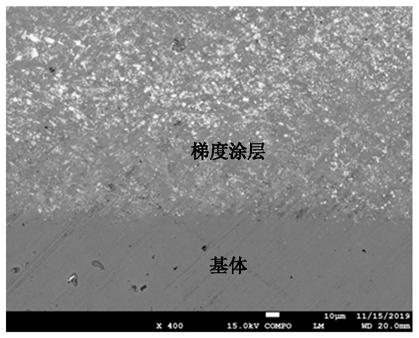

[0022] A wear-resistant and corrosion-resistant gradient coating material for the middle groove of the scraper conveyor is configured according to the following weight fraction ratio, gradient coating-1: 45%Ni50, 50%Ni60, 2%TiC, 3%WC. Gradient coating-2: 40%Ni50, 45%Ni60, 7%TiC, 8%WC. Gradient coating-3: 35%Ni50, 40%Ni60, 12%TiC, 13%WC.

[0023] The Ni50, Ni60, TiC, WC powders are configured according to the above proportions as composite powders for cladding.

[0024] The composite powder is ball-milled with a planetary ball mill, the ball-to-material ratio is 10:1, and the ball-milling time is 7 hours, so that the composite powder can be mixed evenly and the particles can be refined.

[0025] The composite powder after ball milling was cleaned by a constant temperature ultrasonic cleaning machine, the cleaning medium was absolute ethanol, the cleaning time was 40min, and the temperature was 20°C.

[0026] The cleaned composite powder was dried in a drying oven at a drying ...

Embodiment 2

[0030] A wear-resistant and corrosion-resistant gradient coating material for the middle groove of the scraper conveyor is configured according to the following weight fraction ratio, gradient coating-1: 43%Ni50, 52%Ni60, 1%TiC, 4%WC. Gradient coating-2: 38%Ni50, 47%Ni60, 6%TiC, 9%WC. Gradient coating-3: 33%Ni50, 42%Ni60, 11%TiC, 14%WC.

[0031] The Ni50, Ni60, TiC, WC powders are configured according to the above proportions as composite powders for cladding.

[0032] The composite powder is ball-milled with a planetary ball mill, the ball-to-material ratio is 10:1, and the ball-milling time is 7 hours, so that the composite powder can be mixed evenly and the particles can be refined.

[0033] The composite powder after ball milling was cleaned by a constant temperature ultrasonic cleaning machine, the cleaning medium was absolute ethanol, the cleaning time was 40min, and the temperature was 20°C.

[0034] The cleaned composite powder was dried in a drying oven at a drying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com