Fluororesin primer containing poly(ether-ketone-ketone) resin and laminating body using same

A technology of polyether ketone ketone and fluororesin, which is applied in the field of polymers, can solve the problems of poor bonding between anti-corrosion coatings and metal substrates, poor vacuum resistance, etc., to improve service life and practicability, excellent chemical resistance, strong adhesive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

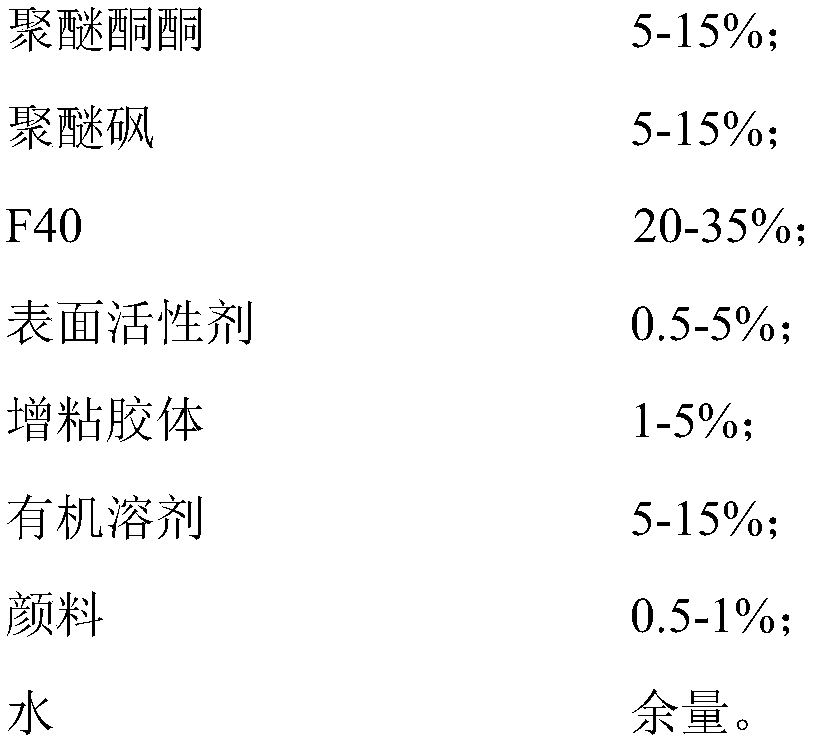

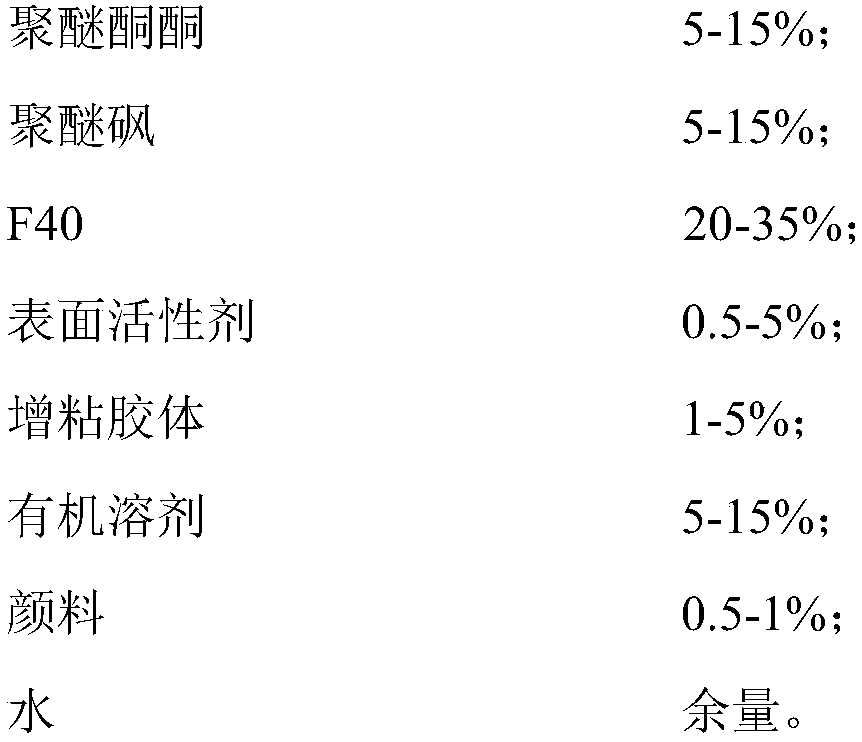

Method used

Image

Examples

Embodiment 1

[0030] Add 40g of surfactant APEO, 96g of N-methylpyrrolidone, and 482g of water into the mixing tank in turn, set the stirring speed at 1500r / min, and stir for 10min. After the solution is mixed evenly, add 63g of polyethersulfone fine powder, polyether 120g of ketone and ketone fine powder, 220g of F40 resin, and 6g of carbon black are successively added to the solution, and the set speed is 1500r / min and stirred for 50min. After the solution system is uniformly dispersed, 30g of hydroxymethyl cellulose ether is added to the solution system, and the Stir the water-based system at a speed of 1000r / min to obtain a uniform and stable water-based primer, filter it with a 150-mesh filter, let it stand still, and use it.

[0031] Weigh 15g of 4,4-diaminodiphenyl ether and 2985g of F40 resin, mix them in a three-dimensional mixer for 30 minutes, take out the materials, first coat the metal substrate with a fluororesin water-based primer containing polyetherketoneketone resin, and wa...

Embodiment 2

