High-antistatic polyether ketone ketone electrostatic spraying powder paint as well as preparation method and application thereof

A polyether ketone ketone, electrostatic spraying technology, applied in powder coating, conductive coating, coating, etc., can solve the problems of powder spit, poor powder discharge, uneven distribution, etc., achieve good fluidity, improve conductivity, and construction simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

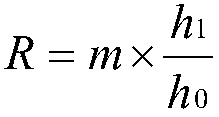

Method used

Image

Examples

Embodiment 1

[0027] Put 500g of polyether ketone ketone resin with a D50 particle size of 50 μm, and 15 g of carbon nanotubes coated with acrylic resin on the surface, and put them into a laboratory high-speed pulverizer and stir at high speed for 2 minutes to obtain coating 1.

Embodiment 2

[0029] Put 500g of polyether ketone ketone resin with a D50 particle size of 50 μm, and 50 g of carbon nanotubes coated with acrylic resin on the surface, and put them into a laboratory high-speed pulverizer and stir at high speed for 2 minutes to obtain coating 2.

Embodiment 3

[0031] Put 500g of polyether ketone ketone resin with a D50 particle size of 50 μm, and 15 g of graphene coated with acrylic resin on the surface, and put them into a laboratory high-speed pulverizer for high-speed stirring for 2 minutes to obtain coating 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com