Patents

Literature

139 results about "Polyetherketoneketone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

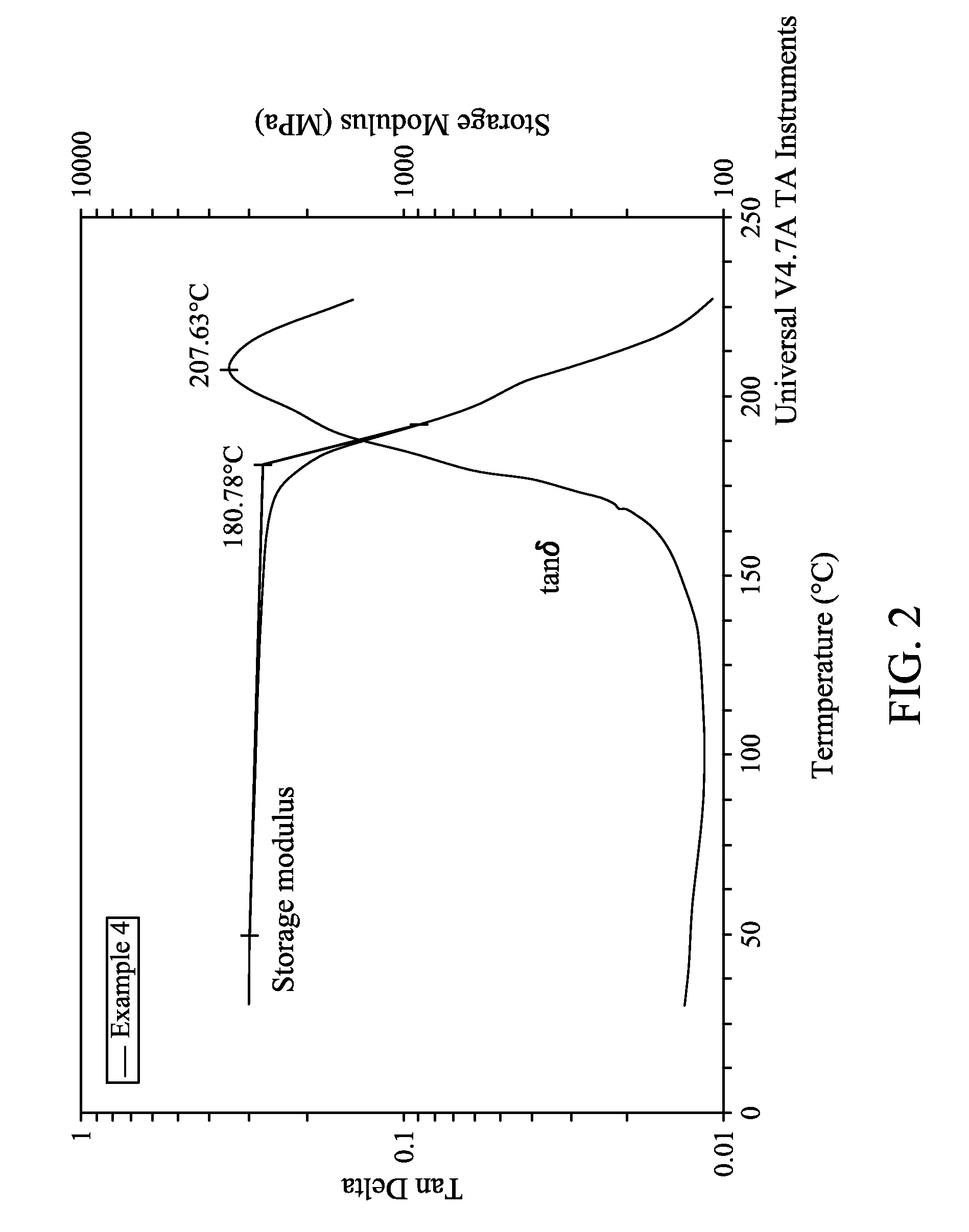

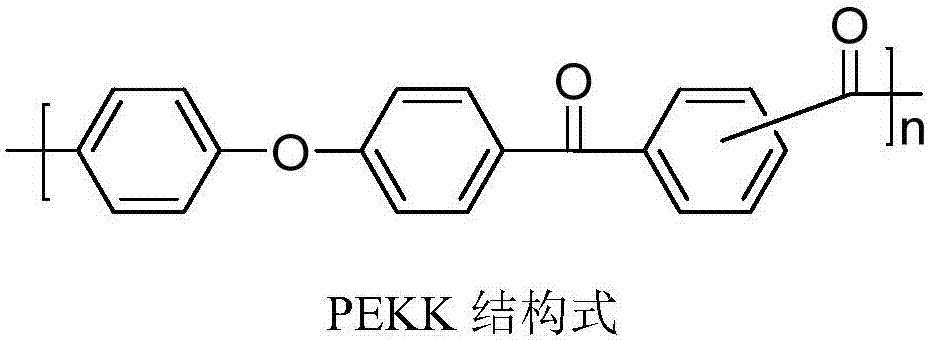

Polyetherketoneketone (PEKK) is a semi-crystalline thermoplastic in the polyaryletherketone (PAEK) family, with high heat resistance, chemical resistance and the ability to withstand high mechanical loads. PEKK's glass transition temperature (Tg) is 162°C.

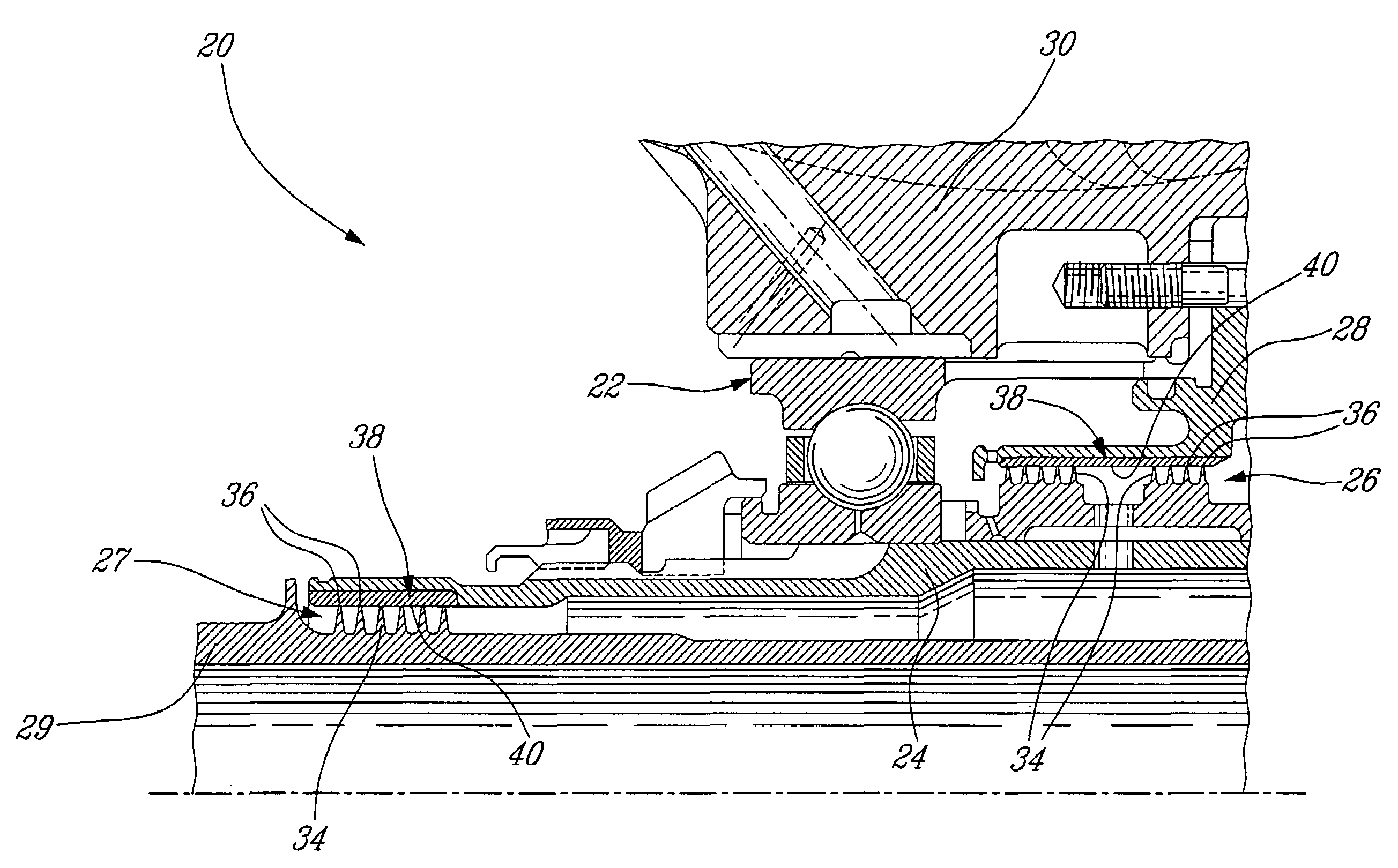

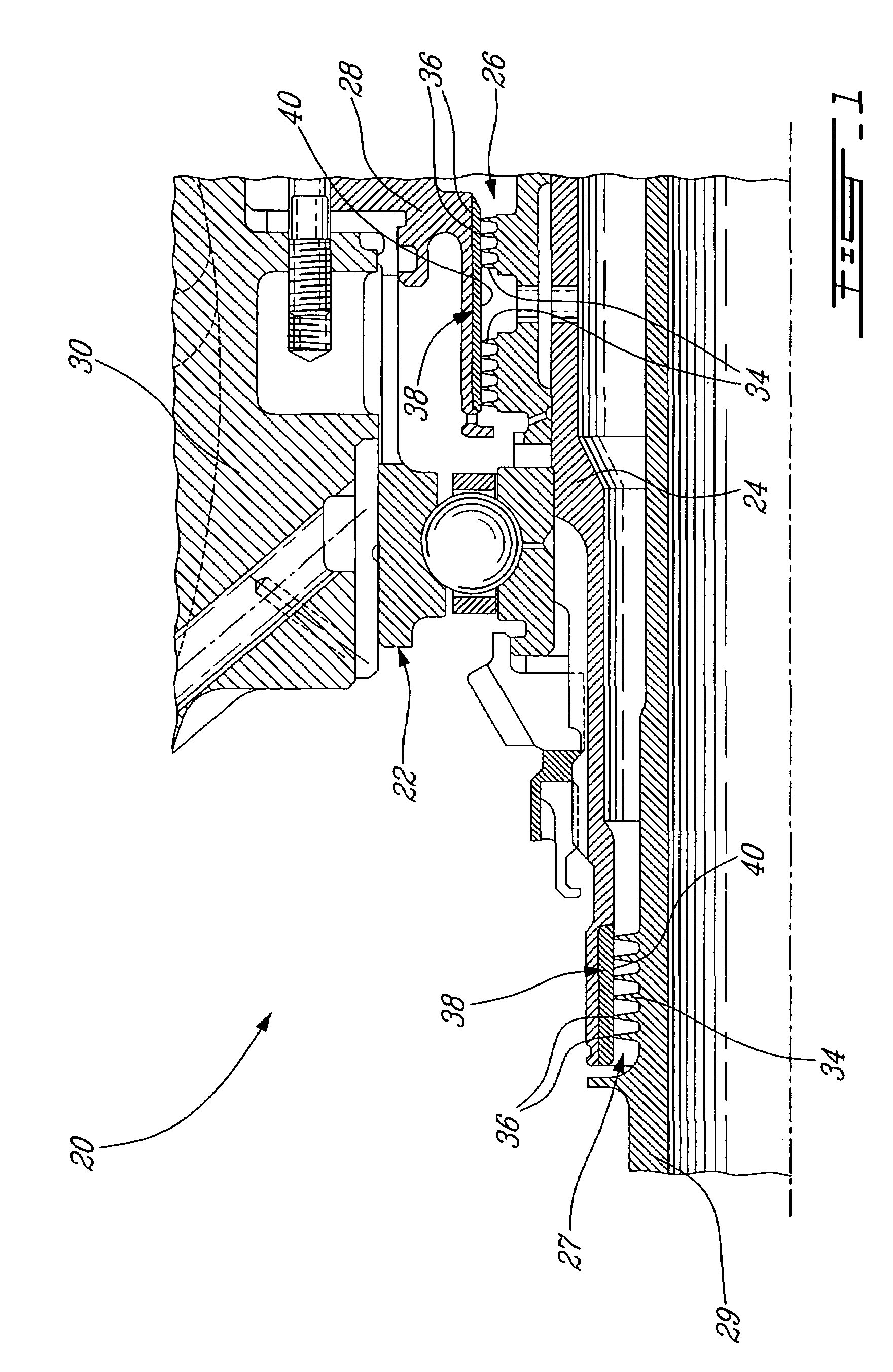

Air-oil seal

An air-oil seal having a runner surface comprising at least one component selected from the group consisting of: polyetheretherketone; polyetherimide; polyphenylene sulfide; and polyetherketoneketone.

Owner:PRATT & WHITNEY CANADA CORP

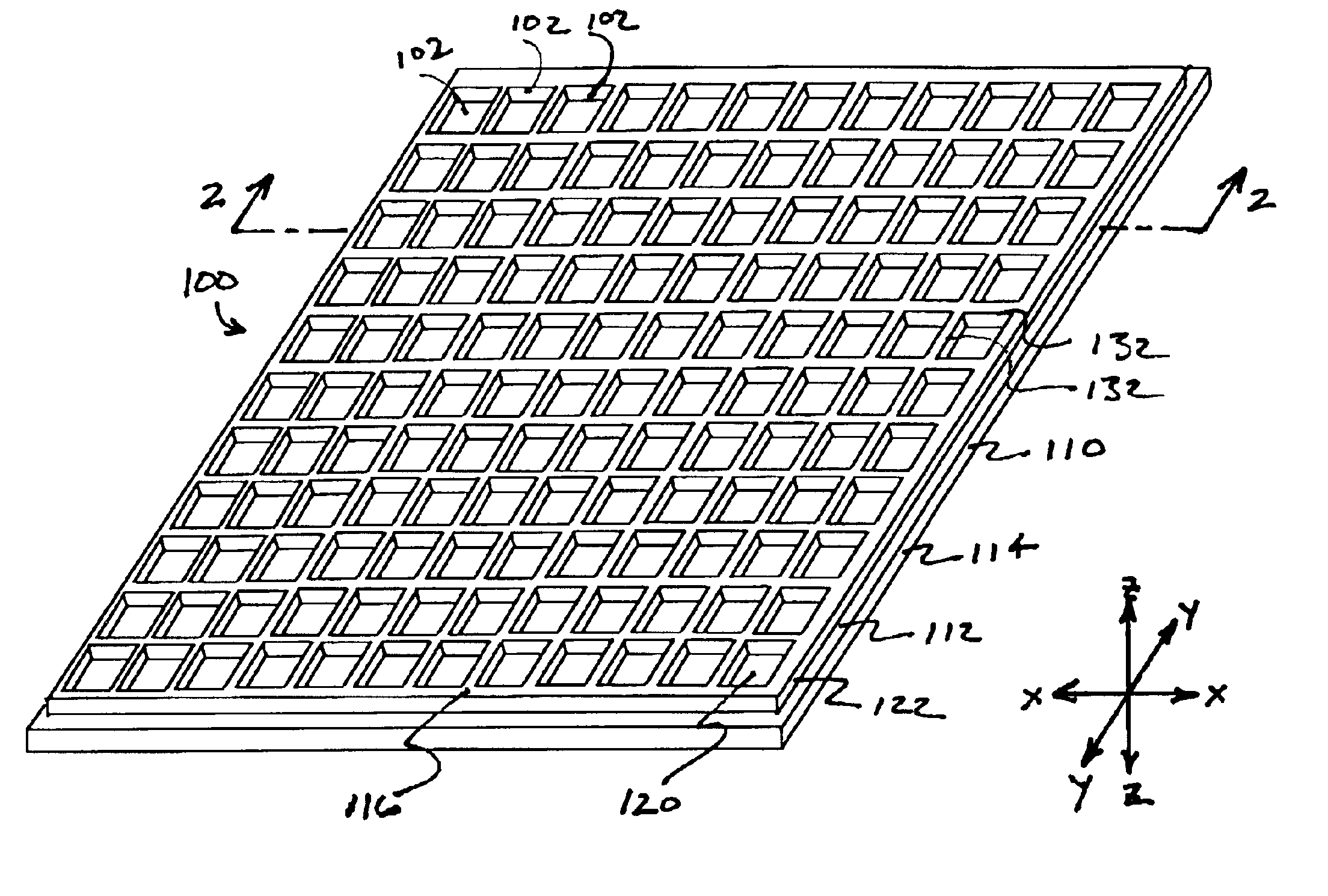

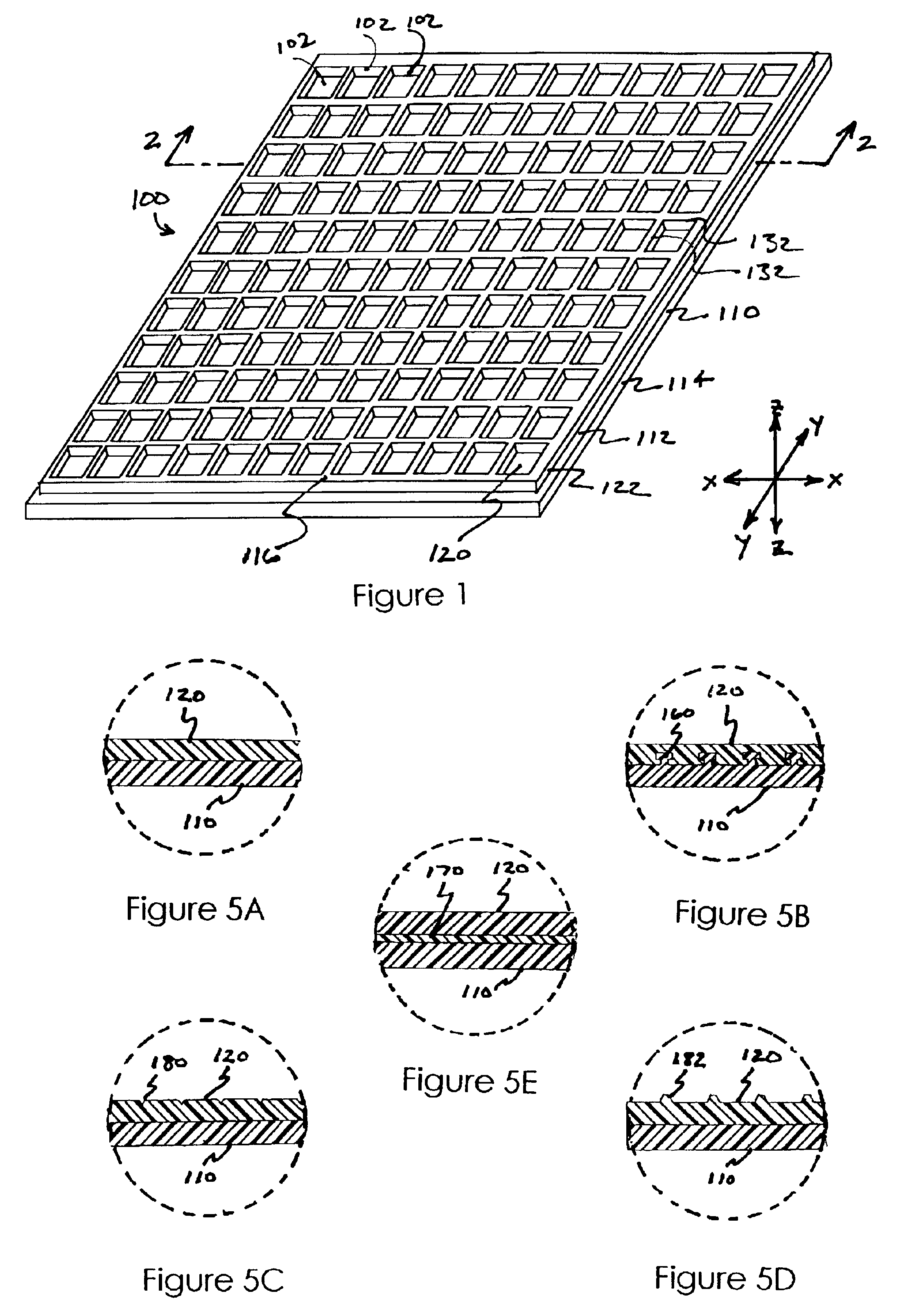

Matrix tray with tacky surfaces

InactiveUS6926937B2Widen meansSufficient forceEnvelopes/bags making machinerySemiconductor/solid-state device detailsPolyetherimidePolybutylene terephthalate

