Anti-stripping iron oxide scale structure on surface of hot rolled plate and control process for anti-stripping iron oxide scale structure

A technology of iron oxide scale and hot-rolled plate, which is applied in the field of hot-rolled sheet rolling, can solve problems such as easy peeling of iron oxide scale, and achieve the effect of avoiding defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Implementation Example 1

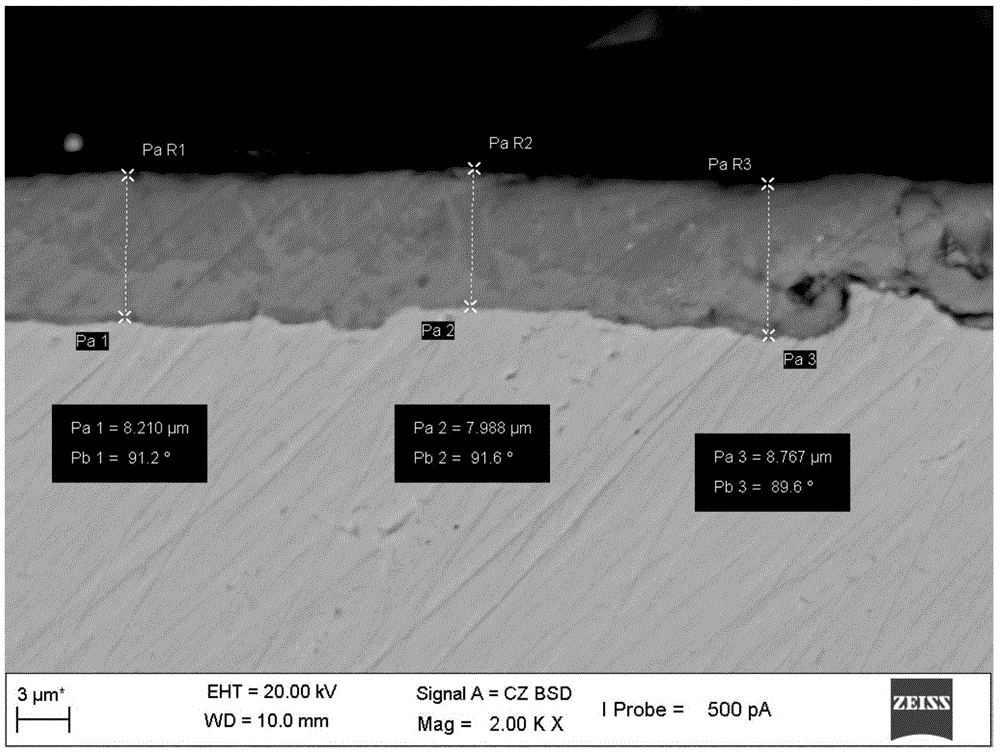

[0017] The molten steel is smelted and continuously cast into slabs, and its chemical composition is Si0.14wt%, C0.09wt%, Mn1.55wt%, P0.015wt%, S0.006wt%, Nb0.055wt%, Ti0.015wt% , Alt is 0.032wt%, and the balance is Fe. The thickness of the slab is 230mm. The slab is heated to 1238°C for 3.5 hours, and then it is taken out of the furnace for high-pressure water descaling. Double descaling is adopted, and the descaling water pressure is 18MPa. Rough rolling is carried out after descaling, and the rough rolling exit temperature is 1043°C , the thickness of the intermediate billet is 32mm, the final rolling temperature is 872°C, the rolling speed of the final stand during the finishing rolling is 7.8m / s, after finishing rolling, it enters the laminar cooling table, and the laminar cooling mode is the front-stage sparse cooling, that is, a group of 4 The water opening method of the drainage pipe is + Interval cooling control mode, the coiling...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com