Patents

Literature

40results about How to "Low creep" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

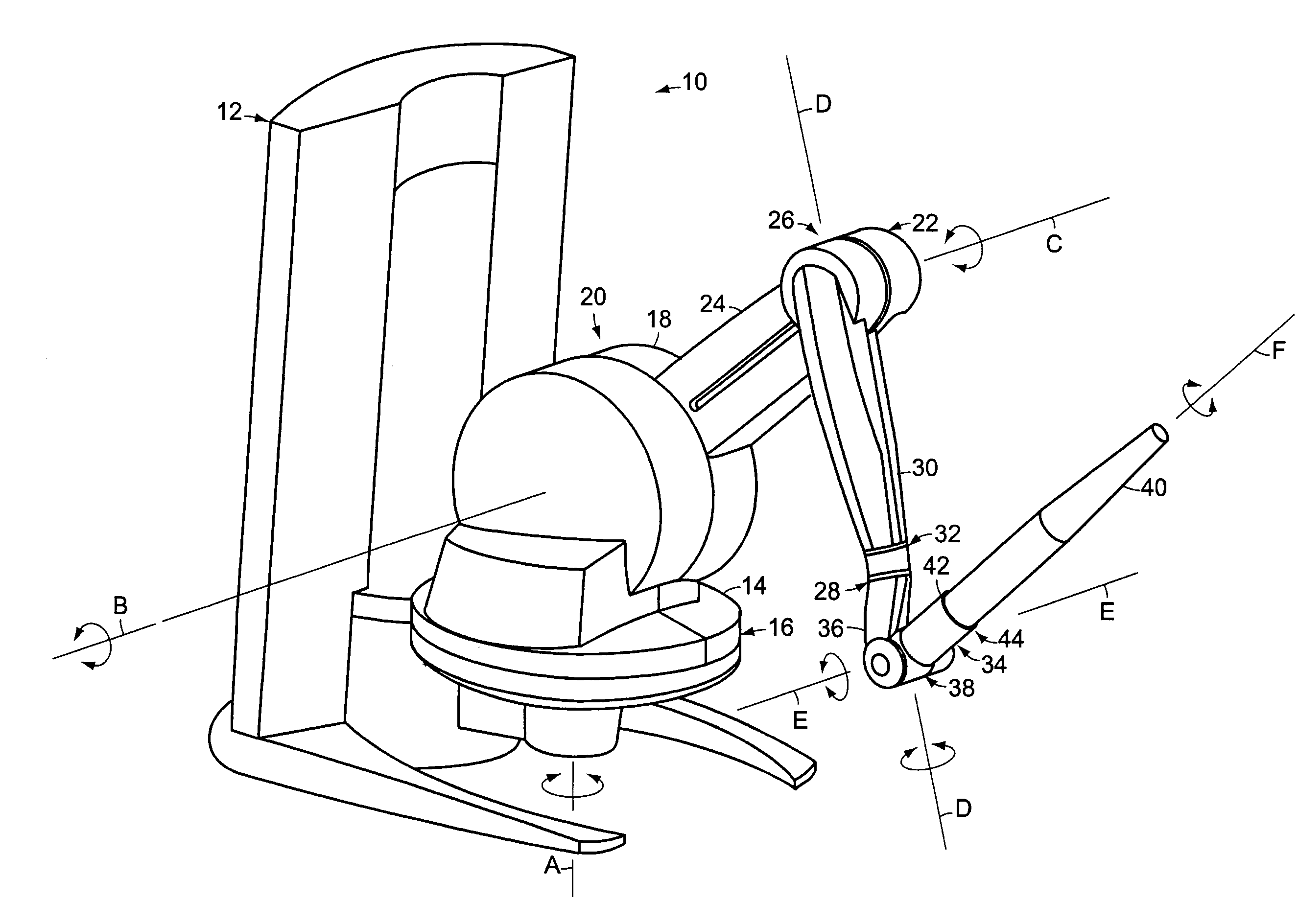

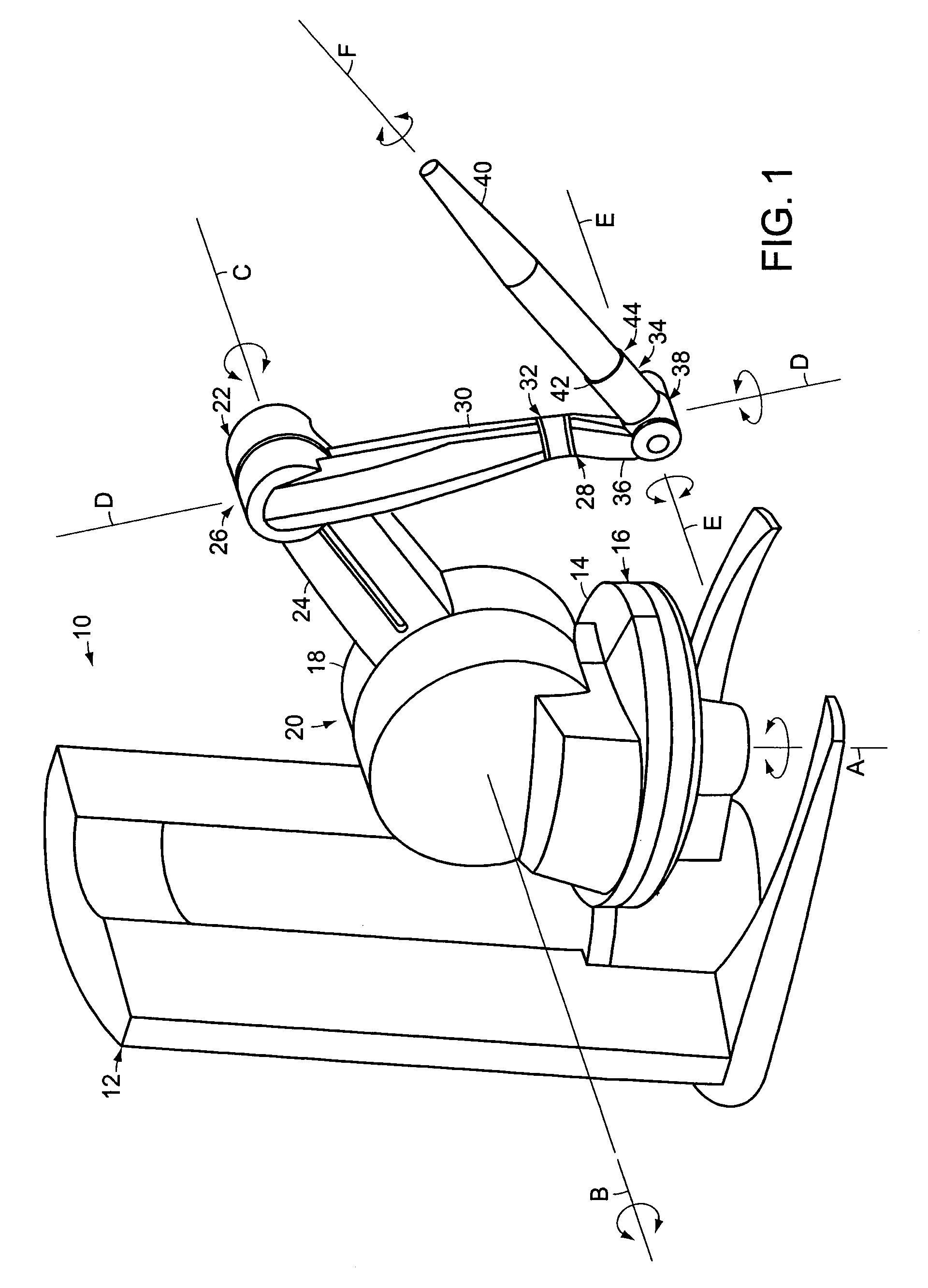

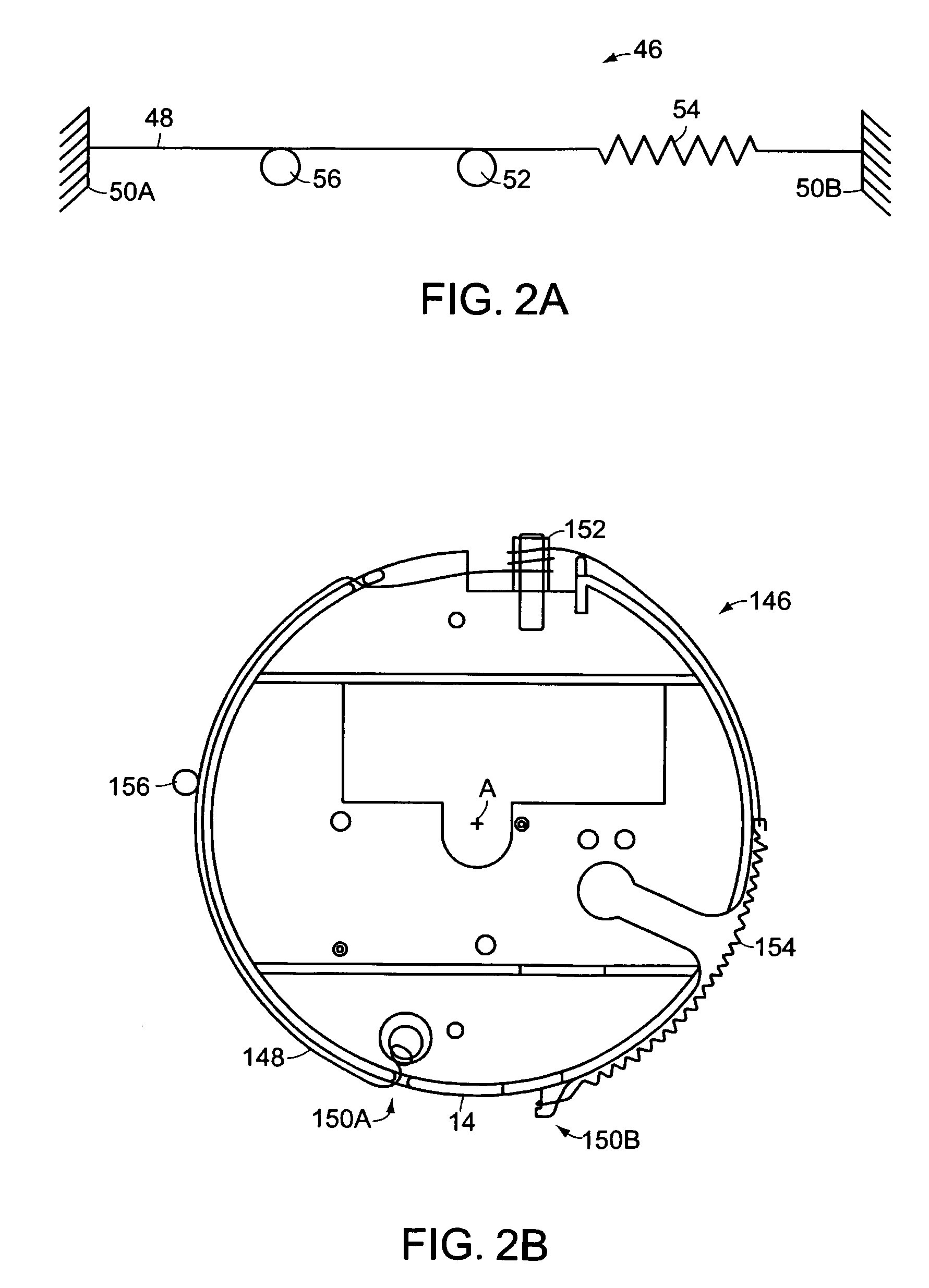

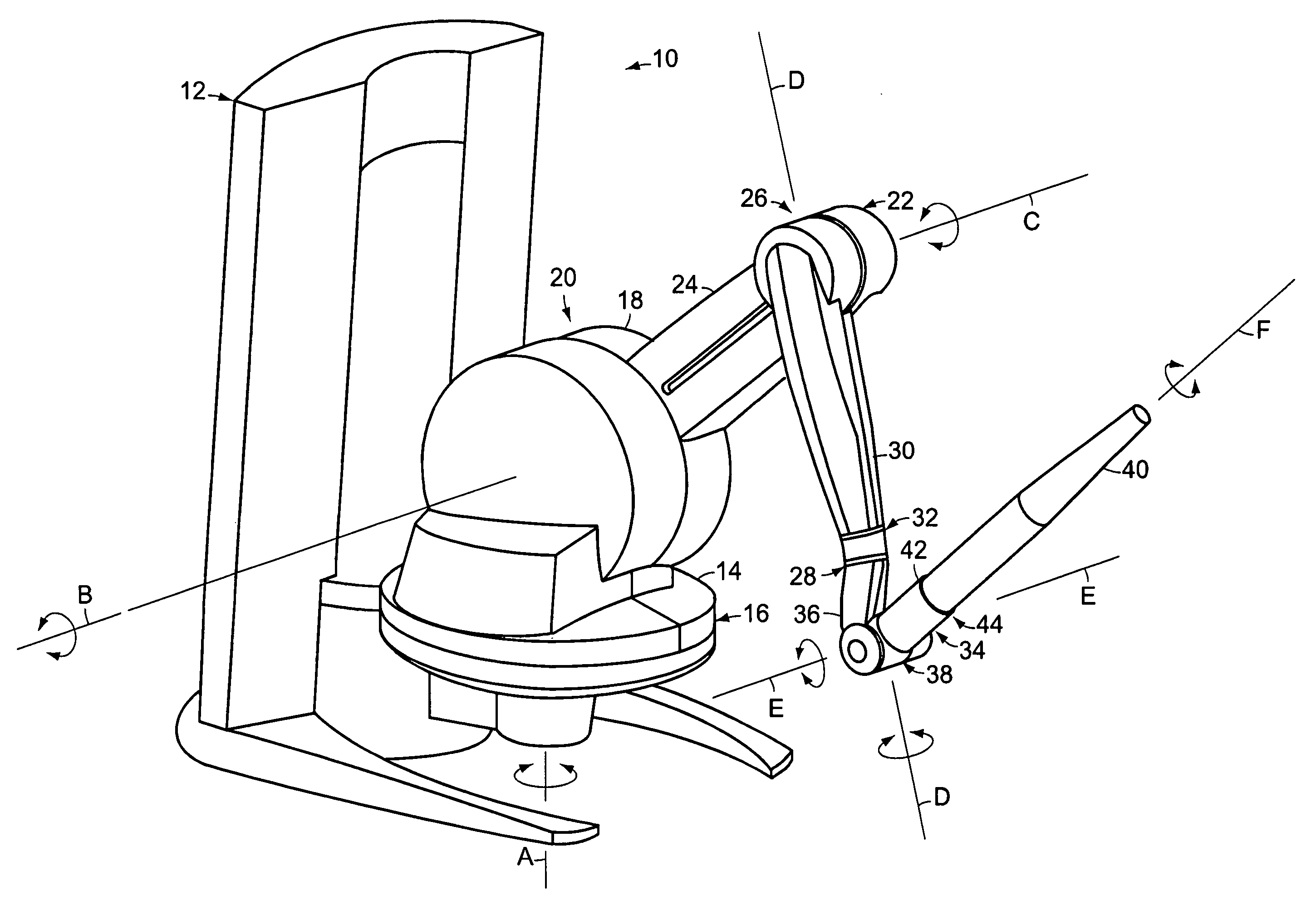

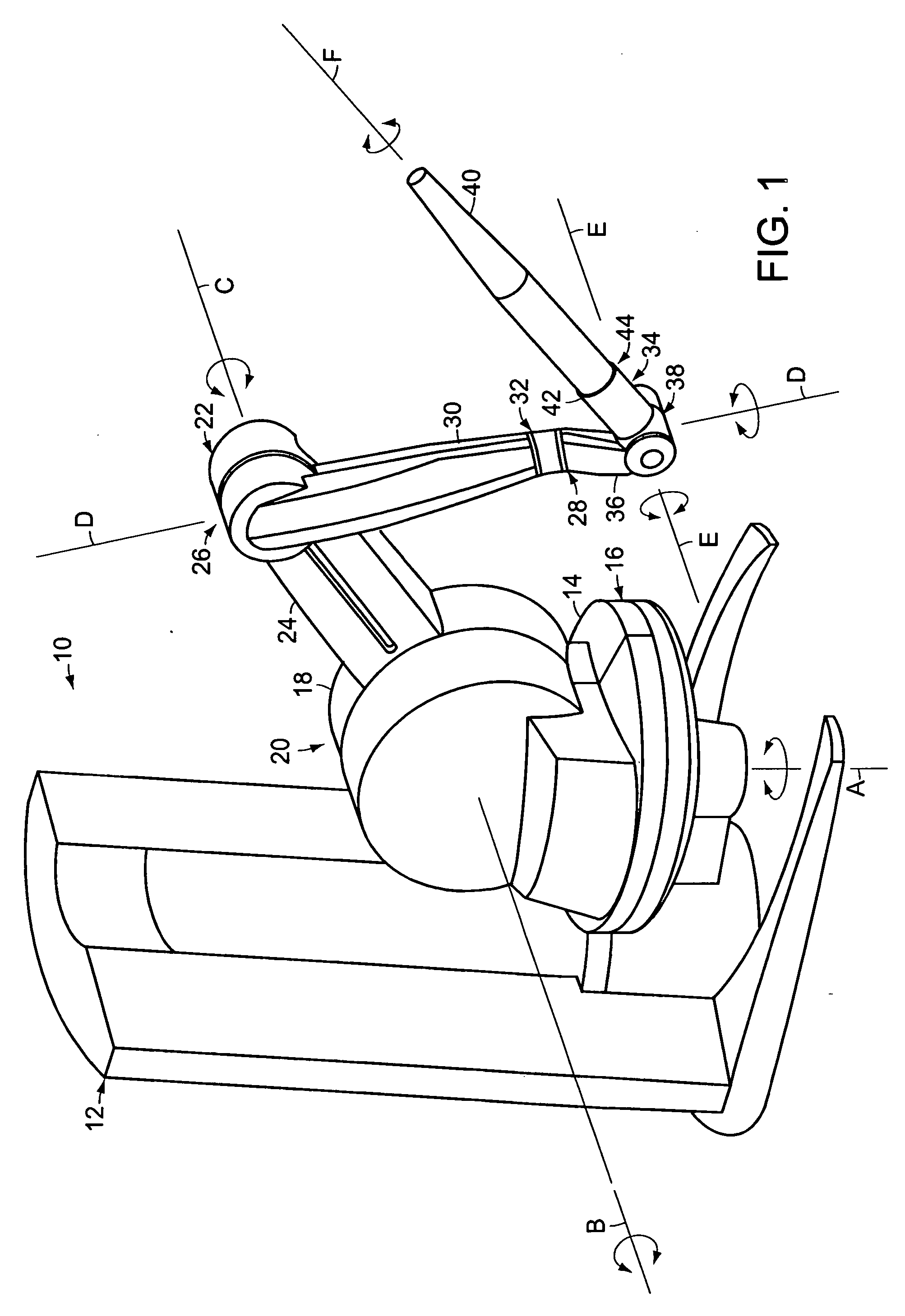

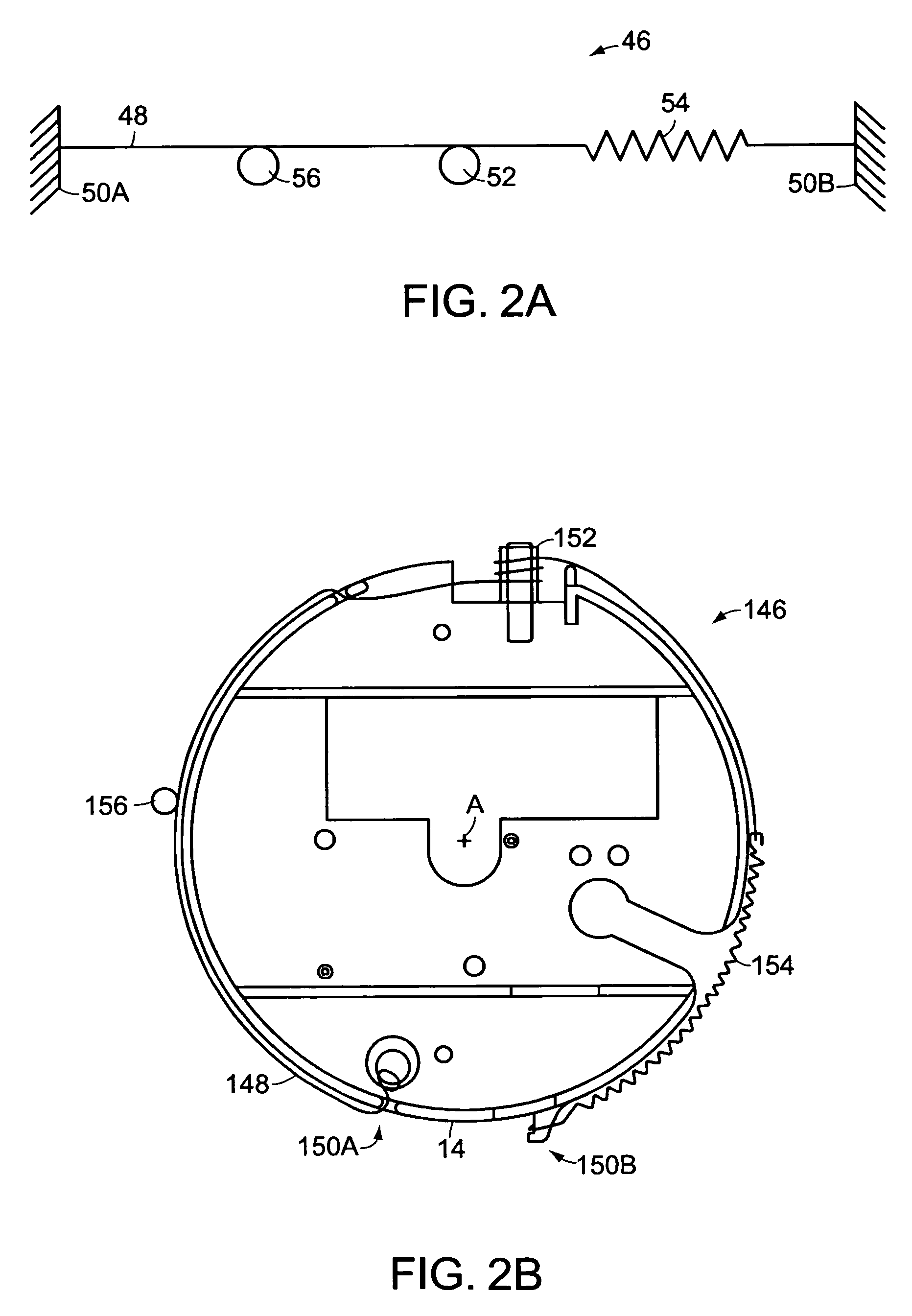

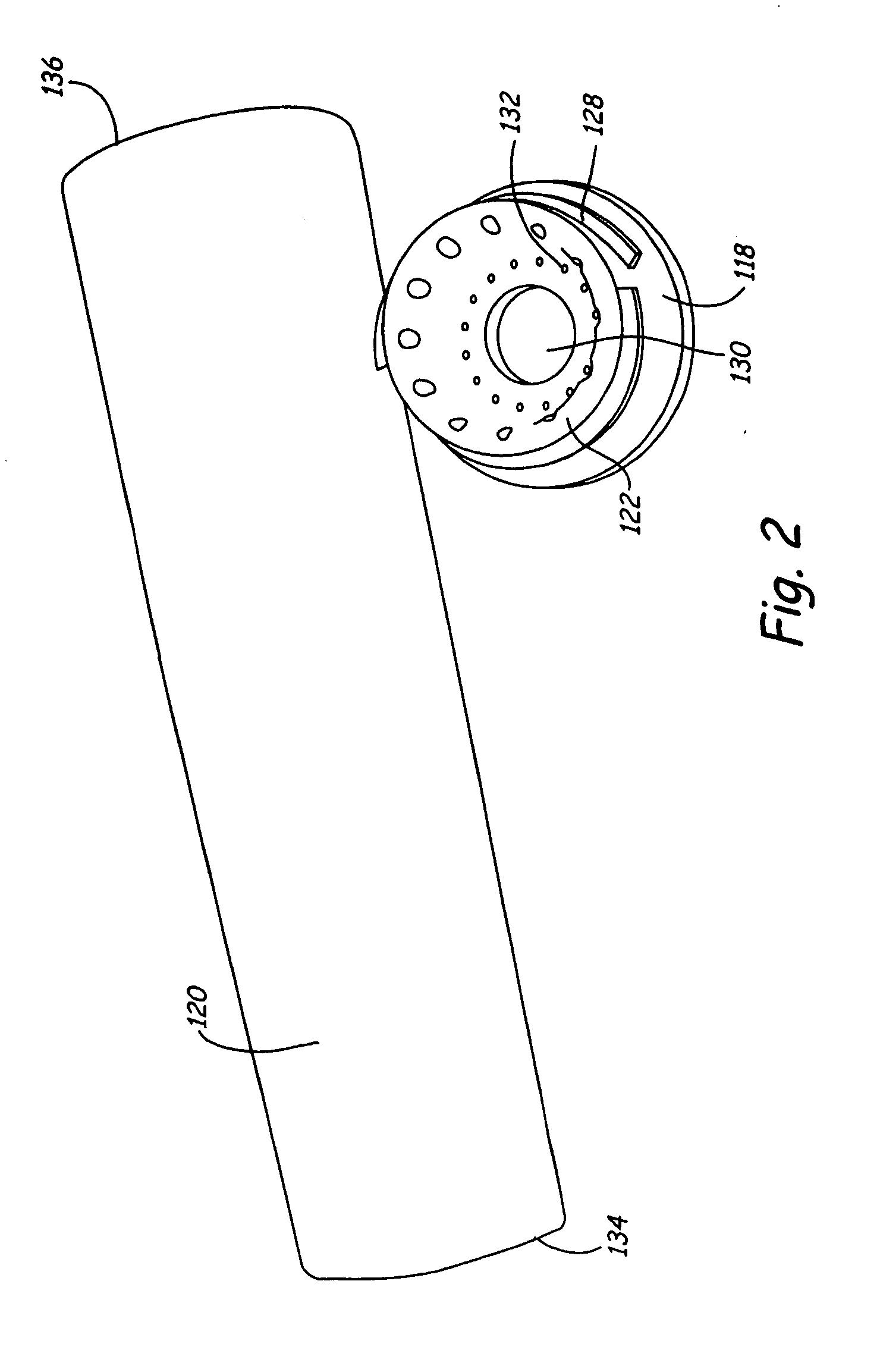

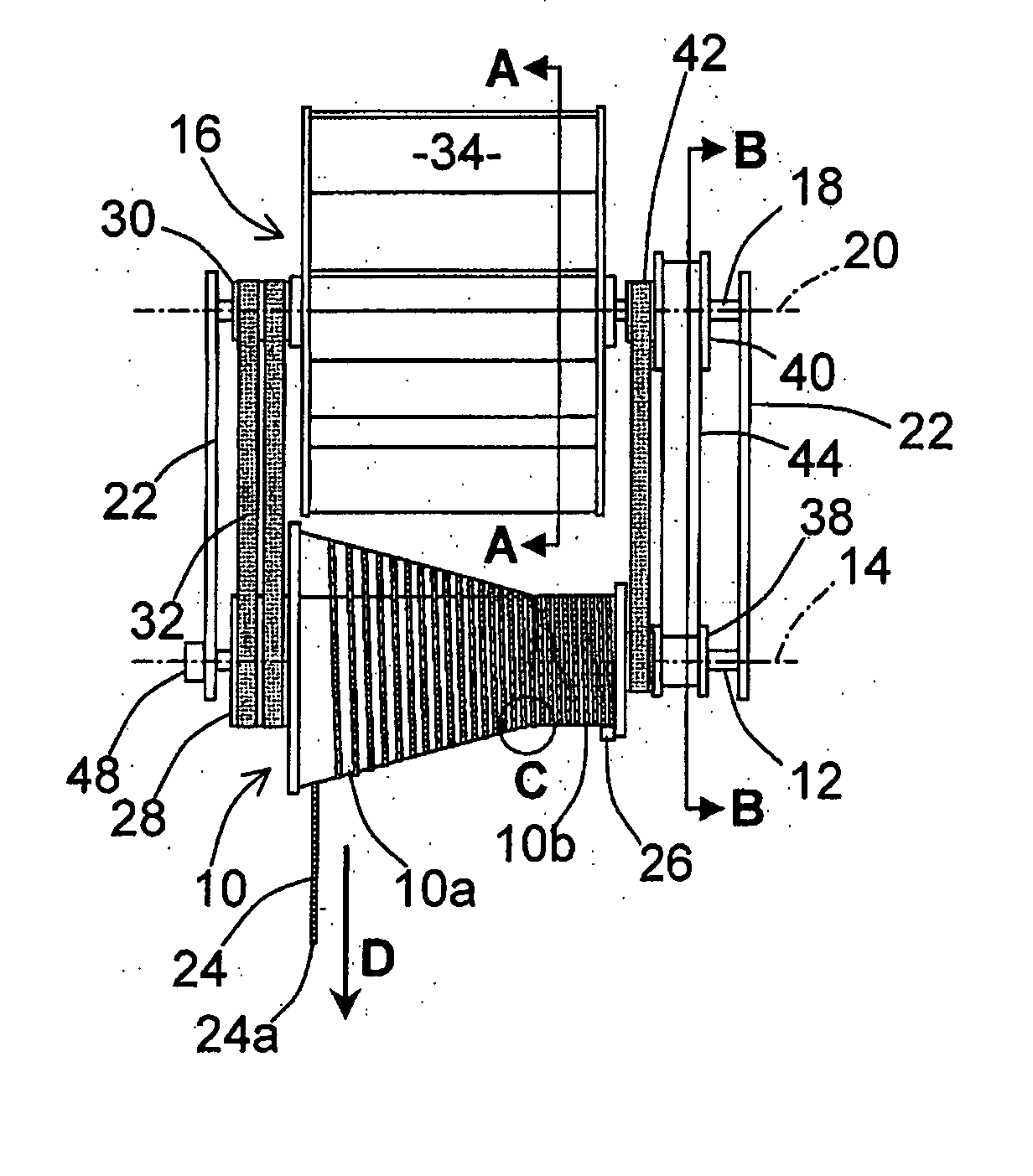

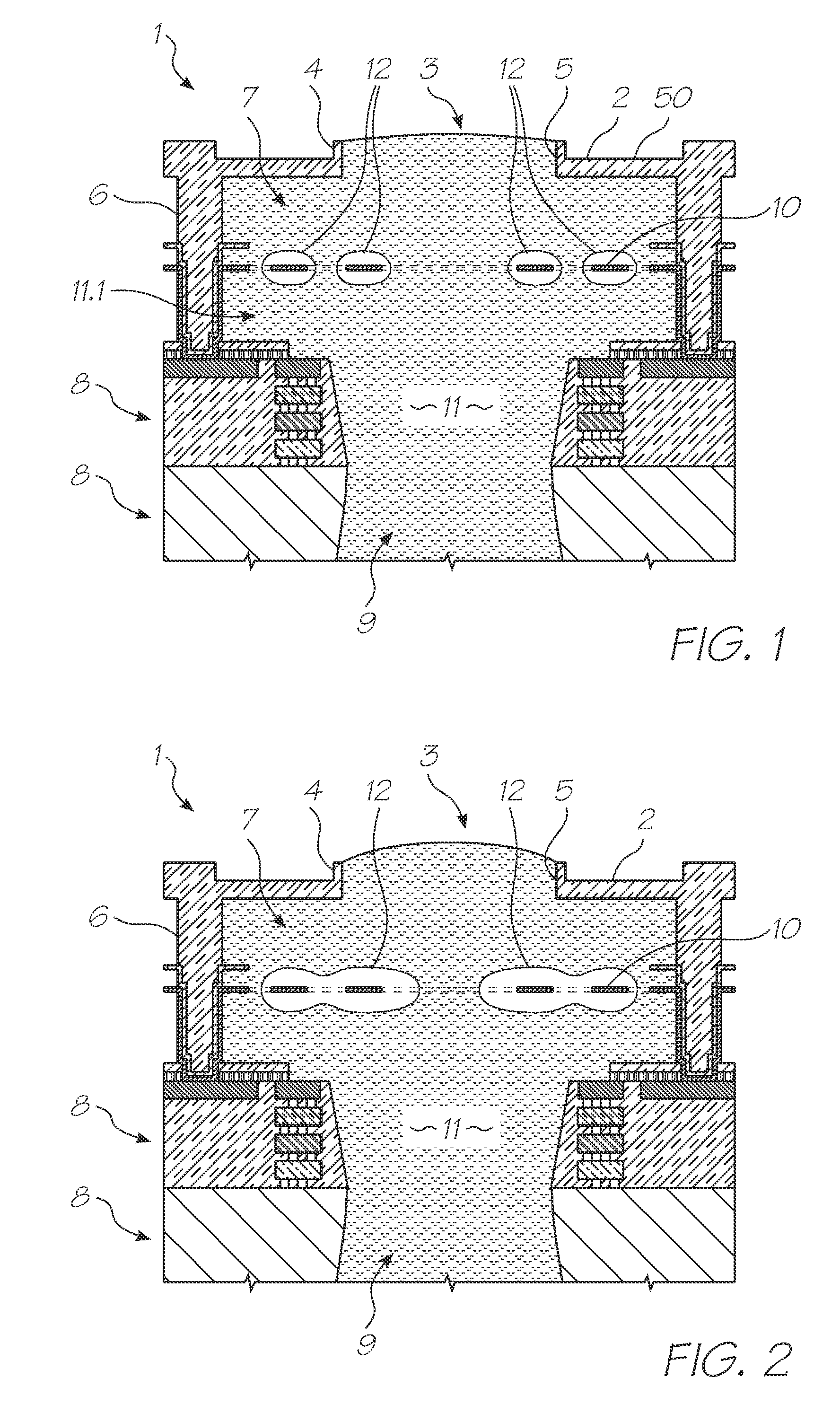

Force reflecting haptic interface

InactiveUS6985133B1Prevent reboundIncrease stiffnessCathode-ray tube indicatorsInput/output processes for data processingEngineeringActuator

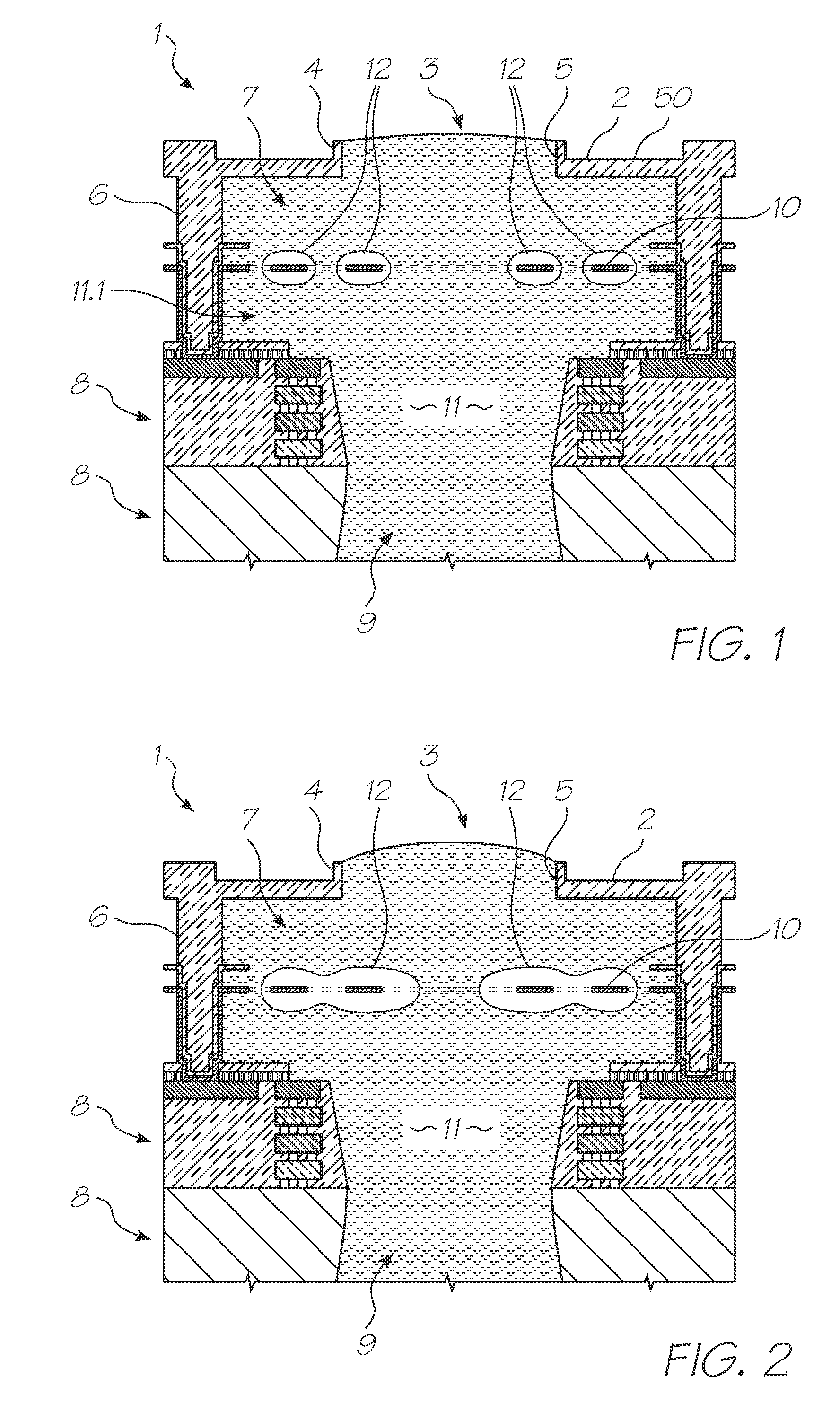

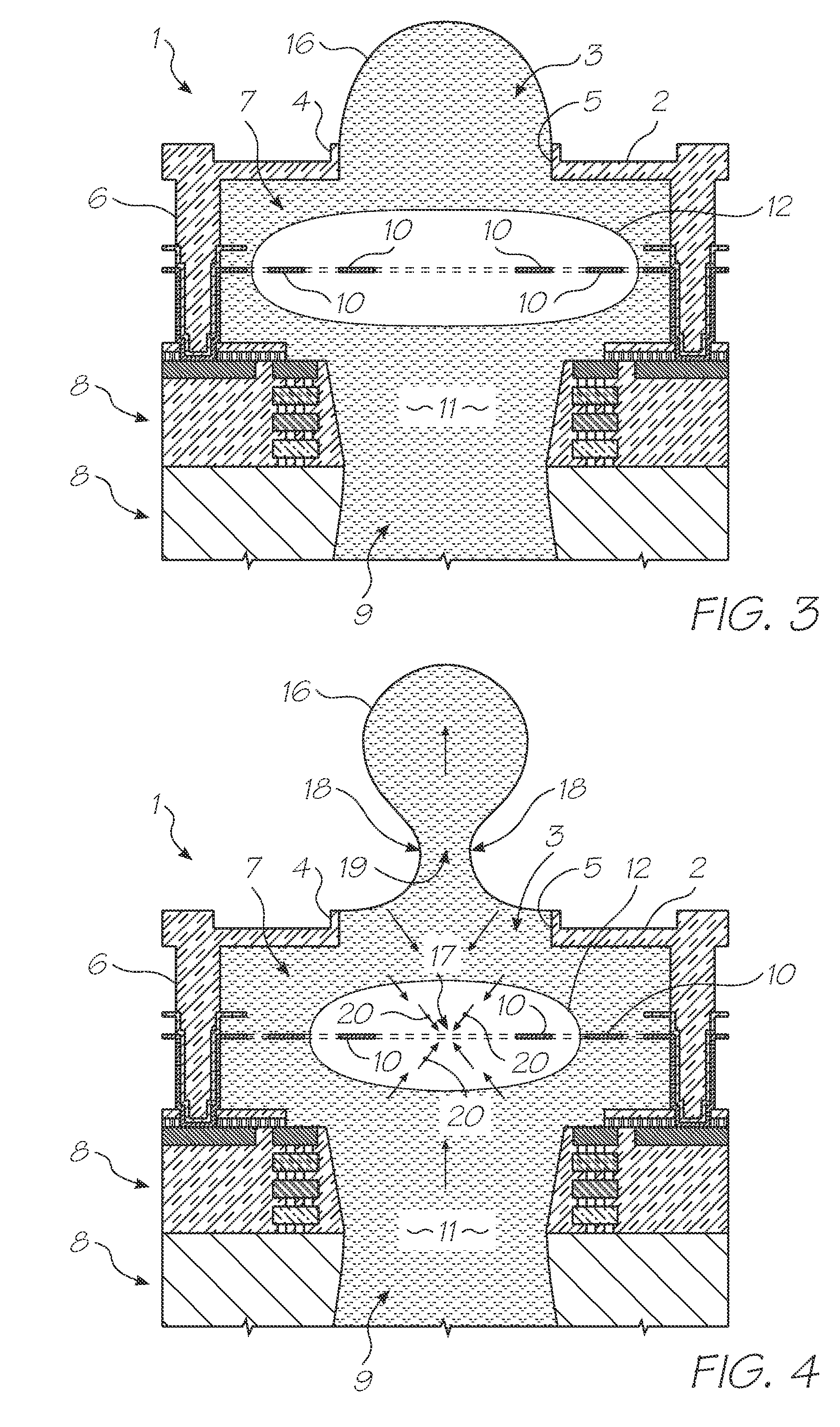

A six degree of freedom force reflecting haptic interface includes three powered axes and three free axes, all of which are tracked so that the position of a user connection element in the work volume can be determined. The interface includes cable drives with polymer composite or metallic cables, automatic cable tensioning devices, and grounded actuator capstans. A nested hub and transfer drive provide a compact, weight balanced interface. User comfort and safety features are also provided.

Owner:3D SYST INC

Force reflecting haptic interface

InactiveUS20060033707A1Prevent reboundIncrease stiffnessCathode-ray tube indicatorsInput/output processes for data processingEngineeringActuator

