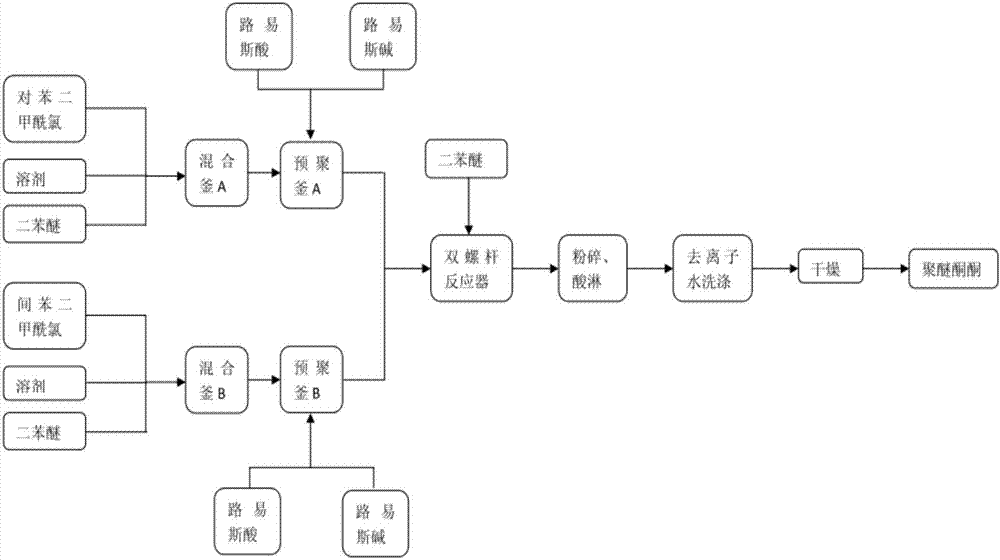

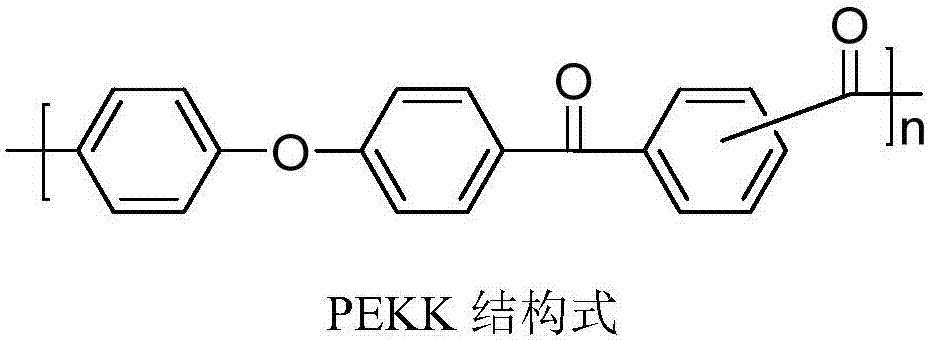

Semi-continuous preparation process for block PEKK (polyetherketoneketone)

A polyetherketoneketone, semi-continuous technology, applied in the field of polymer synthesis, can solve the problems of destroying the feeding ratio, difficult collision of active end groups, difficult handling, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Semi-continuous method prepares the technique of block polyether ketone ketone, and the steps are as follows:

[0050] (1) Add 350kg of dichloromethane to the prepolymerization kettle A, cool down to -15°C, then add 147kg of anhydrous aluminum chloride and 35kg of dimethylformamide to the prepolymerization kettle in batches for reaction to obtain a reaction solution A;

[0051] (2) Add 150kg of dichloromethane to the prepolymerization kettle B, cool down to -15°C, then add 63kg of anhydrous aluminum chloride and 15kg of dimethylformamide to the prepolymerization kettle in batches for reaction to obtain a reaction solution B;

[0052] (3) 42.63kg of terephthaloyl chloride and 35.74kg of diphenyl ether are added to the mixing kettle A, then 42kg of dichloromethane is added for dissolving, and mixed solution A is obtained after mixing;

[0053] (4) 18.27kg of isophthaloyl chloride, 15.32kg of diphenyl ether are added in the mixing kettle B, then 18kg of dichloromethane i...

Embodiment 2

[0057] Semi-continuous method prepares the technique of block polyether ketone ketone, and the steps are as follows:

[0058] (1) Add 300kg of dichloromethane to the prepolymerization kettle A, cool down to -15°C, then add 126kg of anhydrous aluminum chloride and 30kg of dimethylformamide to the prepolymerization kettle in batches for reaction to obtain a reaction solution A;

[0059] (2) Add 200kg of dichloromethane to the prepolymerization kettle B, cool down to -15°C, then add 84kg of anhydrous aluminum chloride and 20kg of dimethylformamide to the prepolymerization kettle in batches for reaction to obtain a reaction solution B;

[0060] (3) 36.54kg of terephthaloyl chloride and 30.62kg of diphenyl ether are added to the mixing kettle A, then 36kg of dichloromethane is added for dissolving, and mixed solution A is obtained after mixing;

[0061] (4) 26.36kg of isophthaloyl chloride, 20.42kg of diphenyl ether are added in the mixing kettle B, then 24kg of dichloromethane i...

Embodiment 3

[0065] Semi-continuous method prepares the technique of block polyether ketone ketone, and the steps are as follows:

[0066] (1) Add 250kg of dichloromethane to the prepolymerization kettle A, lower the temperature to -15°C, then add 105kg of anhydrous aluminum chloride and 25kg of dimethylformamide to the prepolymerization kettle in batches for reaction to obtain a reaction solution A;

[0067] (2) Add 250kg of dichloromethane to the prepolymerization kettle B, lower the temperature to -15°C, then add 105kg of anhydrous aluminum chloride and 25kg of dimethylformamide to the prepolymerization kettle in batches for reaction to obtain a reaction solution B;

[0068] (3) 30.45kg of terephthaloyl chloride and 25.53kg of diphenyl ether are added to the mixing kettle A, then 30kg of dichloromethane is added for dissolving, and mixed solution A is obtained after mixing;

[0069] (4) 30.45kg of isophthaloyl chloride, 25.53kg of diphenyl ether are added in the mixing kettle B, then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com