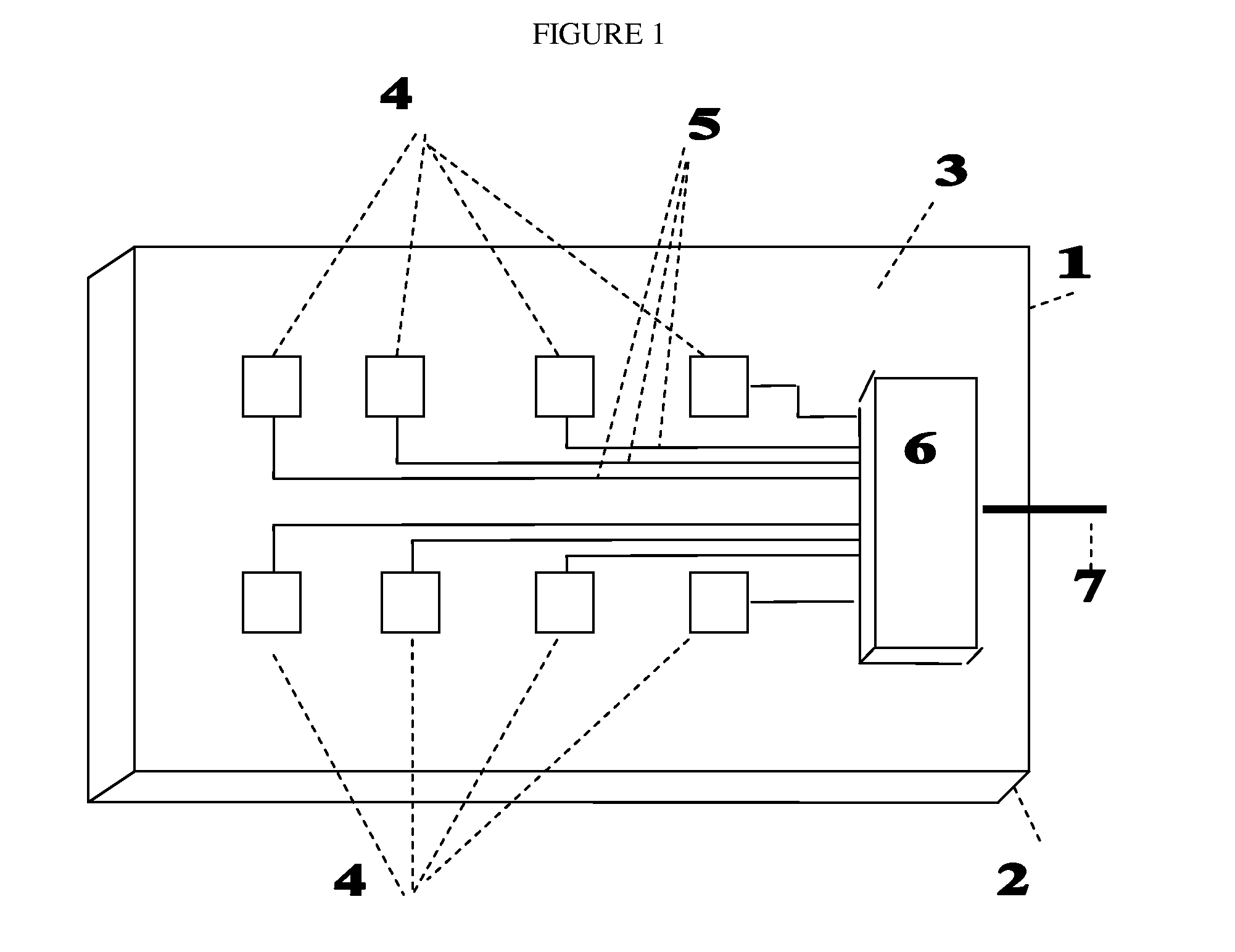

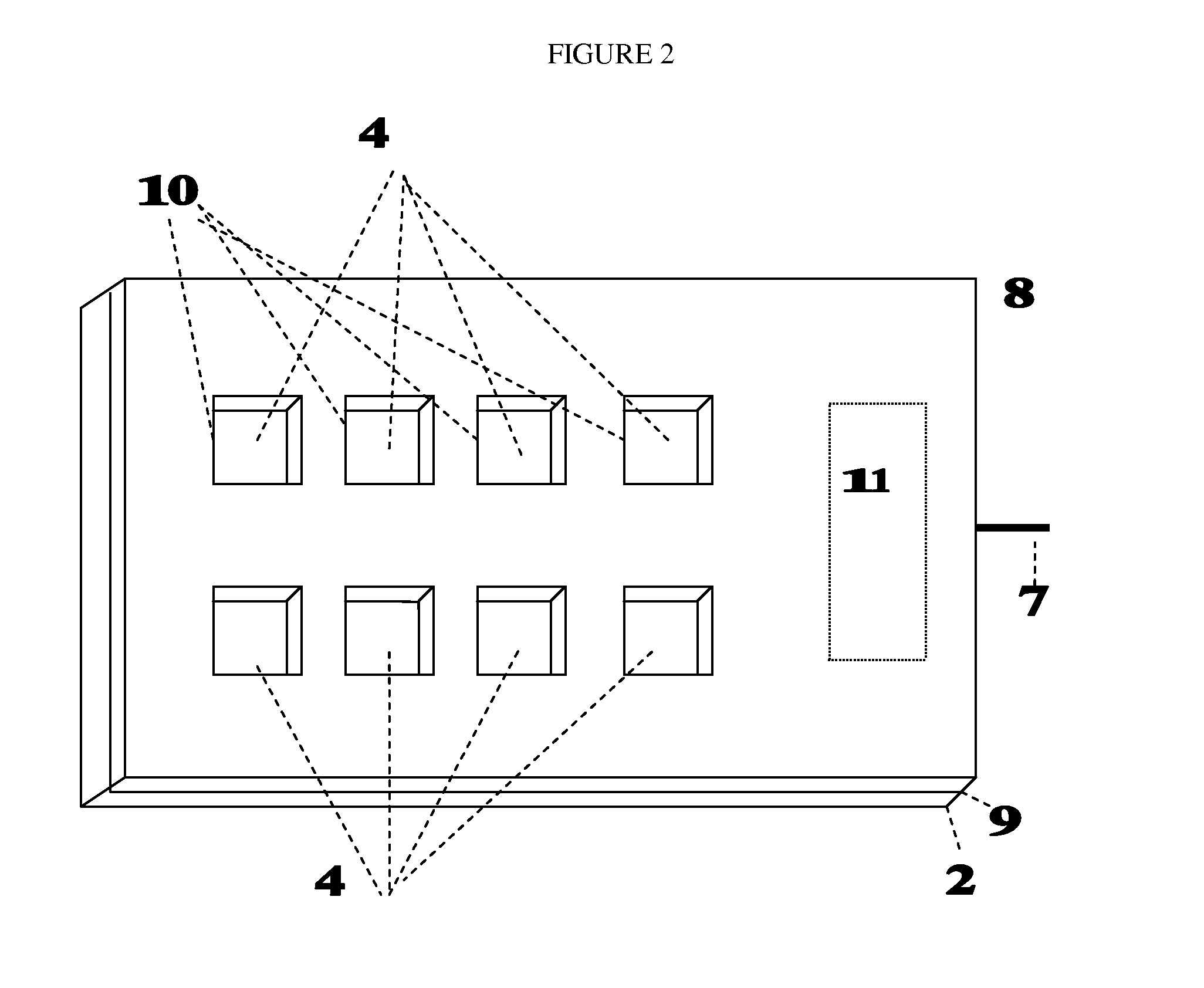

A tray for handling and retaining a plurality of small components comprising a rigid body portion with a plurality of pockets formed therein. Each of the pockets has an elastomeric contact surface for contacting and retaining a component. The contact surface may be formed from a thermoplastic material having a surface energy between 20 dyne / cm and 100 dyne / cm, and a surface electrical resistivity of between about 1×104 ohms / square and 1×1012 ohms / square. The material for the contact portion may be urethane, polybutylene terephthalate, polyolefin, polyethylene terephthalate, styrenic block co-polymer, styrene-butadiene rubber, polyether block polyamide, or polypropylene / crosslinked EDPM rubber. The body portion may be formed from acrylonitrile-butadiene-styrene, polycarbonate, urethane, polyphenylene sulfide, polystyrene, polymethyl methacrylate, polyetherketone, polyetheretherketone, polyetherketoneketone, polyether imide, polysulfone, styrene acrylonitrile, polyethylene, polypropylene, fluoropolymer, polyolefin, or nylon. The body portion may have a peripheral border region and a downwardly projecting skirt portion to facilitate stacking of multiple trays.

Owner:ENTEGRIS INC

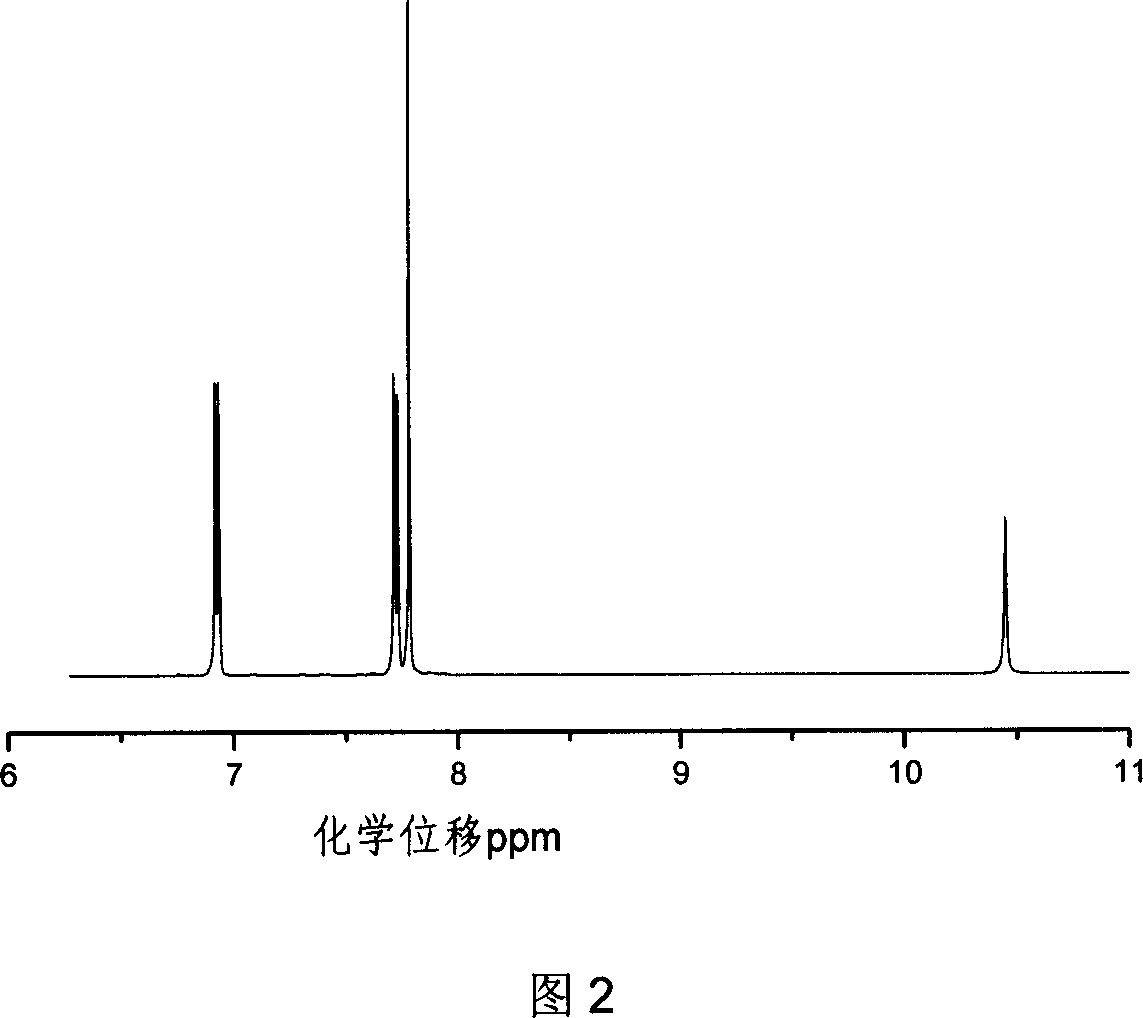

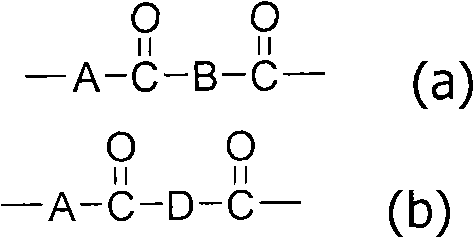

Prepn process of poly (ether-ketone-ketone) as high performance polymer

The present invention belongs to the field of polymer material, and is especially the preparation process of poly(ether-ketone-ketone) prepared through polymerizing bisphenol and bifluoric monomer. The preparation process includes adding bis-(4-hydroxybenzoyl)-benzene, bis-1, 4-(4-fluorobenzoyl)-benzene or bis-1, 3-(4- fluorobenzoyl)-benzene, Na2CO3 as salt-forming agent and diphenyl sulfone as solid solvent into flask with mechanical stirrer, thermometer and nitrogen duct; introducing high purity nitrogen, heating to 100-130 deg.c and stirring to melting solid matter completely; heating slowly to react; pouring the reaction product into water to separating out white solid; crushing, washing with acetone and water for several times, drying at 80-150 deg.c for 10-20 hr to obtain polymer in the yield over 90 %.

Owner:JILIN UNIV

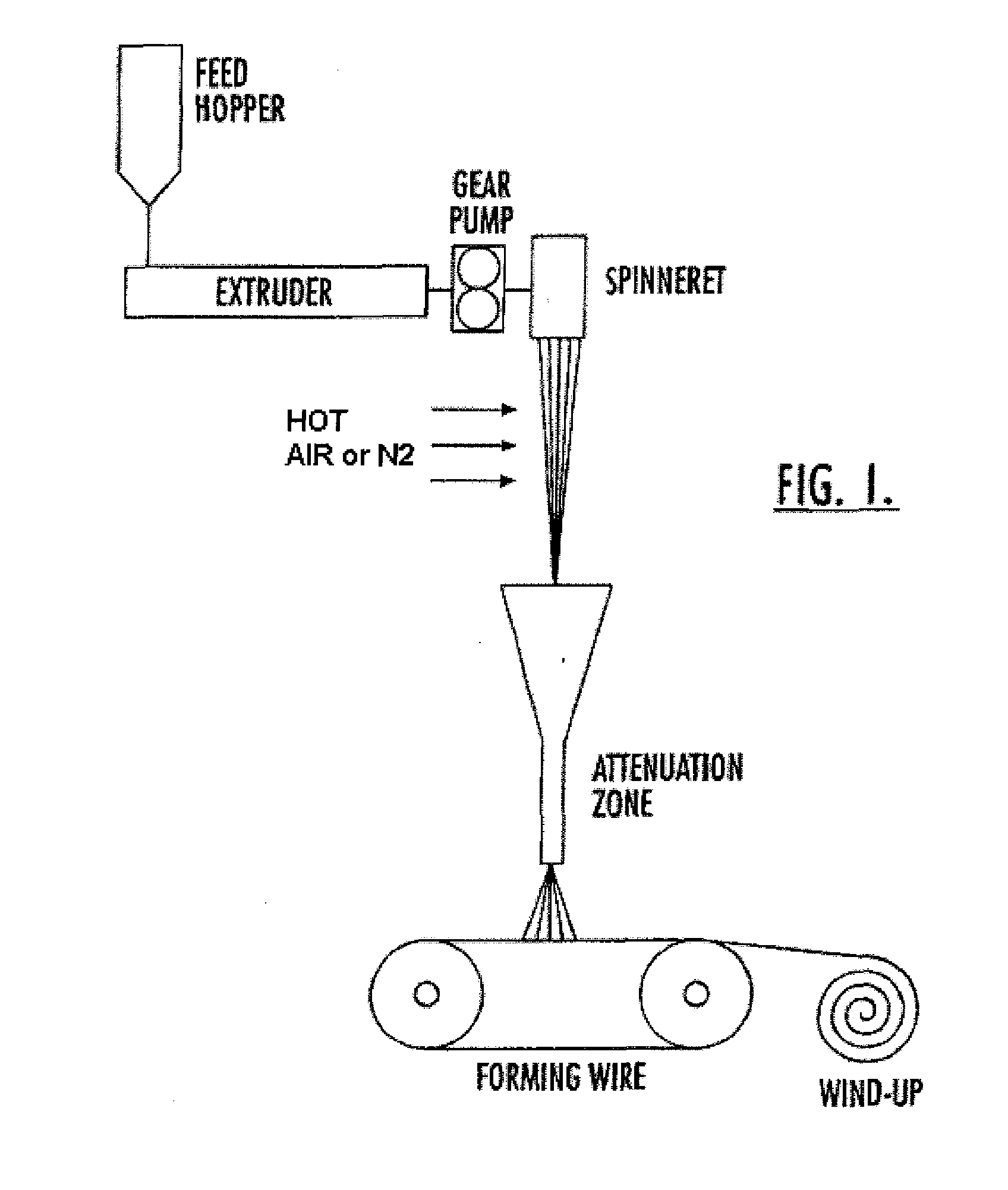

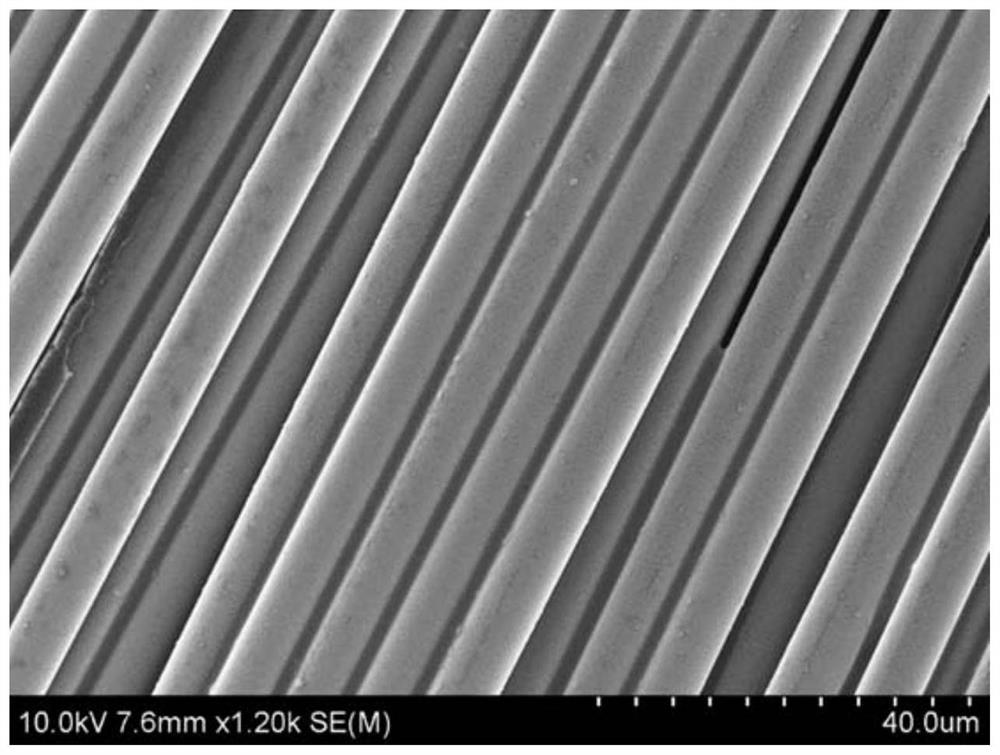

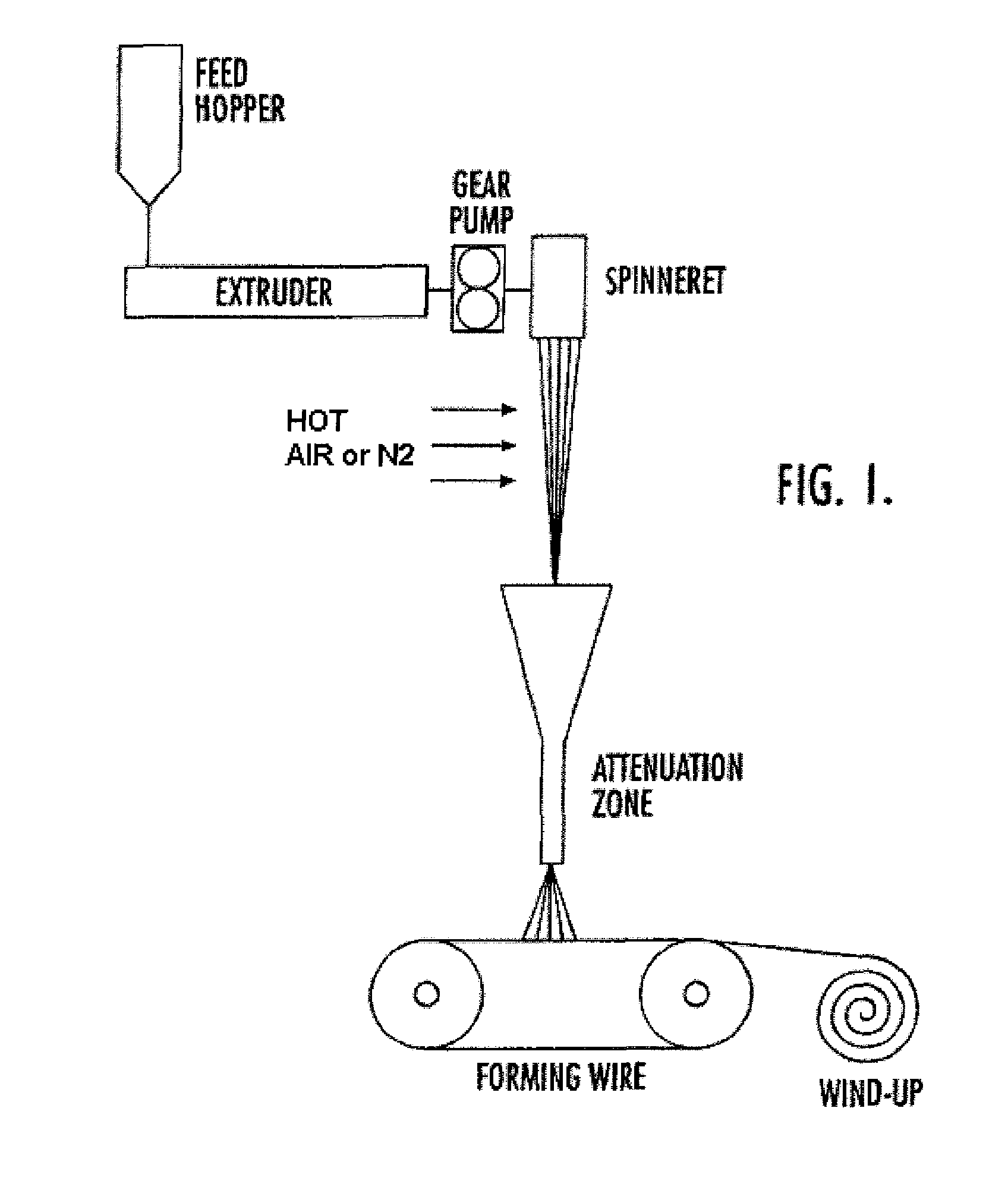

Polyetherketoneketone nonwoven mats

ActiveUS20120015577A1Decreasing TsLow creepSynthetic resin layered productsWoven fabricsFiberPolyetherketoneketone

The invention provides nonwoven mats comprising polyetherketoneketone fibers or mixtures thereof. Also provided are filters, textiles, blankets, and insulation prepared from polyetherketoneketone nonwoven mats, as well as methods for manufacturing the same.

Owner:ARKEMA INC

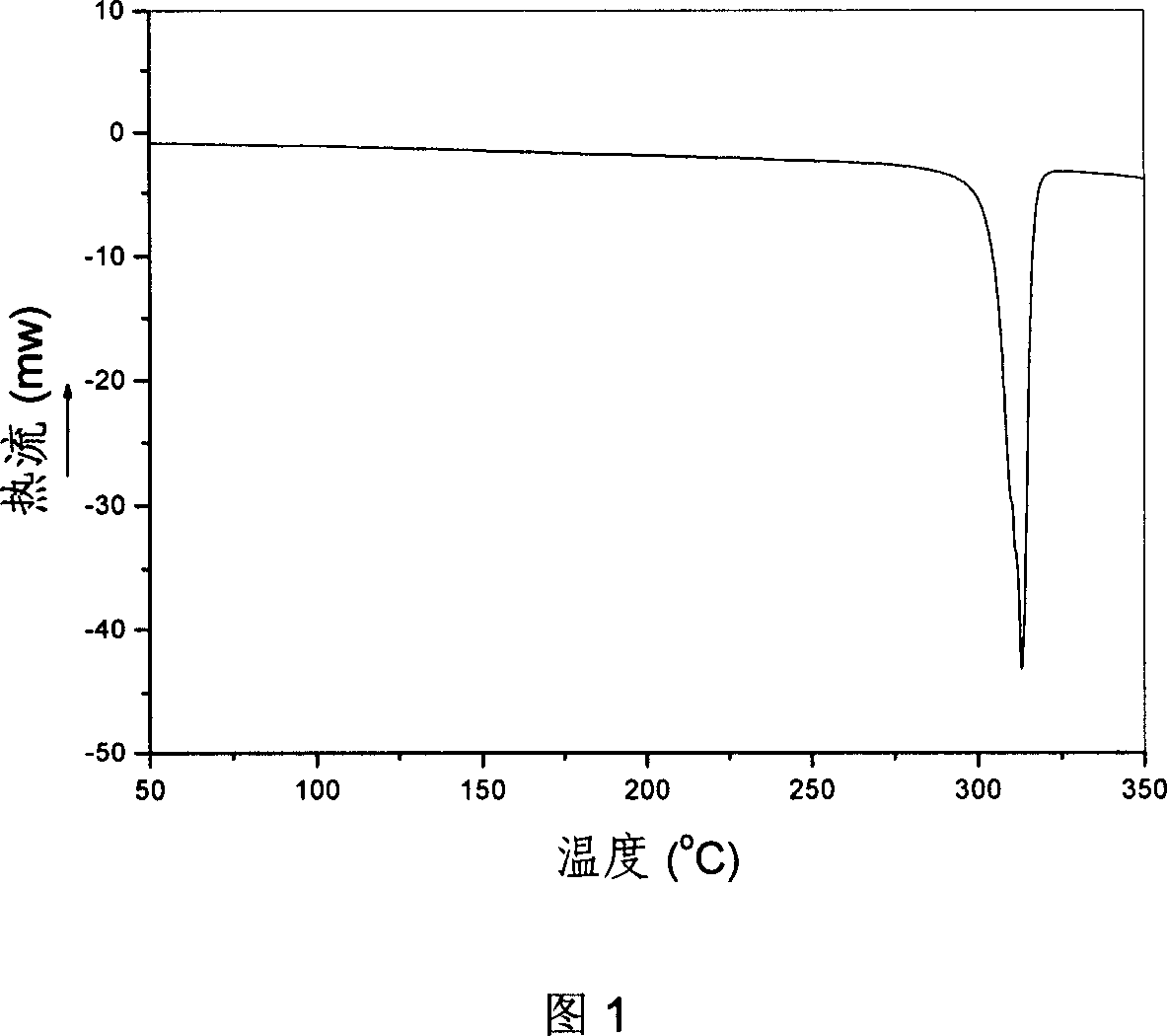

Method for preparing high glass-transition temperature crystal type polyethylene-ketone-ketone resin material

The invention belongs to a new high performance and high polymer material synthesis field, in particular to a method for preparing a novel high glass-transition temperature crystal type polyethylene-ketone-ketone resin material in a such way that a monomer solutions of diphenyl ether and aromatic acyl chloride are dropwise added in a system, and a Friedel-Crafts low temperature solution electrophilic substitution polymerization is carried out. The viscosity of the resin materials synthesized by the method can be precisely controlled within 0.50-1.10+ / -0.10 dL / g, the glass-transition temperature can be controlled between 168 DEG C and 175 DEG C, and the melting temperature can be controlled between 310 DEG C and 360 DEG C. Compared with the FC of the same kind of already commercialized products, under the condition that the materials maintain excellent melting processing performance, the polymer has the glass-transition temperature 15 DEG C higher than that of the products, so that the invention has excellent heatproof performance.