A six degree of freedom force reflecting haptic interface includes three powered axes and three free axes, all of which are tracked so that the position of a user connection element in the work volume can be determined. The interface includes cable drives with polymer composite or metallic cables, automatic cable tensioning devices, and grounded actuator capstans. A nested hub and transfer drive provide a compact, weight balanced interface. User comfort and safety features are also provided.

Owner:3D SYST INC

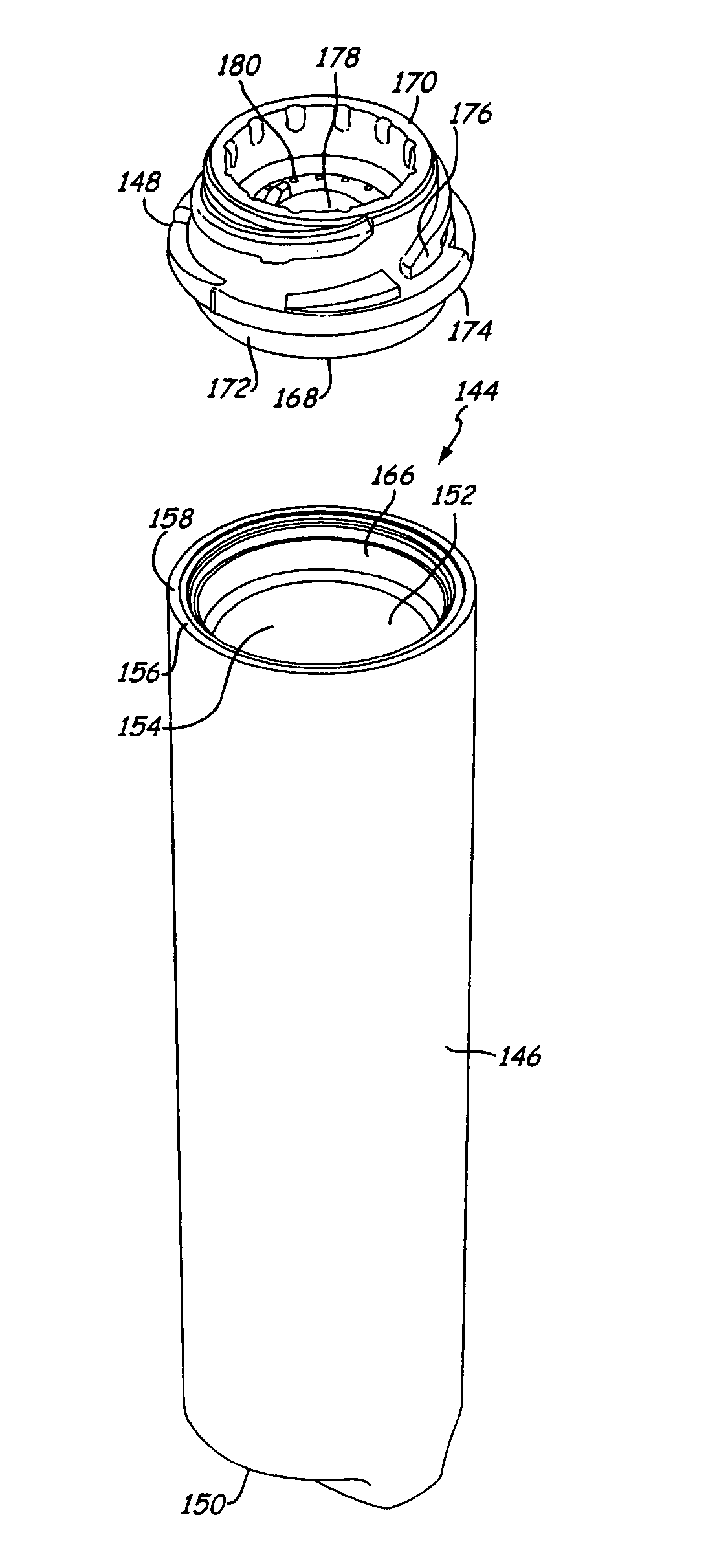

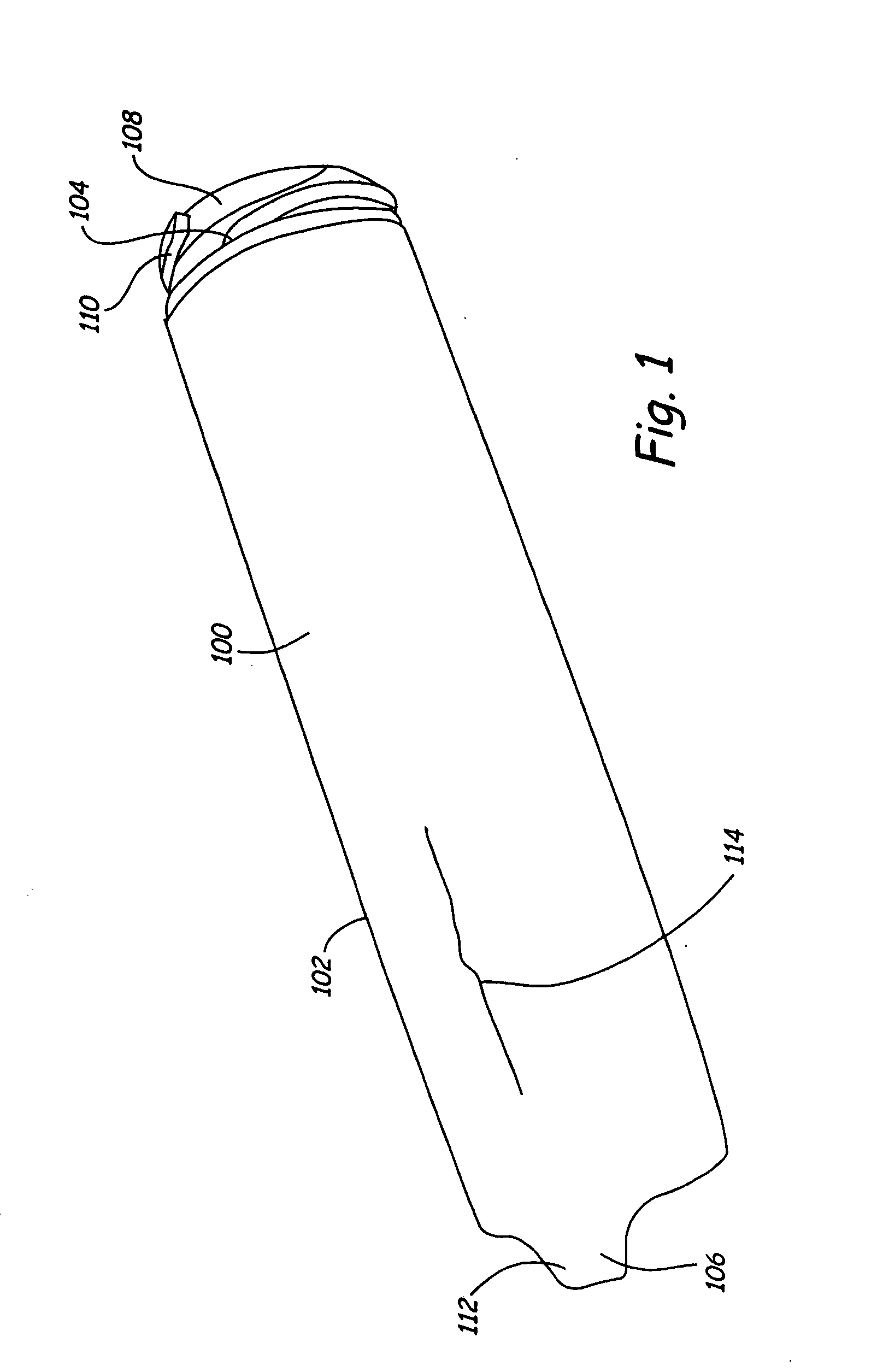

Freeze resistant water filter

InactiveUS20050161394A1Increase elasticityThin wallMembrane filtersCartridge filtersVitrificationPolyolefin

A freeze resistant filter cartridge assembly and methods for fabrication include a filter cartridge including a filter housing and a filter media and having at least one component selected from a list of components consisting of: the filter housing being formed of an increased elasticity polyolefin polymer having elongation and glass transition properties that allow for stretching of the housing during a freezing event rather than rupturing; a sleeve having a volume of air entrapped therein within and being disposed in the interior of the filter cartridge; and the filter housing formed of a conventional polyolefin having a wall thickness great enough to resist freeze induced expansion stresses. A disassemble cartridge filter includes a filter cap, a filter housing and a filter element. The filter cap and filter housing are rotatably attached wherein cap and housing engagement members prevent rotatable disengagement of the filer cap and filter housing.

