Polyetherketoneketone-reinforced high temperature-resistant and anticorrosive fluororesin coating

A polyetherketone ketone and anti-corrosion coating technology, applied in the polymer field, can solve the problems of poor coating adhesion, coating peeling, etc., and achieve strong adhesion, good heat resistance, and improved application range and service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

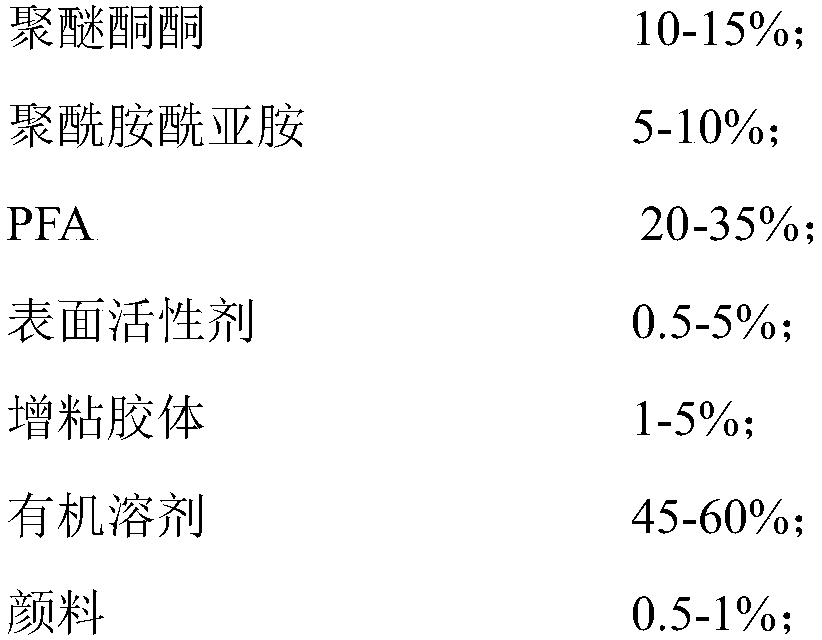

Method used

Image

Examples

Embodiment 1

[0031] Add 40g of surfactant APEO and 578g of N-methylpyrrolidone into the mixing tank in turn, set the stirring speed at 1500r / min, and stir for 10min. Ketone powder 120g, PFA resin 220g, carbon black 6g, join in the solution, set the rotating speed as 1500r / min and stir for 50min, after the solution system is dispersed evenly, add 30g hydroxymethyl cellulose ether to the solution system, set the rotating speed as Stir the system at 1000r / min to obtain a uniform and stable primer, filter it with a 150-mesh filter, let it stand still, and use it.

[0032] Weigh 10g of 4,4-diaminodiphenyl ether, 300g of polyetherketoneketone fine powder and 2990g of PFA resin, mix them in a three-dimensional mixer for 30min, take out the materials, and first coat the metal substrate with fluorine containing polyetherketoneketone Resin primer, after the primer is dried, spray the polyether ketone ketone modified PFA resin topcoat on the primer by electrostatic spraying.

Embodiment 2

[0034] Add 40g of surfactant APEO and 578g of N-methylpyrrolidone into the mixing tank in turn, set the stirring speed at 1500r / min and stir for 15min. Add 140g of fine powder, 240g of PFA resin, and 6g of carbon black into the solution, and stir at a low speed for 60 minutes. After the solution system is uniformly dispersed, add 30g of hydroxymethyl cellulose ether to the solution system, and set the rotation speed at 1000r / min to stir the system. Obtain a uniform and stable primer, filter it with a 150-mesh filter, let it stand still, and use it.

[0035] Weigh 10g of 4,4-diaminodiphenyl ether, 300g of polyetherketoneketone fine powder and 2990g of PFA resin, mix them in a three-dimensional mixer for 30min, and take out the materials. First coat the fluorine resin primer containing polyether ketone ketone on the metal substrate. After the primer is dried, spray the polyether ketone ketone modified PFA resin topcoat on the primer by electrostatic spraying.