Owner:昆山普利米斯聚合材料有限公司

Method Of Sizing Of Fibers And Articles Manufactured From The Same

The method includes the steps of functionalizing a polyaryletherketone (PAEK) polymer, and blending the PAEK polymer with water to form a sizing composition. The method may further include the step of applying the sizing composition to a fiber. The method may further include the step of heating the fibers, coated with sizing composition, for example to between 300C-400C. In some methods, the functionalized PAEK polymer comprises functionalized polyetherketoneketone (PEKK). In yet other methods, the functionalized PAEK polymer comprises sulfonated PEKK (sPEKK).

Owner:OXFORD PERFORMANCE MATERIALS

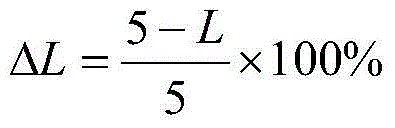

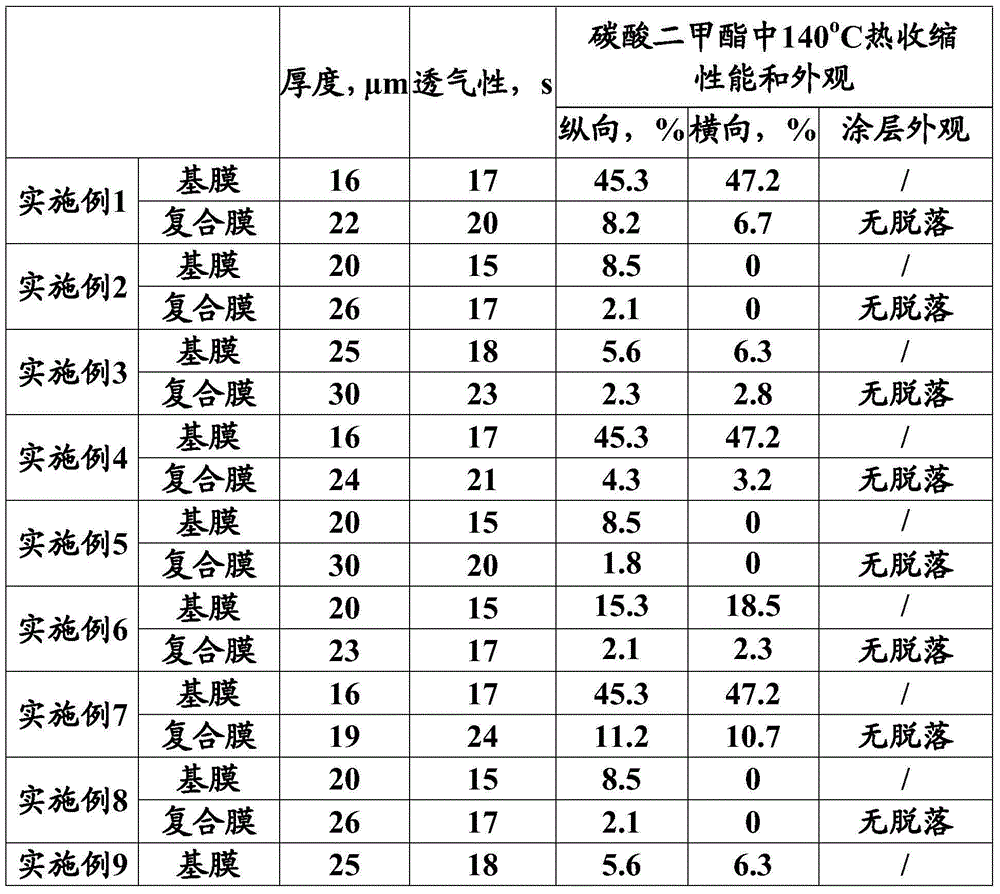

Lithium ion battery composite separation membrane and lithium ion battery containing lithium ion battery composite separation membrane

InactiveCN105390643AEnsure safetyImproved resistance to heat shrinkageSecondary cellsCell component detailsPorous substratePolyetherimide

The present invention relates to a lithium ion battery composite separation membrane, which comprises: (a) a porous substrate having pores; and (b) an organic / inorganic composite layer formed by coating at least a surface of the porous substrate or partial surface area of the porous substrate with a mixture containing inorganic particles, one or a plurality of polymer binders selected from polyetherimide, polyetherketoneketone and polyisophthaloyl metaphenylene diamine, and an optional high temperature closed-cell material, wherein the inorganic particles are connected and are fixed with the polymer binder, and the gap between the inorganic particles forms the pore. According to the present invention, the organic / inorganic composite layer on the separation membrane is firmly bonded onto the porous substrate, and the polymer binder in the organic / inorganic composite layer substantially does not swell in the electrolyte, and further has good heat-shrinkage resistance so as to ensure the safety performance of the lithium ion battery. The present invention further relates to a method for preparing the composite separation membrane and an ion battery containing the composite separation membrane.

Owner:BEIJING NORMAL UNIVERSITY

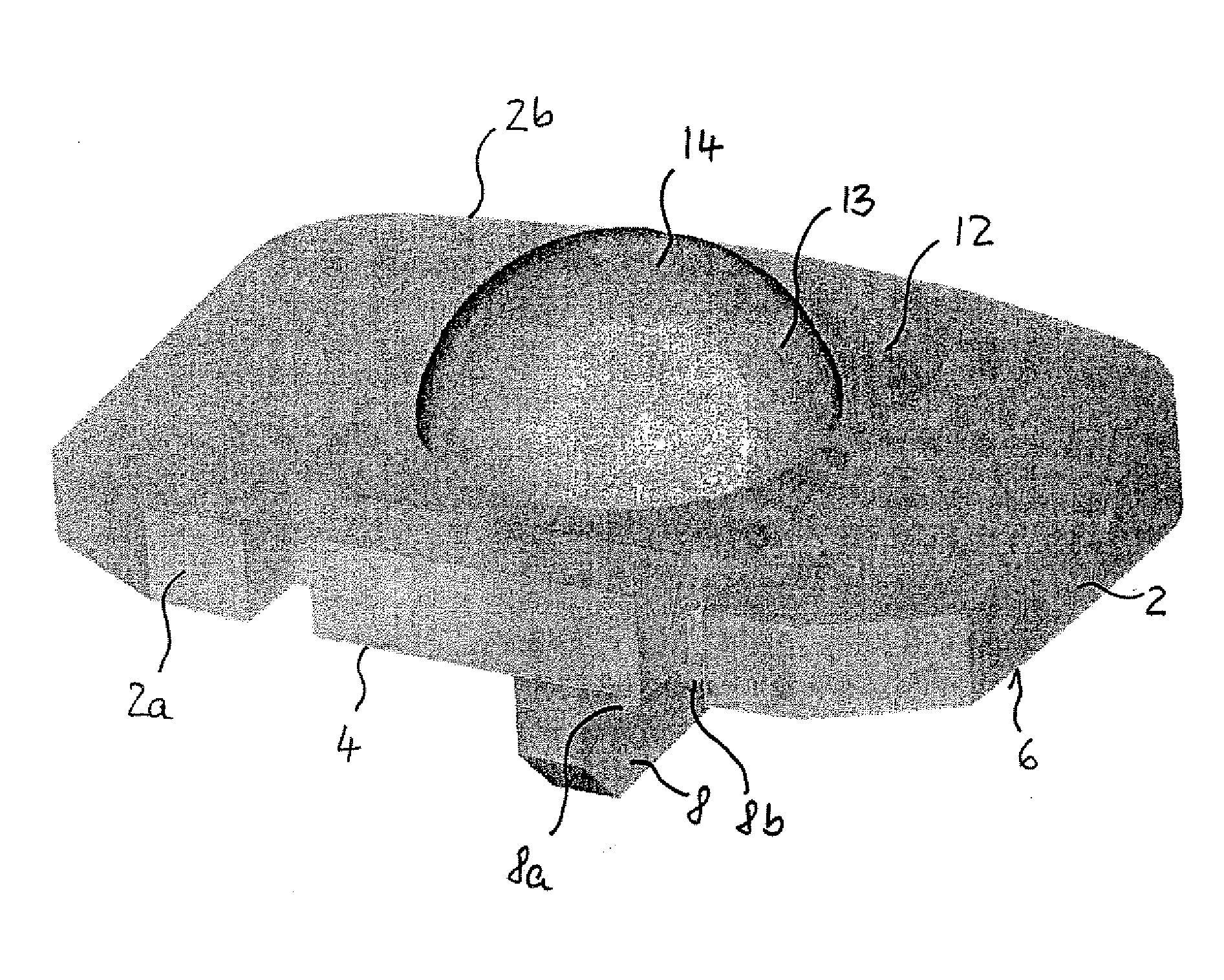

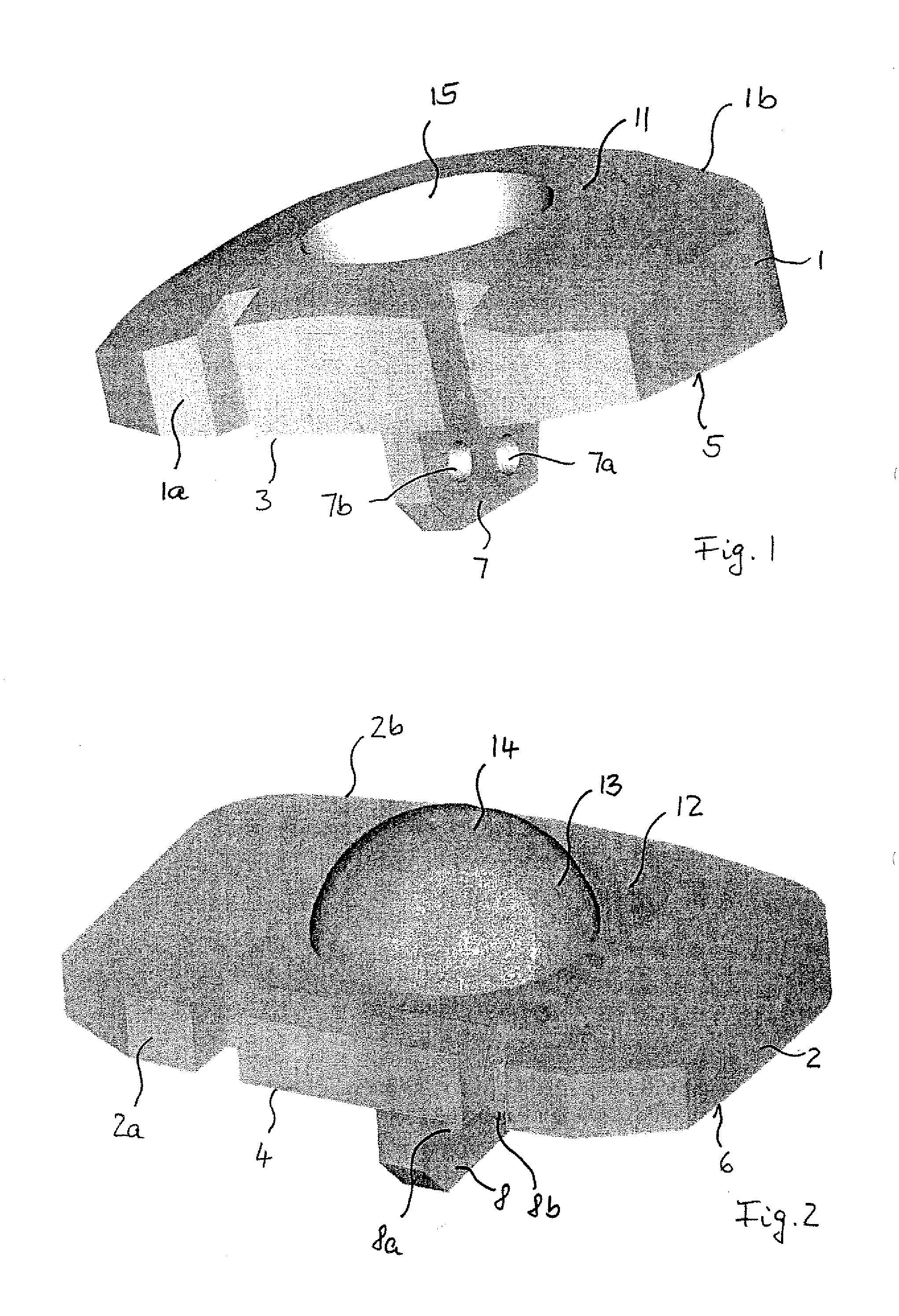

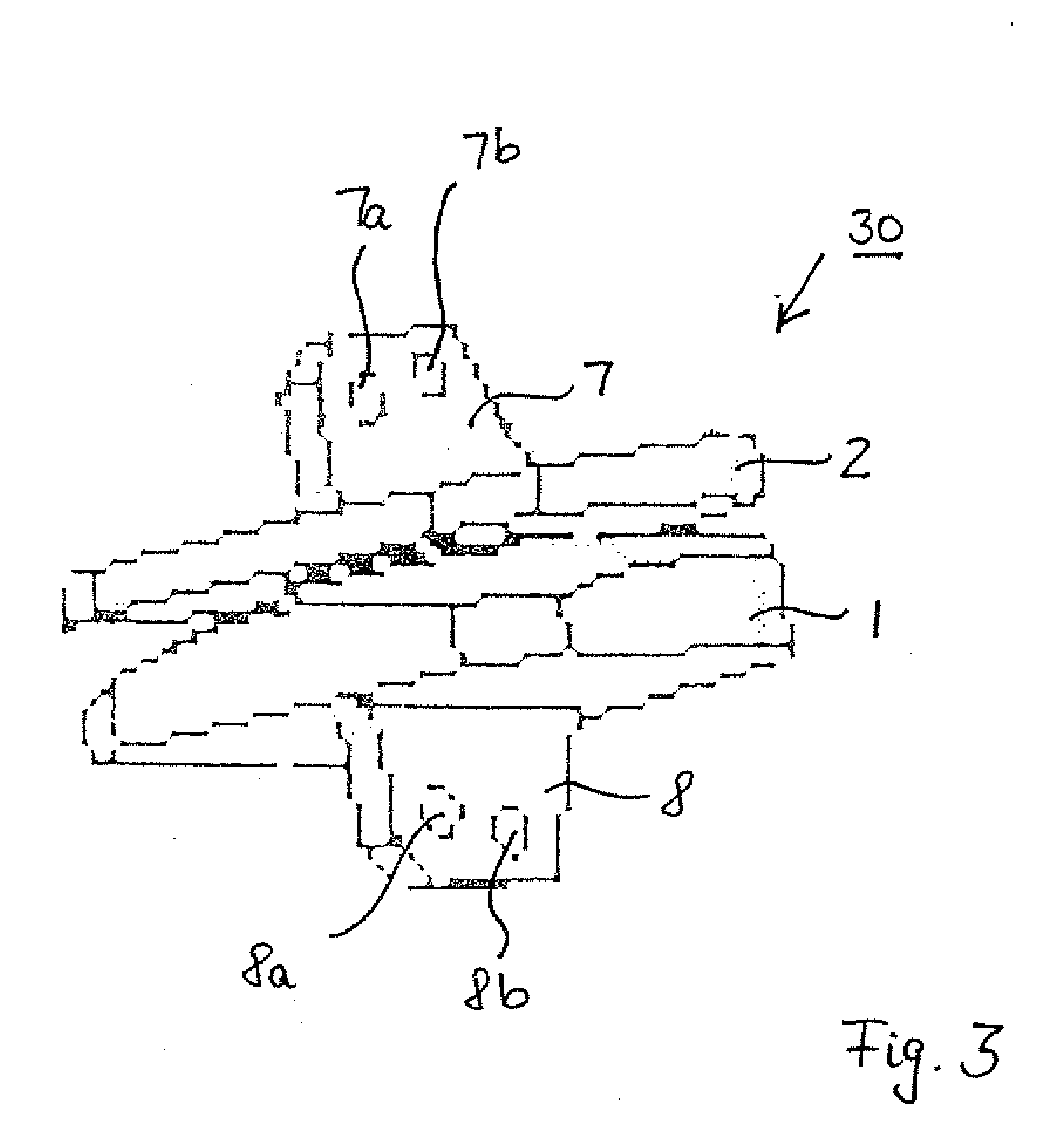

Parts Assembly and Part for a Prosthesis

InactiveUS20090043390A1Manufactured smallCost-effectiveJoint implantsSpinal implantsIntervertebral discProsthesis

The invention relates to a parts assembly for a prosthesis, particularly a cervical spine intervertebral disc prosthesis, comprising two base parts (1, 2), which are coupled to one another in an articulated manner by means of coupling parts (11, 12) formed on said base parts. These base parts, together with an associated coupling part, are provided as a single piece. The base parts and the coupling parts are made of one material, which is selected from the following group of materials: polyetherketone (PEK) polyetheretherketone (PEEK), polyacryletherketone (PAEK), polyetherketoneketone (PEKK), polyetherketoneetherketoneketone (PEKEKK) and polyetherketoneetherketone (PEKEK).

Owner:MEISEL HANS JORG

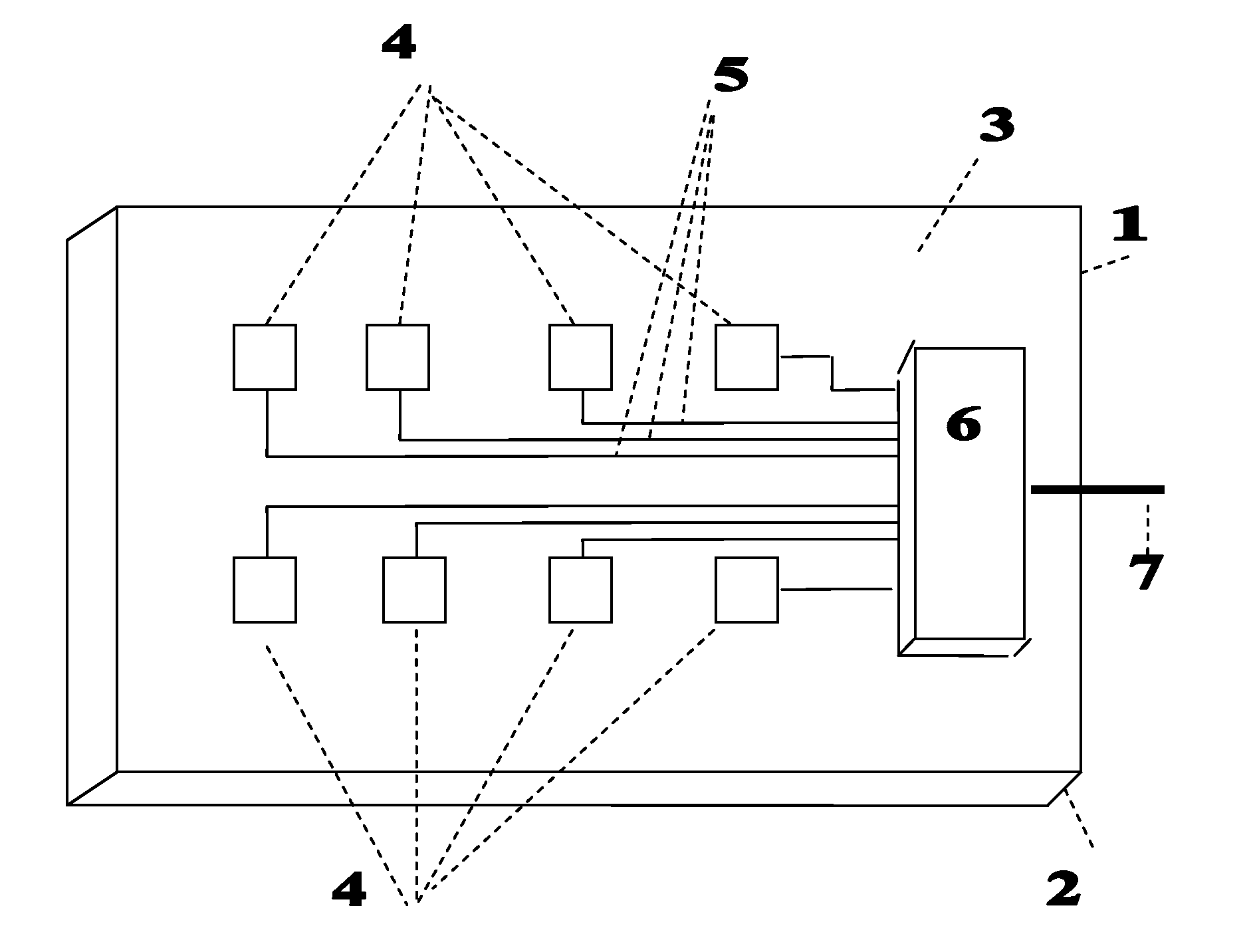

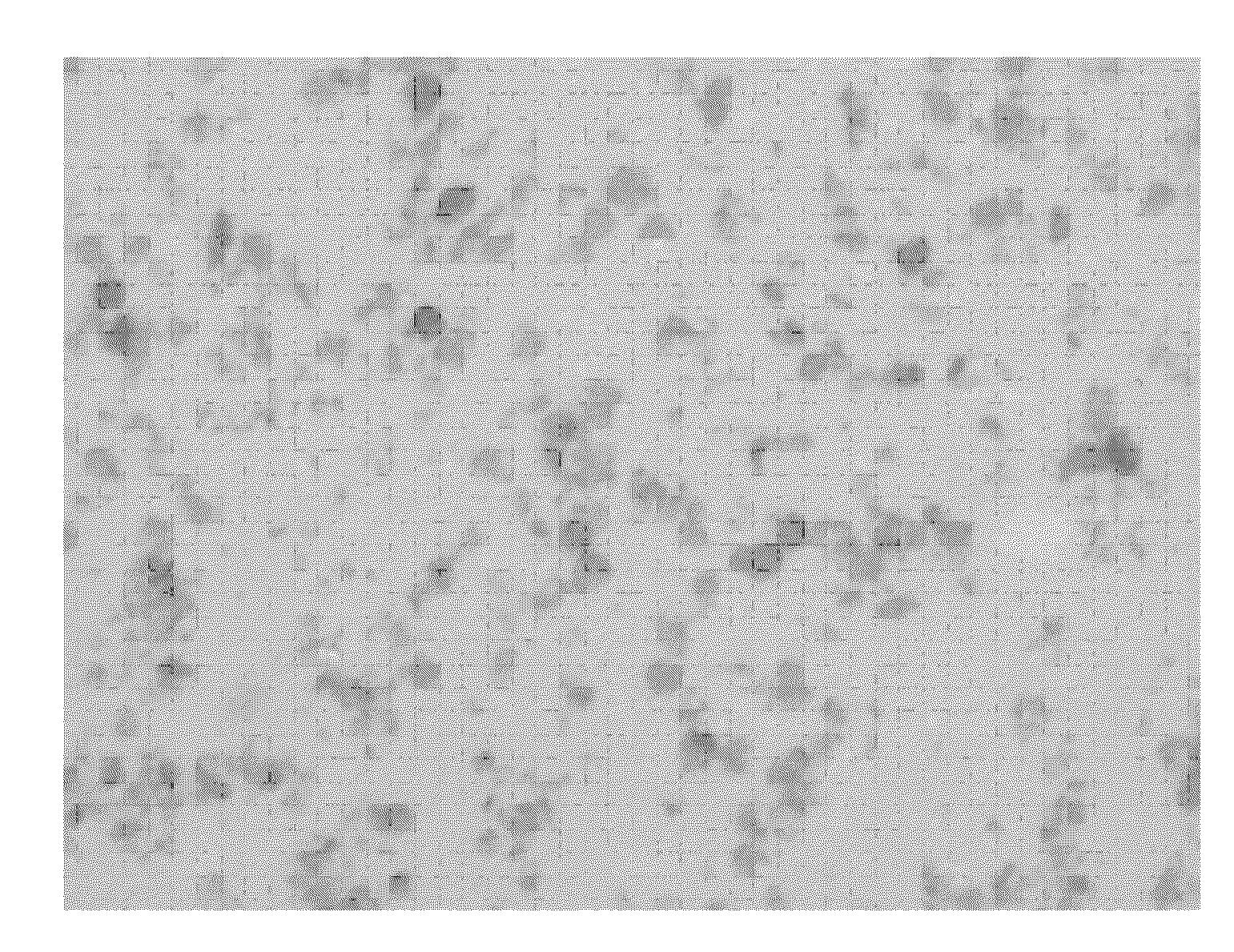

Electrode arrays based on polyetherketoneketone

InactiveUS20110307042A1Exceptional resistance to solvent and waterImprove relationshipSpinal electrodesPrinted circuit assemblingMedical deviceMedical treatment

Laminated assemblies containing electrode-bearing layers comprised of polyetherketoneketone are useful in the fabrication of implantable medical devices.