Owner:3M INNOVATIVE PROPERTIES CO

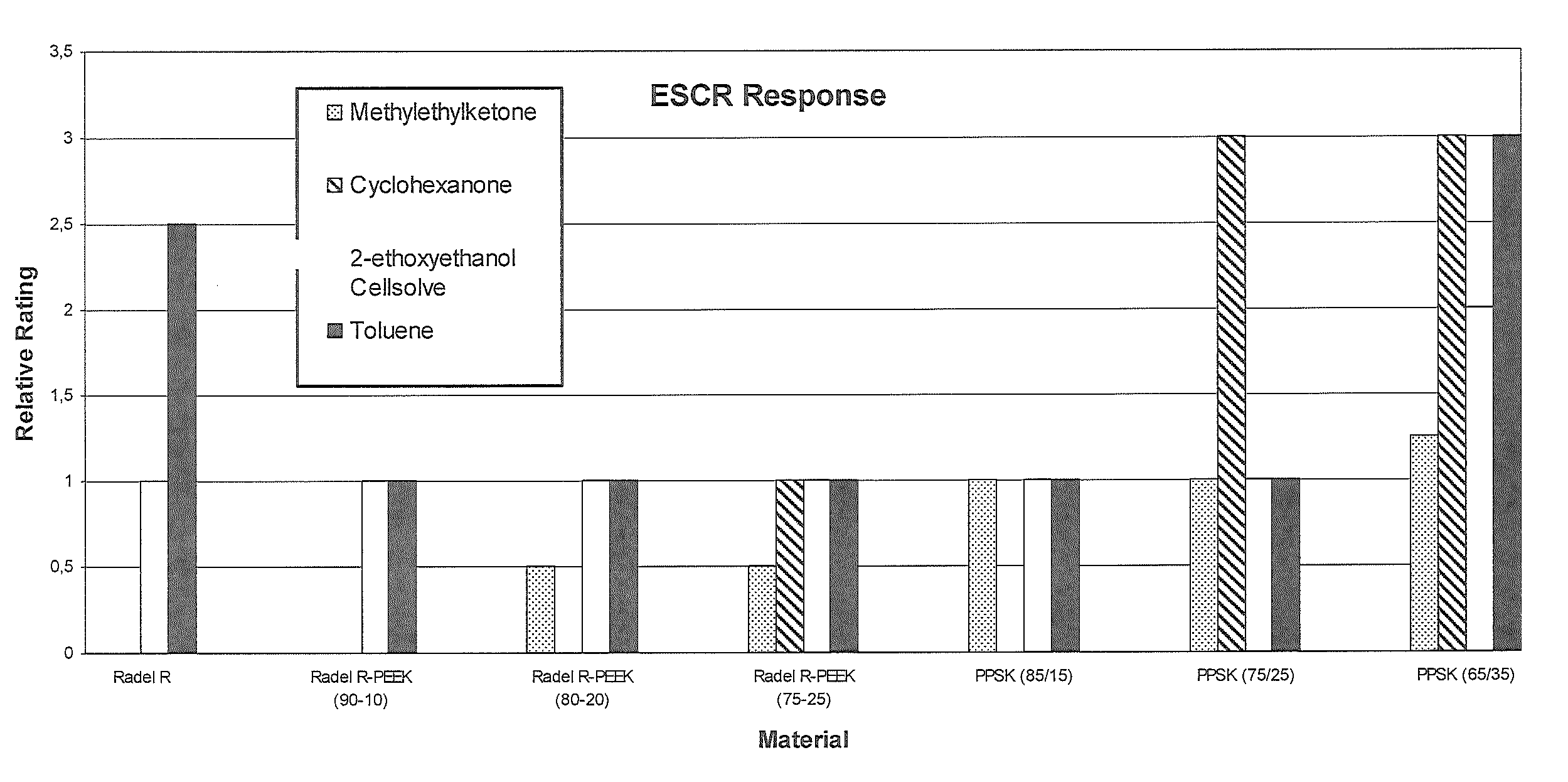

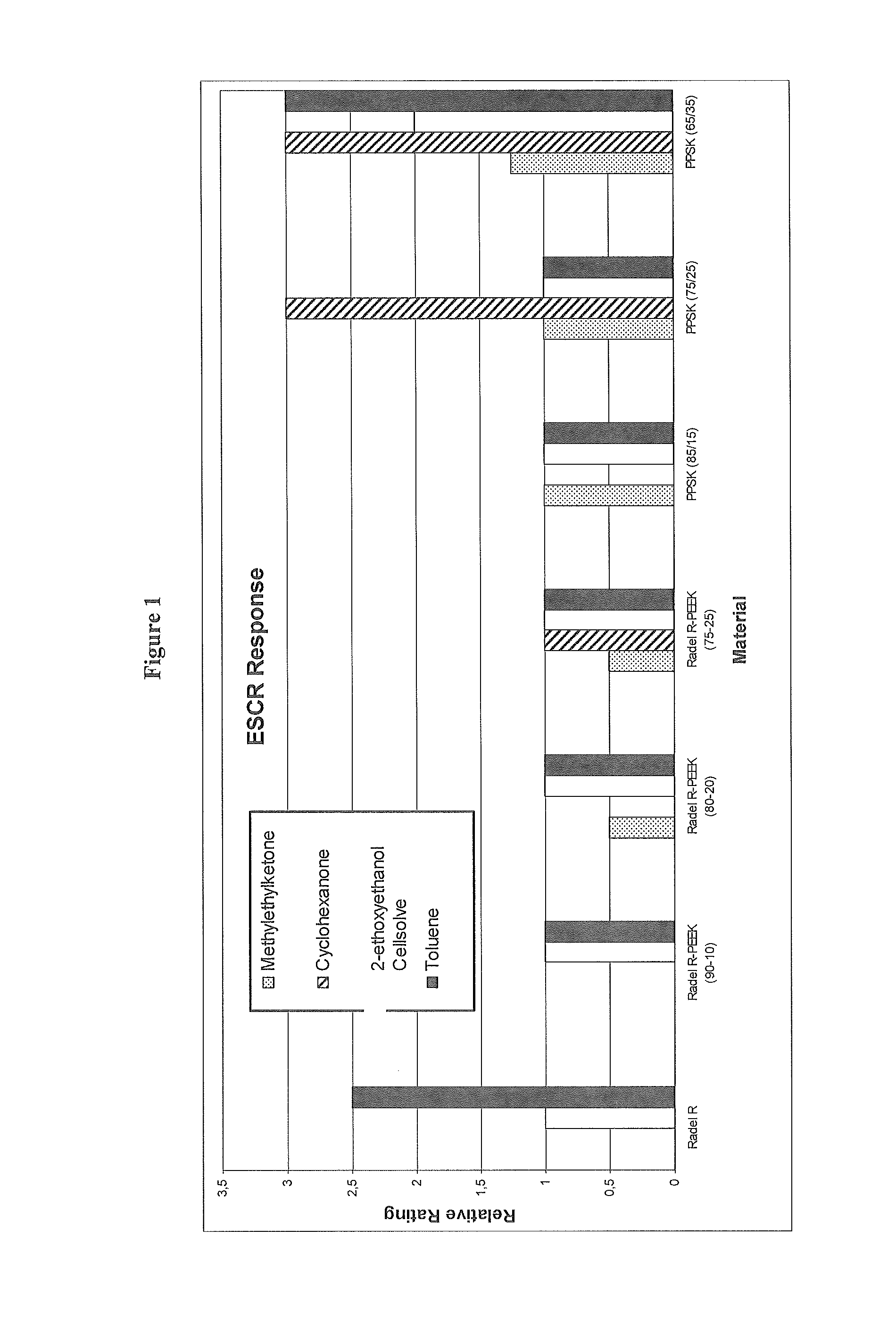

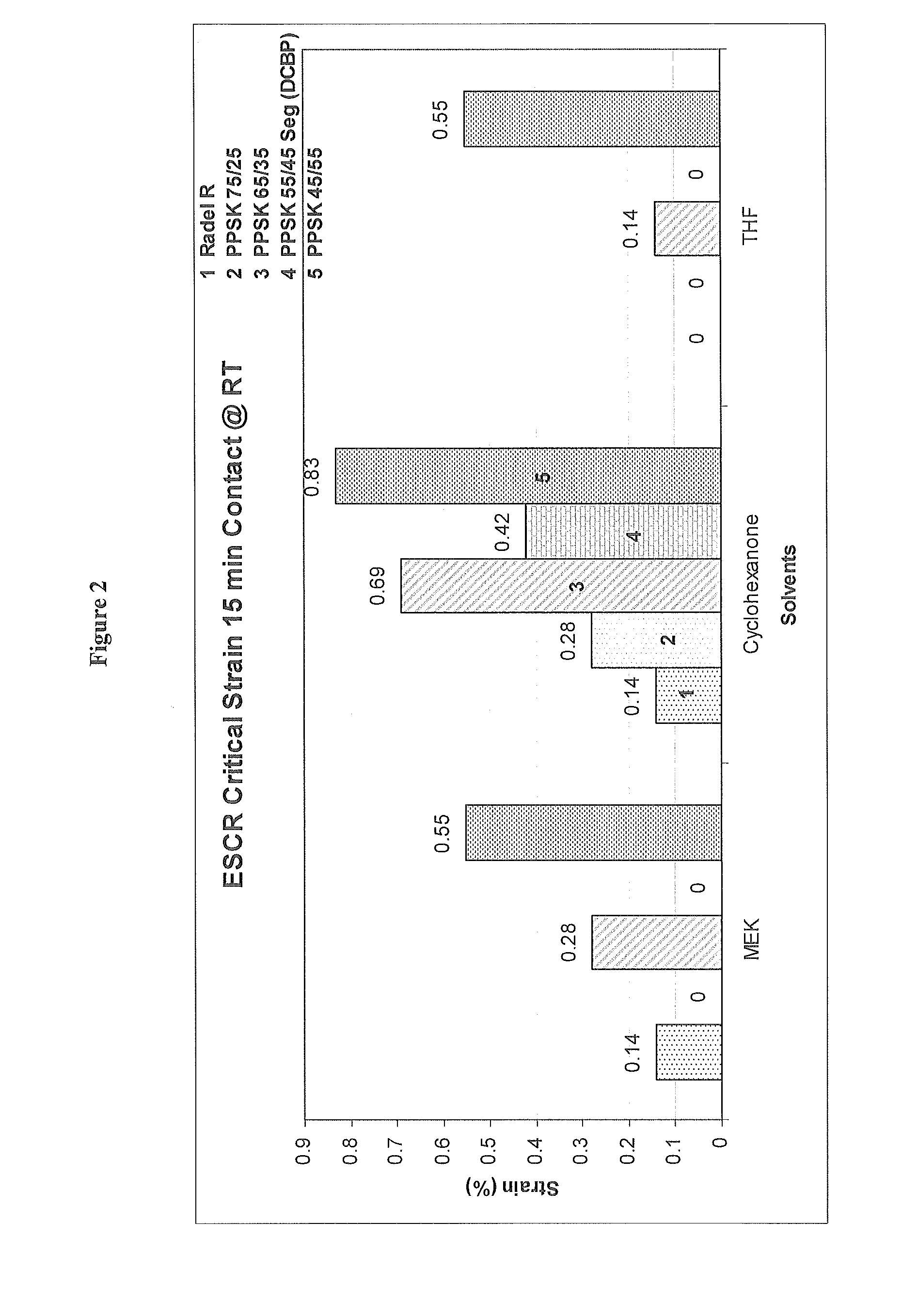

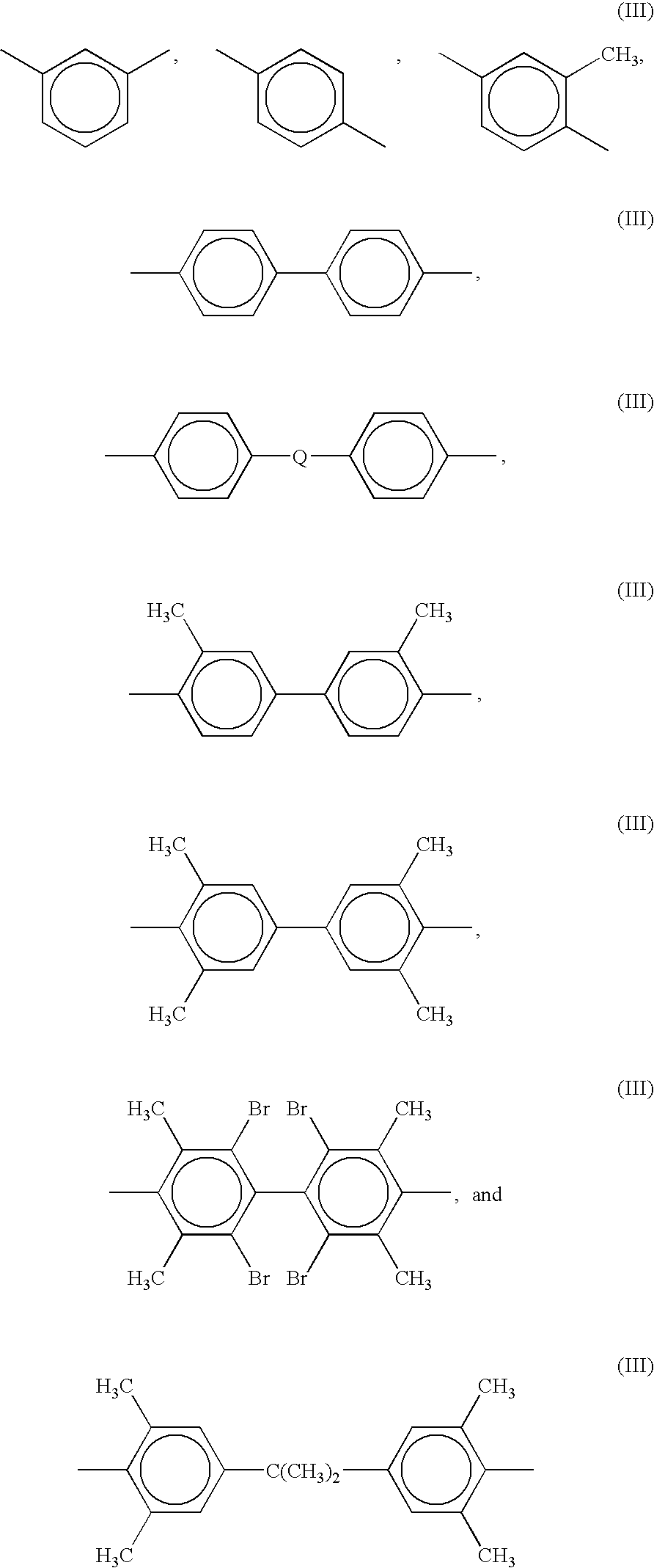

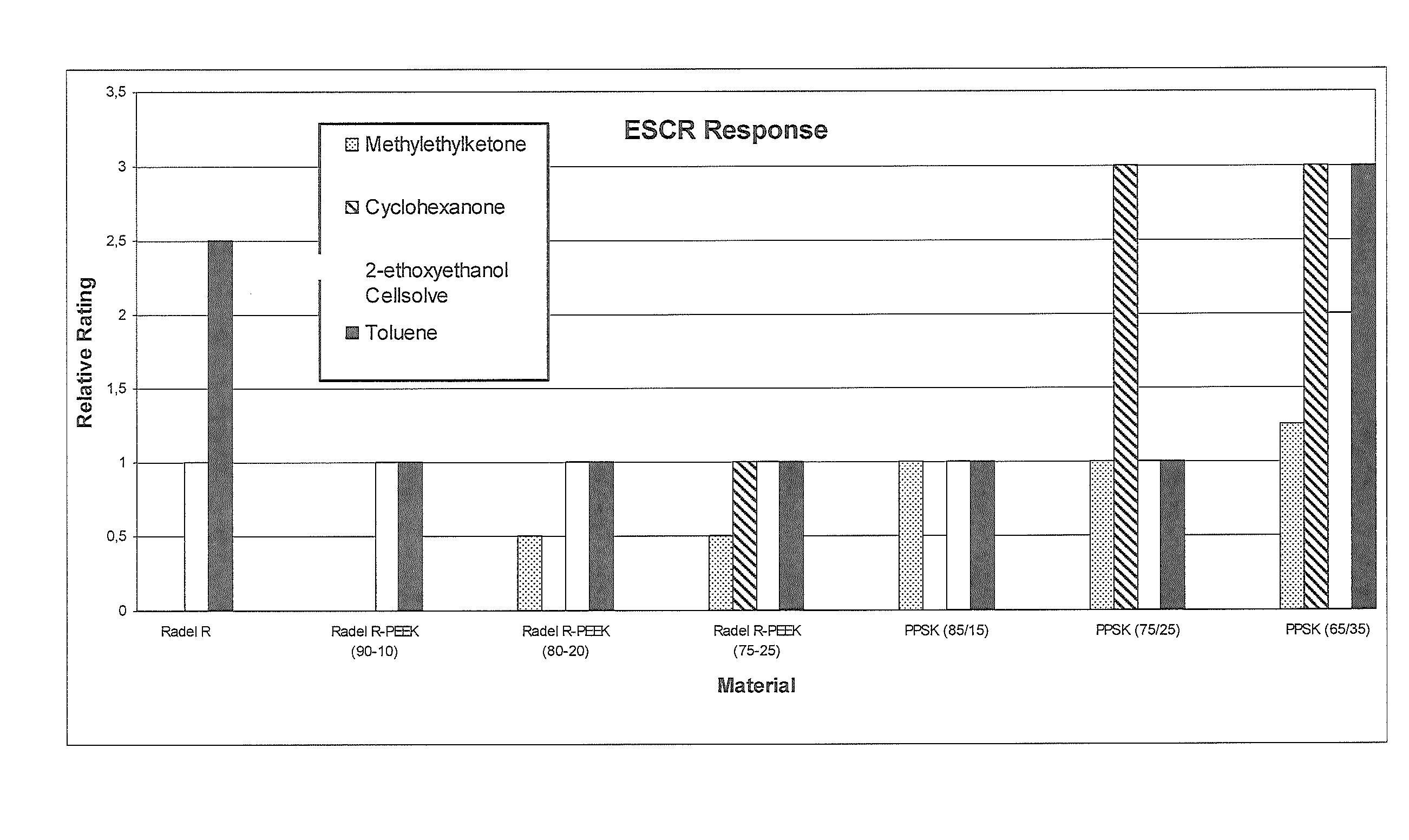

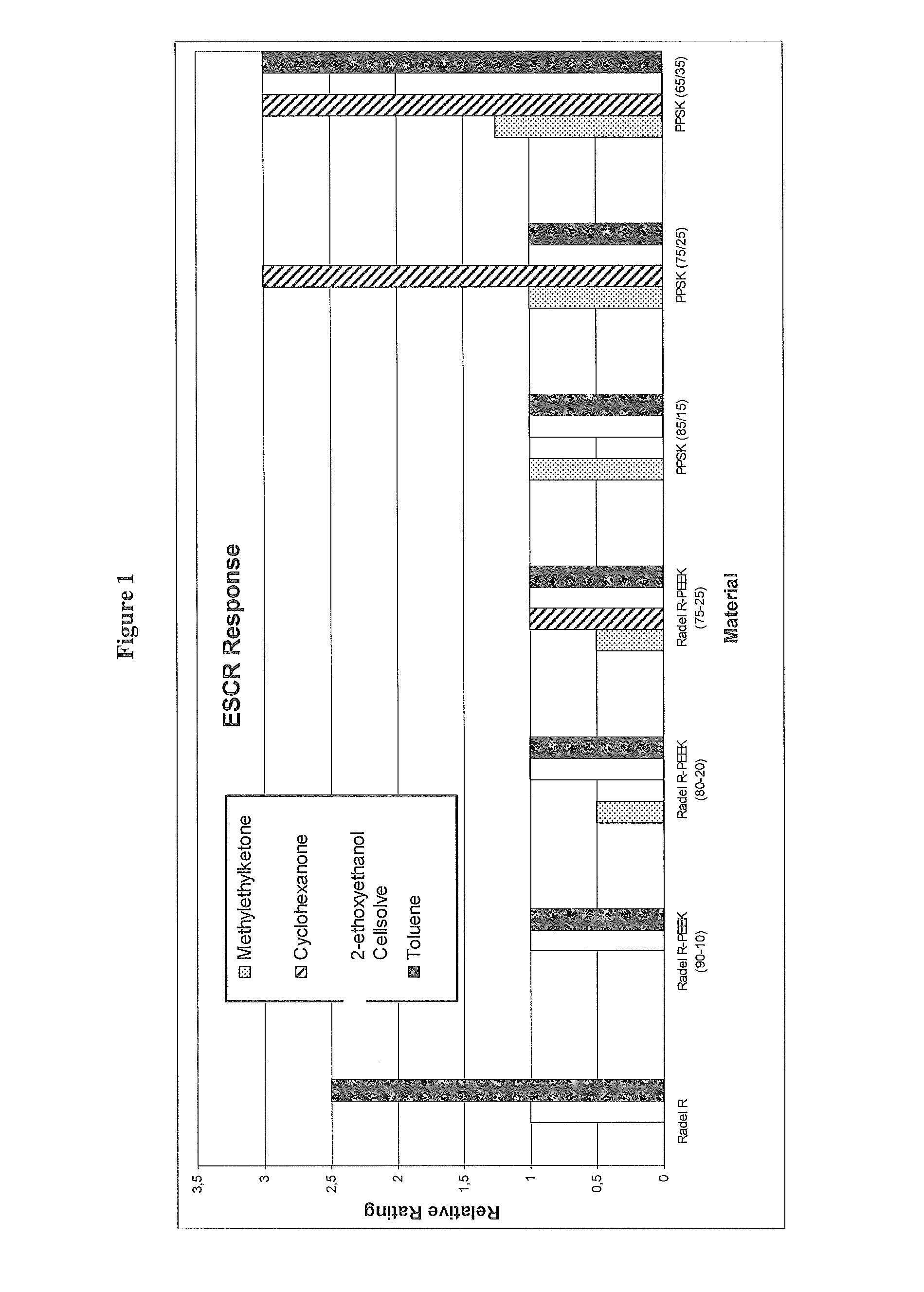

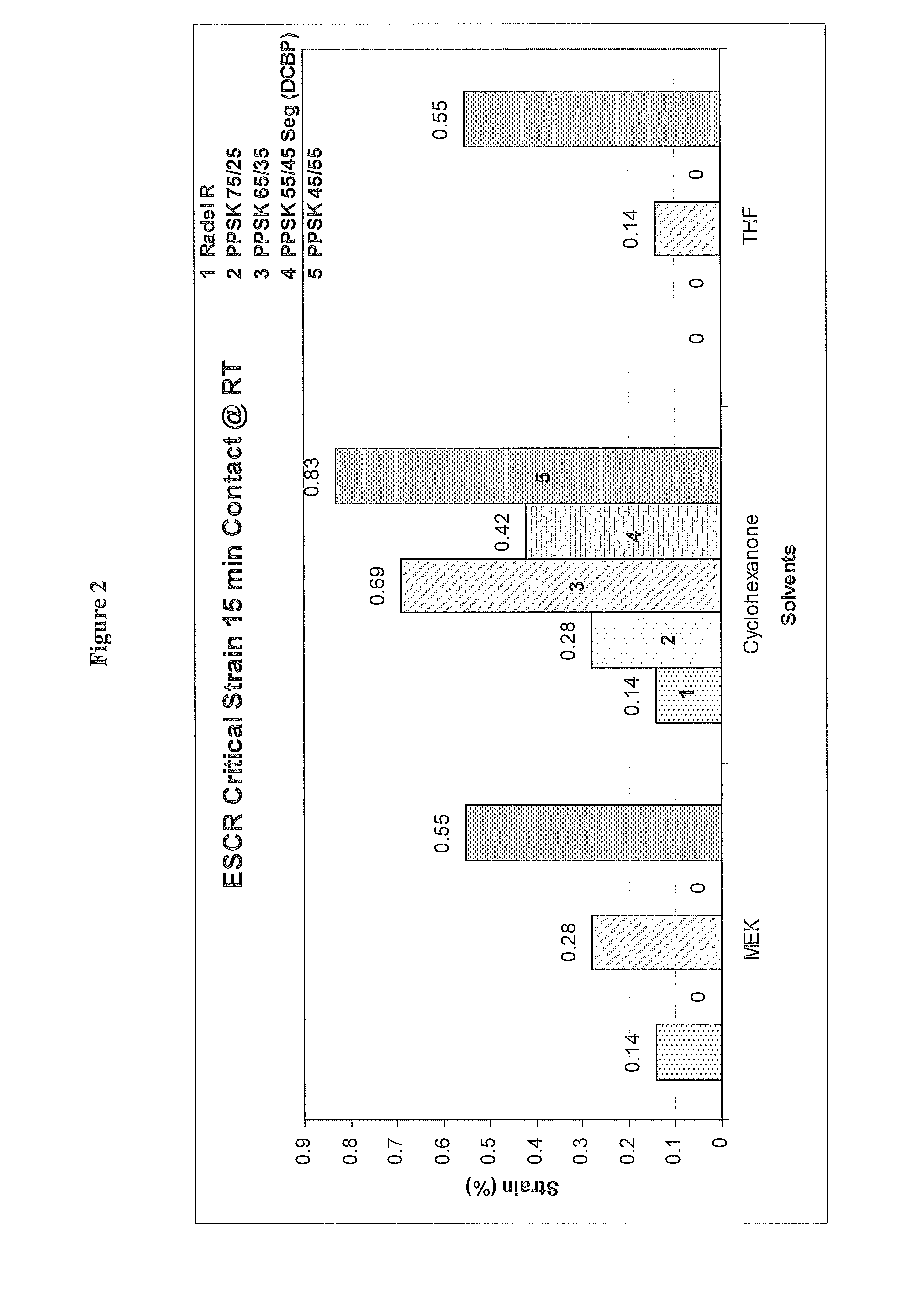

Polyphenyl sulfone ketone copolymers

InactiveUS20100310804A1Improve the immunityLow creepLayered productsThin material handlingPolymer scienceKetone

A polymer comprising sulfone groups, ketone groups and optionally substituted polyarylene groups, wherein the number of moles of sulfone groups over the number of moles of ketone groups ratio is greater than 1. A process for making such polymer, a composition comprising such polymer, and articles made therefrom.

Owner:SOLVAY ADVANCED POLYMERS LLC

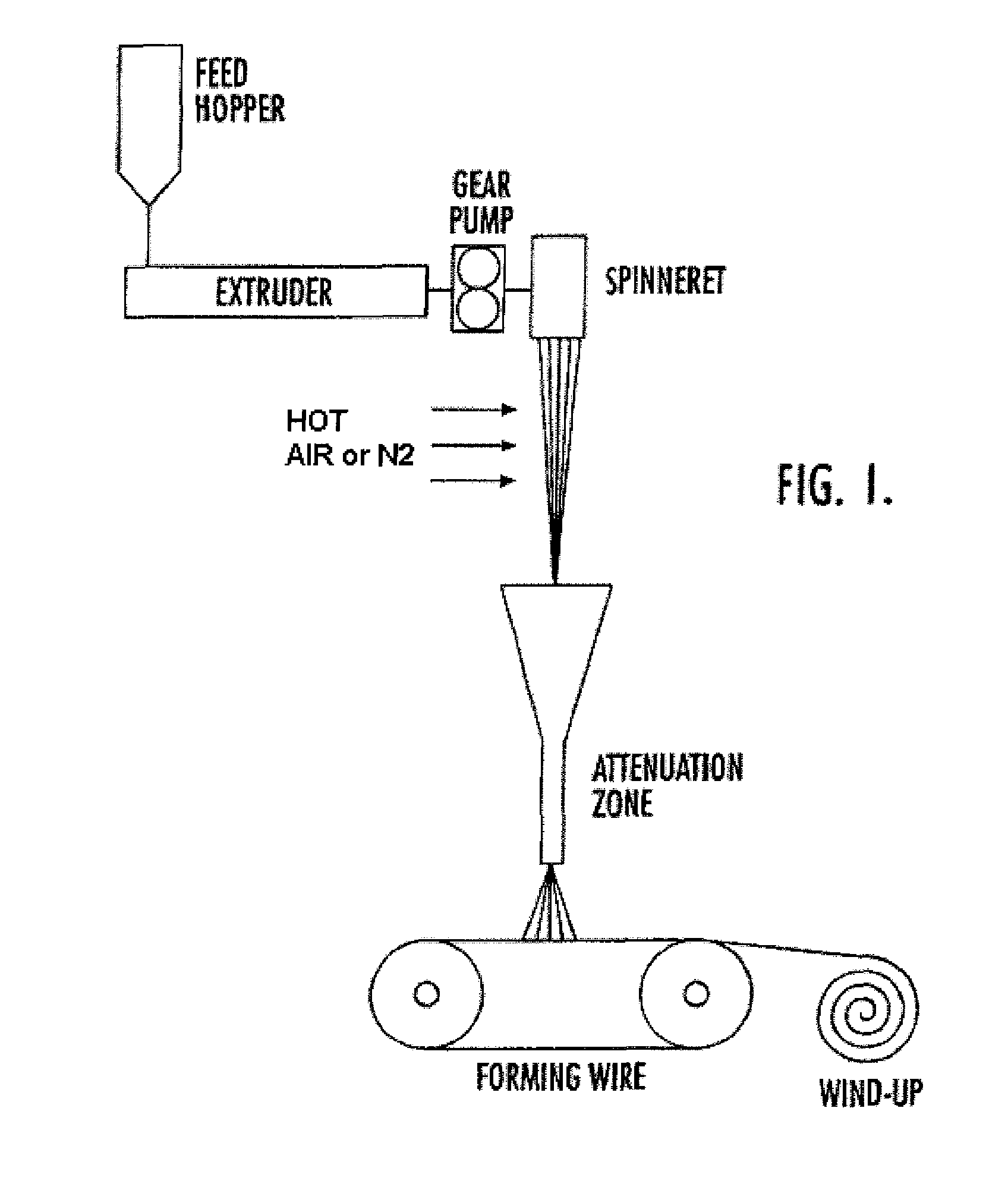

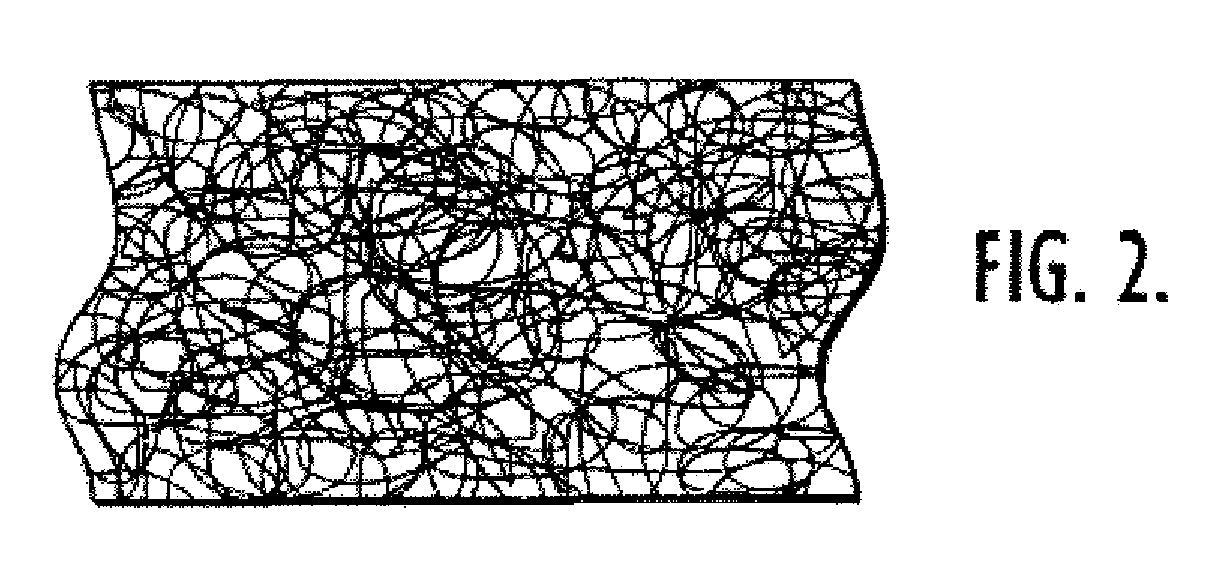

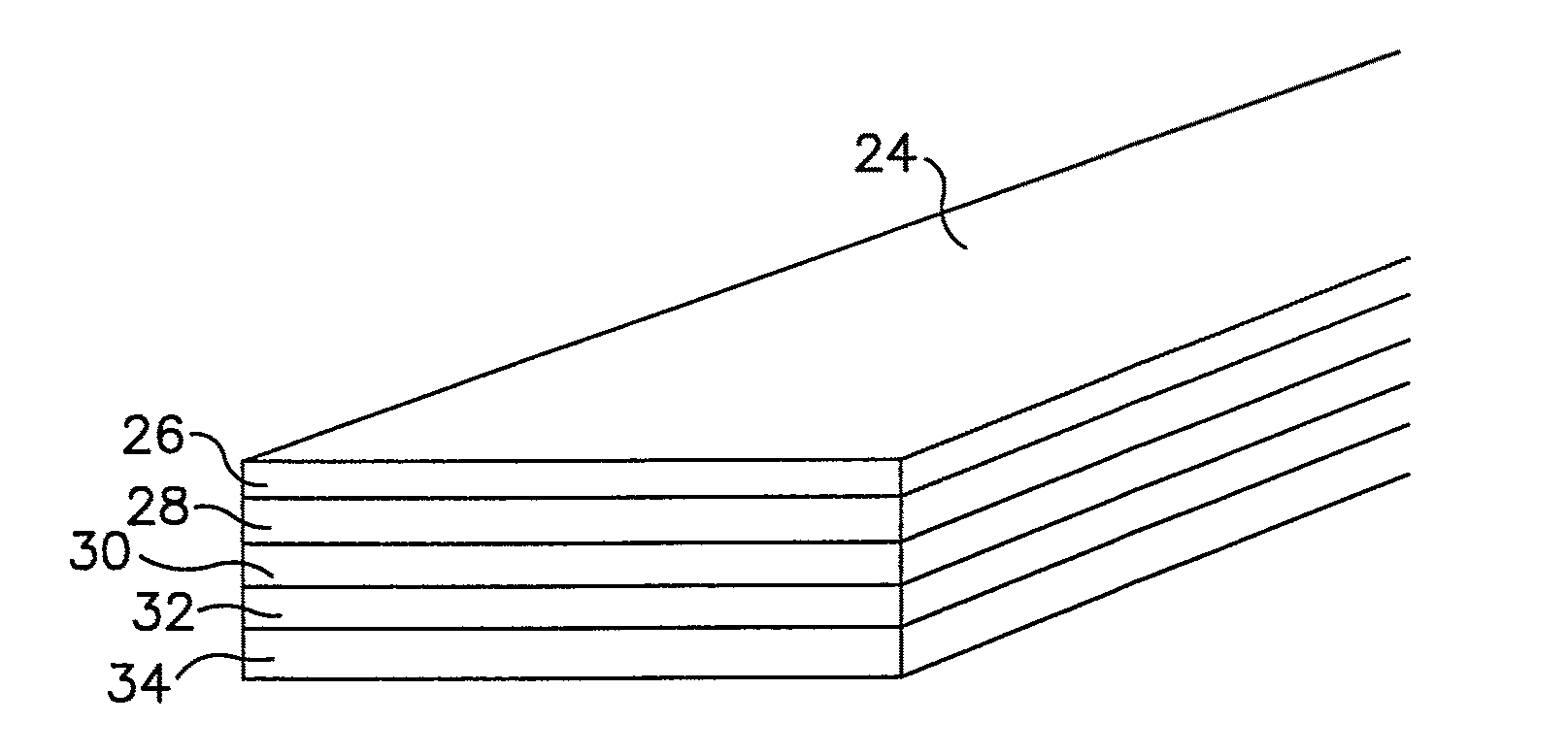

Polyetherketoneketone nonwoven mats

ActiveUS20120015577A1Decreasing TsLow creepSynthetic resin layered productsWoven fabricsFiberPolyetherketoneketone

The invention provides nonwoven mats comprising polyetherketoneketone fibers or mixtures thereof. Also provided are filters, textiles, blankets, and insulation prepared from polyetherketoneketone nonwoven mats, as well as methods for manufacturing the same.