[0033] Add 40g of surfactant APEO, 96g of N-methylpyrrolidone, and 482g of water into the mixing tank in sequence, set the stirring speed at 1500r / min and stir for 15min. Add 72g of ketone powder, 240g of F40 resin, and 6g of carbon black into the solution in turn, and stir at a low speed for 60 minutes. After the solution system is uniformly dispersed, add 30g of hydroxymethyl cellulose ether to the solution system, and set the speed at 1000r / min to stir Water-based system, to obtain a uniform and stable water-based primer, filter it with a 150-mesh filter, let it stand still, and use it.

[0034] Weigh 10g of 4,4-diaminodiphenyl ether and 2990g of F40 resin, mix them in a three-dimensional mixer for 30min, and take out the materials. First, coat the metal substrate with a fluororesin water-based primer containing polyether ketone ketone resin. After the water-based primer is dried, spray the modified F40 resin on the primer by electrostatic spraying.

Embodiment 3

[0036] Add 40g of surfactant APEO, 96g of N-methylpyrrolidone, and 440g of water into the mixing tank in turn, set the stirring speed at 1500r / min and stir for 15min. After the solution is mixed evenly, add 120g of polyethersulfone fine powder, Add 63g of ketone fine powder, 200g of F40 resin, and 6g of carbon black into the solution in turn, set the rotation speed at 1500r / min and stir for 40min. / min Stir the water-based system to obtain a uniform and stable water-based primer, filter it with a 150-mesh filter, and use it statically.

[0037] Weigh 14g of 4,4-diaminodiphenyl ether and 2970g of F40 resin, mix them in a three-dimensional mixer for 30 minutes, take out the materials, first coat the metal substrate with a fluororesin water-based primer containing polyetherketoneketone resin, and wait for the water-based primer After the paint is dried, spray the modified F40 resin on top of the primer by electrostatic spraying.

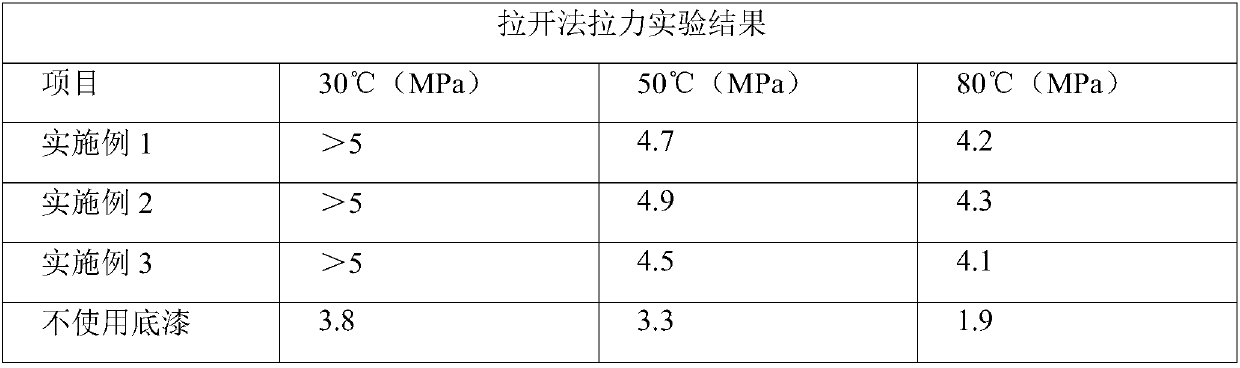

[0038] The bonding force of the products of Exam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com