Owner:OXFORD PERFORMANCE MATERIALS

Methods and Systems For Local Administration of Therapeutics

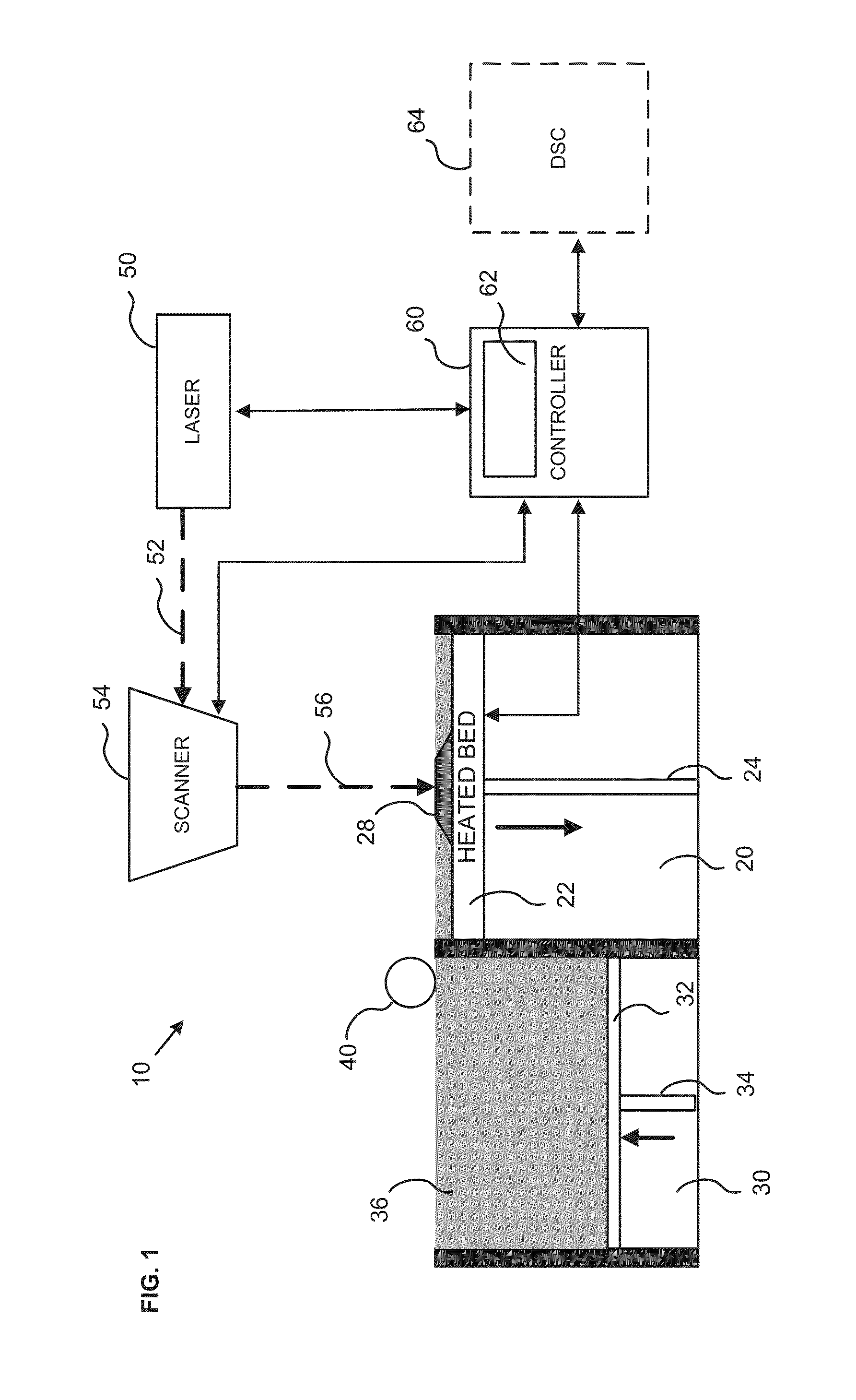

InactiveUS20160166284A1Promotes bone formationReduce image noiseAdditive manufacturing apparatusSurgerySelective laser sinteringOsseointegration

A load-bearing implant includes a body with a shape fabricated using selective laser sintering, the body being made of Polyetherketoneketone, at least one reservoir forming an internal cavity inside the body, the reservoir having an opening that provides fluid access to the internal cavity from outside the body, at least one fluid channel extending through the body between the at least one reservoir and an exterior surface of the body, and a fluid stored in the reservoir, the fluid facilitating osseointegration between the body and a bone. The at least one fluid channel communicates the fluid from the reservoir to the exterior surface of the body and provides a controlled rate of delivery of the fluid through at least one outlet in the exterior surface of the body.

Owner:OXFORD PERFORMANCE MATERIALS

Fibers sized with polyetherketoneketones

ActiveUS20110294943A1Improve adhesionGood dispersionCarbon fibresSynthetic resin layered productsFiberPolymer science

Fibers sized with a coating of amorphous polyetherketoneketone are useful in the preparation of reinforced polymers having improved properties, wherein the amorphous polyetherketoneketone can improve the compatibility of the fibers with the polymeric matrix.

Owner:ARKEMA FRANCE SA

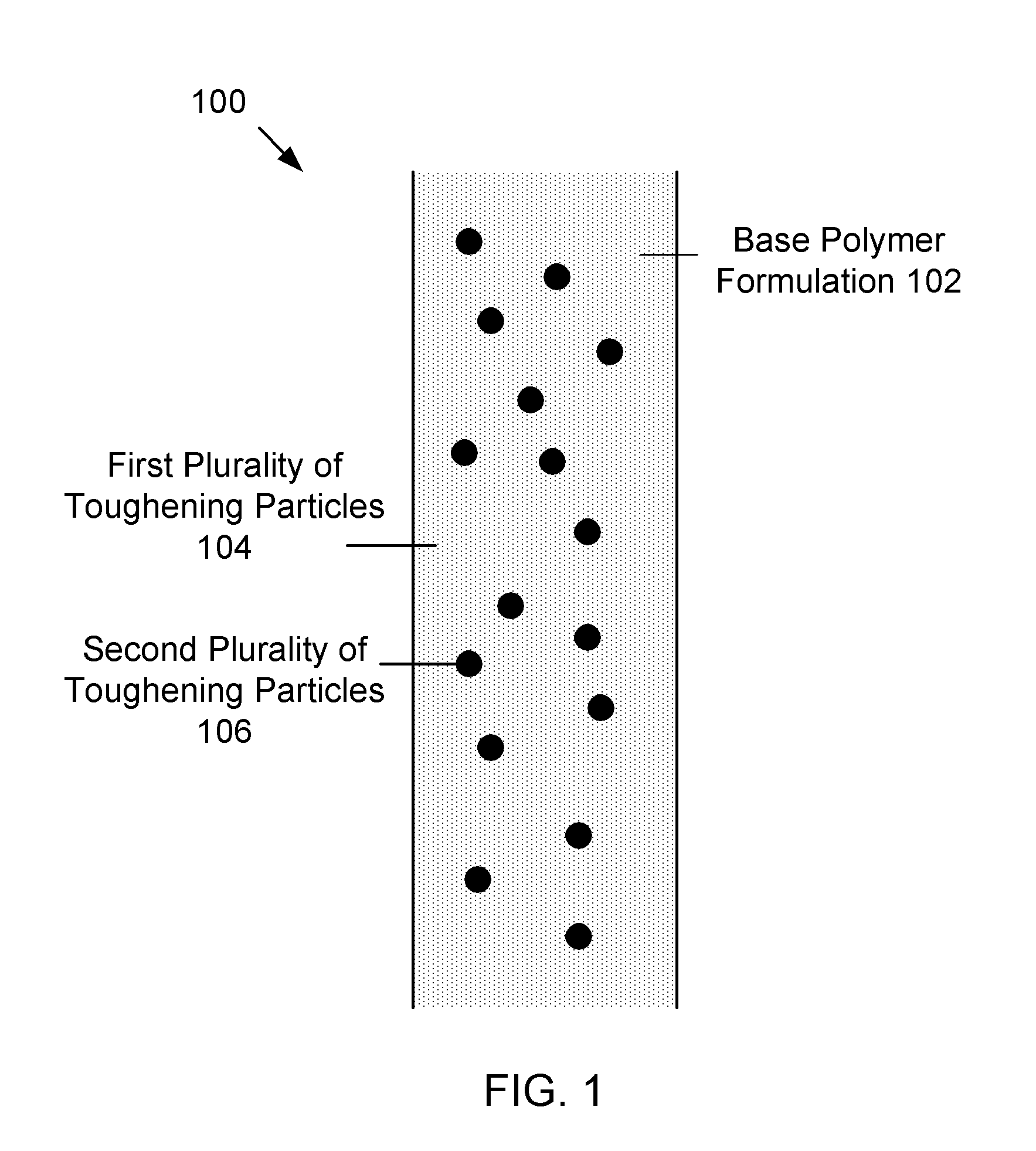

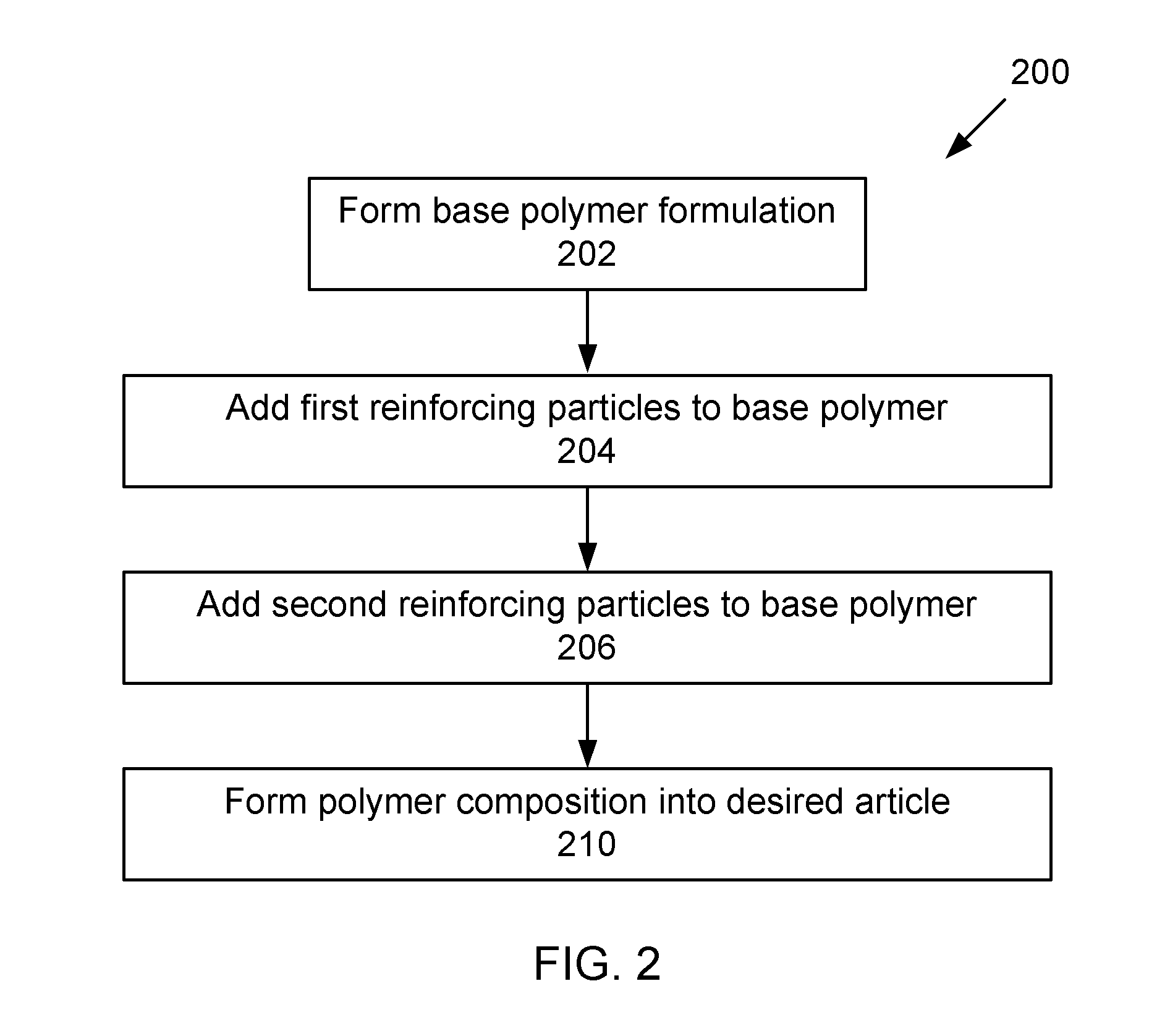

Particle-toughened polymer compositions

ActiveUS20100305274A1Interference be notOther chemical processesHeat-exchange elementsPolyetherimideKetone