Owner:ARKEMA INC

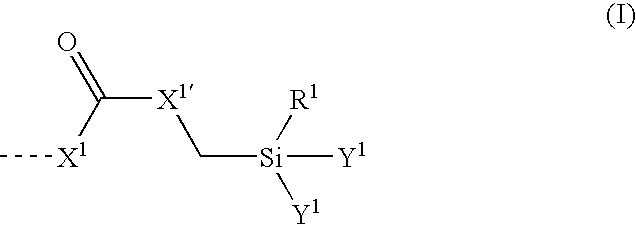

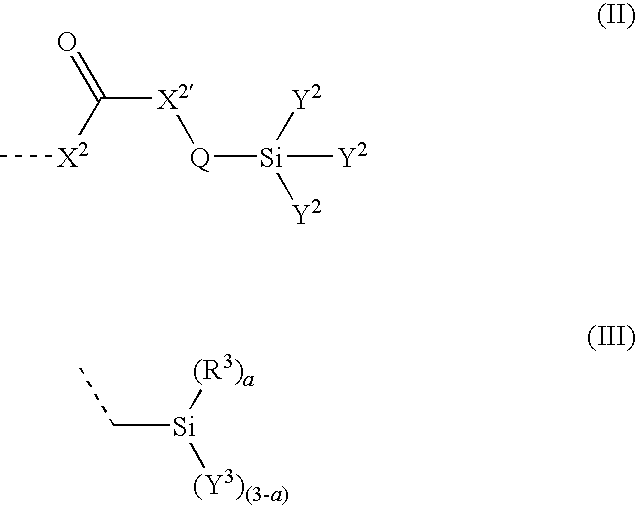

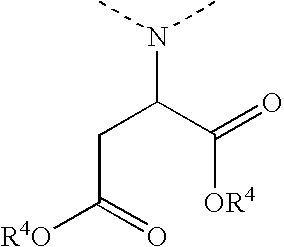

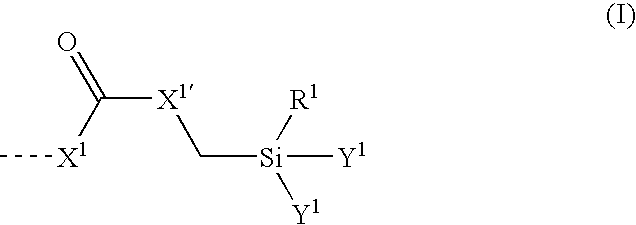

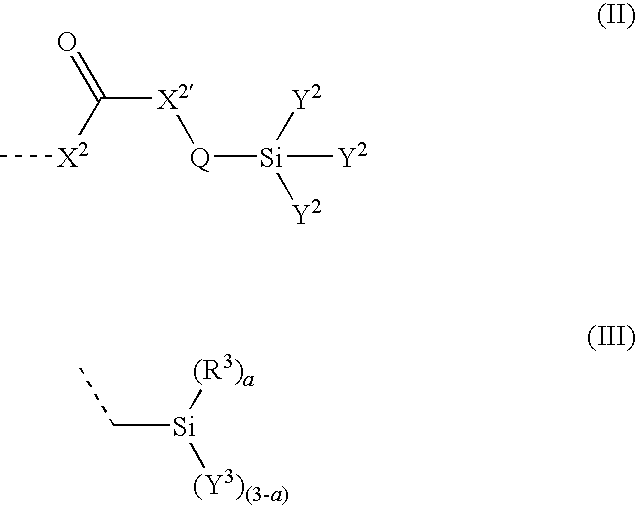

Moisture-curing composition comprising at least two polymers having silane groups

The present invention relates to moisture-curing compositions that comprise, in addition to a first type of polymer having a specific end group, at least one additional type of polymer having a different specific end group. It has been shown that such compositions have a surprisingly quick adhesive formation and a low amount of seepage.

Owner:SIKA TECH AG

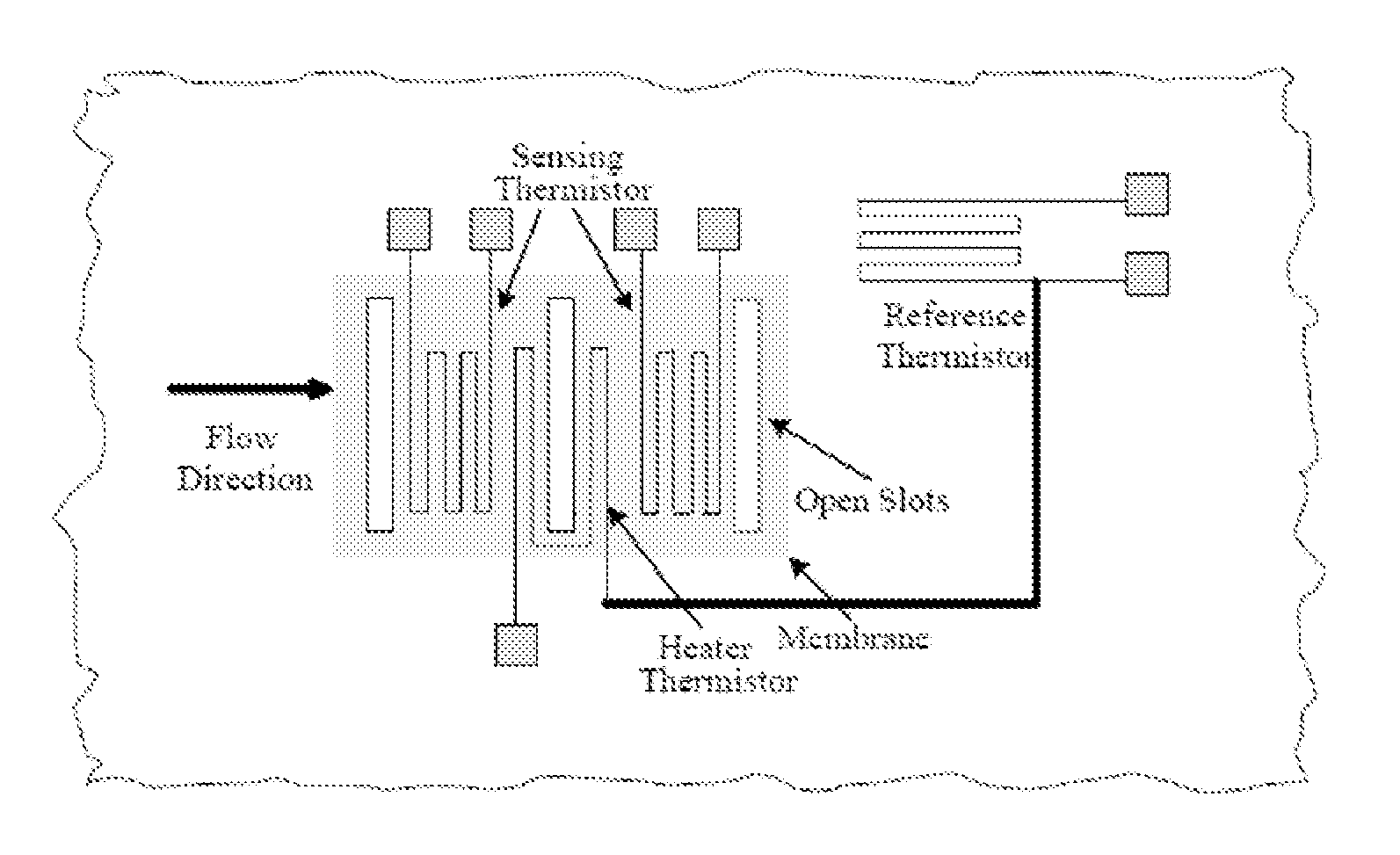

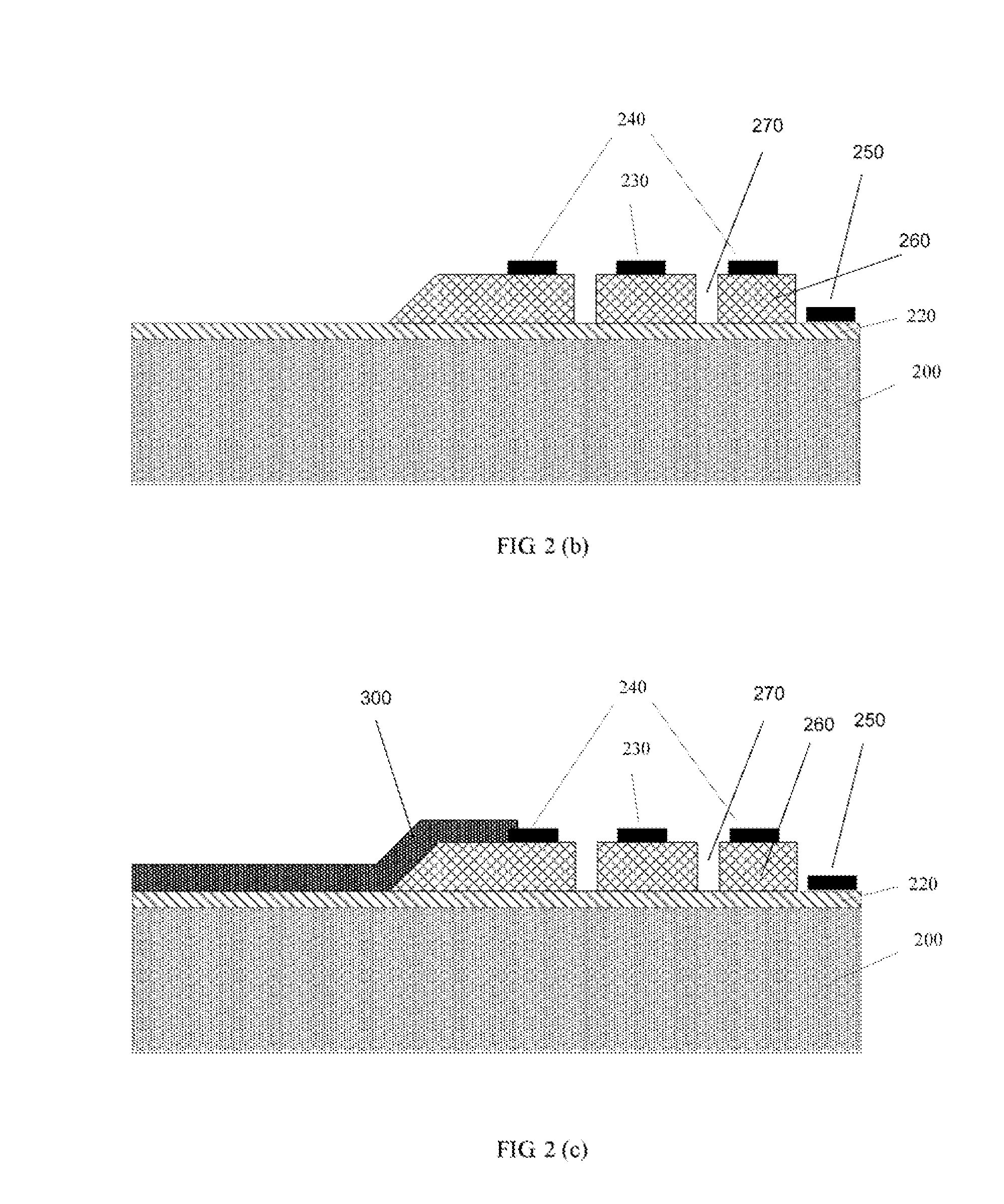

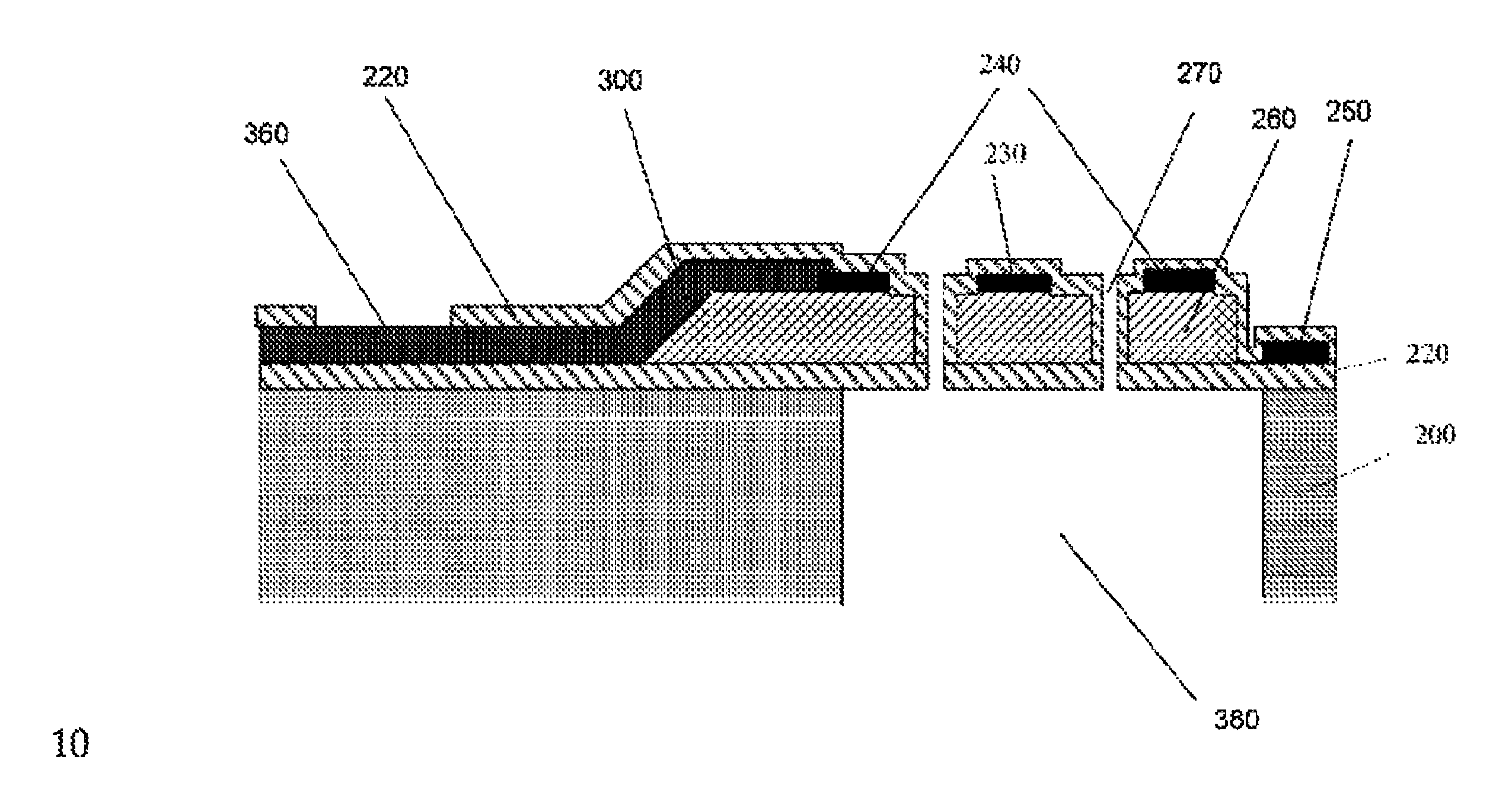

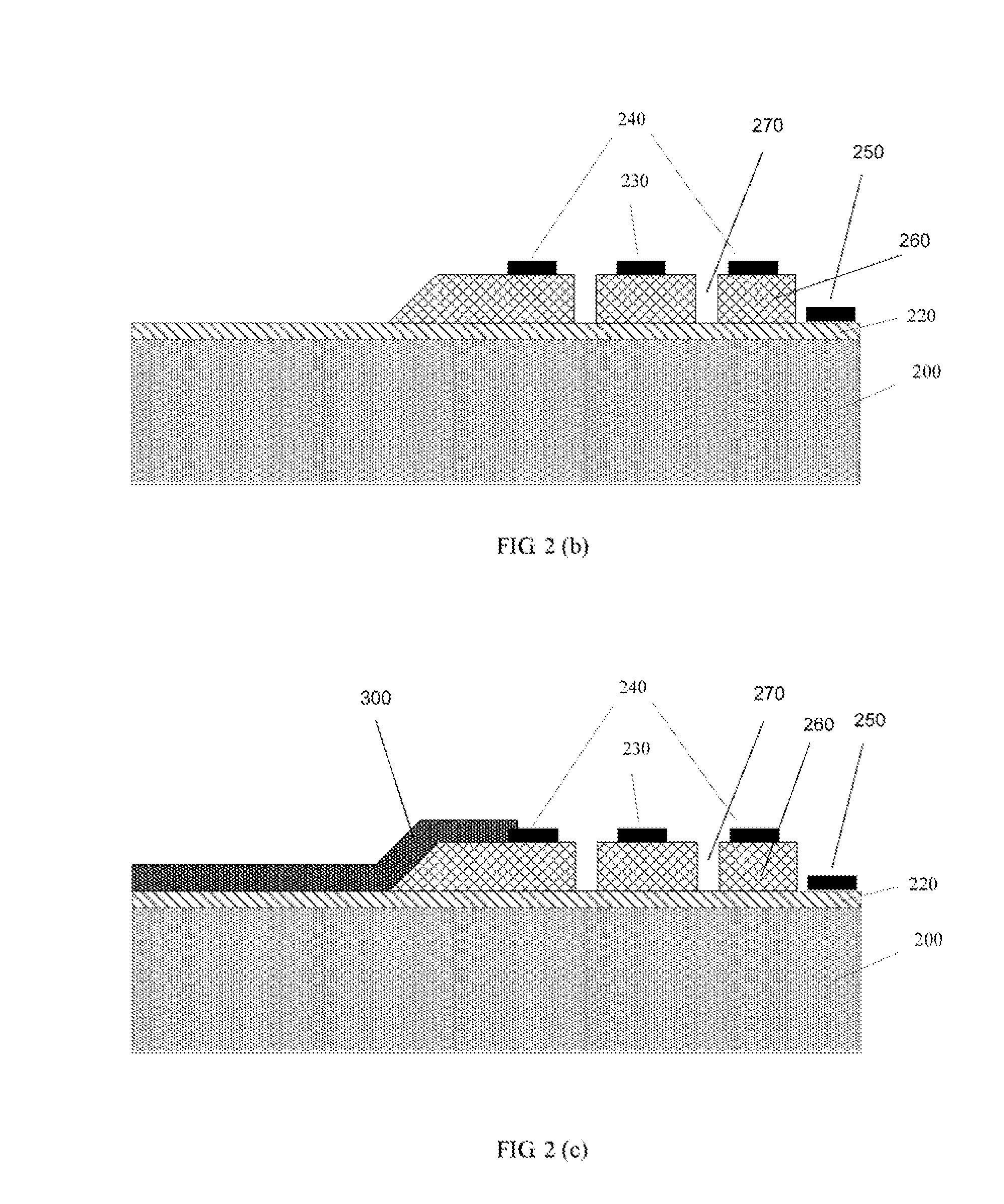

Robust micromachining thermal mass flow sensor and method of making the same

ActiveUS20110030468A1Strong and sturdy supportGood chemical resistanceVolume/mass flow by thermal effectsHigh volume manufacturingFragility

The present invention is generally related to a novel micromachining thermal mass flow sensor and, more particularly, to a device incorporated with high strength and robust characteristics, which therefore is capable of operating under harsh environments. The new disclosed sensor is made of essential material which can provide robust physical structure and superior thermal properties to support the flow measuring operation. The invented thermal mass flow sensor is featuring with the advantages of micro-fabricated devices in terms of compact size, low power consumption, high accuracy and repeatability, wide dynamic range and easiness for mass production, which could avoid the drawbacks of fragility and vulnerability.

Owner:M TECH INSTR HLDG

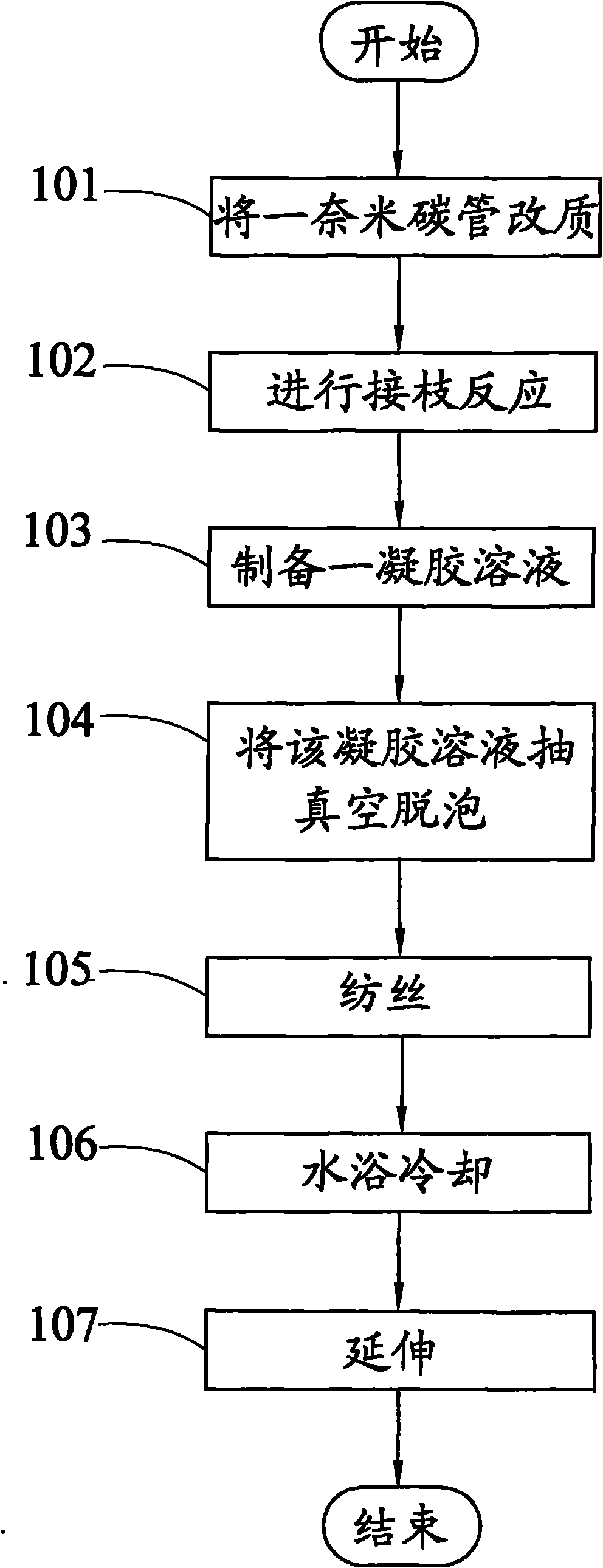

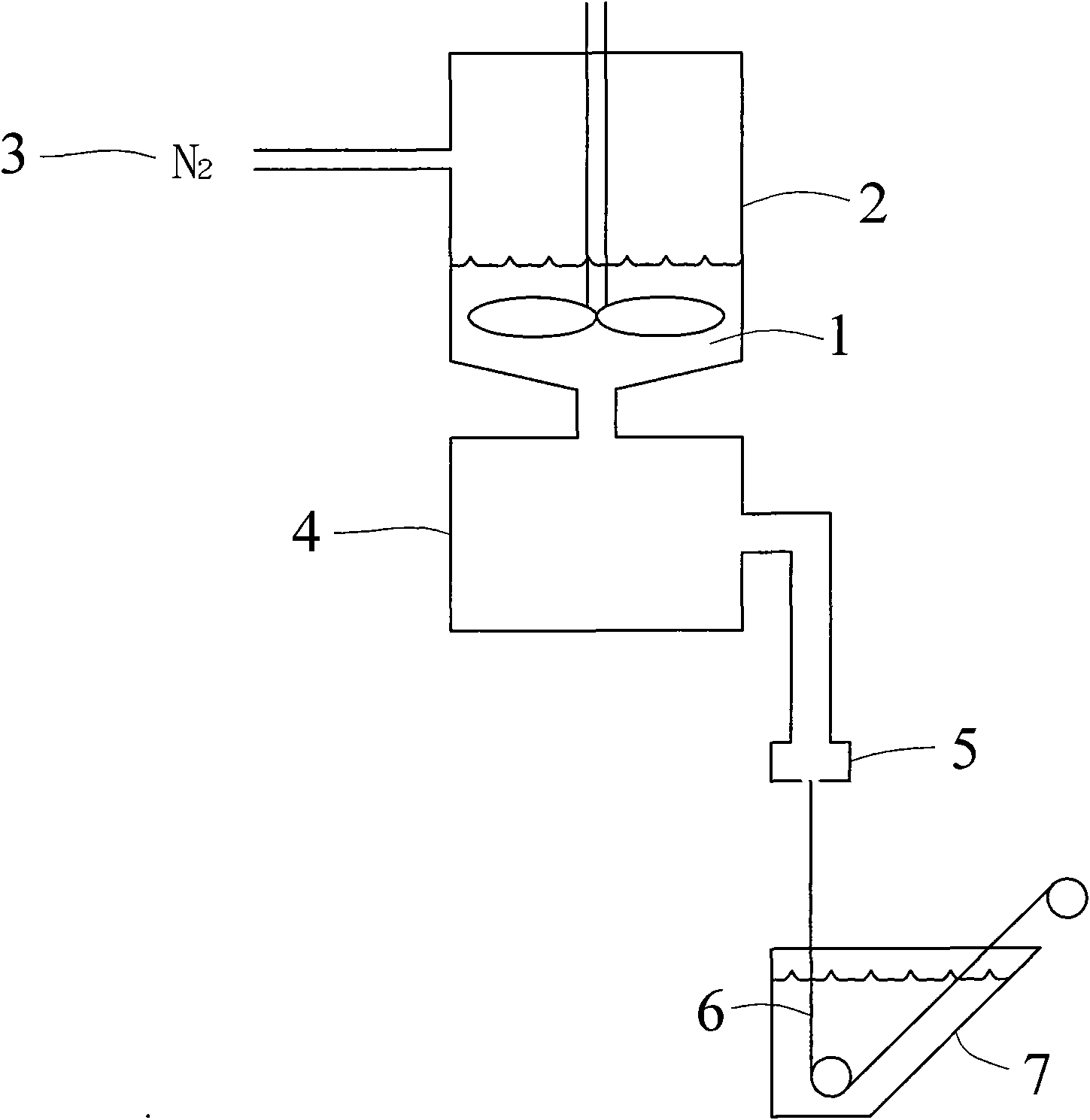

Ultra-high molecular weight polyethylene (UHMPE) and nano-inorganic substance composite material and manufacturing method of high-performance fiber thereof

InactiveCN101988221AHigh fiber strengthLess frizzMelt spinning methodsMonocomponent polyolefin artificial filamentFiberPolymer science

The invention discloses an ultra-high molecular weight polyethylene (UHMPE) and nano-inorganic substance composite material and a manufacturing method of high-performance fiber thereof, belonging to the field of a composite material.The manufacturing method of the composite material comprises the following steps: preparing UHMPE and a nano-inorganic substance, such as attapulgite, a carbon nanotube, sepiolite, wollastonite, montmorillonite and the like into gel solution; in the case of light transmittance close to zero under certain concentration, heating the gel solution for dissolving; and vacuumizing, defoaming, spinning with different spinneret boards containing various spinneret angles as well as feed length and discharge length, carrying out air-quenching, carrying out aqueous-phase curing, performing multi-segment temperature change extension and the like to finally obtain the composite material for the ultra-high strength fiber the light transmittance of which is close to zero. The obtained composite material can increase the strength and modulus of UHMPE fiber and solve the defects of the UHMPE fiber, such as high crimp, high creep, light transmittance and the like.

