High-temperature-resistant water-based carbon fiber universal sizing agent and preparation method and application thereof

A carbon fiber, high temperature resistant technology, applied in the direction of carbon fiber, fiber processing, fiber type, etc., can solve the problems of high price, the influence of composite materials use and subsequent use, graphene oxide is easy to agglomerate, etc., to achieve increased heat resistance and mechanical properties. , Excellent damp heat stability, good environmental adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Weight ratio Weigh 1 part of polyether ketone ketone powder and 10 parts of concentrated sulfuric acid, add the two into a reaction flask, control the reaction temperature at 30°C and stir for 72 hours. Then the product was slowly added dropwise into deionized water in an ice-water bath, and after the two were fully stirred, the mixture was separated by centrifugation. Subsequently, the mixture was washed with a large amount of deionized water, and ultrasonic dispersion and centrifugation were repeated until the sulfuric acid in the mixture was washed away. Then deionized water was added to the product again to adjust the pH value to 7. The product was separated by suction filtration, the solid matter was transferred to an oven, and the temperature was controlled at 60° C. for drying for about 12 hours. Finally, light yellow sulfonated polyether ketone ketone powder is obtained, which is stored in a vacuum desiccator.

[0043] Weigh the sulfonated polyether ketone ket...

Embodiment 2

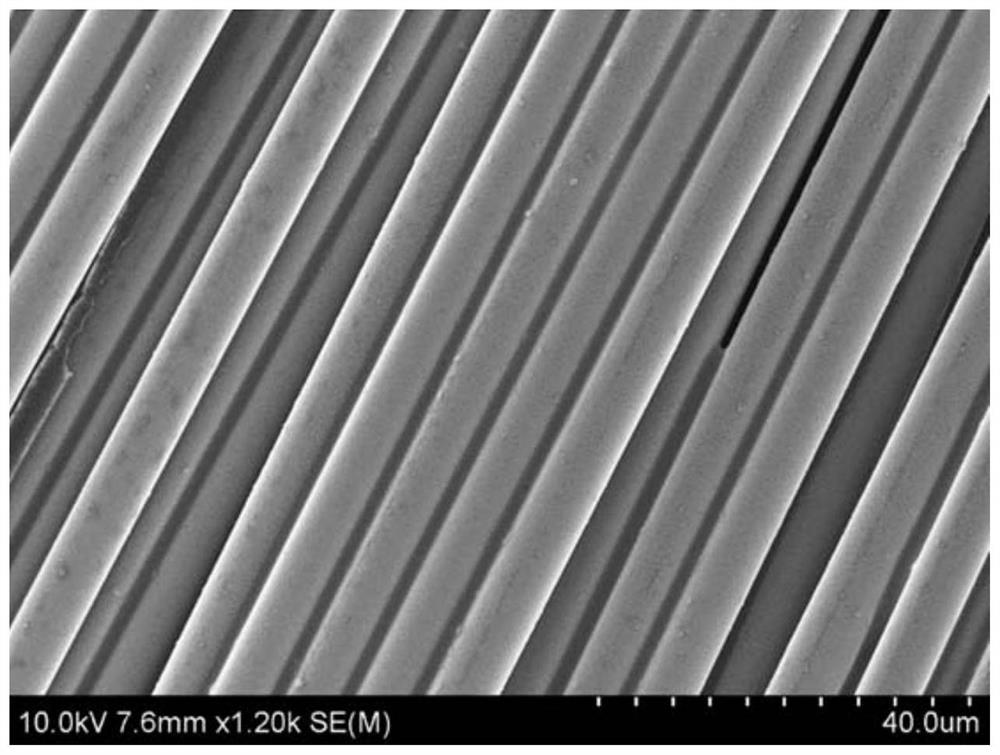

[0045] Sulfonated polyether ketone ketone powder was prepared according to the method of Example 1.