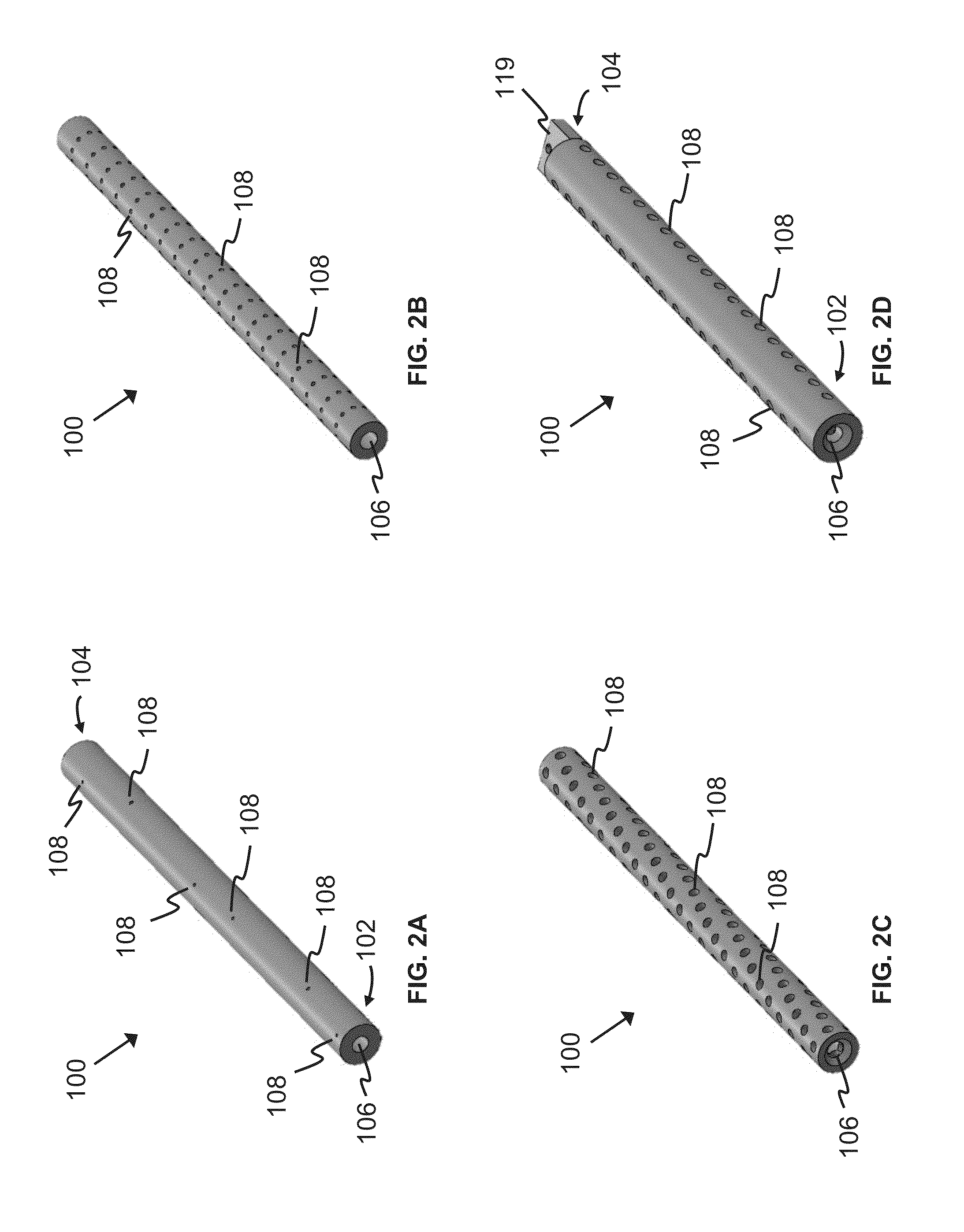

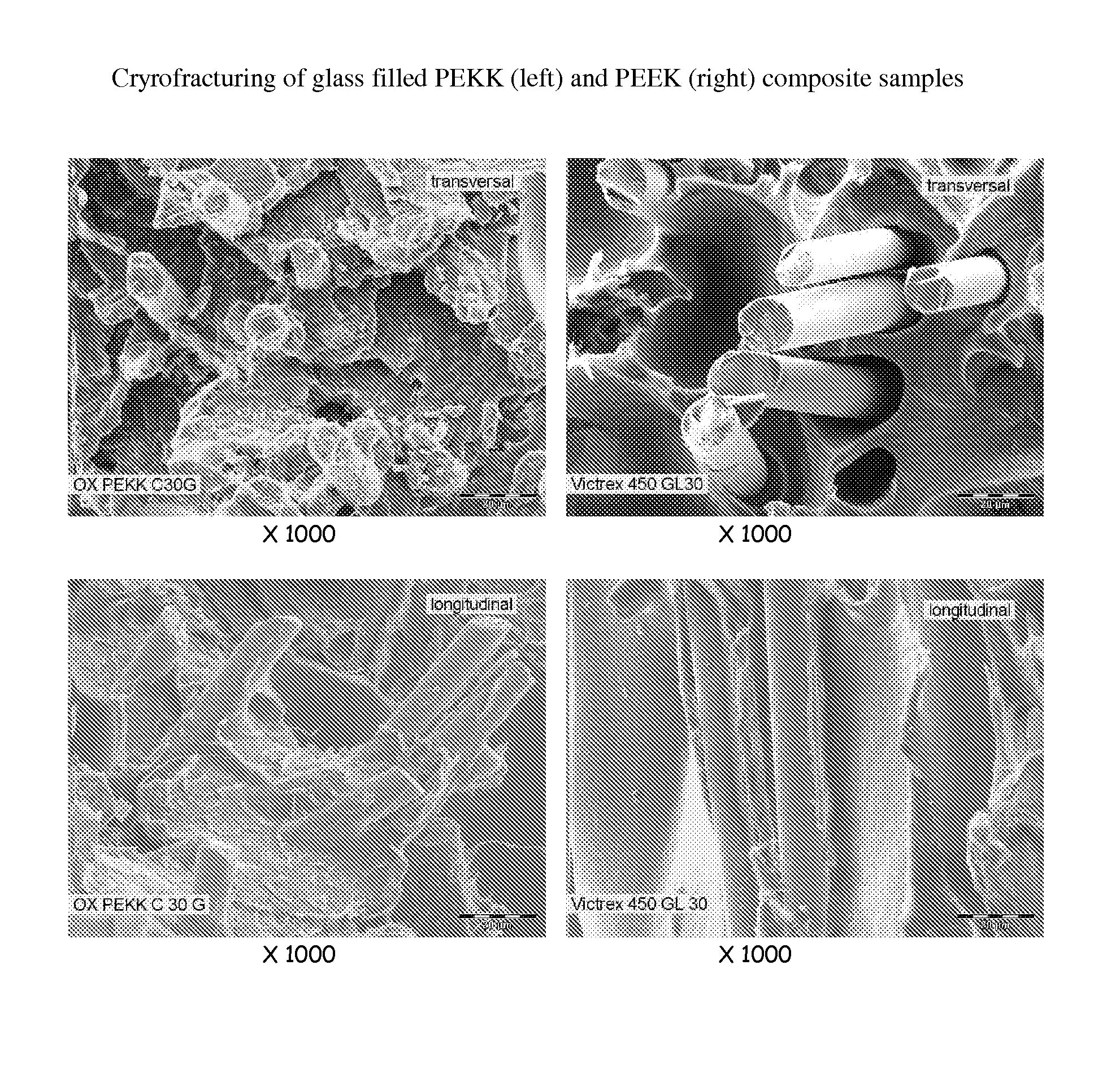

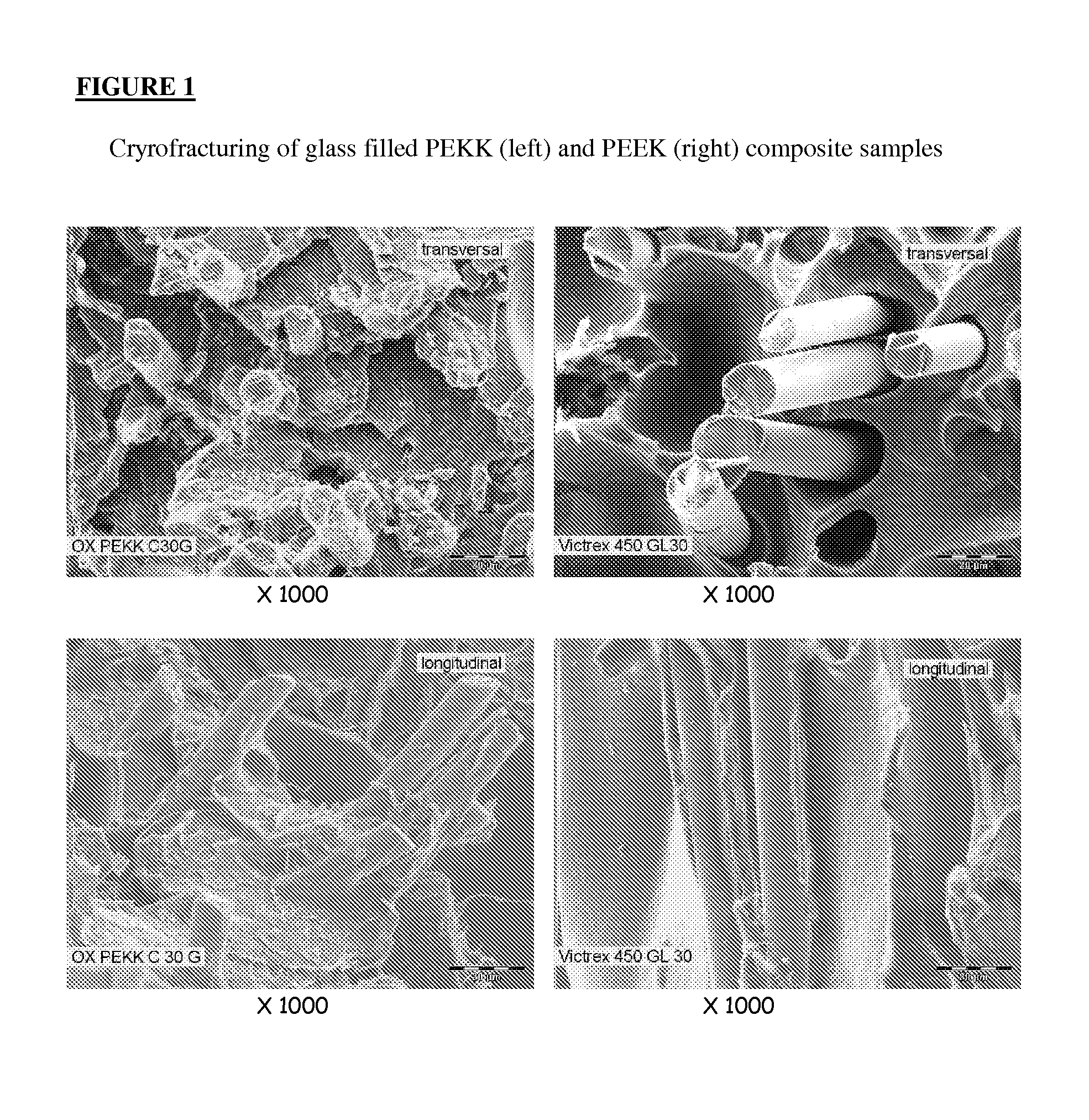

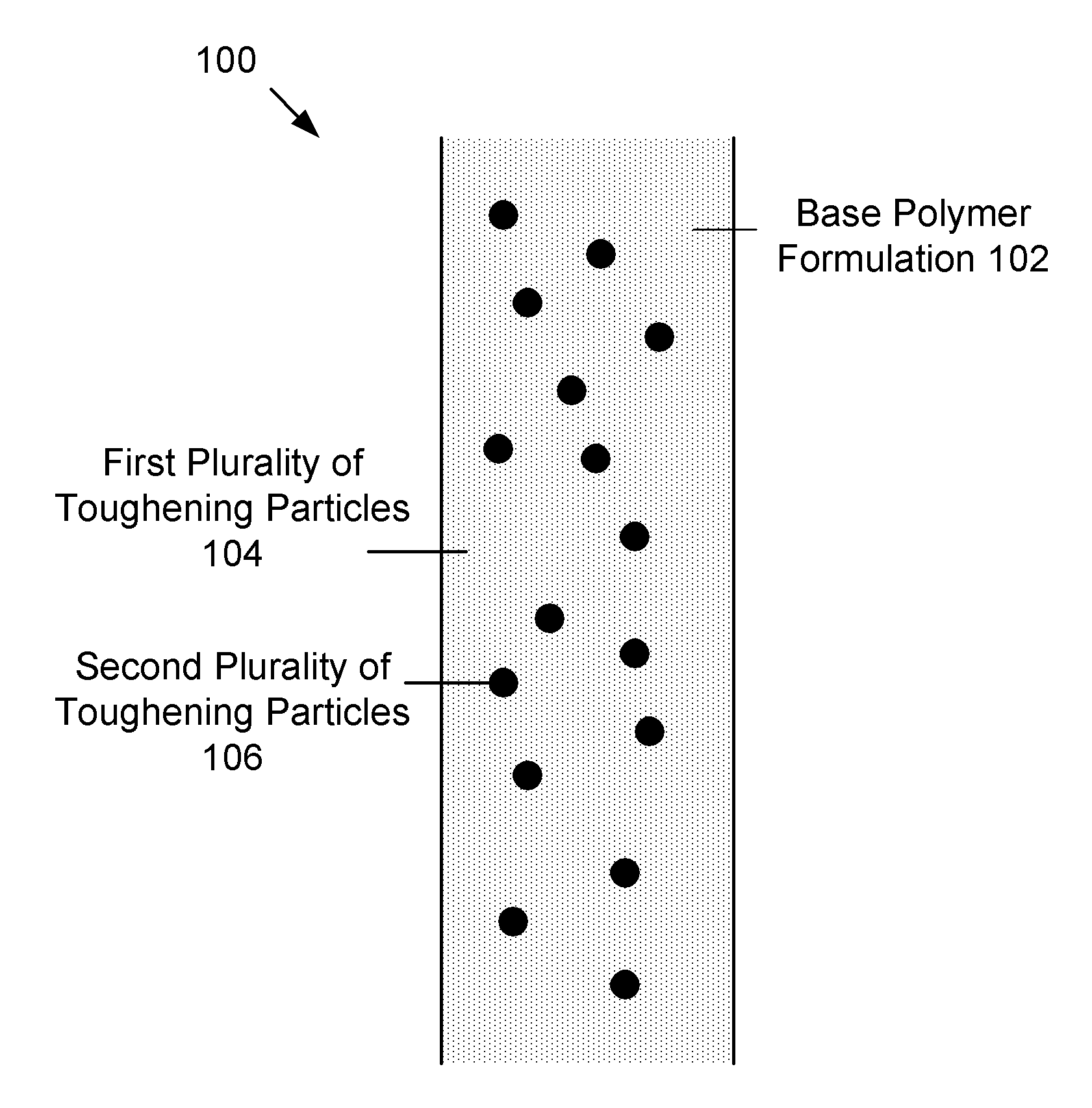

Particle-toughened polymer compositions include a base polymer formulation and a plurality of toughening particles. In certain embodiments, the base polymer formulation includes bismaleimides or other polymer resins capable of high temperature service. A first plurality of toughening particles may include core shell rubbers. A second plurality of toughening particles may be selected from a variety of polymer compositions, including polyimides, polyether ketone (PEK), polyether ether ketone (PEEK), polyether ketone ketone (PEKK), polyether imide, polyether sulfones, and polyphenylene oxide. It is found that increasing concentration of the core shell rubbers may improve the toughness of the composition while preserving thermal properties of the composition, such as glass transition temperature.

Owner:CYTEC TECH CORP

Assemblies containing polyetherketoneketone tie layers

Tie layers comprised of amorphous polyetherketoneketone are used to join substrates to form laminates and other assemblies.

Owner:ARKEMA INC

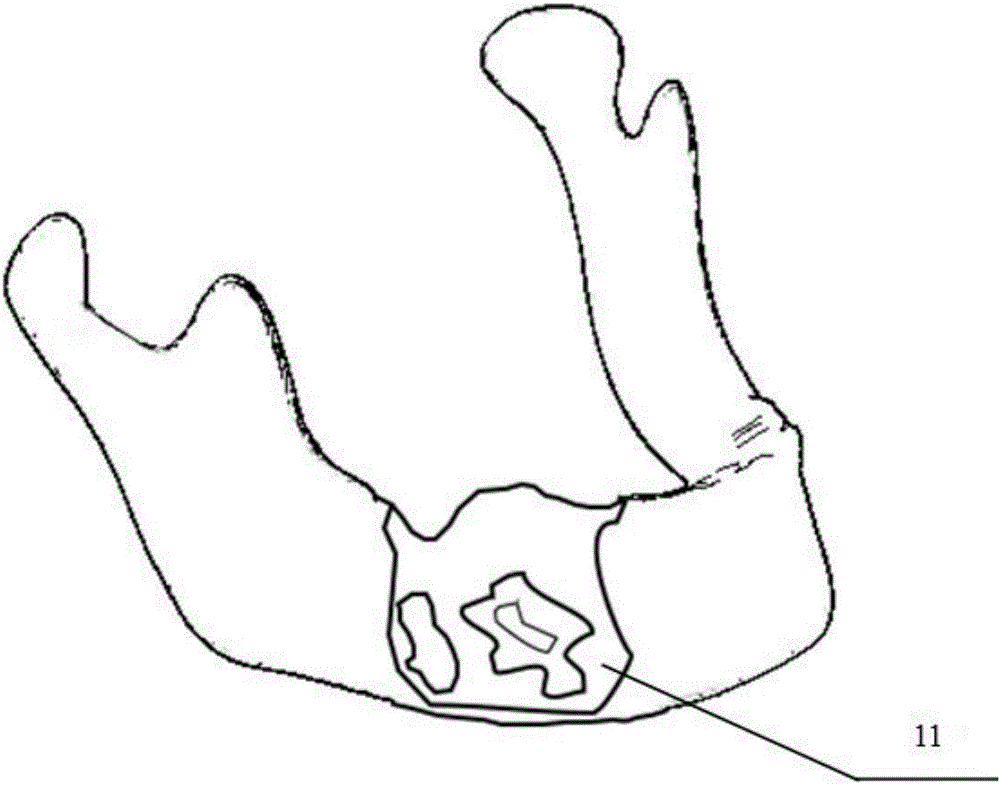

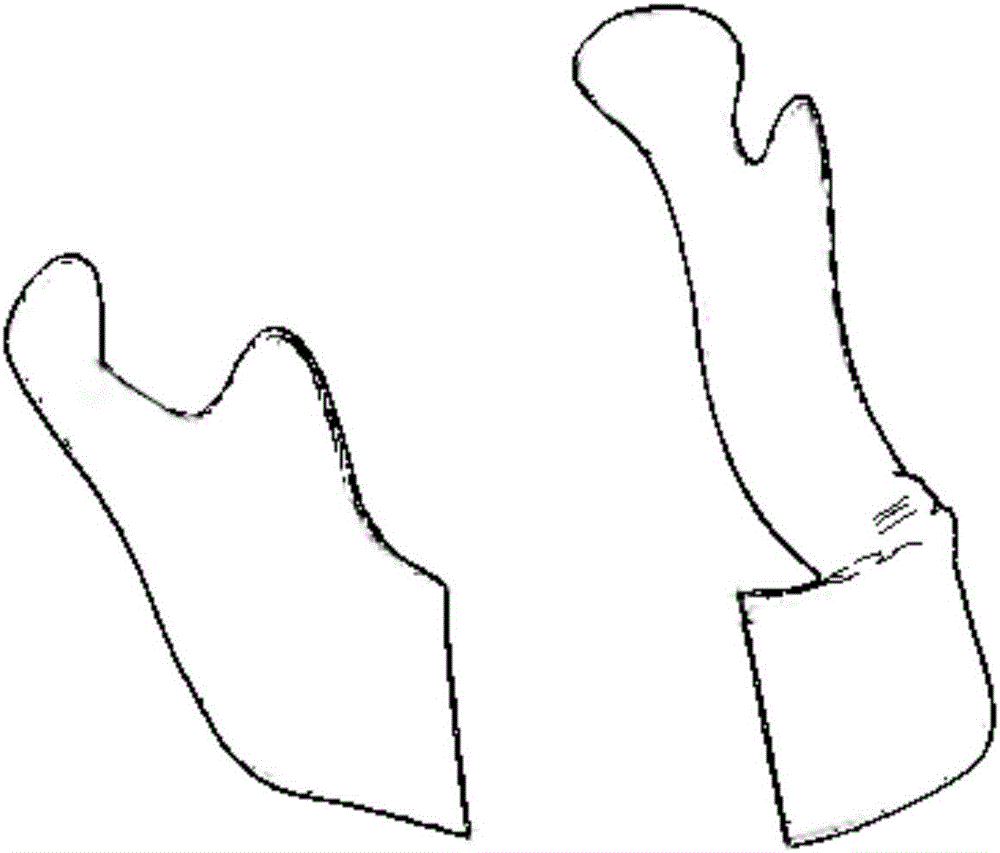

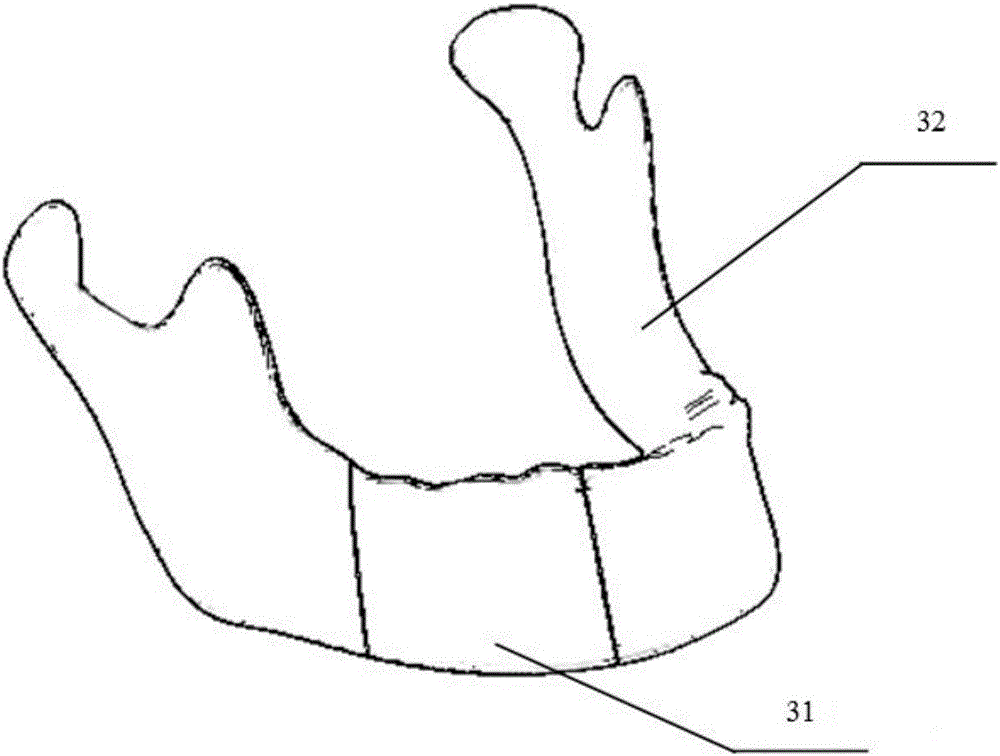

Implant and method for manufacturing mandibular implant with PEKK (polyetherketoneketone) supporting and fixing units and tissue engineering growth unit

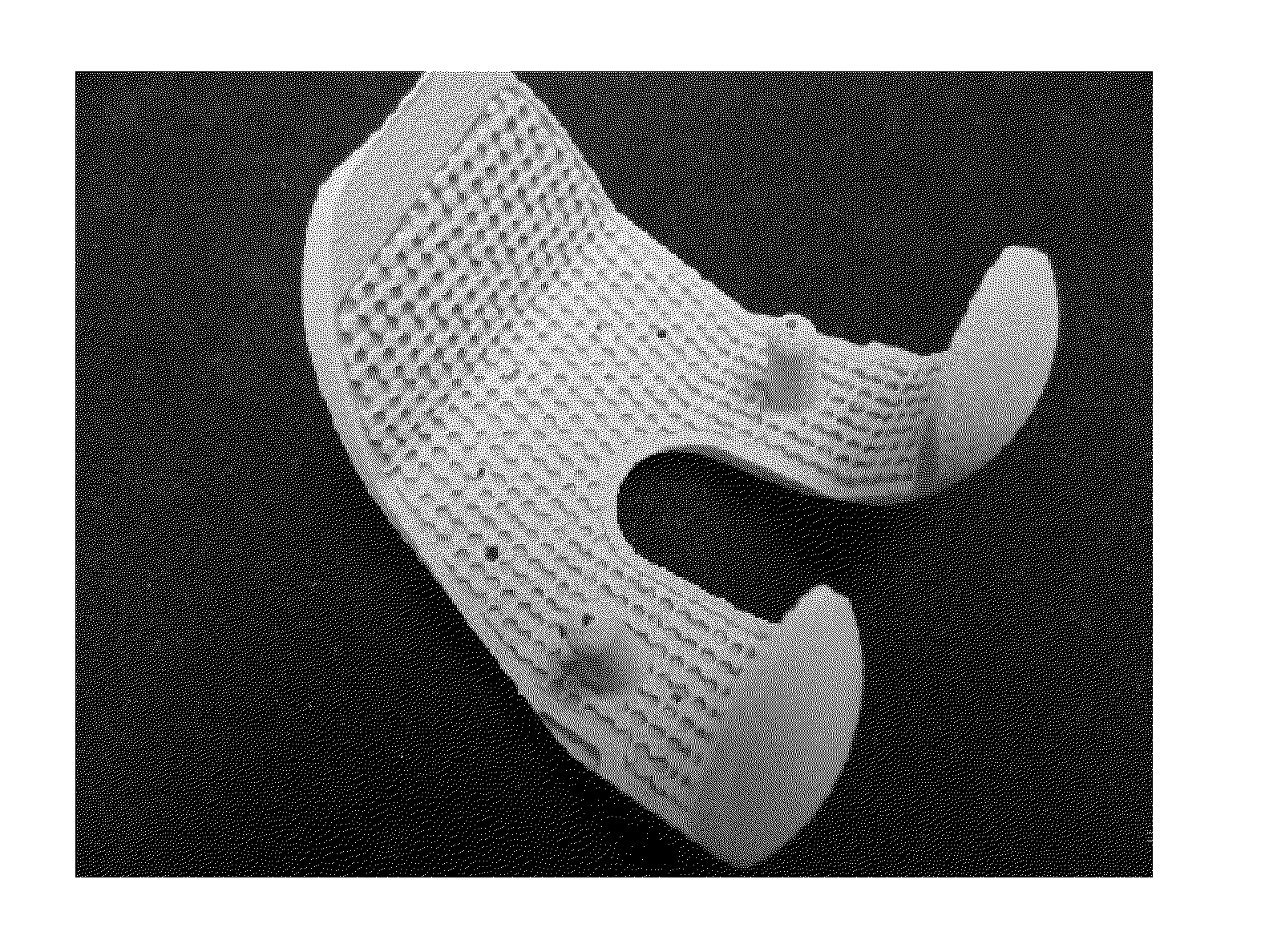

ActiveCN106580520APrevent atrophyAvoid adverse effects such as implant looseningBone implant3D printingUltimate tensile strengthPolyetherketoneketone

The invention provides an implant and a method for manufacturing a mandibular implant with PEKK (polyetherketoneketone) supporting and fixing units and a tissue engineering growth unit. The method includes steps: 1) image acquisition and three-dimensional model establishment; 2) molding unit and fixing unit design; 3) supporting unit design; 4) growth unit design; 5) individual composite-structure implant assembly; 6) individual composite-structure implant manufacturing; 7) in-vitro culture. A molding unit, fixing units, supporting units and the growth unit jointly form an individual composite-structure implant, the supporting units, the fixing units and the molding unit are made of PEKK materials and capable of providing sufficient mechanical strength to keep structural integrity from occlusion functional reconstruction, and the growth unit which is an internally degradable stent is capable of guiding new bone generation.