Owner:叶正涛 +1

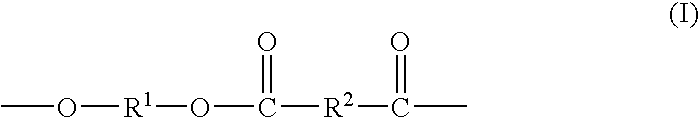

Method of manufacture of polyester molding compositions and articles produced therefrom

A thermoplastic molding composition comprises a resin composition having 50 to about 90 weight percent of a polyester, about 8 to about 48 weight percent of a polyetherimide, about 2 to about 25 weight percent of a high rubber graft impact modifier, each based on the total resin composition, and up to about 15 weight percent of a particulate filler. A making the composition comprises pre-melt compounding a polyester, a polyetherimide, and a high rubber graft impact modifier to form a pre-compounded blend, wherein the pre-compounded blend has a Tg of greater than or equal to about 110° C.; and dry-blending a crystallized polyester with the pre-compounded blend to form the molding composition. Such molding compositions are particularly useful in blow-molding containers for liquids such as beer.

Owner:SABIC GLOBAL TECH BV

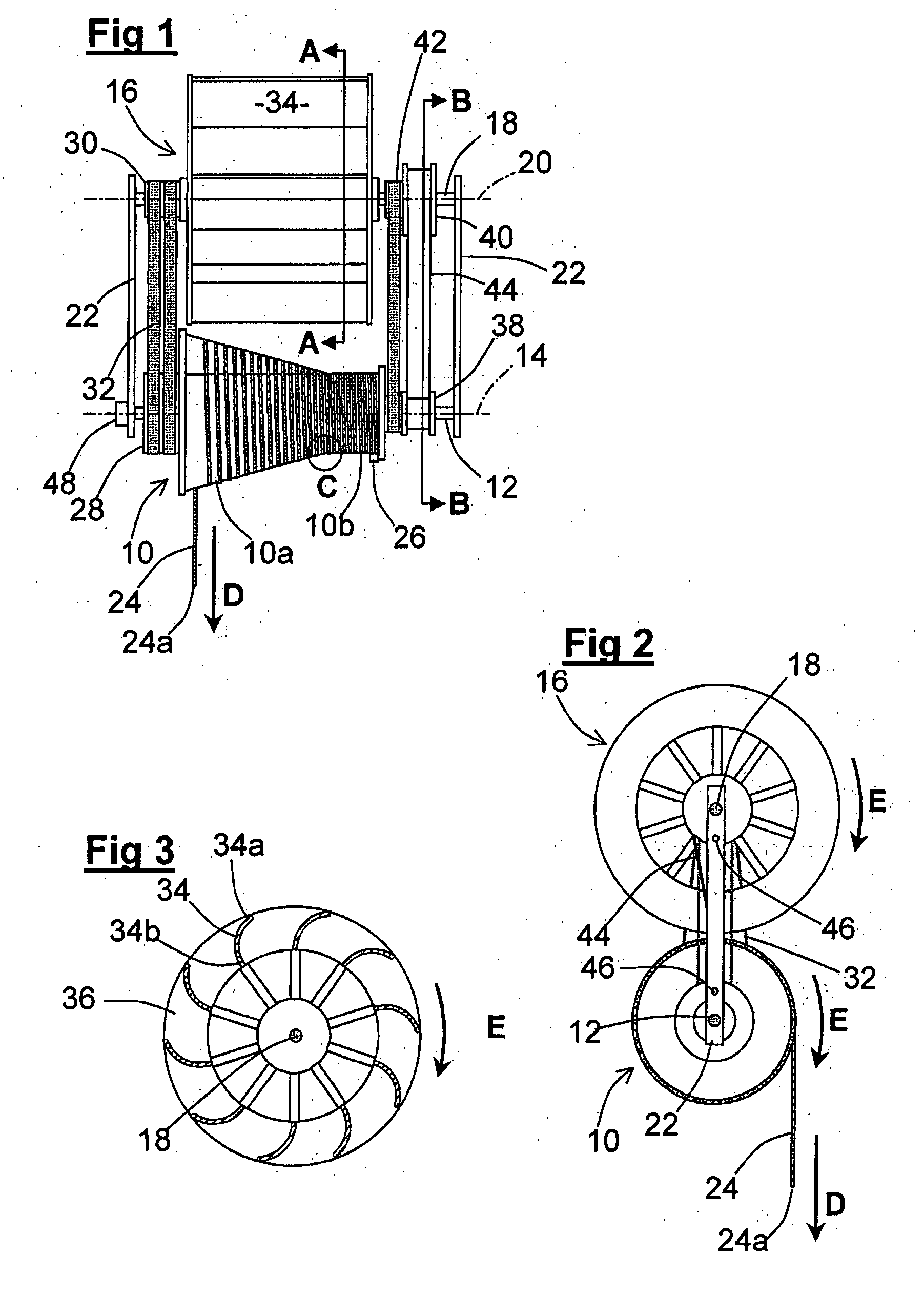

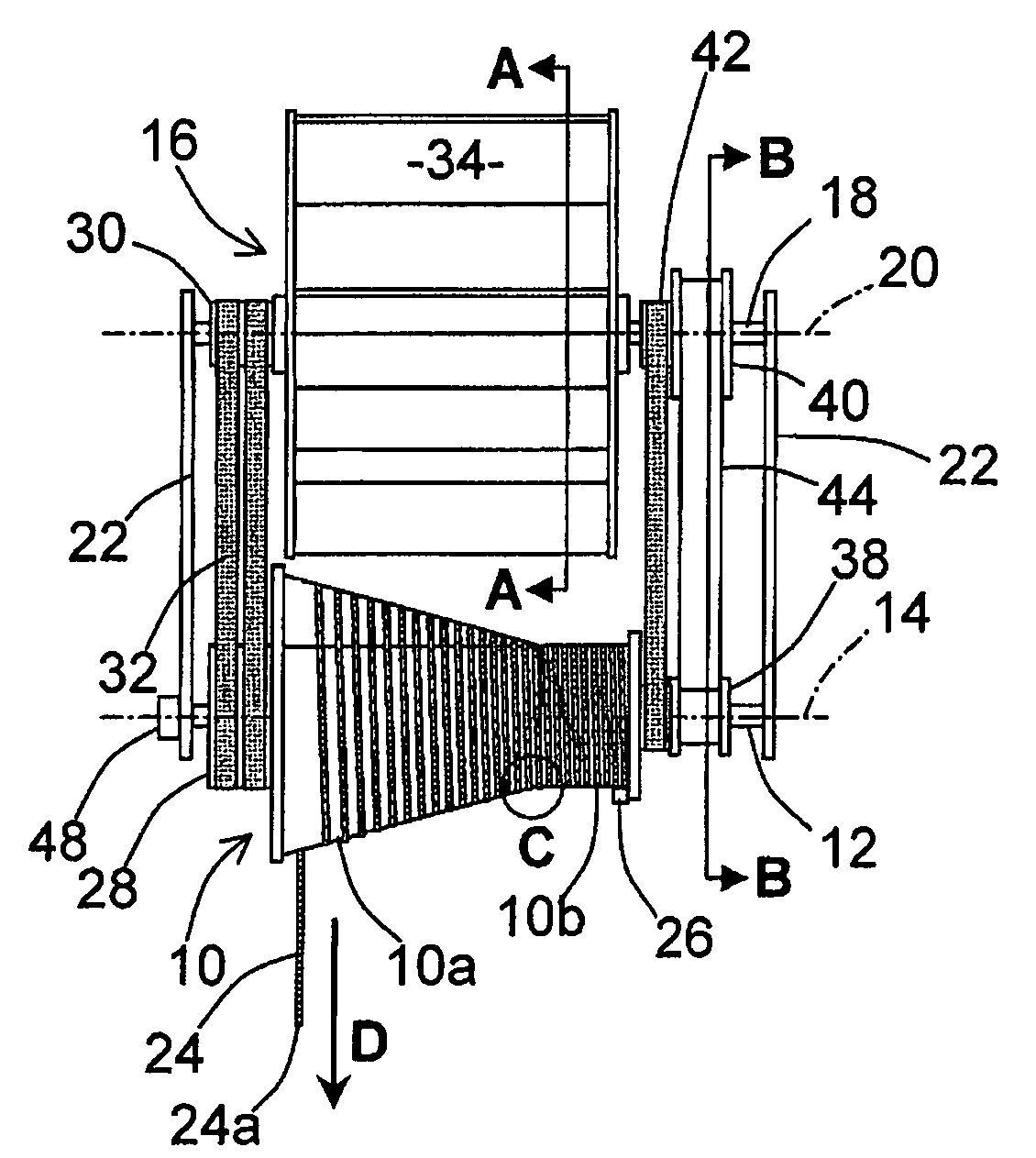

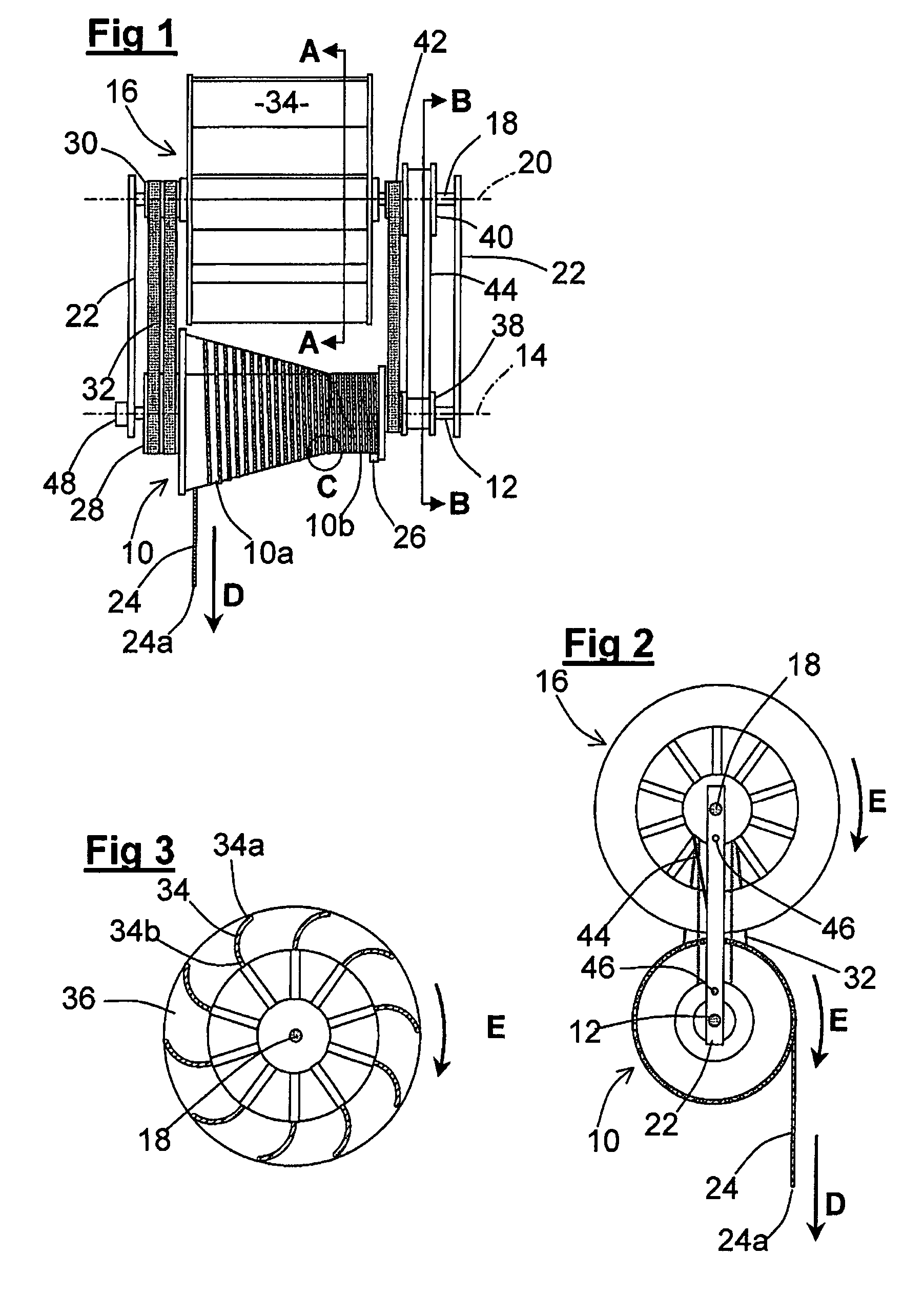

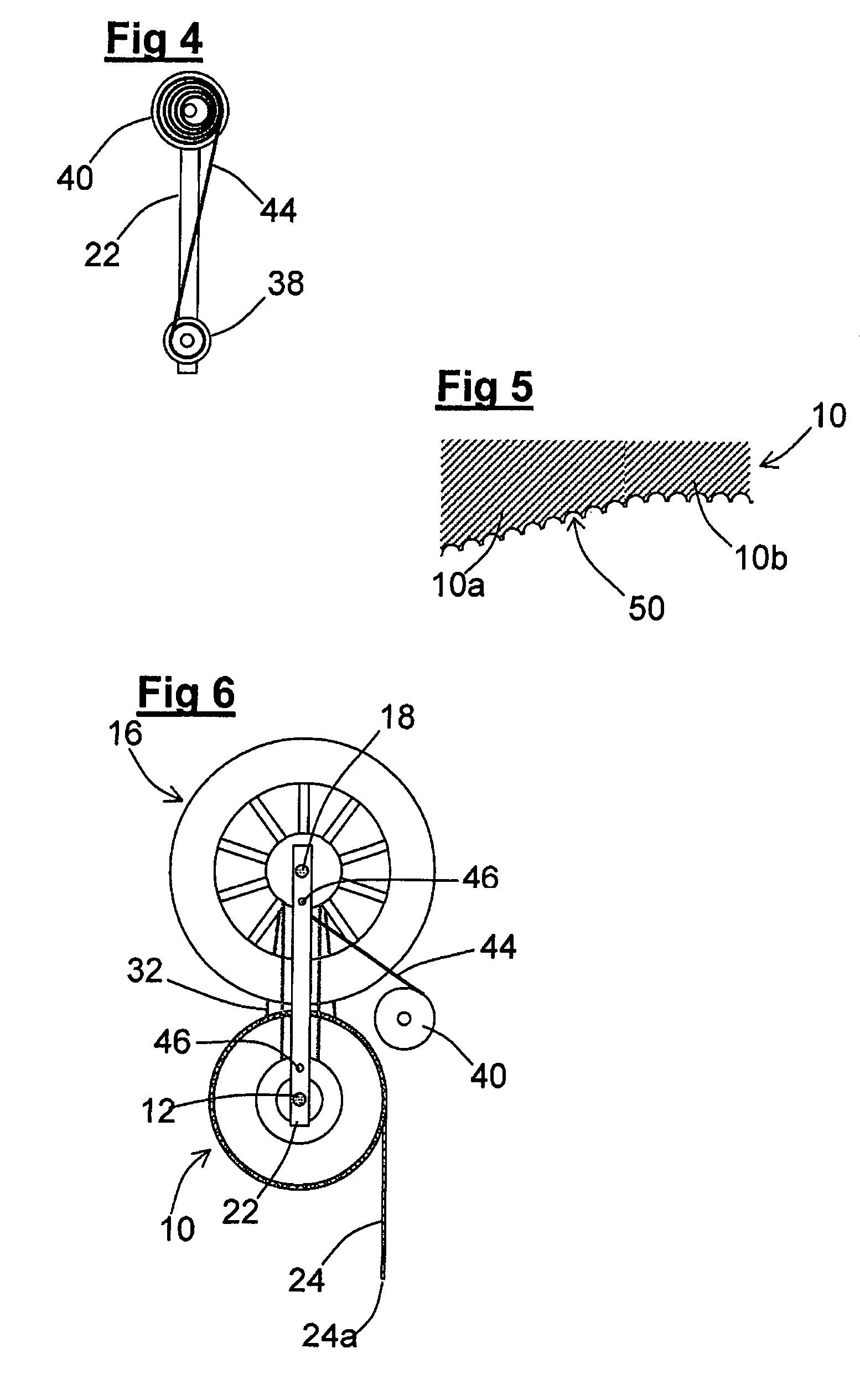

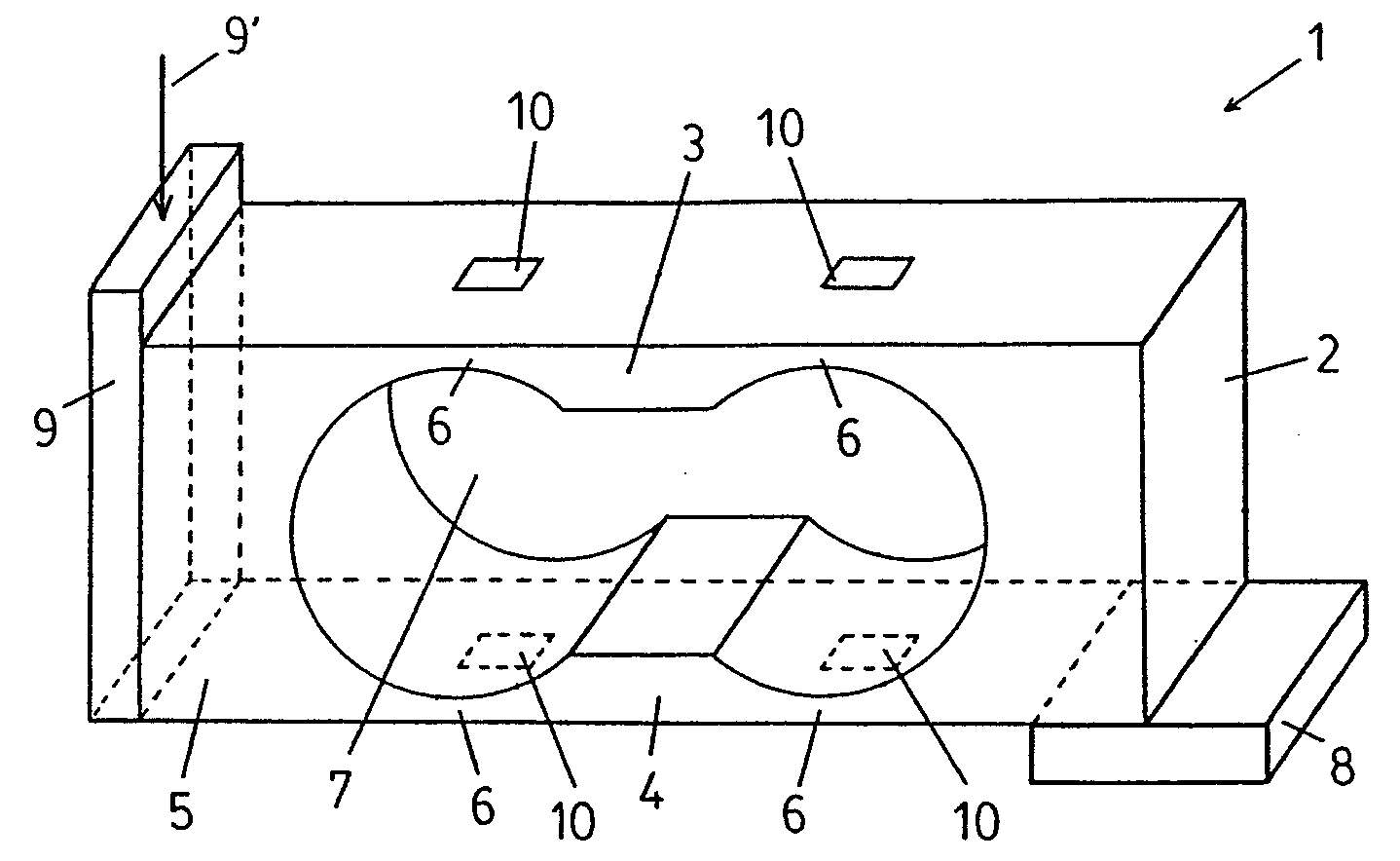

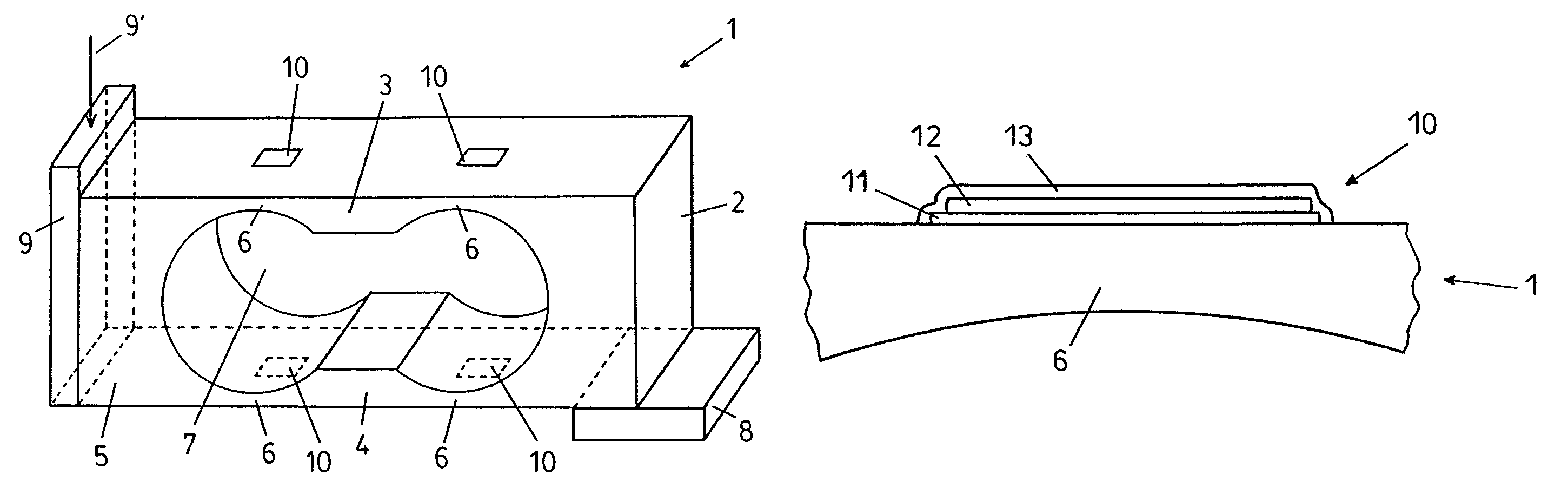

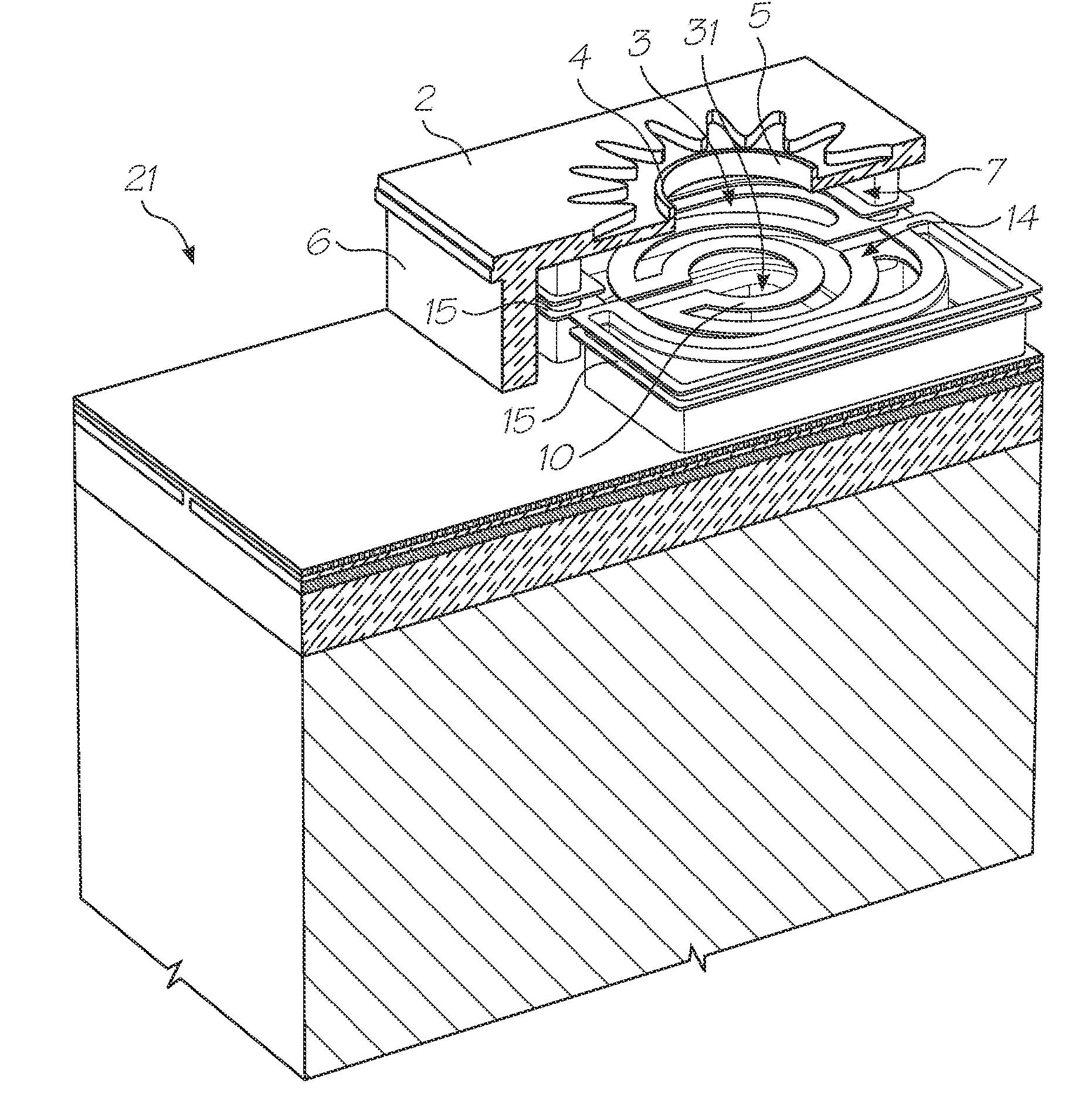

Windage braking

ActiveUS20070240940A1Compact windage brakeDifferent speedBuilding rescueHoisting equipmentsImpellerEngineering

A windage brake for a fan descender comprises a rotatable spool connected by drive belts to a fan comprising a radial flow air impeller. A line is wound helically upon the spool. A user of the fan descender puts on a harness (not shown) at the free end of the line and jumps from an elevated position. The line is thereby drawn off the spool and rotates it. The rotating spool drives the fan and also winds a power spring formed by a resilient strip. The windage of the fan regulates the descent of the jumper, the fan being accelerated to a speed at which the braking force is such that the jumper descends at a rate safe for landing on the ground. When the jumper is on the ground, he removes the harness and releases the free end of the line. The line is then automatically retrieved by the power spring and rewound on the spool.