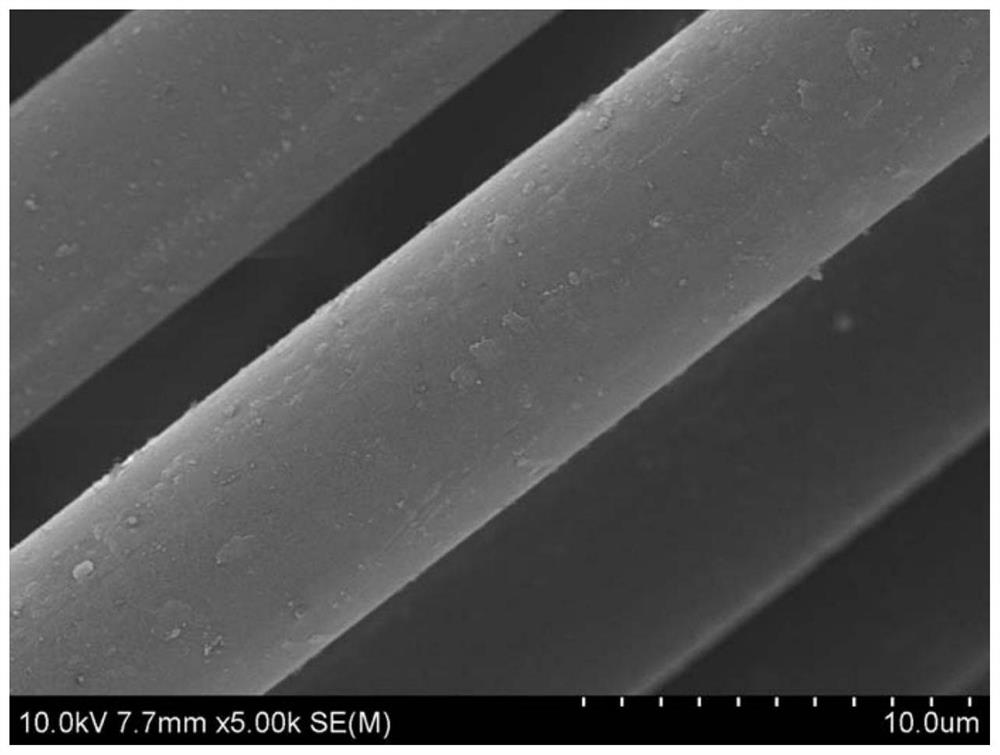

[0046] Weigh the sulfonated polyether ketone ketone according to the weight ratio, add it into deionized water, stir at 60° C. at a speed of 250 r / min for 2 hours, and obtain a uniform water-based sizing agent. The concentration of sulfonated polyether ketone ketone is 2% in proportion. Then the original continuous carbon fiber with 70% of the total weight of the sizing agent was weighed, its surface was cleaned with ethanol and deionized water, and then placed in an oven for drying. Then soak the surface-treated carbon fiber into the prepared sizing agent and ultrasonically treat it for 1 hour. Afterwards, the carbon fibers were taken out, transferred to an oven, and dried at a controlled temperature of 140°C for 12 hours. Finally, the sized carbon fiber is taken out. In this example, referring to "GB / T3357-1982 Test Method for Interlaminar Shear Strength of Unidirectional...

Embodiment 3

[0048] Sulfonated polyether ketone ketone powder was prepared according to the method of Example 1.

[0049] Weigh the sulfonated polyether ketone ketone according to the weight ratio, add it into deionized water, stir at 60° C. at a speed of 250 r / min for 2 hours, and obtain a uniform water-based sizing agent. The concentration of sulfonated polyether ketone ketone is 2% in proportion.

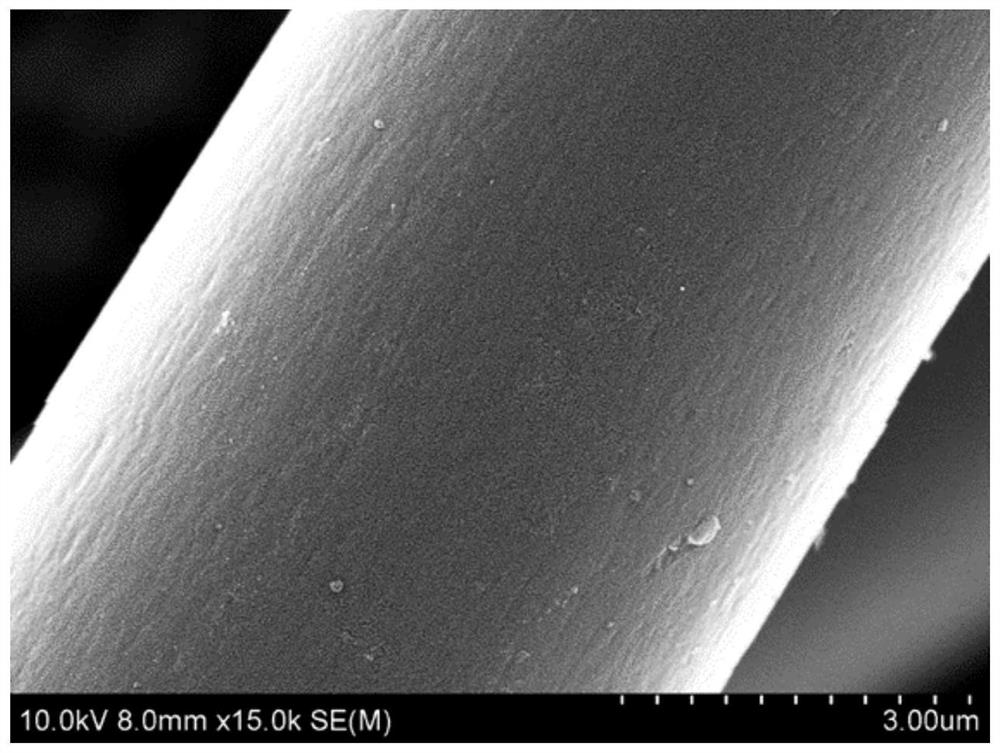

[0050] Weigh the original carbon fiber according to 60% of the total weight of the sizing agent, firstly use ethanol and deionized water to clean the surface of the carbon fiber, and then transfer it to an oven for drying. Spread the dried carbon fiber on the substrate, use a high-pressure watering can to evenly spray the prepared carbon fiber sizing agent on the surface of the carbon fiber, let it stand for a period of time, transfer it to an oven, and control the temperature at 140°C for 12 hours. Finally, the continuous carbon fibers were evenly cut into 6mm chopped carbon fibers by a she...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com