Owner:ZHEJIANG UNIV OF TECH

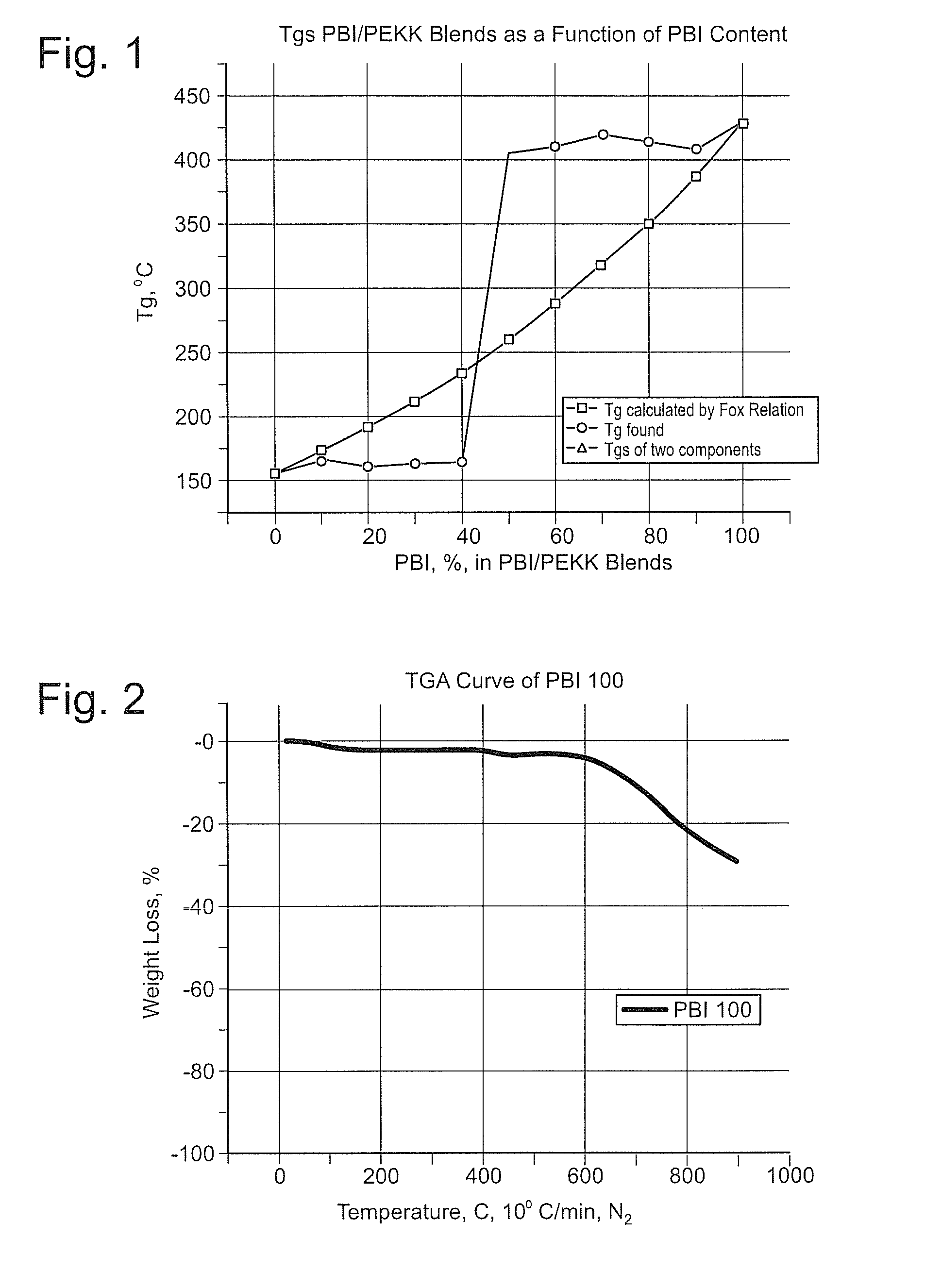

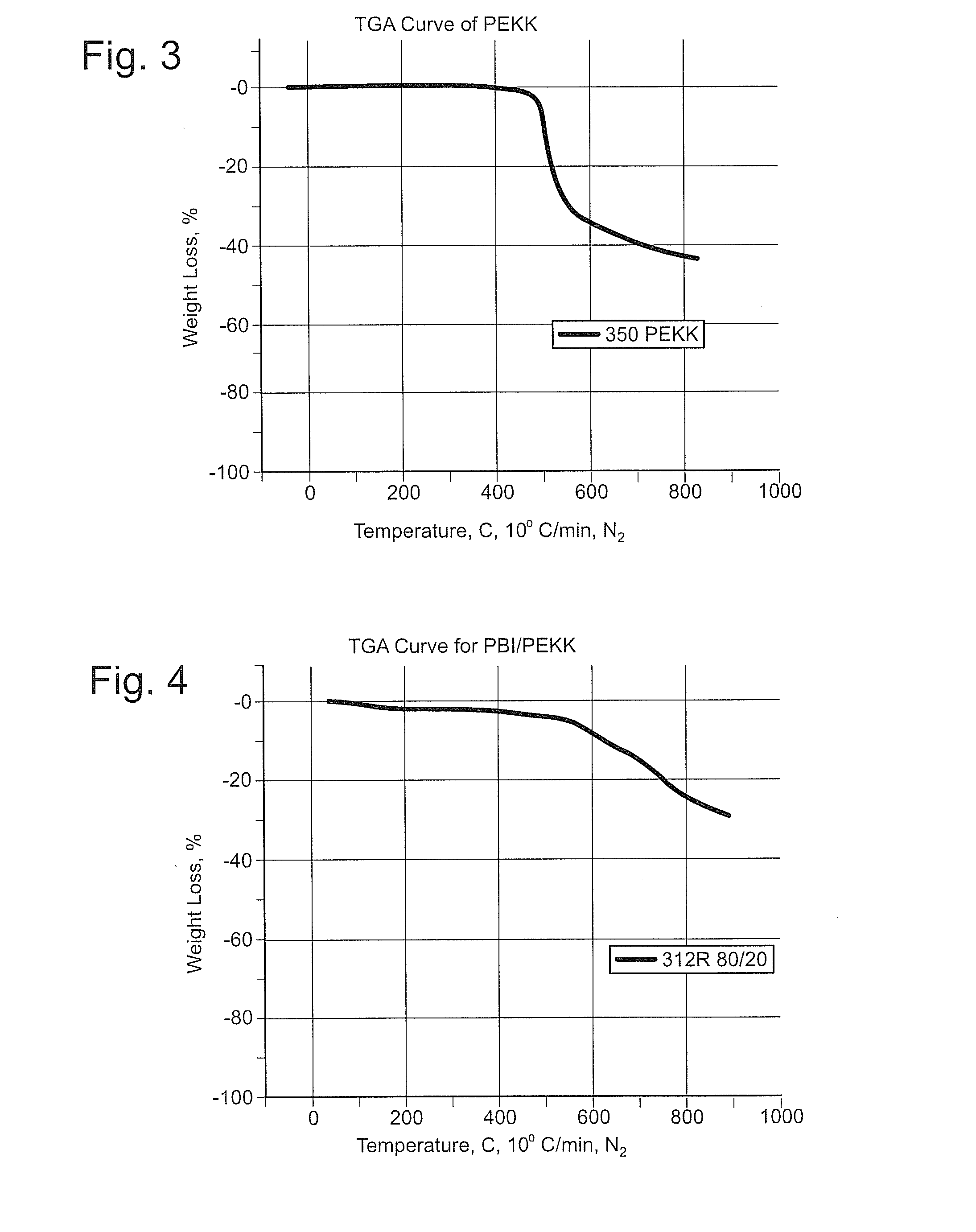

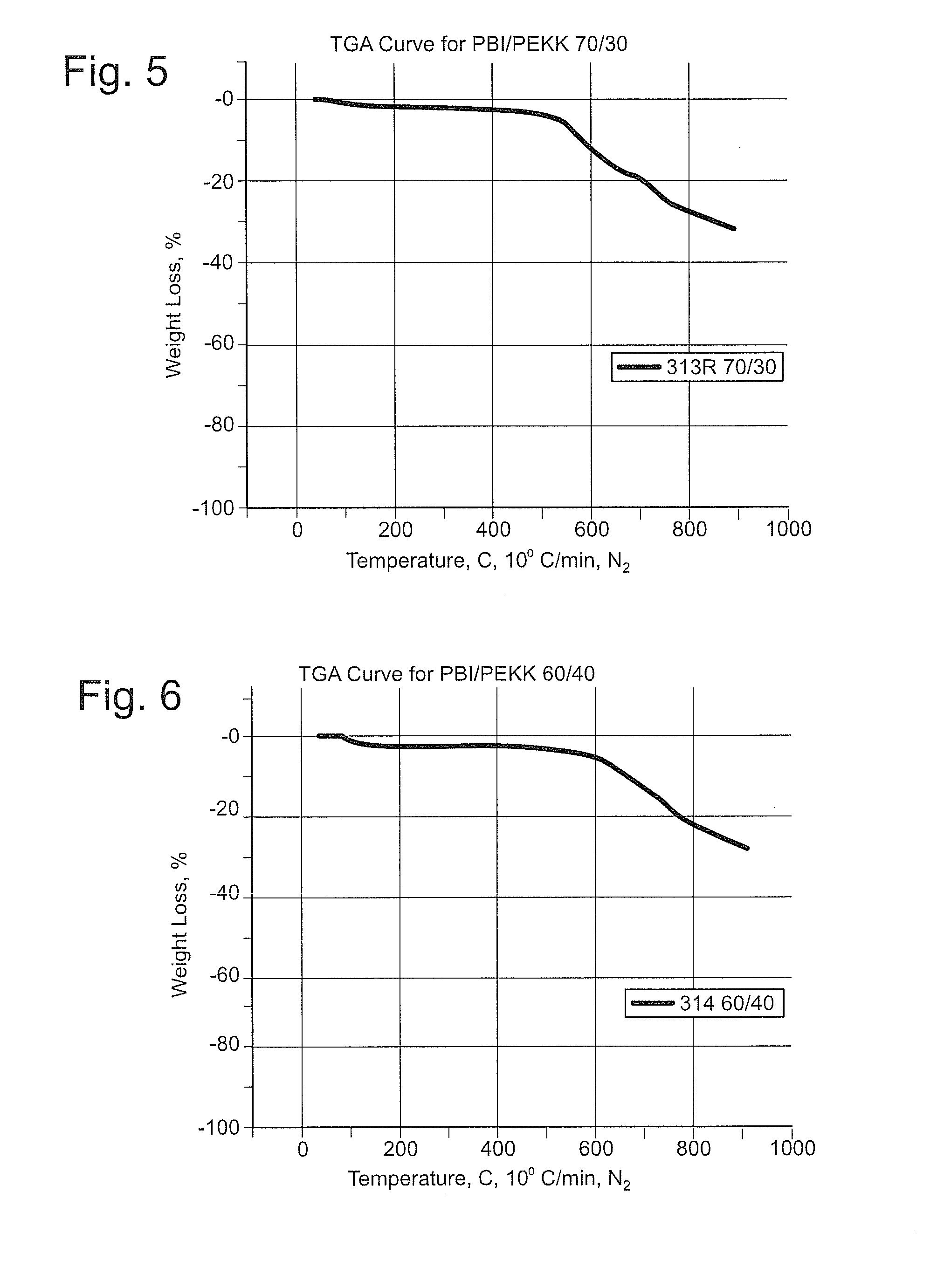

Polybenzimidazole-polyetherketoneketone blends and miscible blends

A process for producing a solution blend of a polybenzimidazole (PBI) and a polyetherketoneketone (PEKK). The PBI is mixed with sulfuric acid at a temperature between 40° C. and 80° C. for 30 minutes to 2 hours to produce a PBI solution then cooled to room temperature to form a cooled PBI solution. Then PEKK is added to the cooled PBI solution to form a mixture and that mixture is stirred from 30 minutes to 2 hours at room temperature to form a stirred mixture. The stirred mixture is poured into an excess of water being stirred swiftly to form an aqueous mixture. The aqueous mixture is filtered to produce a blend. The blend is washed with water and dried. The resulting blend can yield a blend in all proportion from 1 / 99 PBI / PEKK to 99 / 1 PBI / PEKK.

Owner:PBI PERFORMANCE PROD INC

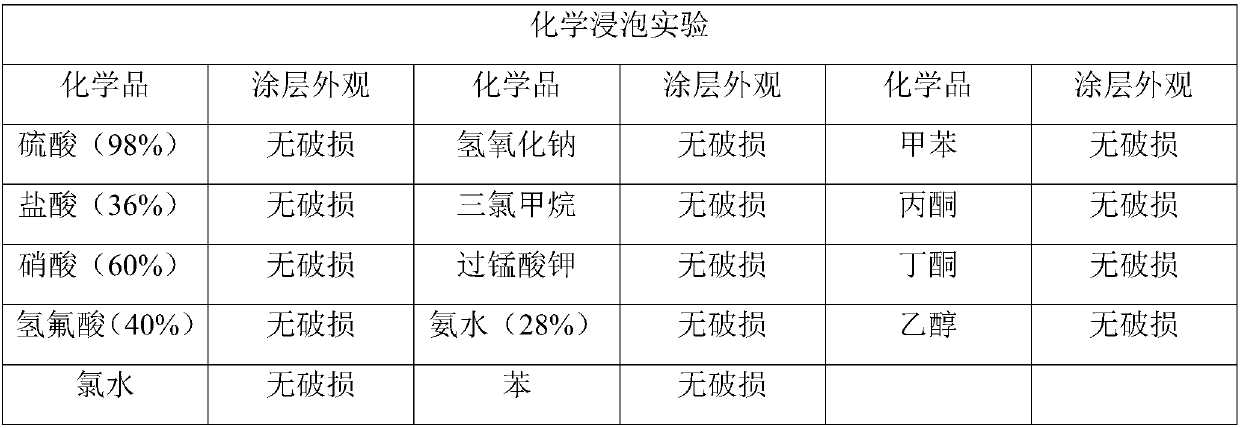

High-antistatic polyether ketone ketone electrostatic spraying powder paint as well as preparation method and application thereof

ActiveCN107674559AImprove liquidityEvenly dispersedPowdery paintsElectrically-conductive paintsAcrylic resinSpray coating

The invention belongs to the technical field of paint, and particularly relates to high-antistatic polyether ketone ketone electrostatic spraying powder paint as well as a preparation method and application thereof. The high-antistatic polyether ketone ketone electrostatic spraying powder paint is prepared from polyether ketone ketone resin and conductive fillers coated with acrylic resin at the surface according to the mass ratio of (90 to 99.5):(10 to 0.5); the melt index of the polyether ketone ketone resin is 20 to 80g / 10min; the test conditions are as follows: the temperature is 380 DEG C, and the load is 2.16kg; the powder grain diameter D50 of the polyether ketone ketone resin is 30 to 120mu m. The high-antistatic powder paint provided by the invention has better flowability; duringthe antistatic spray coating, the construction is simple; the conductive fillers in a formed coating are uniformly dispersed in the resin; the electric conductivity of the prepared electrostatic spraying coating is improved. The invention also provides the preparation method and application of the high-antistatic polyether ketone ketone electrostatic spraying powder paint.

Owner:SHANDONG KAISHENG NEW MATERIALS

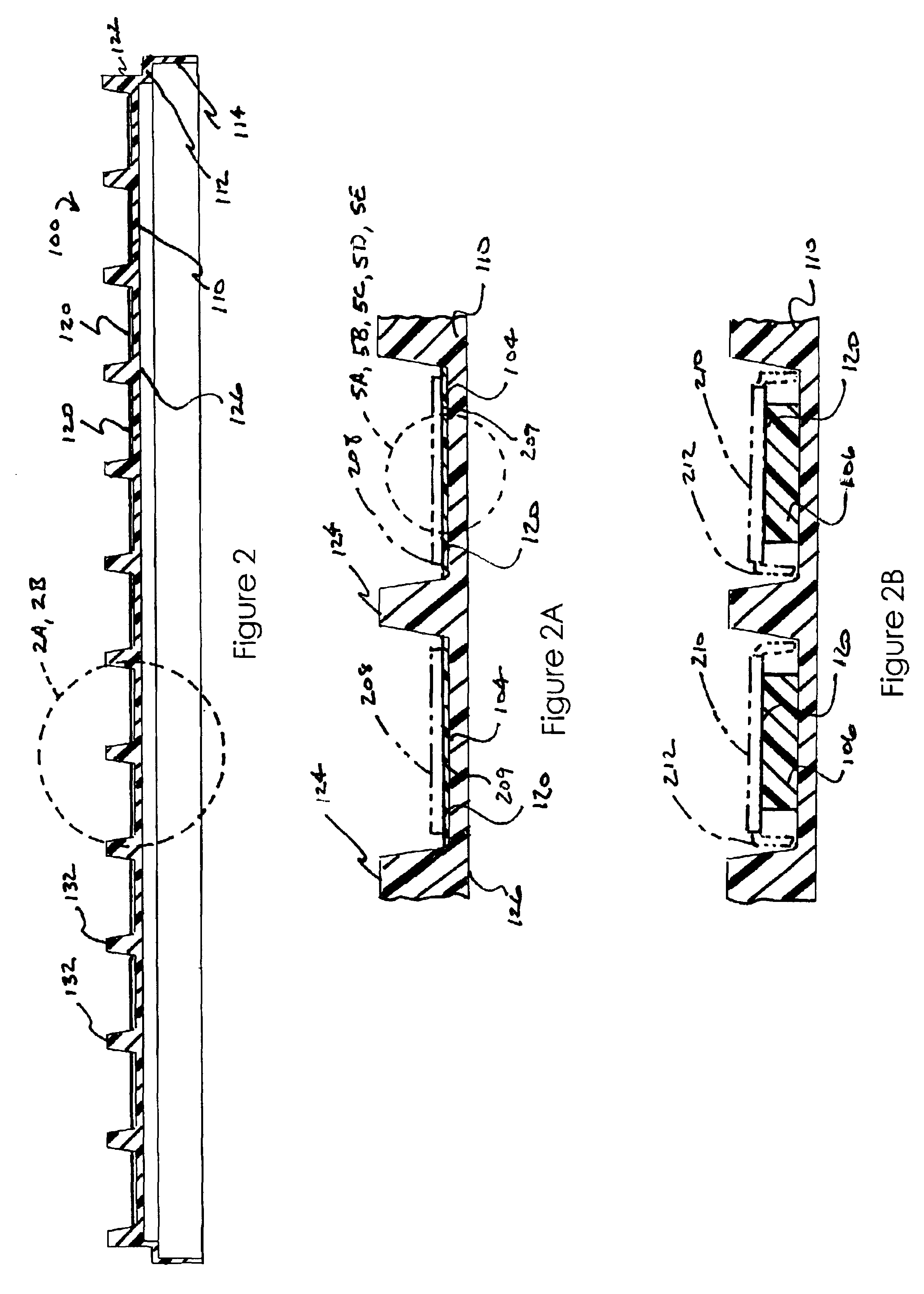

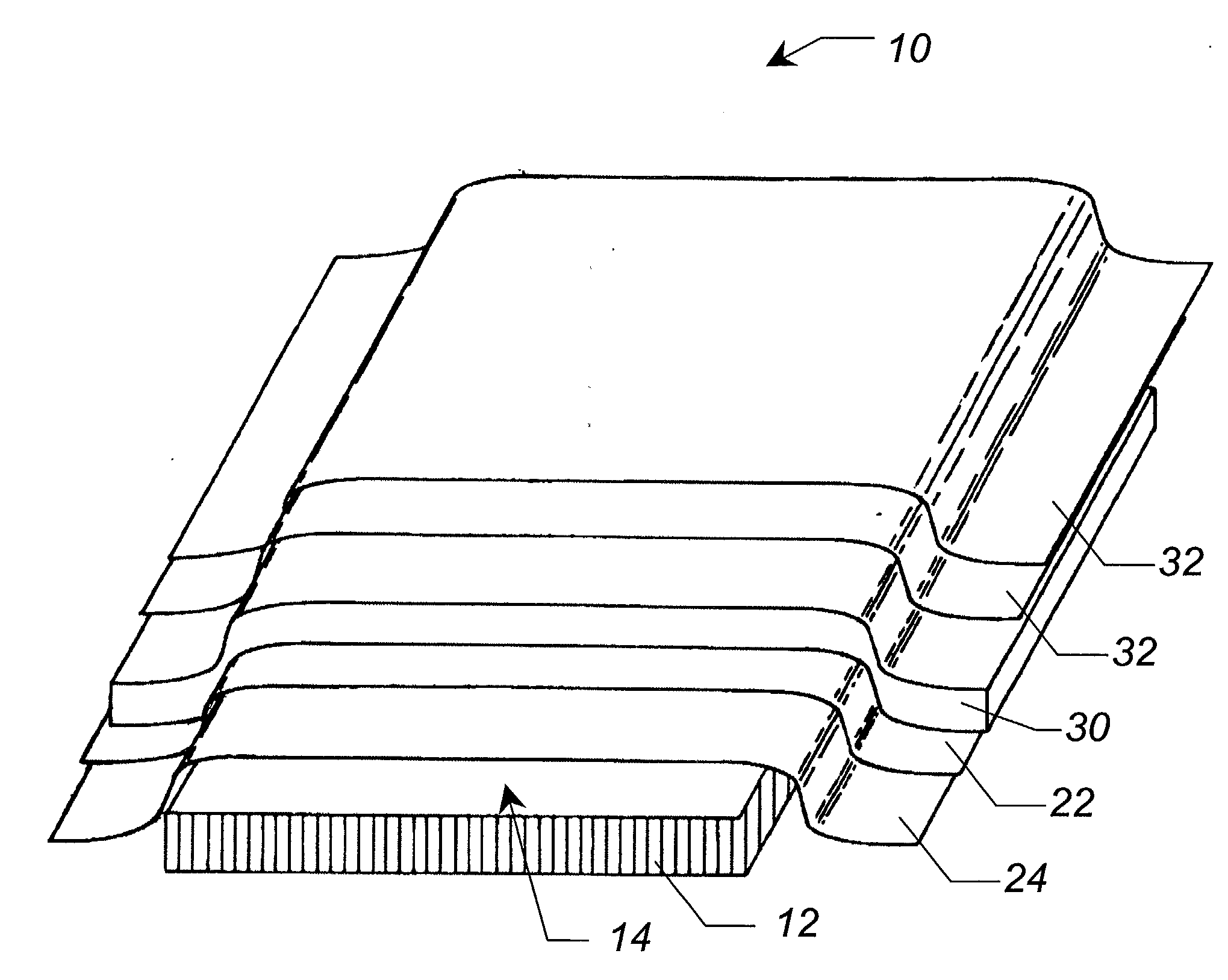

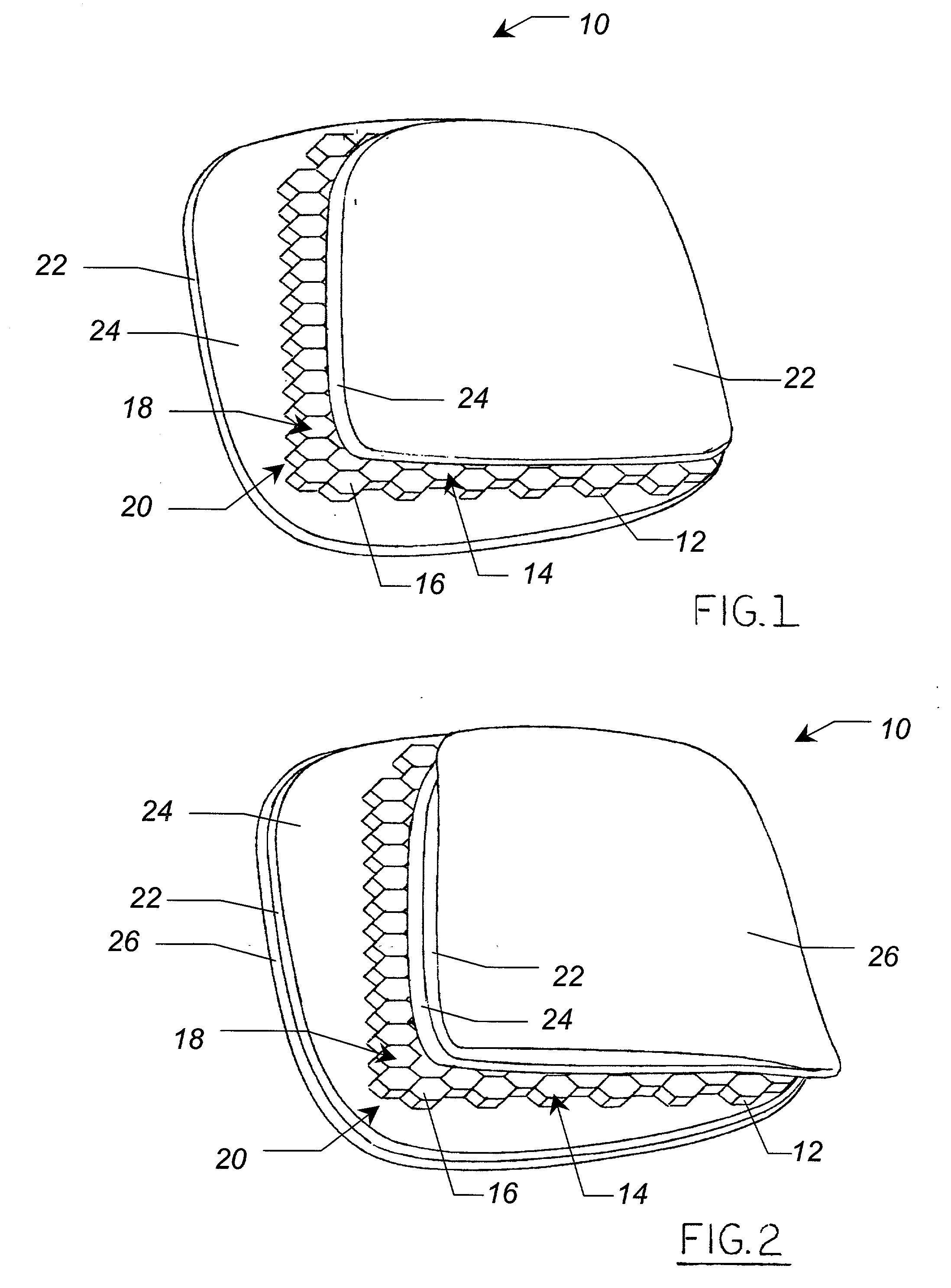

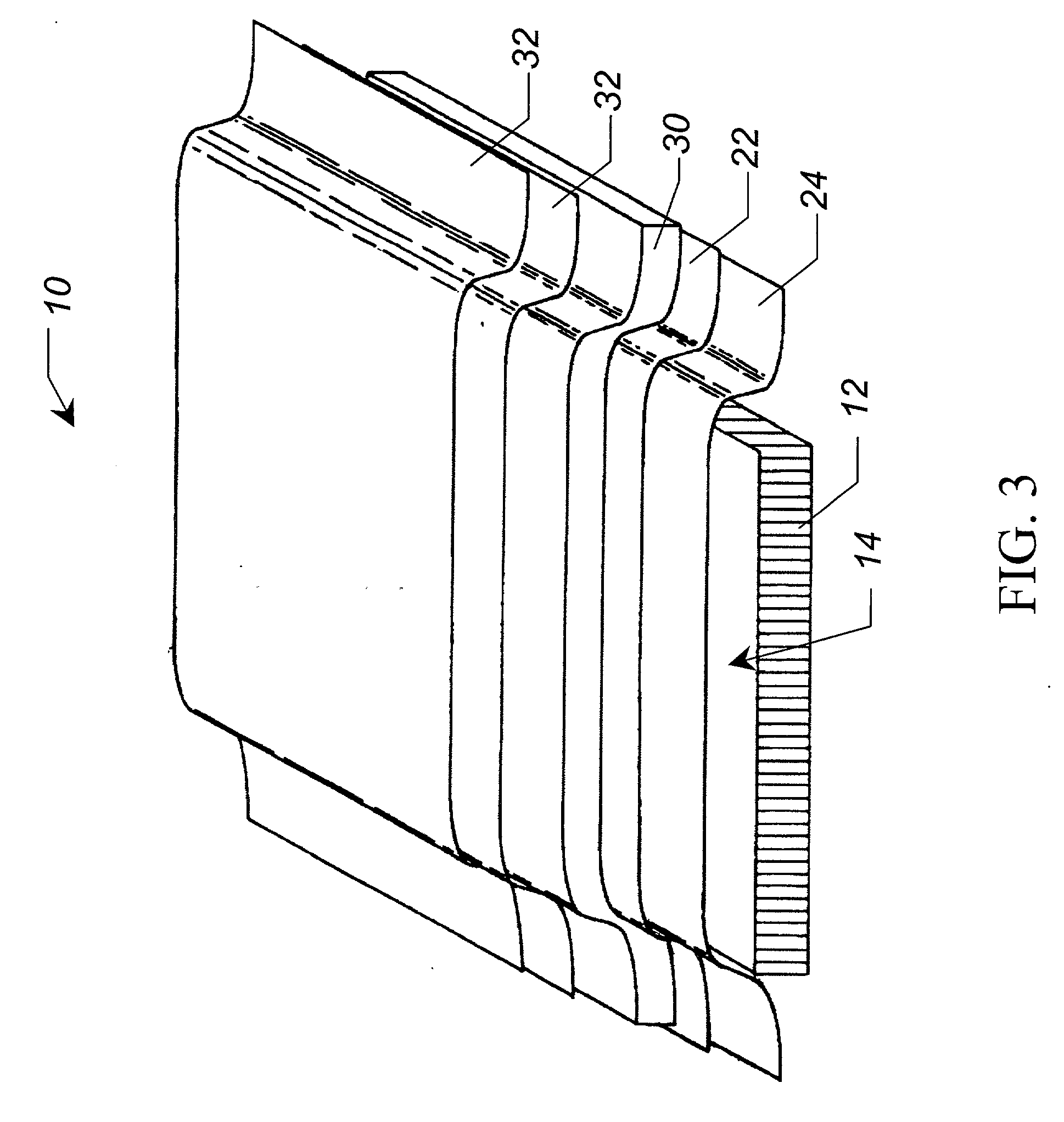

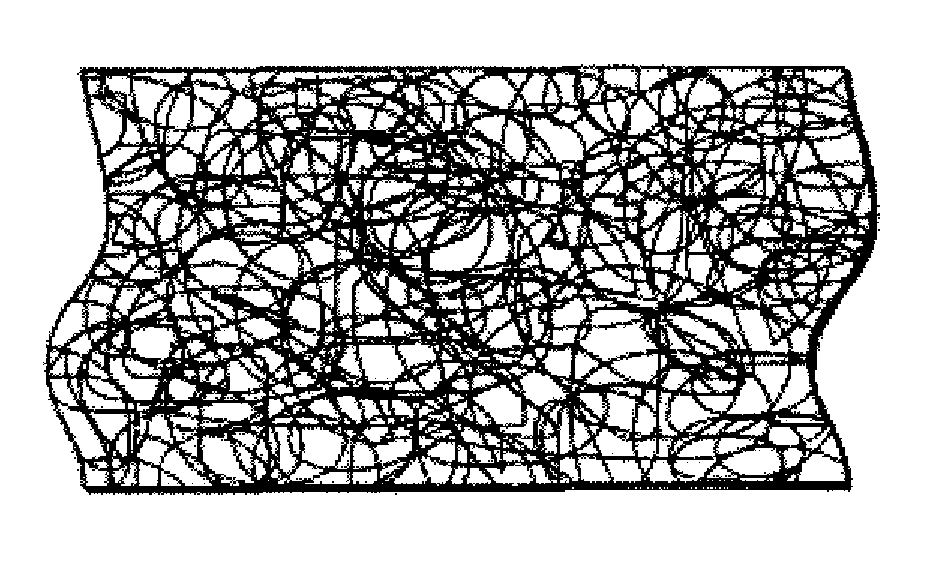

Liquid molded hollow cell core composite articles

InactiveUS20040086686A1Increase in composite assembly weightIncrease in manufacturing timeAdhesive processes with surface pretreatmentSynthetic resin layered productsLiquid stateShell molding

A hollow core composite assembly 10 is provided, including a hollow core base 12 having an open core surface 14, a polyetherketoneketone film 22 applied to the hollow core base 12, and an adhesive layer 24 positioned between the polyetherketoneketone film 22 and the open core surface 14. The resultant hollow core composite assembly 10 can be cured to provide a structure suitable for use within a liquid molding process.