Owner:DROP ZONE UK

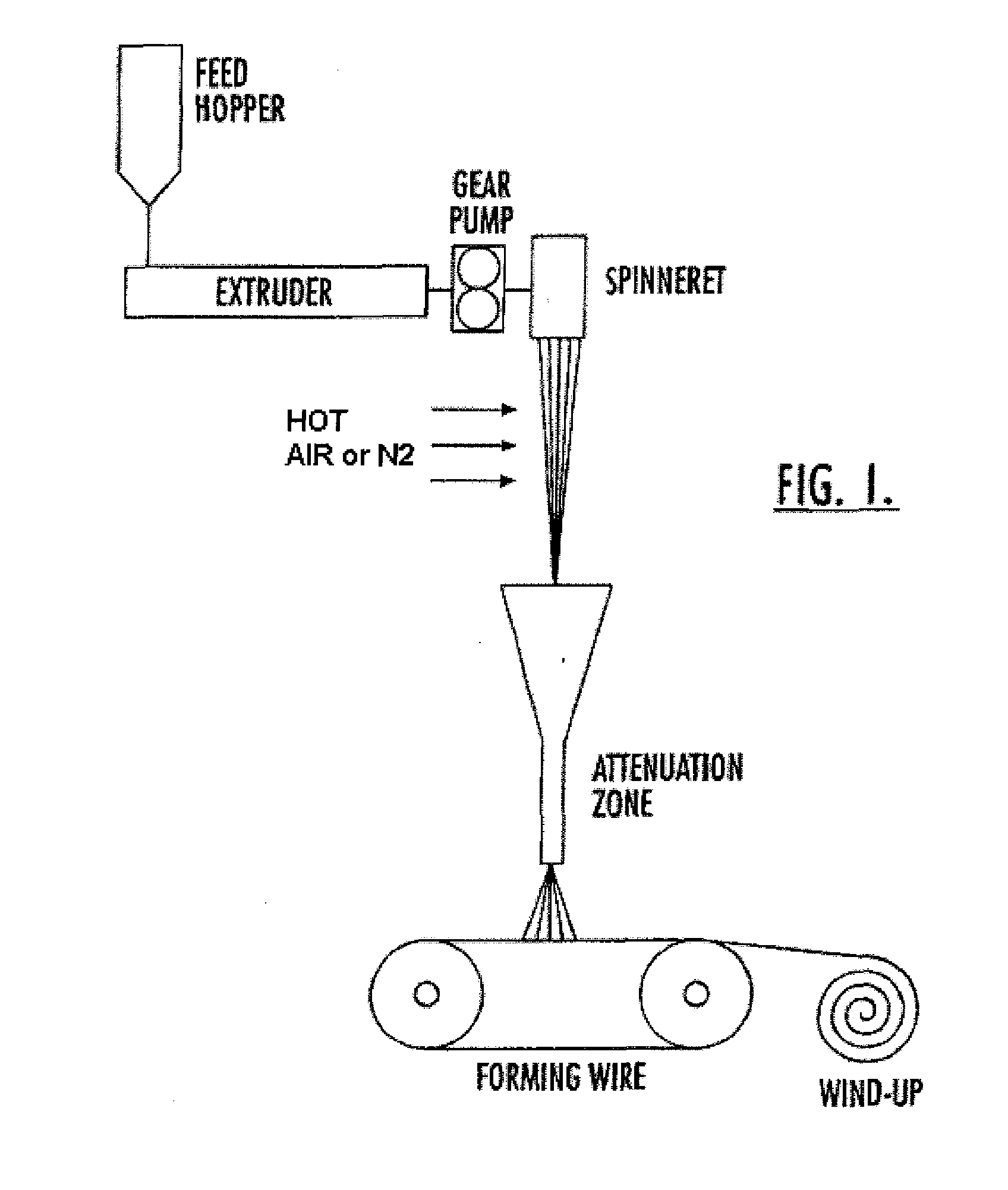

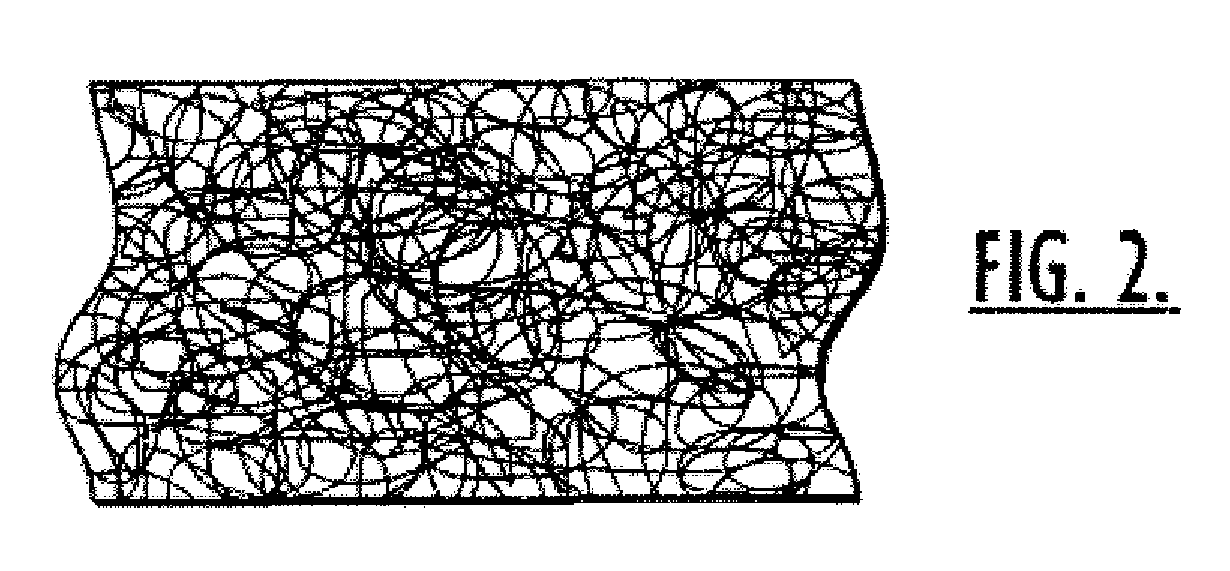

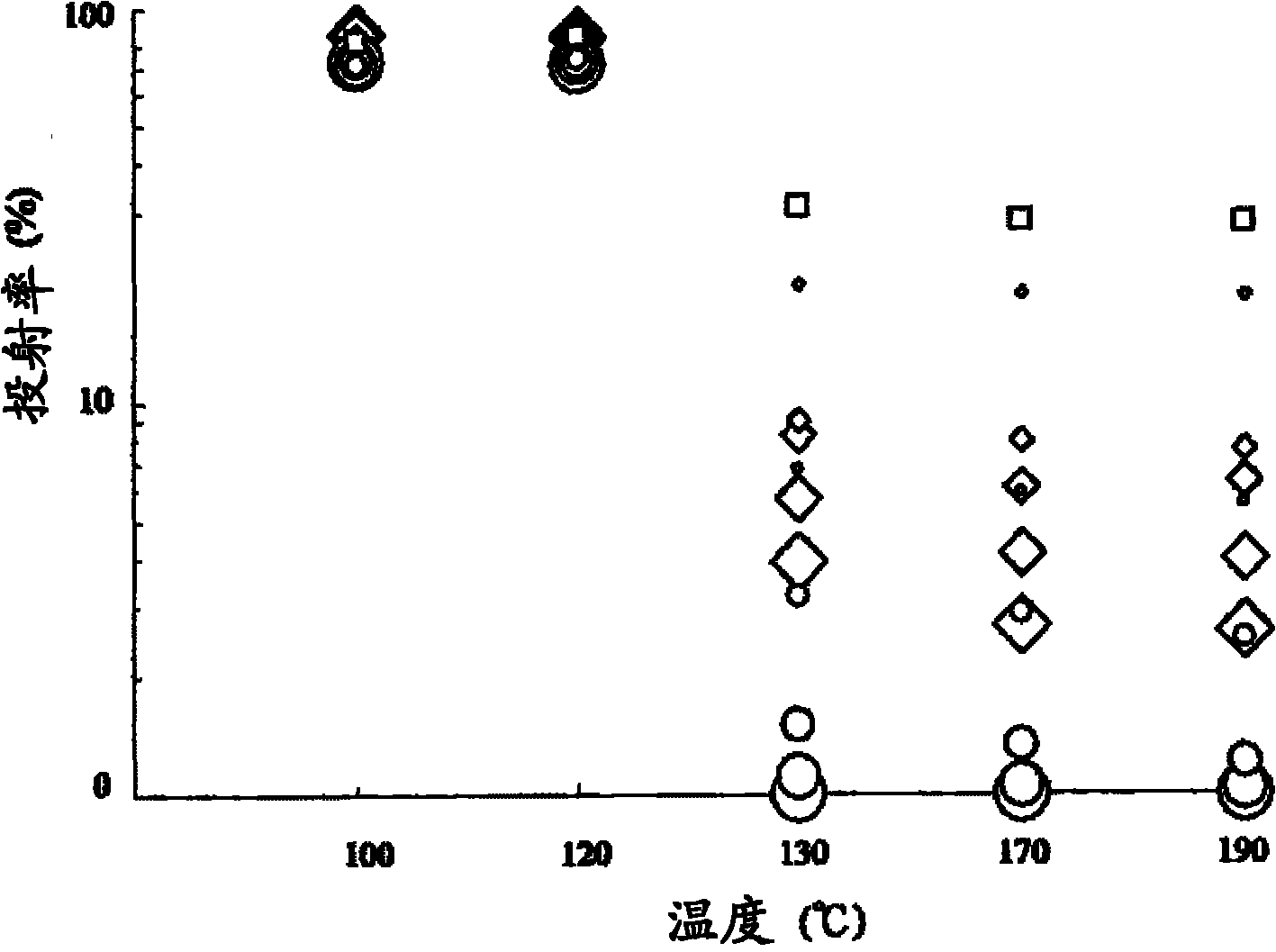

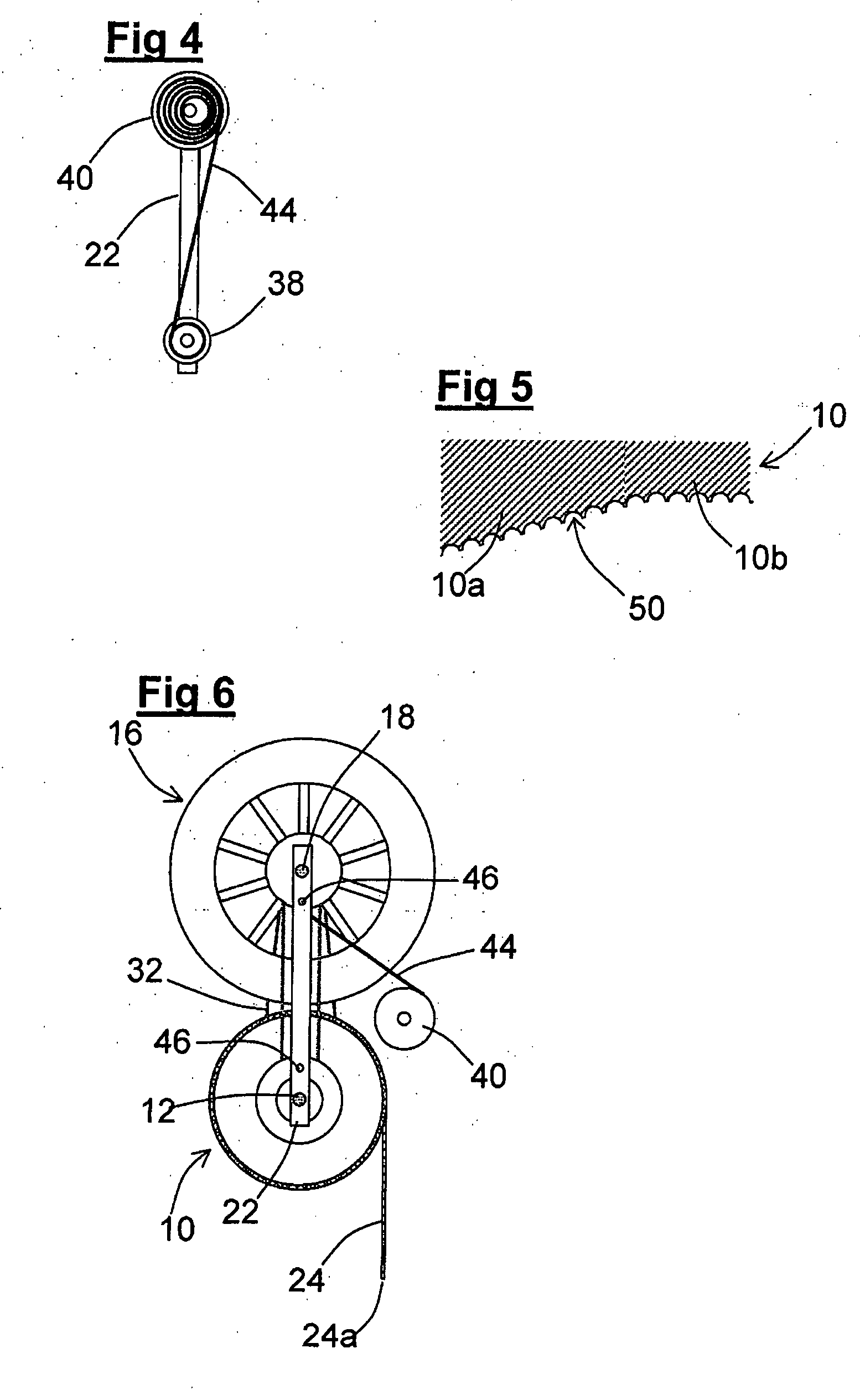

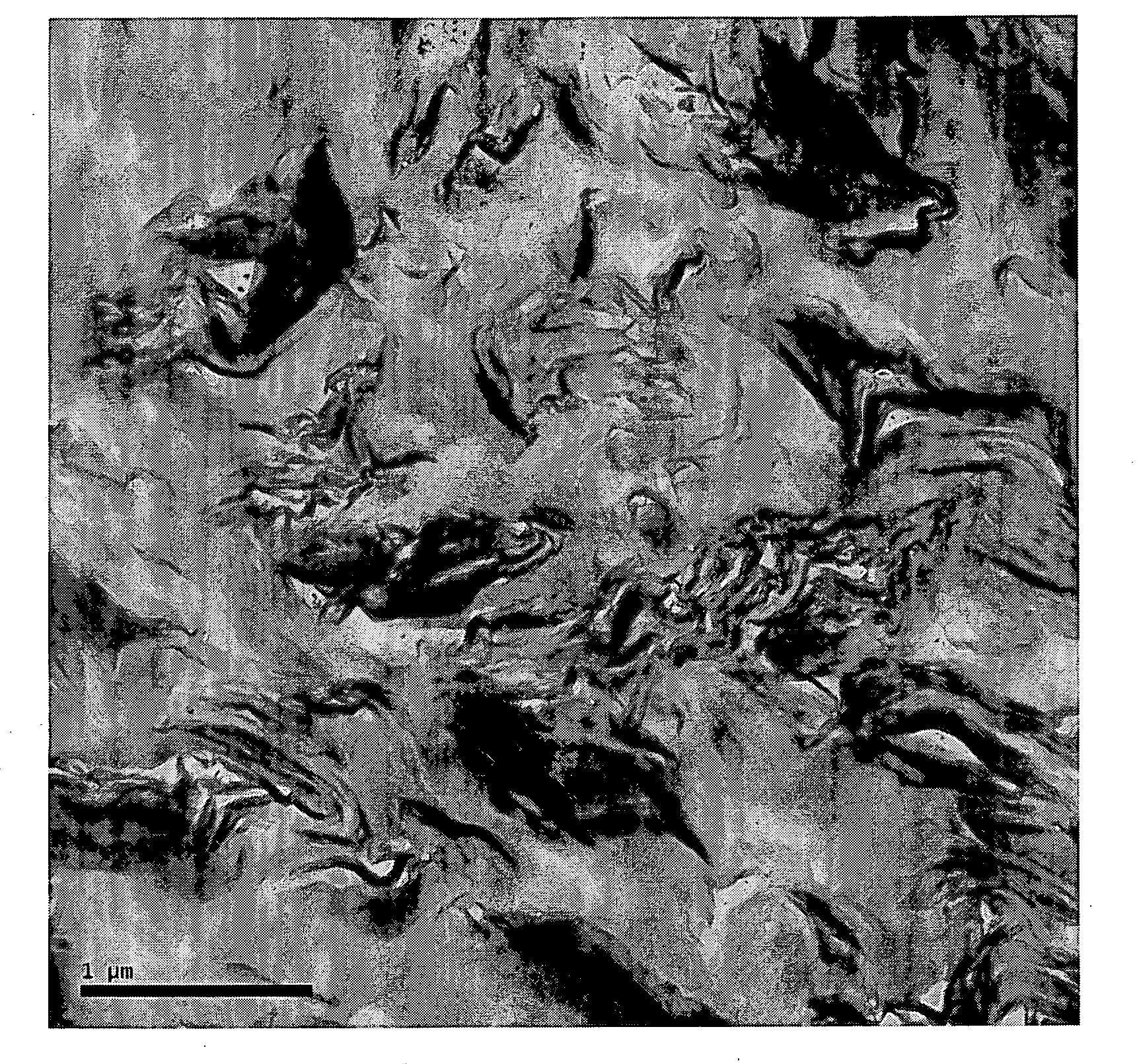

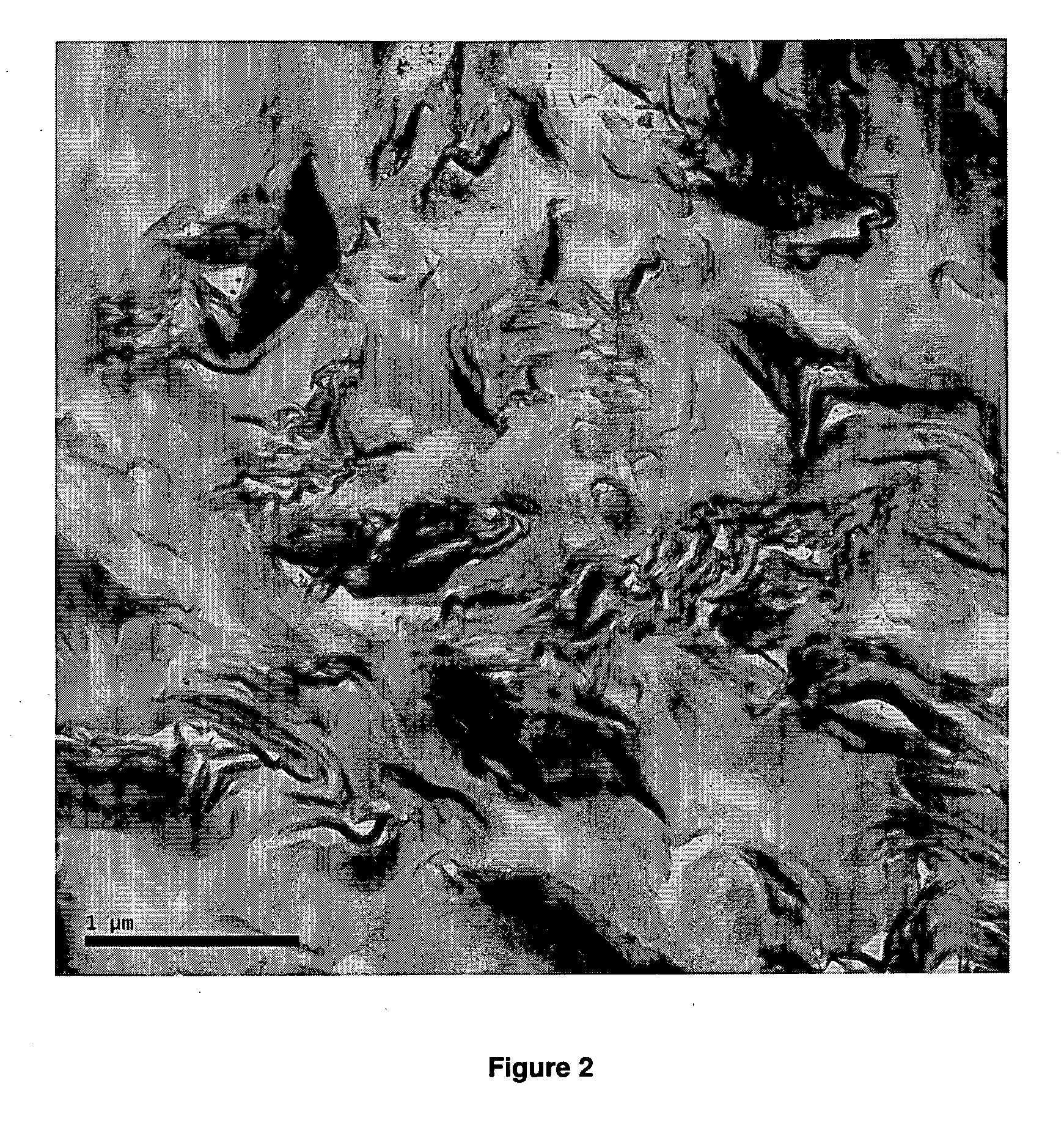

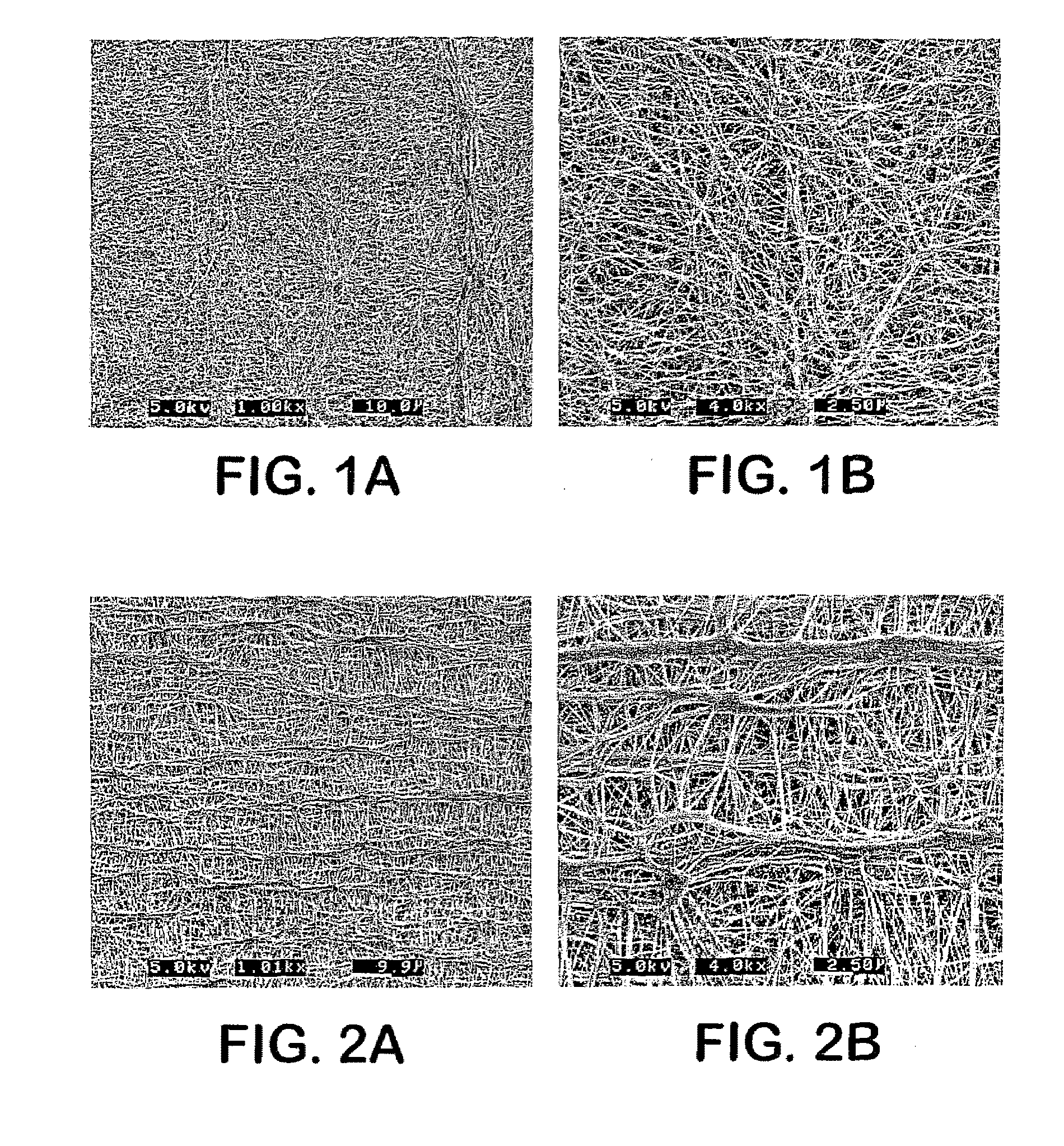

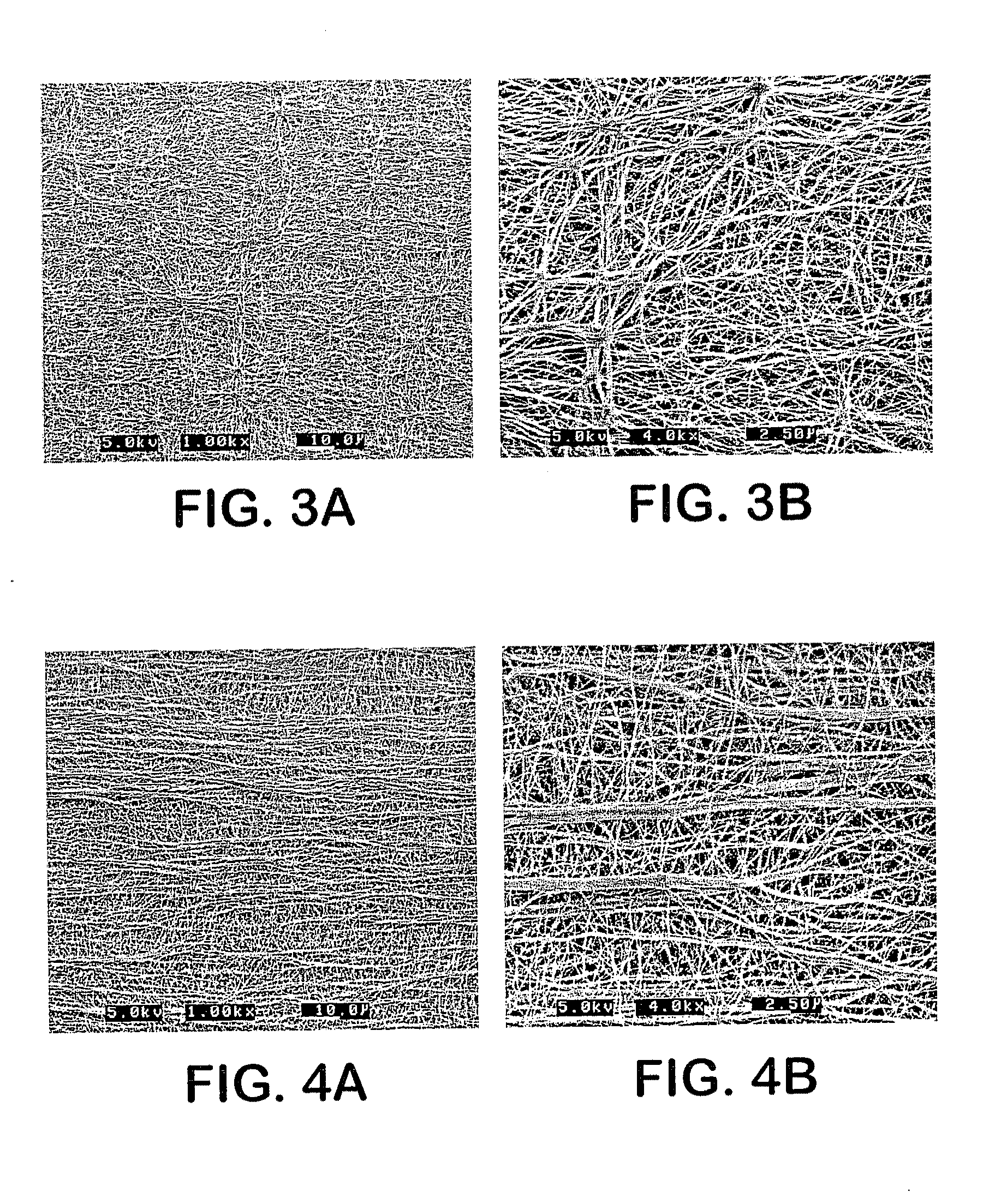

Process for the production of high tensile strength and low creep polymer yarns, high tensile strength and low creep polymer or copolymer yarns, and, the use of such yarns

InactiveUS20090123748A1High tensile strengthLow creepPigmenting treatmentAntifouling/underwater paintsSolventNanometre

The present invention relates to a process for the production of high tensile strength and low creep polymer yarns, wherein it comprises the following steps: (a) preparing a mixture of: (i) a first ultra high molecular weight polyolefin polymer or copolymer, (ii) a second clay nanocomposite polyolefin polymer or copolymer, and (iii) a non-polar spinning solvent, (b) feeding the resulting suspension through an extruder at a temperature of at least 180° C., causing the formation of a gel, (c) spinning the gel so obtained in a spinneret with a length to diameter ratio (L / D) of at least 15, (d) cooling the yarn to a temperature below 2° C., (e) subsequently removing the non-polar spinning solvent, and (f) drawing the yarn so obtained so as to obtain a tensile strength value of at least 18 cN / Dtex and a creep value lower than 0.07% per hour, wherein the first ultra high molecular weight polyolefin polymer or copolymer has a weight-average molecular weight higher than 2,000,000 g / mol and a polydispersivity of at least 7, and the second clay nanocomposite polyolefin polymer or copolymer is obtained via in situ polymerization of an olefin and an exfoliated layered clay, the polyolefin so obtained having a weight-average molecular weight of at least 400,000 g / mol.