Embodiment 3

[0037] Add 40g of surfactant APEO and 536g of N-methylpyrrolidone into the mixing tank in turn, set the stirring speed at 1500r / min and stir for 15min. Add 110g of fine powder, 220g of PFA resin, and 6g of carbon black into the solution, set the rotation speed at 1500r / min and stir for 40min. Stir the system to obtain a uniform and stable primer, filter it with a 150-mesh filter, and use it statically.

[0038] Weigh 10g of 4,4-diaminodiphenyl ether, 300g of polyether ketone ketone fine powder and 2990g of PFA resin, mix in a three-dimensional mixer for 30min, take out the materials, and first coat the metal substrate with fluororesin containing polyether ketone ketone Primer, after the primer is dried, spray the polyether ketone ketone modified PFA resin topcoat on the primer by electrostatic spraying.

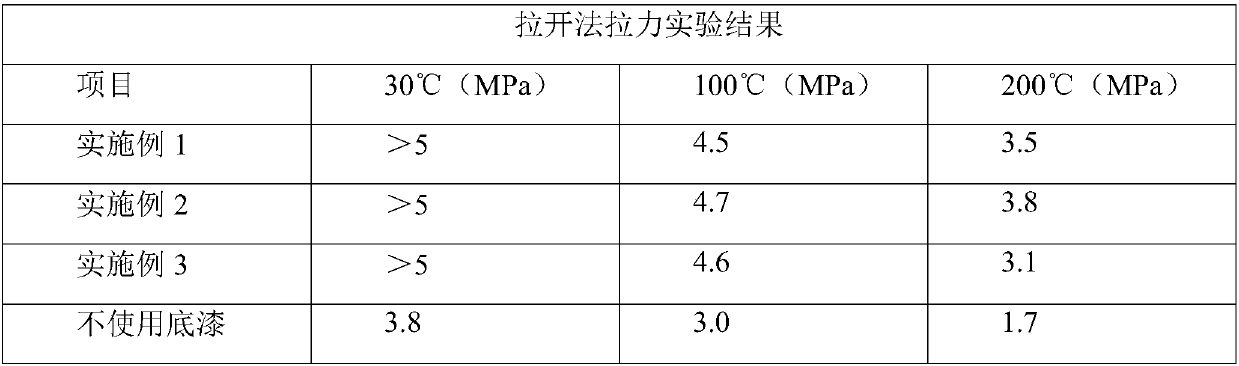

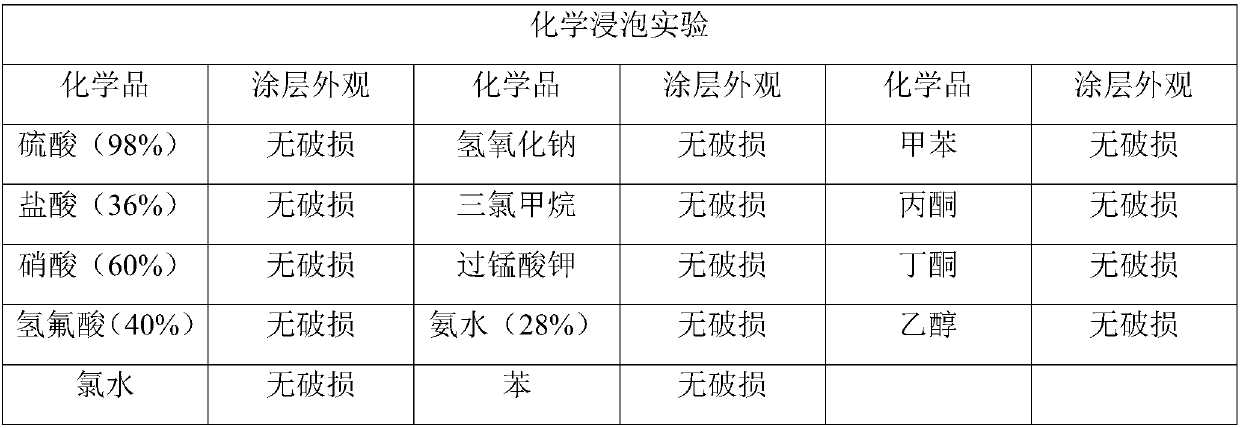

[0039] The bonding force and anti-corrosion performance of the products of Examples 1-3 at different temperatures were measured and evaluated by the pull-off adhesion test, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com