Owner:THE BOEING CO

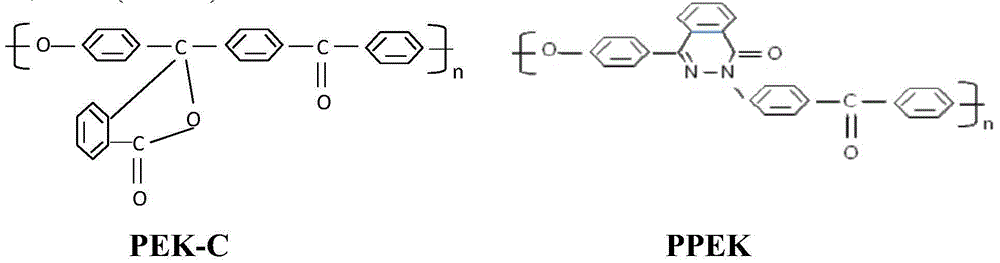

High temperature polymer blends of poly(aryl ether ketone phthalazinone)

The present invention provides high temperature compositions comprising blends of a first polymer, poly(aryl ether ketone phthalazinone)s, and a second polymer, selected from poly(aryl ether ketone)s, poly(aryl ketone)s, poly(ether ether ketone)s, poly(ether ketone ketone)s, or polybenzimidazoles, thermoplastic polyimides, polyetherimides, poly(aryl ether sulfone)s, poly(phenylene sulfide)s, and mixtures thereof. The compositions have improved high temperature characteristics, e.g., improved high temperature load capability and improved high temperature melt processibility.

Owner:POLYMER INSTR & CONSULTING SERVICES LTD

High-heat-conductivity vacuum-tolerant high-temperature-tolerant anticorrosion coating

ActiveCN106810964AImprove bindingFlat surfaceFireproof paintsLiquid surface applicatorsEngineering plasticSulfide

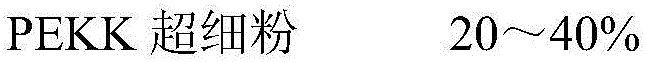

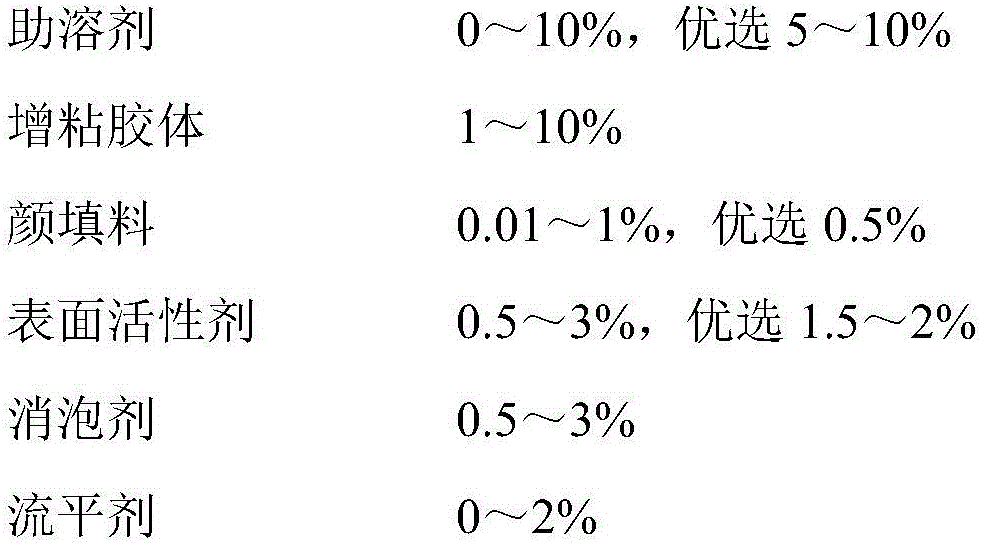

The invention relates to a high-heat-conductivity vacuum-tolerant high-temperature-tolerant anticorrosion coating and belongs to the technical field of macromolecular special engineering plastic; the high-heat-conductivity vacuum-tolerant high-temperature-tolerant anticorrosion coating comprises a bottom coating and a surface coating; the bottom coating is prepared from, by applying, by weight, 20-40% of PEKK (polyetherketoneketone) superfine powder, 0-10% of a cosolvent, 1-10% of tackified glue, 0.01-1% of pigment-filler, 0.5-3% of a surfactant, 0.5-3% of a defoaming agent, and 0-2% of a leveling agent; the surface coating is prepared from, by applying, by weight, 86-98.5% of PFA (perfluoroalkoxy alkane) fine powder, 0-10% of PPS (polyphenylene sulfide) micropowder, 1-3% of diamond micropowder, and 0.5-1% of hydrophilic silicon dioxide. The high-heat-conductivity vacuum-tolerant high-temperature-tolerant anticorrosion coating is very suitable for application in the field of high-temperature-tolerant anticorrosion coating requiring heat transfer, particularly high-heat-conductivity high-temperature-tolerant anticorrosion application for thin-walled devices, and has the advantages of high binding force, surface smoothness, and good heat conductivity.

Owner:SHANDONG KAISHENG NEW MATERIALS

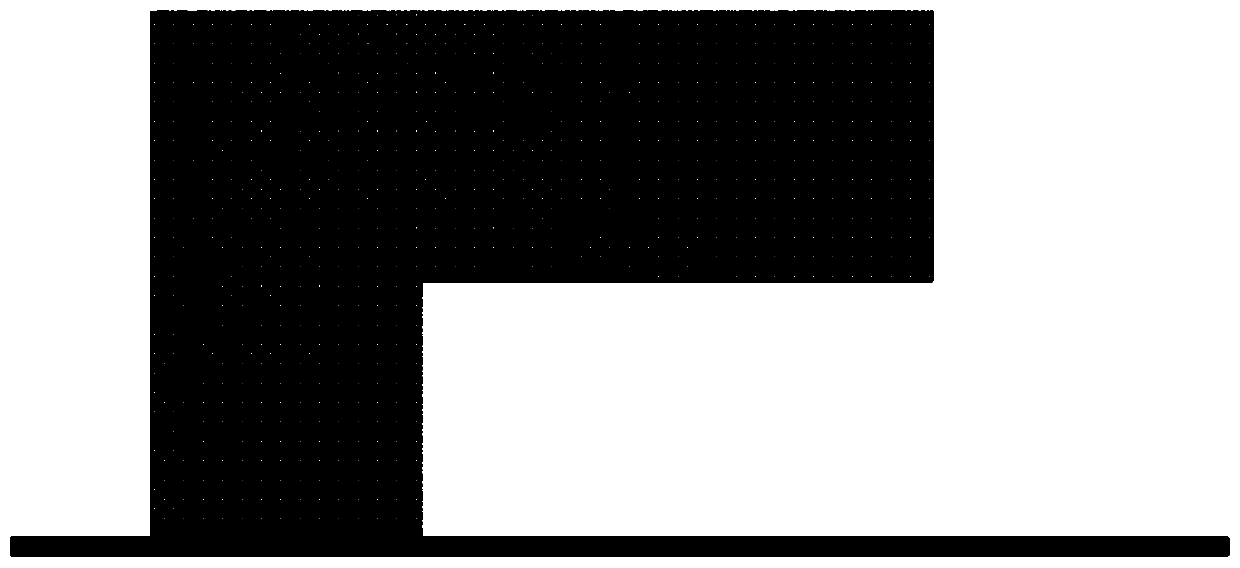

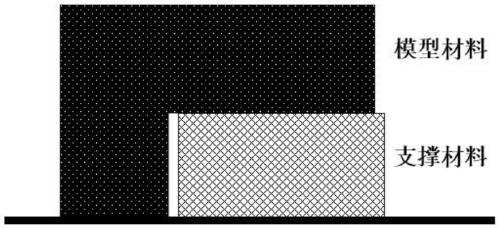

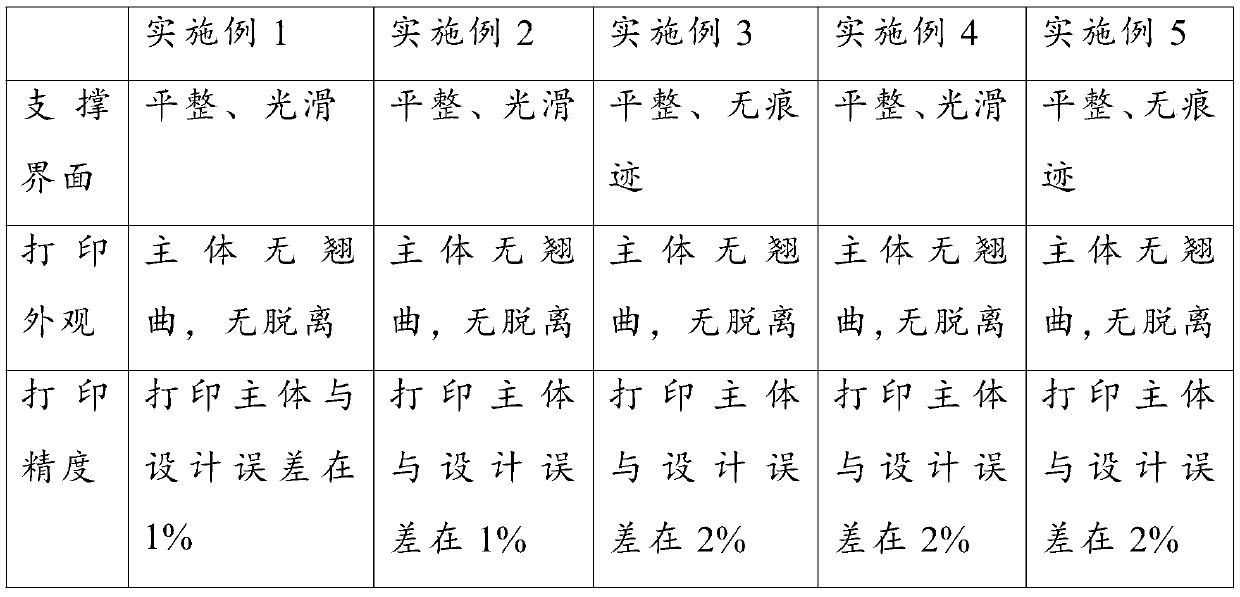

3D printing special engineering plastic support material and preparation method of wires of support material

InactiveCN110437598ABuild stabilityImprove adhesionAdditive manufacturing apparatusPolyetherimideAntioxidant

The present invention discloses a 3D printing special engineering plastic support material and a preparation method of wires of the support material. The material is composed of the following components by weight percentage: 75-90 parts of polycarbonate resin; 5-15 parts of reinforcement material; 1-10 parts of compatibilizer; 2-5 parts of plasticizer; and 0.1-3 parts of antioxidant. The supporting wires prepared by the material ensures the stable establishment of a support portion in a 3D printing process of special engineering plastics under high temperature environment, is well bonded withthe special engineering plastics such as PEEK (polyetheretherketone), polyetherimide, PES (polyether sulfone), PEKK(polyetherketoneketone), PPS (polyphenylene sulfide), poly(phenylene sulfone),etc. atthe same time, products are put into a non-toxic environment-friendly solvent after printing is finished, and the support portion can be quickly removed by dissolution or swelling. The preparation method of the 3D printing support material of the invention has high chemical stability and a simple production process, an existing twin-screw extrusion mechanism can be used for preparation, and the 3D printing special engineering plastic support material is easy to prepare, suitable for industrial production and conducive to the market promotion of the 3D printing material.