Owner:BRASKEM SA

Windage braking

ActiveUS8061483B2Compact windage brakeDifferent speedBraking element arrangementsSafety beltsImpellerEngineering

A windage brake for a fan descender comprises a rotatable spool connected by drive belts to a fan comprising a radial flow air impeller. A line is wound helically upon the spool. A user of the fan descender puts on a harness (not shown) at the free end of the line and jumps from an elevated position. The line is thereby drawn off the spool and rotates it. The rotating spool drives the fan and also winds a power spring formed by a resilient strip. The windage of the fan regulates the descent of the jumper, the fan being accelerated to a speed at which the braking force is such that the jumper descends at a rate safe for landing on the ground. When the jumper is on the ground, he removes the harness and releases the free end of the line. The line is then automatically retrieved by the power spring and rewound on the spool.

Owner:DROP ZONE UK

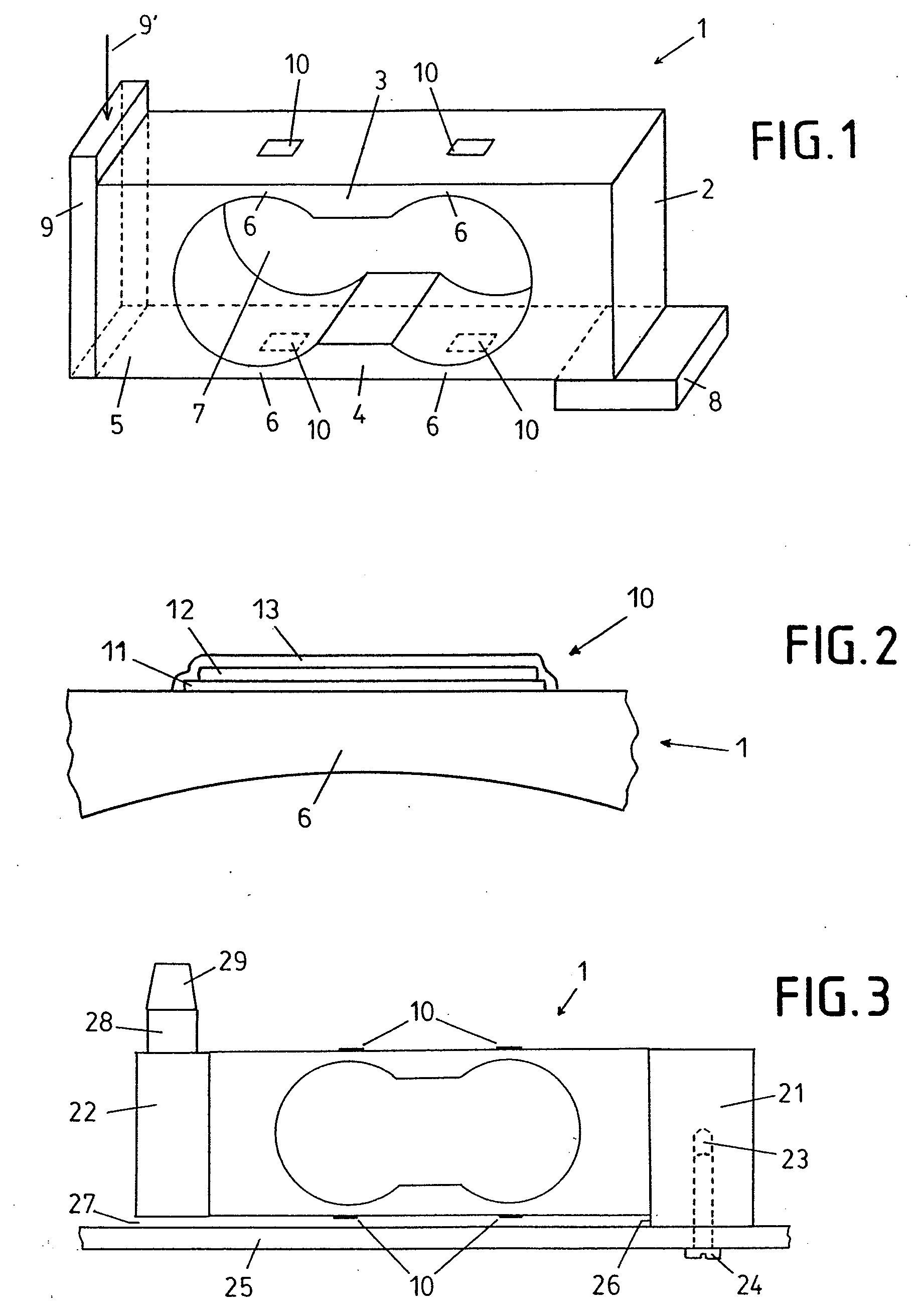

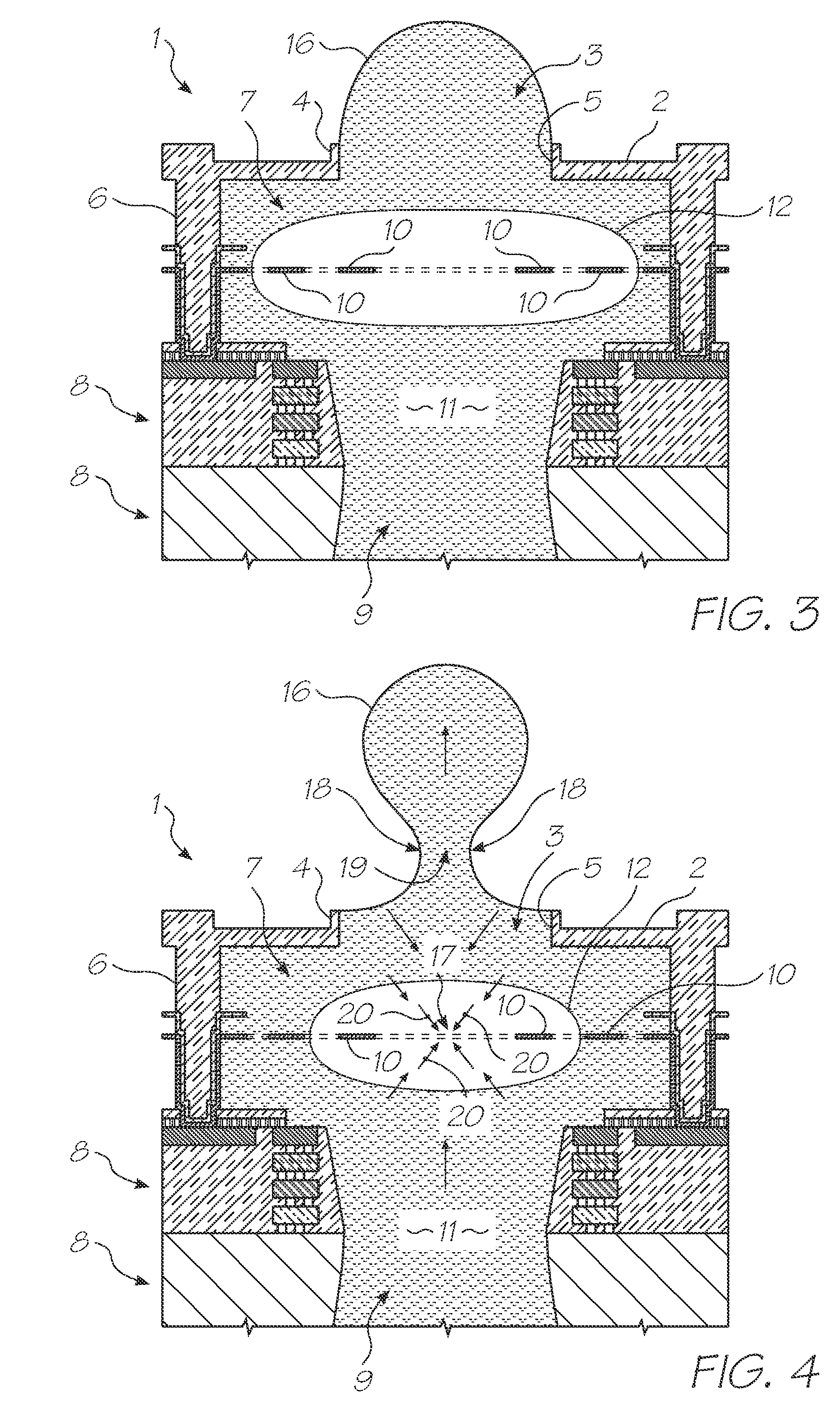

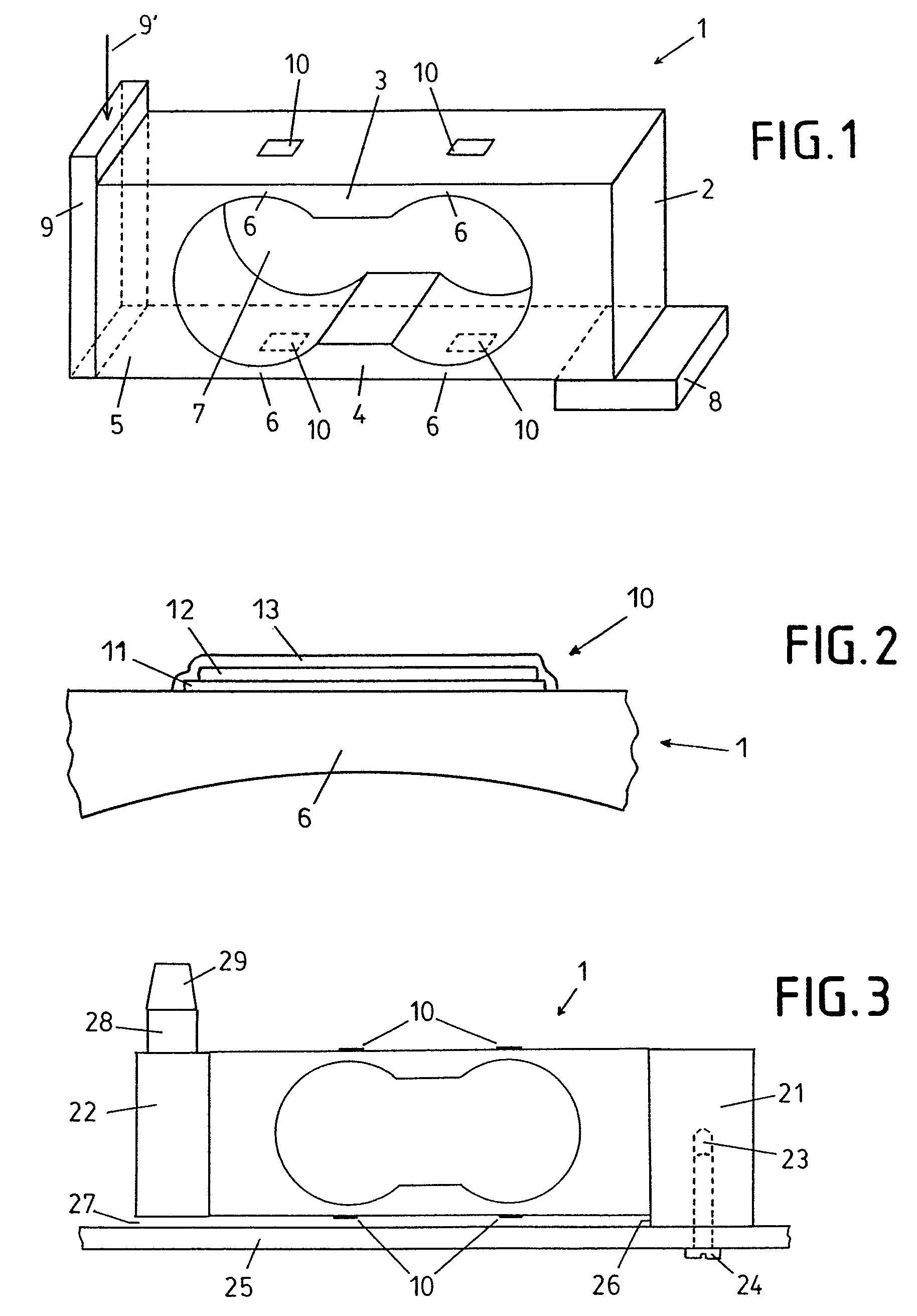

Nickel alloy precision force transducer with strain gauge elements

InactiveUS20080236300A1Improve accuracyLow creepWeighing apparatus using elastically-deformable membersElectrical/magnetic solid deformation measurementPolymer freeStrain gauge

A precision force transducer having a spring element (1) whose load-dependent deflection is converted into an electrical signal by means of strain gauge elements (10). The spring element (1) is made of a precipitation-hardenable nickel-based alloy with a nickel content in the range of 36 to 60 percent and a chromium content in the range of 15 to 25 percent. The strain gauge elements (10) are composed of a polymer-free layered film system. This makes it possible to produce a precision force transducer that features great accuracy, low creep and low moisture sensitivity.

Owner:SARTORIUS LAB INSTR GMBH & CO KG

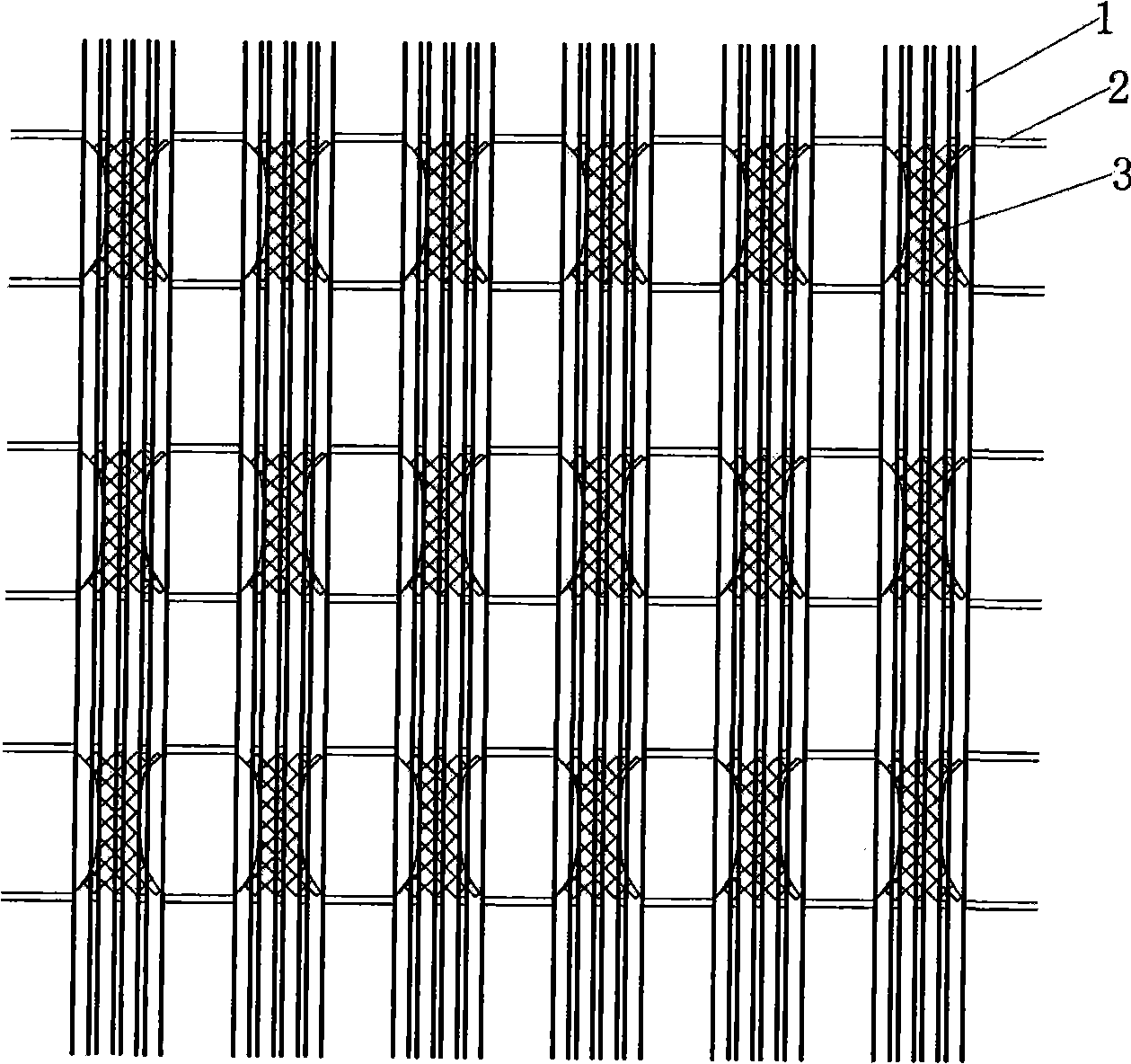

High-strength earth work grille net

InactiveCN101255686AHigh tensile strengthImprove corrosion resistanceExcavationsSoil preservationHigh intensityHigh wear resistance

A high-strength earth work grille net is characterized in that the grille net is waved by the high-strength high-modulus northylen. The grille net is weaved by a plurality of high-strength high-modulus polythene cords. Each cord comprises a plurality of folds, and each fold comprises a plurality of threads. Each lattice of the grille net is quadrangle. The outer layer of the grille net is coated with art glue. The grille net of the invention has the advantages of remarkably high tensile strength, high corrosion resistance, high wearing resistance, low specific elongation, less creep deformation, stronger locking and engaging function to the soil body, effectively processing the soft earth base and the steep bank, restricting the lateral displacement of the soil body, overcoming the differential descending of the soil body, greatly increasing the bearing capacity of the ground work and increasing the whole capability of the ground work.

Owner:SHANGHAI NEW TECHTEXTILES

Inkjet printhead with titanium aluminium alloy heater

Owner:SILVERBROOK RES PTY LTD

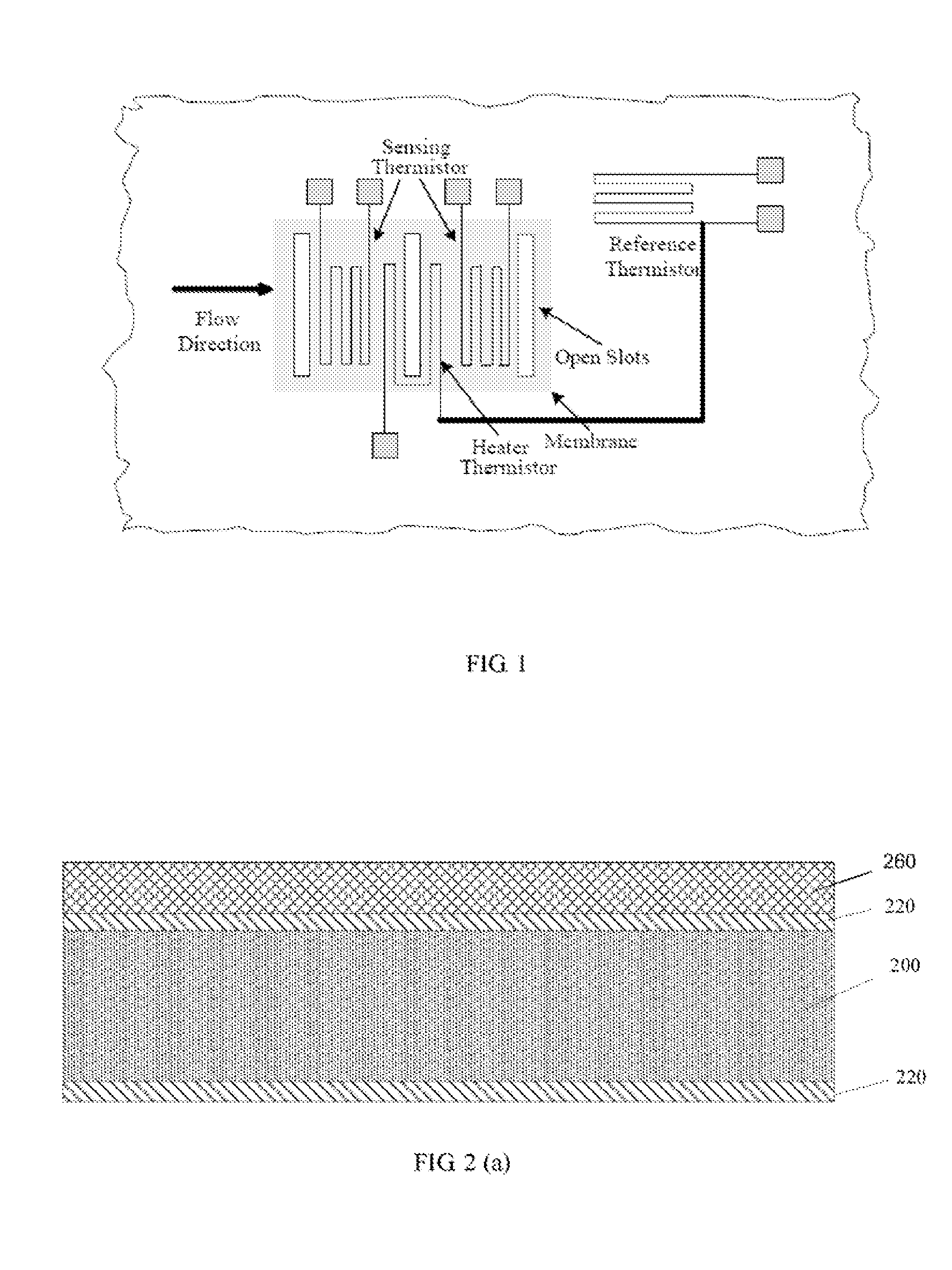

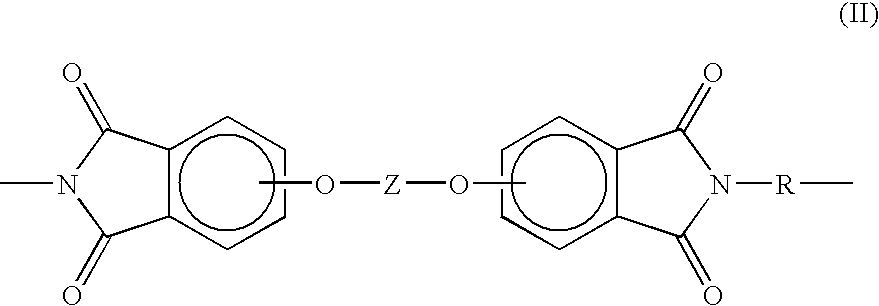

Robust micromachined thermal mass flow sensor with double side passivated polyimide membrane

ActiveUS8132455B2Strong and sturdy supportGood chemical resistanceVolume/mass flow by thermal effectsGas phaseEngineering

A micromachined thermal mass flow sensor comprises a high mechanical strength polyimide film as a supporting layer of suspending membrane. The polyimide film provides superior thermal insulating properties to reduce the power consumption of device. Due to the tendency of humidity absorption, the polyimide suspending membrane is double side passivated on both top and bottom surfaces to sustain its long term stability from rush and humid working environment. A thin layer of silicon dioxide deposited by plasma enhanced chemical vapor deposition is overlaid between the silicon nitride and polyimide film to enhance the adhesion property of passivation layers to polyimide surface. With such embodiments, a sturdy and robust micromachined thermal mass flow sensor with high measurement accuracy could be formed.

Owner:M TECH INSTR HLDG

Nickel alloy precision force transducer with strain gauge elements

InactiveUS7732721B2Low creepHigh strengthWeighing apparatus using elastically-deformable membersElectrical/magnetic solid deformation measurementElectricityPolymer free

A precision force transducer having a spring element (1) whose load-dependent deflection is converted into an electrical signal by means of strain gauge elements (10). The spring element (1) is made of a precipitation-hardenable nickel-based alloy with a nickel content in the range of 36 to 60 percent and a chromium content in the range of 15 to 25 percent. The strain gauge elements (10) are composed of a polymer-free layered film system. This makes it possible to produce a precision force transducer that features great accuracy, low creep and low moisture sensitivity.