Owner:INTAMSYS TECH CO LTD

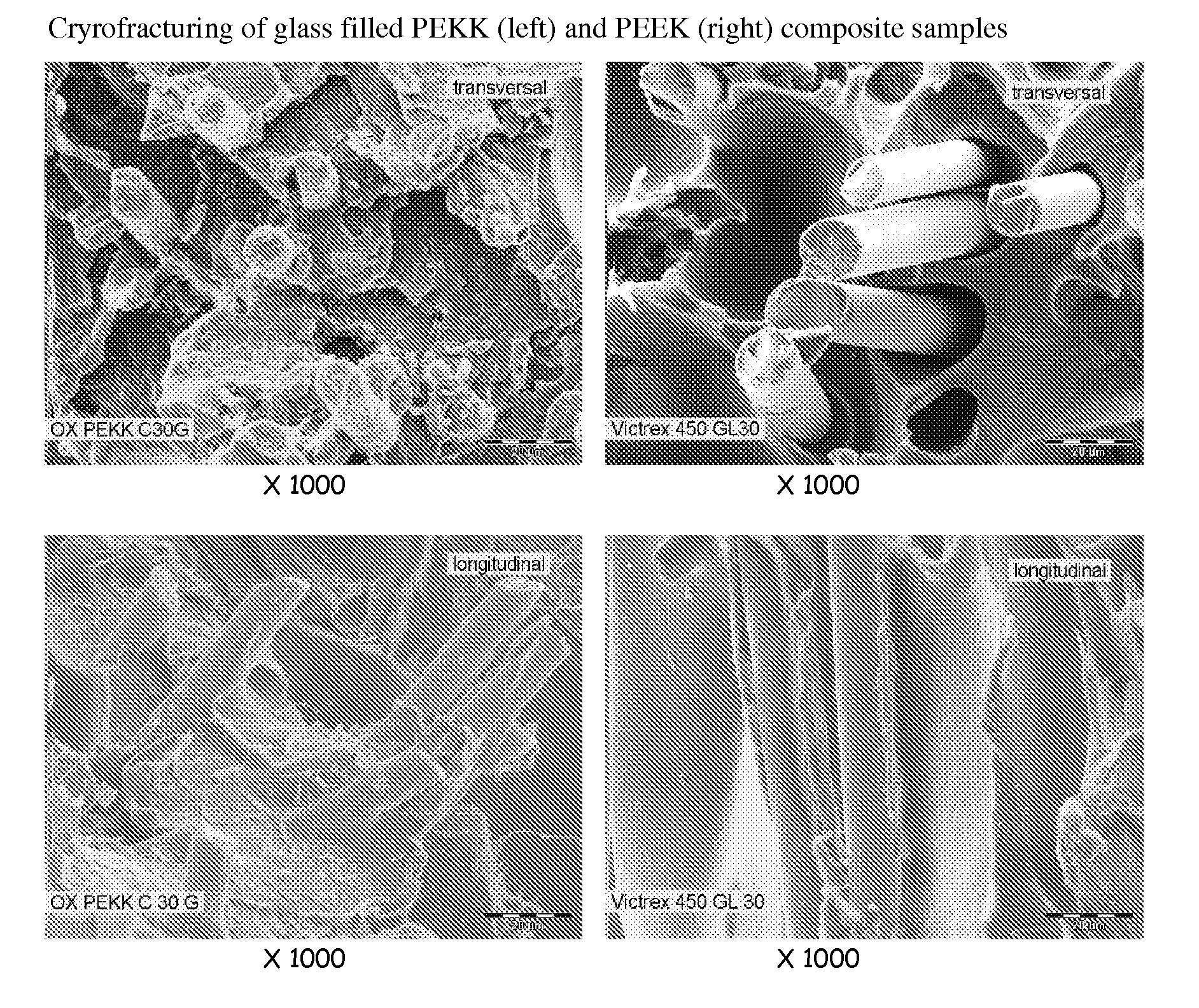

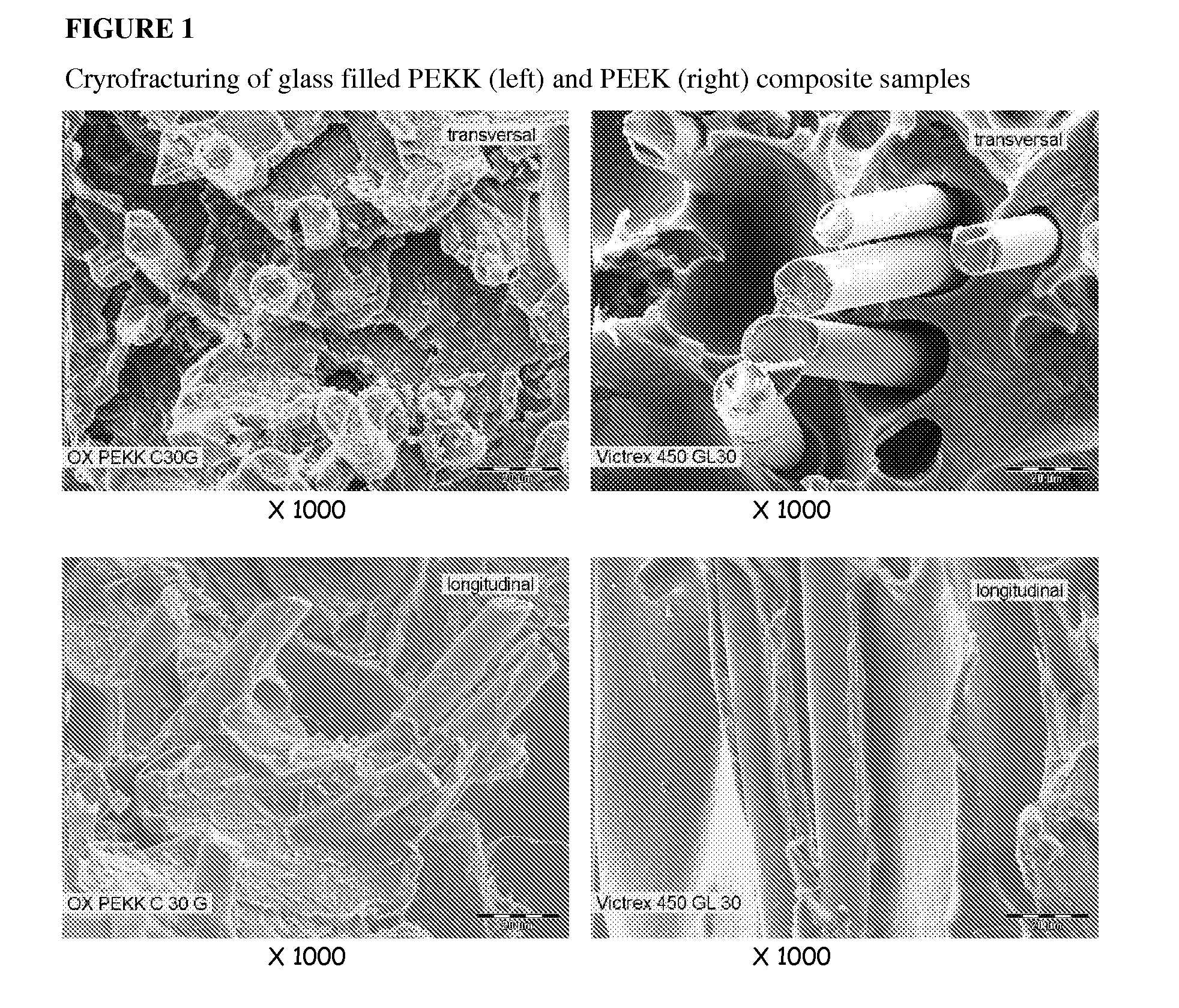

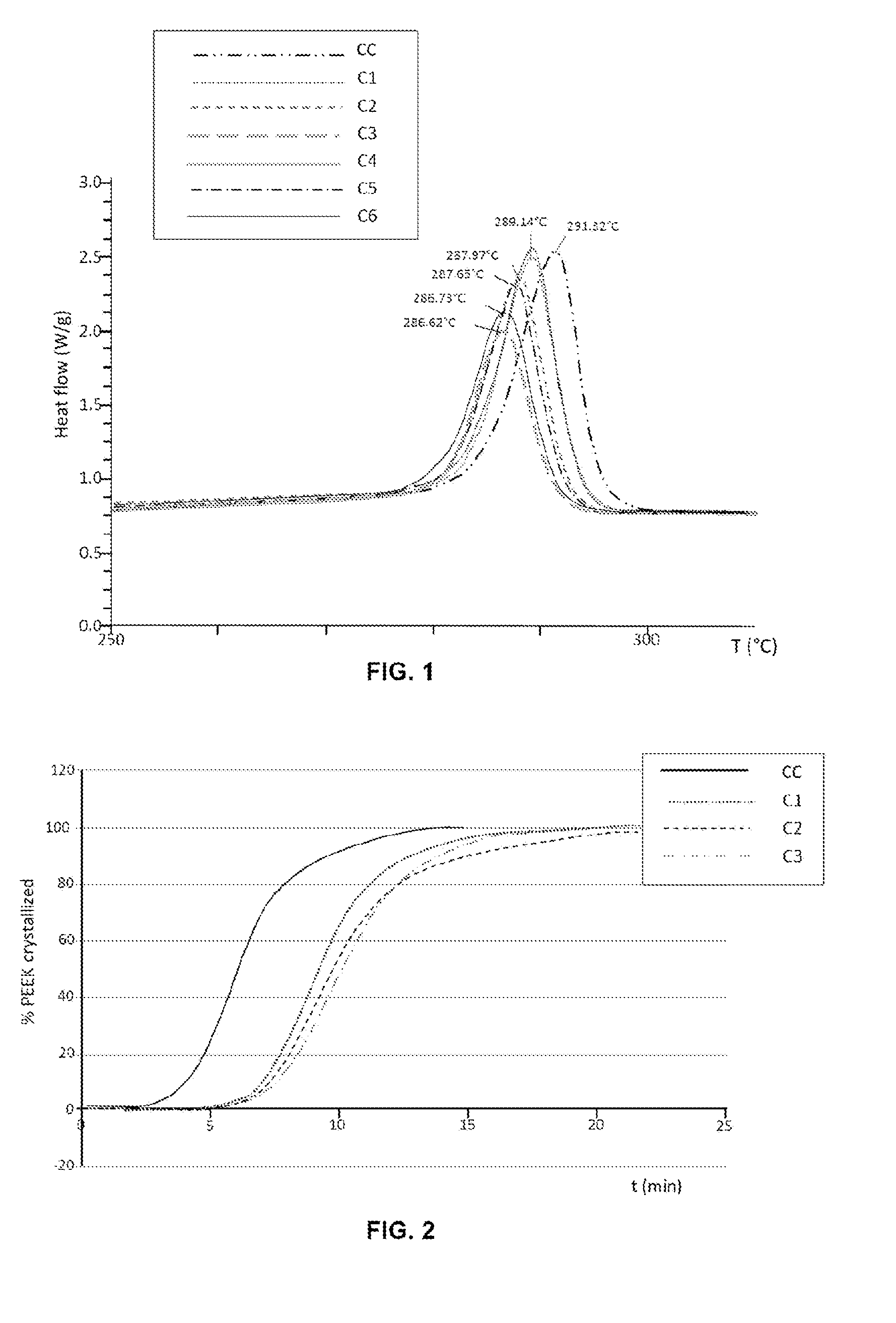

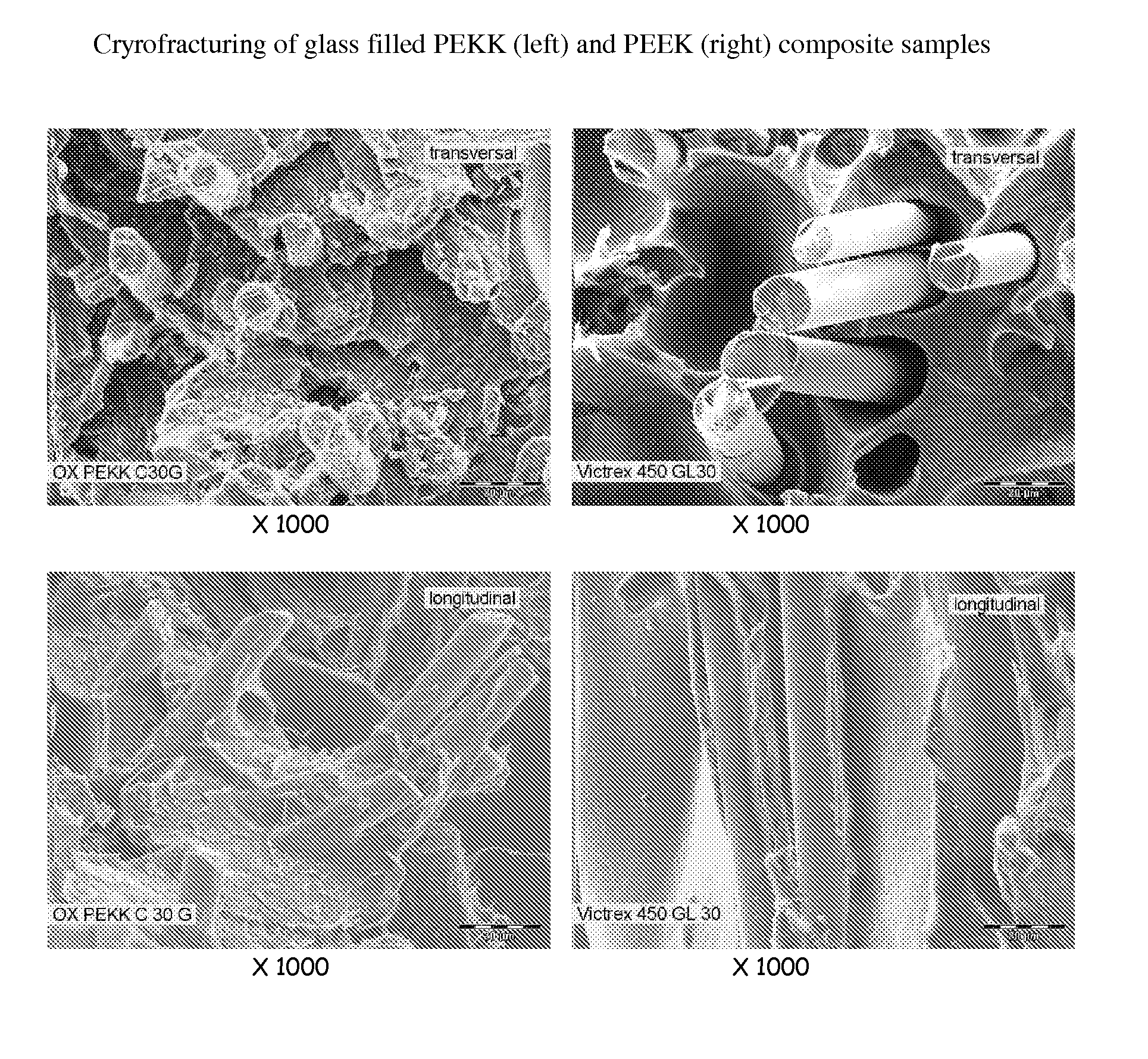

Composition based on poly(arylene ether ketone) having improved properties

The present invention relates to a composition based on poly(ether ether ketone) (PEEK) comprising poly(ether ketone ketone) (PEKK), characterized in that the poly(ether ketone ketone) (PEKK) comprises a mixture of terephthalic and isophthalic units, the percentage by weight of terephthalic units, with respect to the sum of the terephthalic and isophthalic units, being between 55 and 85%, limits included, and preferably between 55 and 70%, the said composition comprising between 1 and 40%, limits included, preferably between 5 and 40% and more preferably still between 10 and 30% by weight of PEKK, with respect to the total weight of the composition.

Owner:ARKEMA FRANCE SA

Anti-static polyether ketone ketone powder coating and preparation method thereof

ActiveCN106675360ALow densityImprove conductivityPolyether coatingsPowdery paintsSpray coatingKetone

The invention relates to a polyether ketone ketone powder coating, and concretely relates to an anti-static polyether ketone ketone powder coating and a preparation method thereof. The coating is prepared from polyether ketone ketone resin and a conductive agent with the mass ratio being (99 to 99.8) : (1 to 0.2), wherein the conductive agent is a compound conductive material prepared by coating the surface of a carbon-series conductive filler with silver powder. The anti-static polyether ketone ketone powder coating provided by the invention adopts the compound conductive material as the conductive agent, so that the conductivity of the anti-static polyether ketone ketone powder coating is better than the conductivity of a carbon-series conductive agent which is independently used according to the same usage amount, and compared with a metal series, the density of the conductive agent is smaller, and the power utilization rate during electrostatic spraying is high; the anti-static polyether ketone ketone powder coating is prepared by adopting a hot bonding technology, the conductive agent and the base resin are dispersed uniformly and bonded tightly, and the recycled powder coating can be reutilized without the need for re-treating, so that the waste is reduced; an electrostatic spraying coating has the alternative conductivity being 7.10*10<8> to 3.25*10<4>s / m under the frequency of 103Hz, and has an anti-static function.

Owner:SHANDONG KAISHENG NEW MATERIALS

Polyether ketone ion exchange membrane and preparation method and application thereof

InactiveCN105633444ARigid molecules are strongImprove stabilityRegenerative fuel cellsCollectors/separatorsVanadium redox batteryPoly ether ether ketone

The invention proposes a polyether ketone ion exchange membrane and a preparation method and application thereof. The preparation method comprises the processes of sulfonation, chloromethylation, membrane forming and quaternization on one or more of raw materials of polyether ketone (PEK), polyethylene ketone ketone (PEKK) and poly ether ether ketone ketone (PEEKK). The prepared exchange membrane simultaneously contains a sulfonic group and an ammonium group on molecules, thus, the exchange membrane becomes an amphoteric ion exchange membrane compatible with a function of cation and anion exchange, and protons can be effectively transmitted; and meanwhile, vanadium ion penetration can be effectively prevented through a Donnan effect, and the ion change membrane with excellent performance can be specially used for a vanadium redox battery (VRB).

Owner:XIHUA UNIV

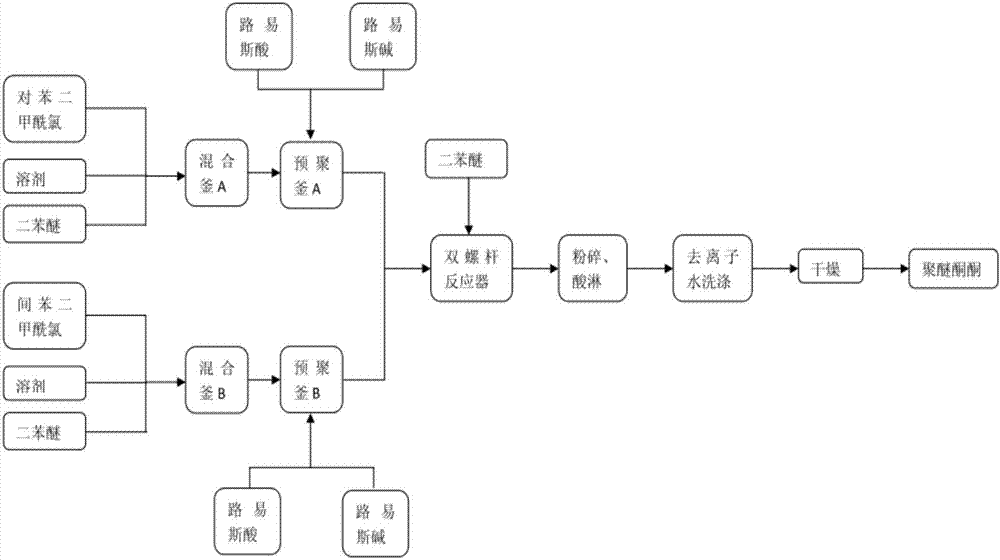

Semi-continuous preparation process for block PEKK (polyetherketoneketone)

InactiveCN107880262AIncreased chance of collisionHigh intrinsic viscosityDiphenyl etherPolymer science

The invention belongs to the technical field of polymer synthesis and particularly relates to a semi-continuous preparation process for block PEKK (polyetherketoneketone). A solvent, a Lewis acid anda Lewis base are added to two prepolymerization reactors respectively; diphenyl ether and isophthaloyl dichloride or terephthaloyl chloride are added in equal molar ratio for reactions, and a prepolymer A and a prepolymer B which have better flowability are formed; then the prepolymer A and the prepolymer B which have better flowability as well as residual diphenyl ether are quantitatively added to a twin-screw reactor by a feeder, the materials are mixed under the strong shear action of the twin-screw reactor, the probability of collision of active end groups is increased, the polymerizationreaction rate is increased, and PEKK with high intrinsic viscosity is prepared within short time.

Owner:SHANDONG KAISHENG NEW MATERIALS

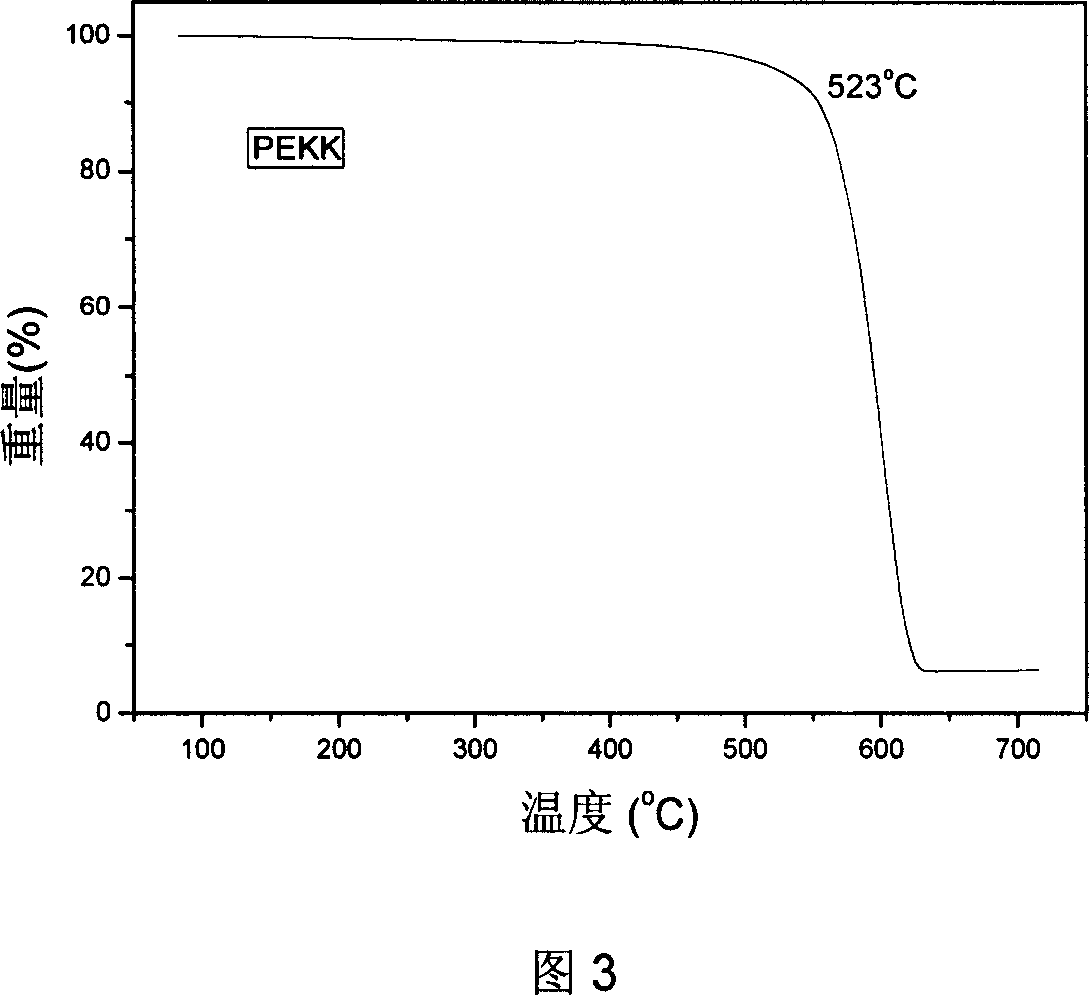

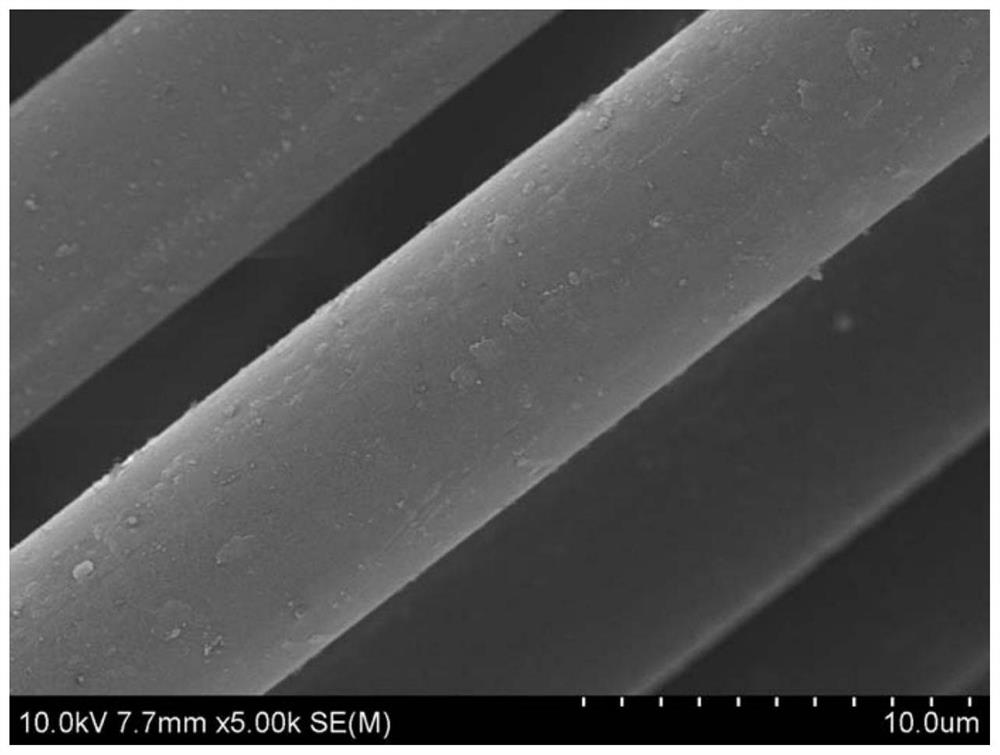

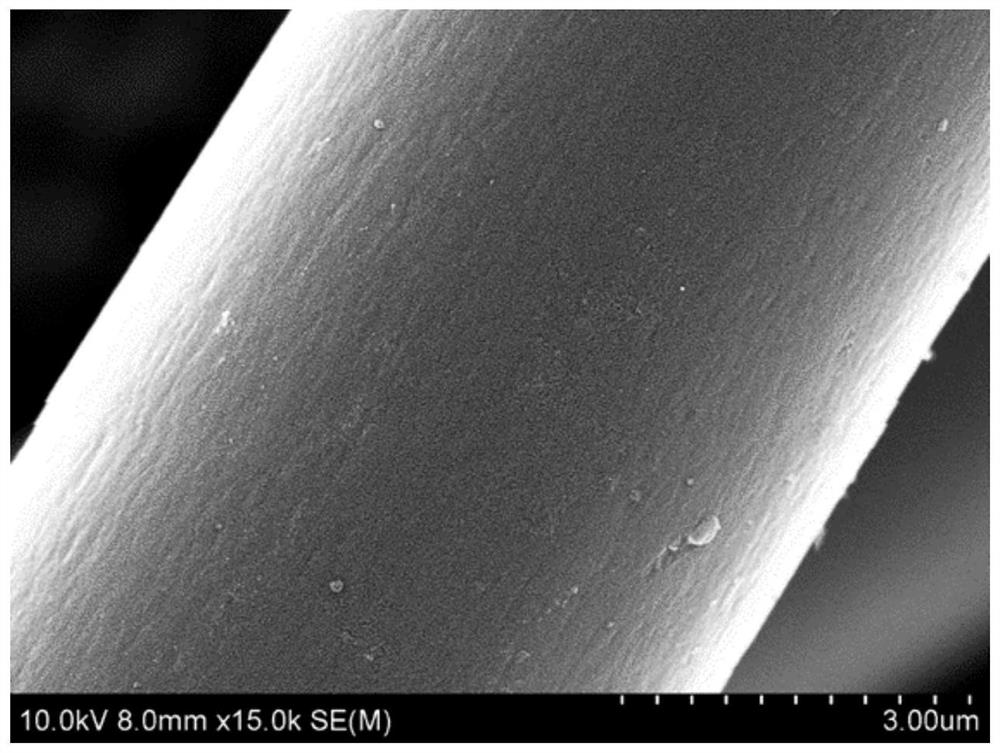

High-temperature-resistant water-based carbon fiber universal sizing agent and preparation method and application thereof

ActiveCN113430831AImprove heat resistanceImprove mechanical propertiesCarbon fibresFiberCarbon fibers

The invention relates to a high-temperature-resistant water-based carbon fiber universal sizing agent and a preparation method and application thereof. The sizing agent comprises the following components in percentage by weight of 0.1-10% of sulfonated polyetherketoneketone and 80-99% of deionized water. Compared with the prior art, the prepared sizing agent can be widely applied to sizing treatment of original carbon fibers, continuous carbon fibers and recycled short carbon fibers. The maximum decomposition temperature of a product is higher than 300 DEG C, and the sizing agent can be suitable for high-temperature processing and manufacturing conditions and application environments.

Owner:SHANGHAI JIAO TONG UNIV

High performance connectors

InactiveUS20110287225A1Efficiently effectively transmittingPrecise alignmentPlastic/resin/waxes insulatorsLayered productsElectricityFiber

High performance connectors, such as electrical connectors intended for use in circuit boards that are to be subjected to reflow soldering or rework or fiber optic connectors to be employed in harsh operating conditions, are manufactured using polymeric compositions containing polyetherketoneketone and mineral nanotubes. These polymeric compositions provide connectors having exceptional dimensional stability at high temperatures and facilitate the precise and high quality molding of connectors with thin or finely detailed features.

Owner:ARKEMA INC

Fibers sized with polyetherketoneketones

ActiveUS8829108B2Improve adhesionGood dispersionPlastic/resin/waxes insulatorsCarbon fibresFiberPolymer science

Owner:ARKEMA FRANCE SA

Polyetherketoneketone nonwoven mats

ActiveUS9422654B2Low creepIncrease resistanceSynthetic resin layered productsWoven fabricsFiberPolyetherketoneketone

The invention provides nonwoven mats comprising polyetherketoneketone fibers or mixtures thereof. Also provided are filters, textiles, blankets, and insulation prepared from polyetherketoneketone nonwoven mats, as well as methods for manufacturing the same.

Owner:ARKEMA INC

Method for preparing polyetherketoneketone (PEKK) membrane material

The invention relates to a preparation method of a polyetherketoneketone (PEKK) membrane material, and belongs to the technical field of polymer materials, and the preparation method comprises the following steps: (a) dispersing synthesized PEKK powder in N-methylpyrrolidone (NMP), stirring at 100DEG C or above to dissolve quickly to obtain a solution; (b) spreading the solution on a clean glass plate, placing the glass plate in an oven at 100DEG C or higher to volatilize a solvent, and then removing solvent residue in a vacuum oven at 150DEG C or higher; and (c) performing heat treatment at 300DEG C or higher to obtain a PEKK membrane. The method only uses one common solvent NMP, the membrane forming process is simple, and the obtained PEKK membrane material has excellent mechanical properties.

Owner:ZHANGJIAGANG XIANGCHENG MEDICAL MATERIAL SSCI & TECH CO LTD

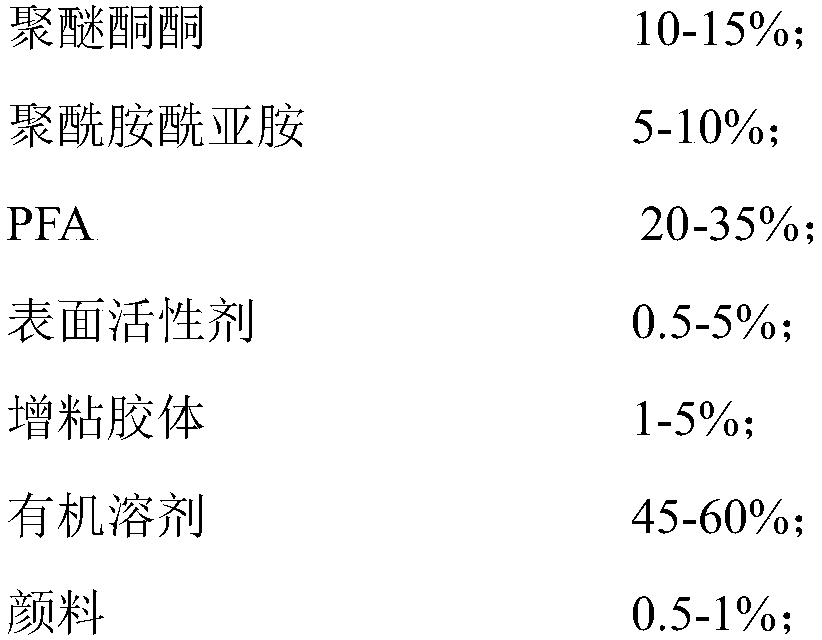

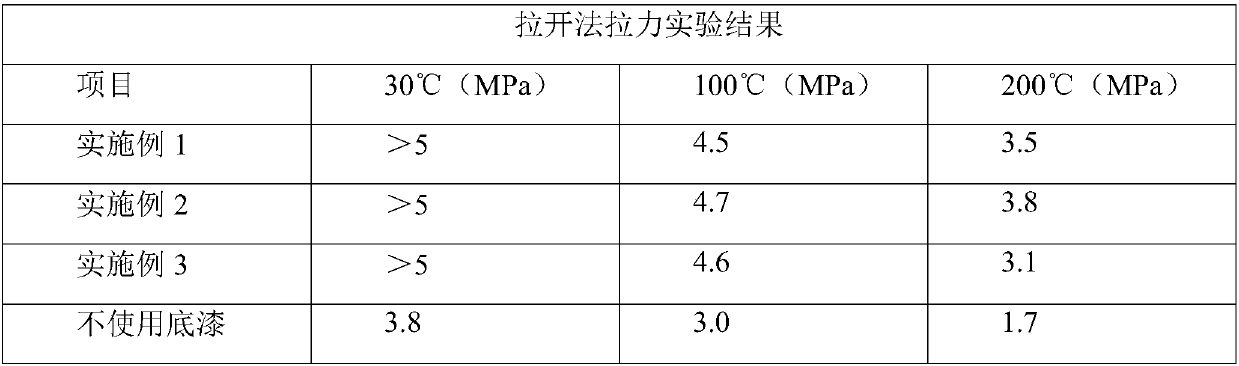

Polyetherketoneketone-reinforced high temperature-resistant and anticorrosive fluororesin coating

ActiveCN109651902AImprove adhesionImprove heat resistanceFireproof paintsAnti-corrosive paintsOrganic solventPolyetherketoneketone

The invention relates to a polyetherketoneketone-reinforced high temperature-resistant and anticorrosive fluororesin coating, and belongs to the technical field of polymers. The coating comprises a polyetherketoneketone-containing fluororesin primer and a polyetherketoneketone-modified fluororesin finish, and the polyetherketoneketone-containing fluororesin primer comprises, by mass, 10-15% of polyetherketoneketone, 5-10% of polyamideimide, 20-35% of PFA, 0.5-5% of a surfactant, 1-5% of tackifying colloid, 45-60% of an organic solvent and 0.5-1% of a pigment; and the polyetherketone modifiedfluororesin finish comprises fluororesin, polyetherketoneketone and a crosslinker, wherein the polyetherketoneketone accounts for 7-15% of the mass of the fluororesin, and the crosslinker accounts for0.1-0.5% of the mass of the fluororesin. The polyetherketoneketone reinforced fluororesin vacuum-resistant and high temperature-resistant coating has the resistance to vacuum, the high temperature and corrosion.

Owner:SHANDONG KAISHENG NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com