Owner:SARTORIUS LAB INSTR GMBH & CO KG

Polyetherketoneketone nonwoven mats

ActiveUS9422654B2Low creepIncrease resistanceSynthetic resin layered productsWoven fabricsFiberPolyetherketoneketone

The invention provides nonwoven mats comprising polyetherketoneketone fibers or mixtures thereof. Also provided are filters, textiles, blankets, and insulation prepared from polyetherketoneketone nonwoven mats, as well as methods for manufacturing the same.

Owner:ARKEMA INC

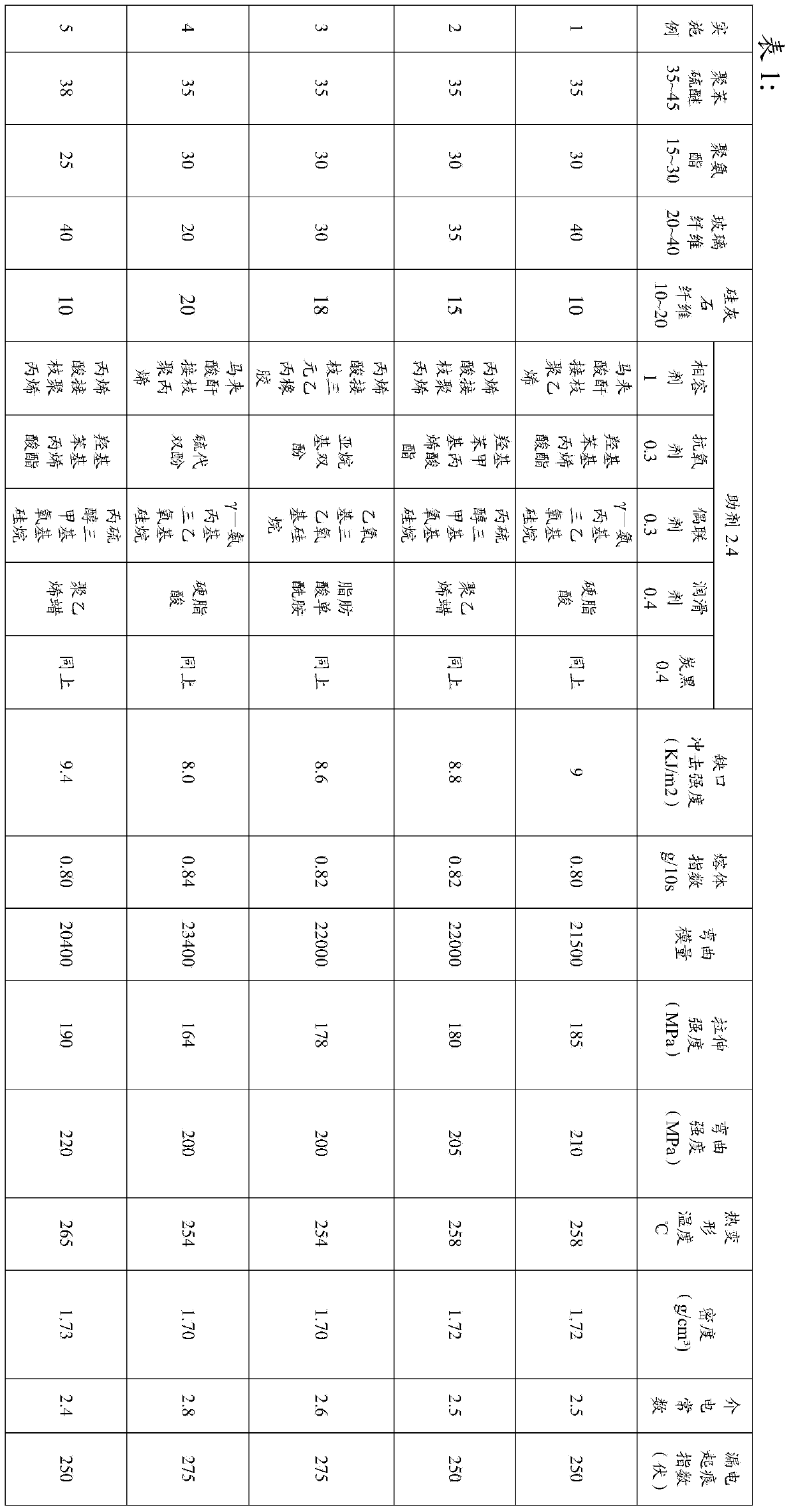

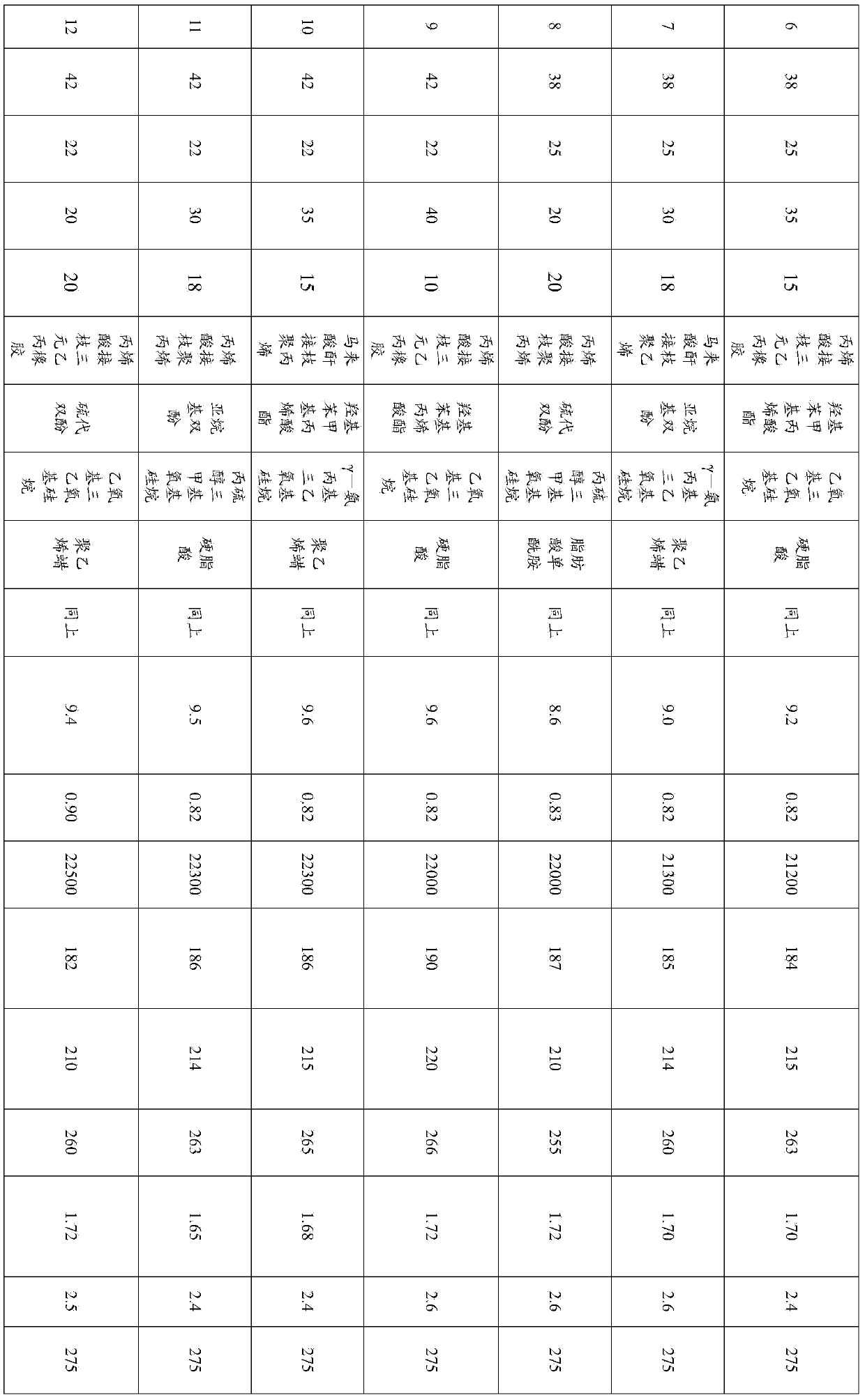

Polyurethane co-mixed modified polyphenylene sulfide composite material and preparation method thereof

The invention discloses a polyurethane co-mixed modified polyphenylene sulfide composite material which comprises polyphenylene sulfide, polyurethane, glass fibers, wollastonite fibers and an assistant, wherein the assistant comprises a compatilizer, an antioxidant, a coupling agent, a lubricant and carbon black. The invention further discloses a method for preparing the polyurethane co-mixed modified polyphenylene sulfide composite material. The method comprises the following steps: (1) stirring and mixing the polyphenylene sulfide, the polyurethane, the glass fibers, the wollastonite fibers, the compatilizer, the antioxidant, the coupling agent, the lubricant and the carbon black to obtain a mixed material; (2) adding the mixed material into an extruder and extruding to obtain the strip-like composite material. The polyurethane co-mixed modified polyphenylene sulfide composite material disclosed by the invention not only has the characteristics of high strength, low creep, good mobility, easiness in processing and the like, but also has the characteristics of high toughness, low density, small dielectric constant, high comparative tracking index and the like.

Owner:GUANGZHOU GAOBAER PLASTIC

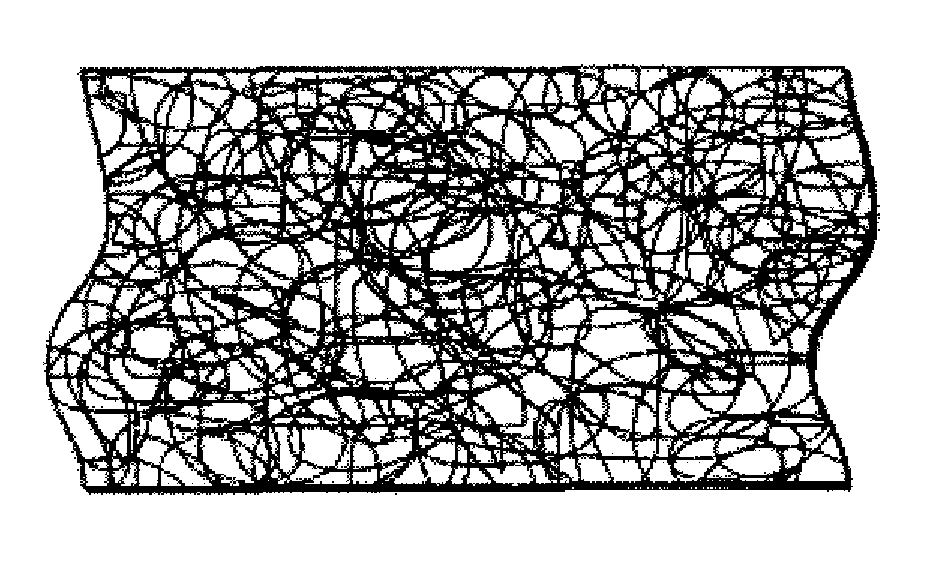

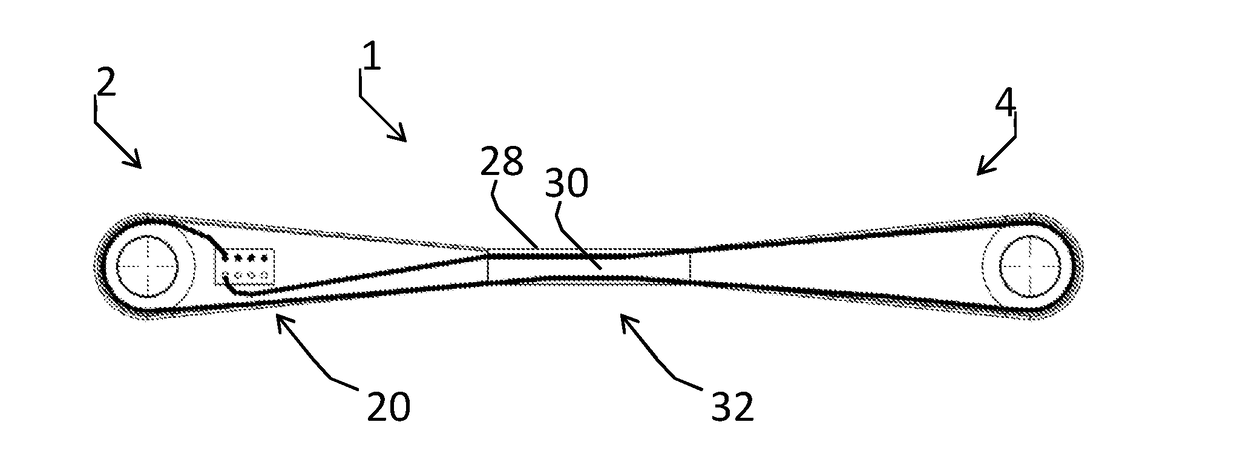

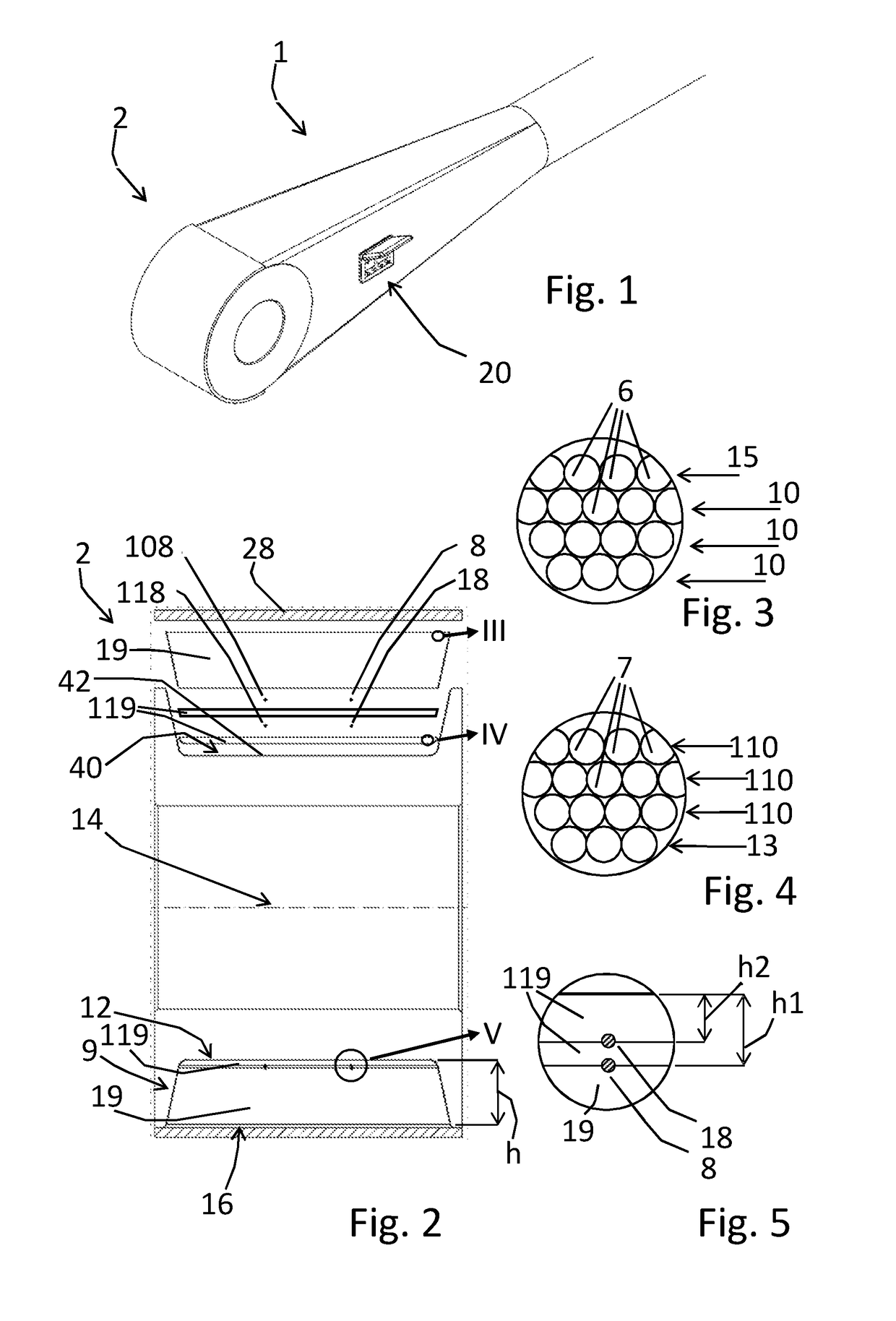

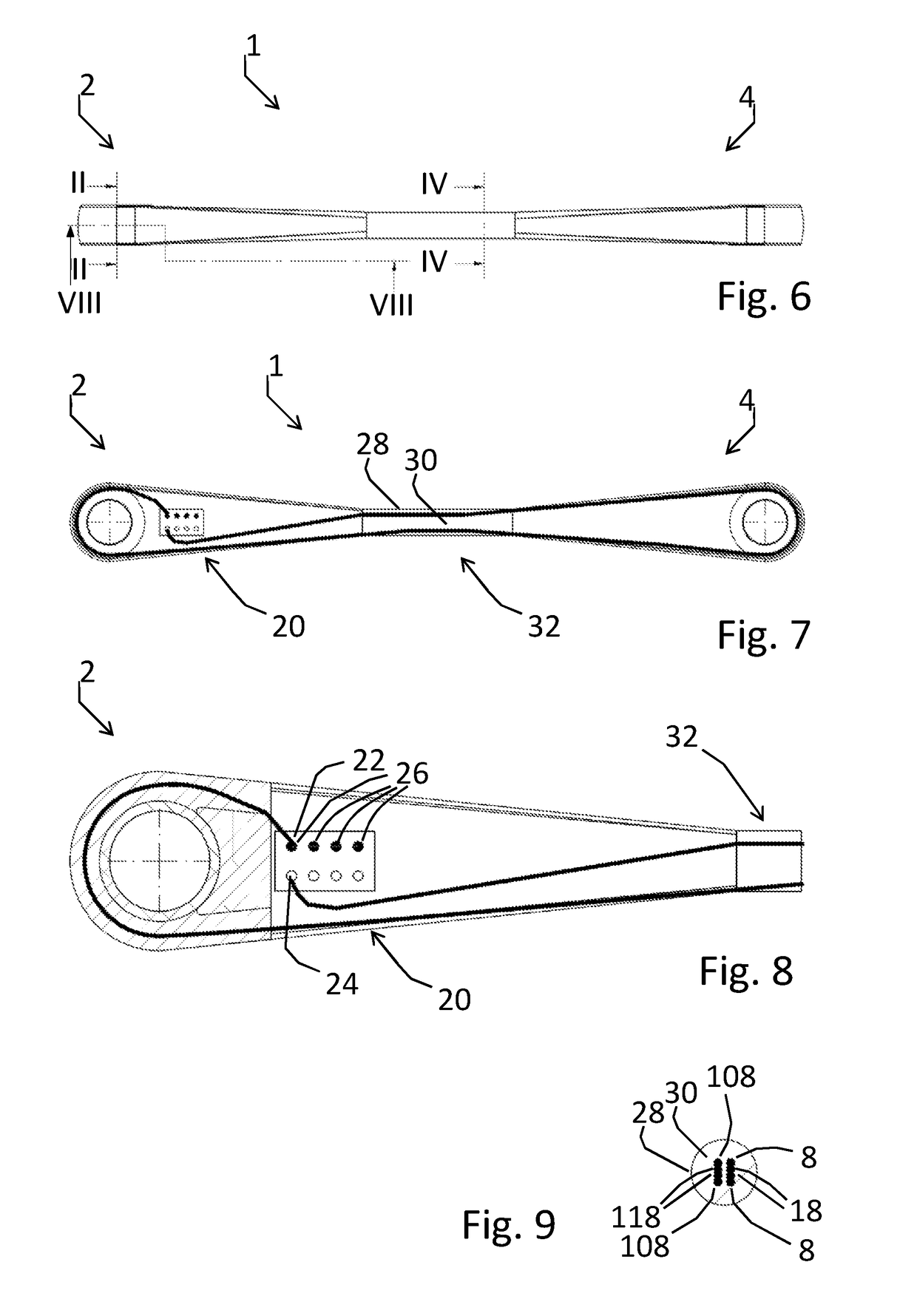

Cable with a first and a second thimble and at least one yarn, and method for producing an endless winding cable

ActiveUS20180334776A1Lower overall heightDirect contact guaranteeControlRopes and cables for vehicles/pulleyYarnConductor Coil

A cable comprises a first and a second thimble (2, 4), and at least one main yarn (6) and an auxiliary yarn (7). The first and the second thimble are provided at opposite ends of the cable. The at least one main yarn (6) and the auxiliary yarn (7) each forms turns around the first and second thimble (2, 4). Each thimble (2, 4) comprises a bearing surface (40), and holds a stack (19) of layers (10) of turns of the main yarn (6). A stack (119) of turns of the auxiliary yarn (7) comprising at least a first layer (13) of turns of the auxiliary yarn (7) lies on the bearing surface (40) of the respective thimble (2, 4).

Owner:CABIN AIR GRP

Bioengineering plastic and preparation method thereof

ActiveCN108329532ASimple processRaw materials are easy to getChemical industryBio engineeringFluorenone

The invention discloses bioengineering plastic which is prepared from, by weight, 60-70 parts of fluorenone-chitosan polycondensate, 30-40 parts of polyhydroxyalkanoate PHA, 5-8 parts of biomass-basedgraphene and 1-3 parts of silane coupling agent KH560. A preparation method of the bioengineering plastic includes following steps: well mixing fluorenone-chitosan polycondensate, PHA, biomass-basedgraphene and the silane coupling agent KH560; adding the same into a double-screw extruder for extrusion molding to obtain the bioengineering plastic. The bioengineering plastic is high in strength and mechanical modulus, low in latent degeneration, high in wear resistance, excellent in fatigue resistance, chemical drug resistance, electricity resistance, flame resistance, weatherability, impact resistance, thermal resistance and size stability, energy-saving and environment-friendly.

Owner:四川嘉亿盛材料科技有限公司 +1

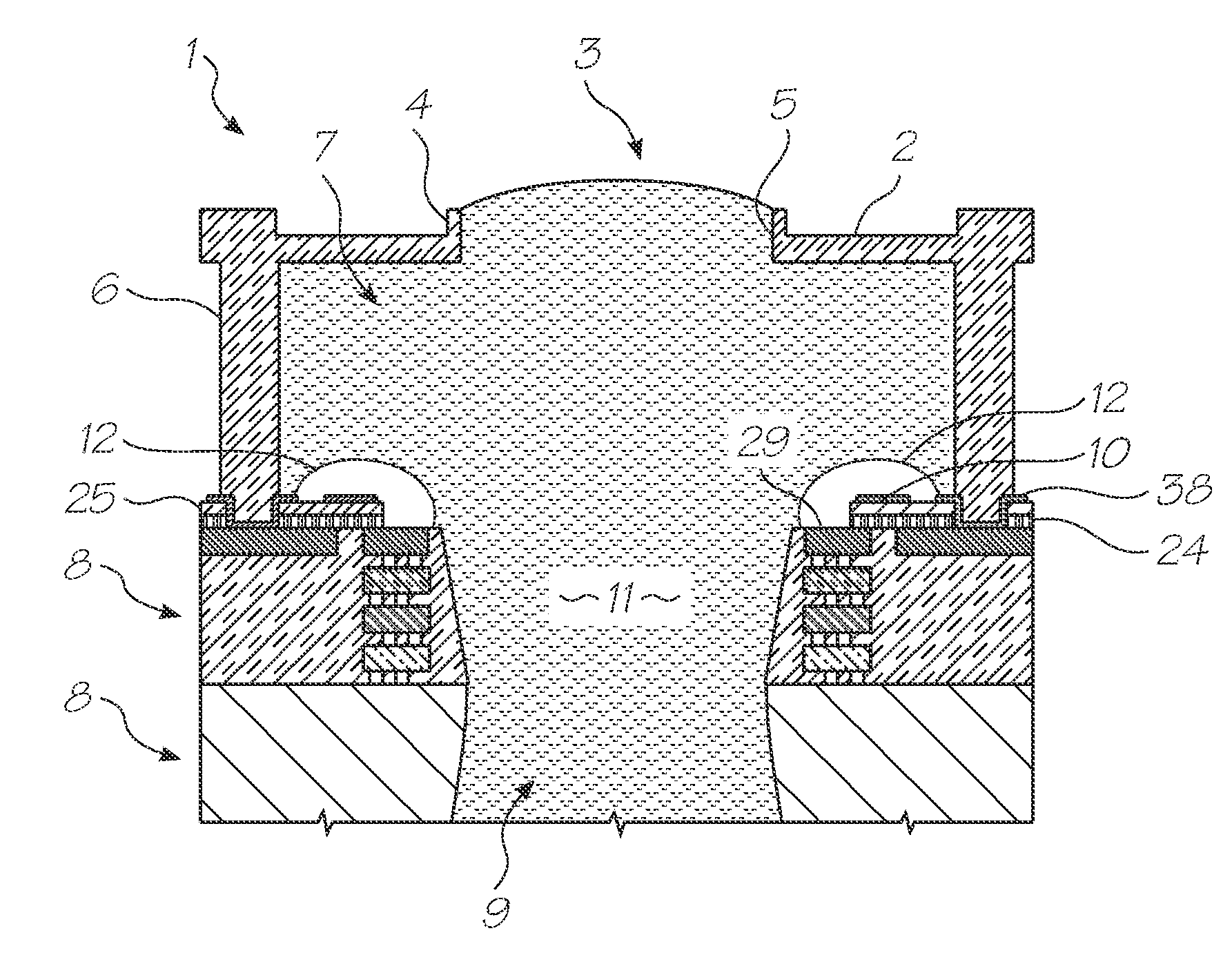

PTFE Membranes and Gaskets Made Therefrom

InactiveUS20100009180A1Improve mechanical propertiesStrength can be balancedDomestic sealsEngine sealsExpanded PTFEMechanical property

Improved expanded PTFE materials and improved gasket materials made therefrom, the gaskets being capable of forming a seal with greater bolt load retention than is possible with existing PTFE gaskets. The expanded PTFE membranes of the invention can be tailored to exhibit a matrix tensile strength in at least one direction of at least 25,000 psi, a matrix tensile strength ratio in two orthogonal directions of between 0.025 and 4, an orientation index of 50° or less, and a density of 2.0 g / cc or less. The improved gaskets exhibit improved mechanical properties such as high bolt load retention, low creep, high tensile strength, low stress to seal and high crystallinity index.

Owner:WL GORE & ASSOC INC

Inkjet printhead with titanium aluminium alloy heater

An inkjet printhead with a resistive heaters for vaporizing ink to eject drops through respective nozzles. The heater is formed from a TiAlX alloy where Ti contributes more than 40% by weight, Al contributes more than 40% by weight and X contributes less than 5% by weight and comprises zero or more of Ag, Cr, Mo, Nb, Si, Ta and W.

Owner:SILVERBROOK RES PTY LTD

Long fiberglass reinforced polypropylene automobile water tank bracket

ActiveCN103571066AEasy to prepareImprove performancePropulsion coolingThermal dilatationPolymer science

The invention discloses a long fiberglass reinforced polypropylene automobile water tank bracket, which is manufactured from a long fiberglass reinforced polypropylene material, wherein the long fiberglass reinforced polypropylene material comprises the following components in parts by weight: 65 to 68 parts of polypropylene random copolymer, 3 to 5 parts of homo-polypropylene, 19 to 21 parts of long fiberglass, 5 to 6 parts of compatilizer and 4 to 5 parts of additive. According to the long fiberglass reinforced polypropylene automobile water tank bracket, a preparation method is simple; the long fiberglass reinforced polypropylene automobile water tank bracket is high in comprehensive performance, impact resistance, modulus, strength, dimensional stability, abrasion resistance, fatigue resistance and chemical resistance, isotropic and low in shrinkage and creep, and has a thermal expansion coefficient similar to that of metal.

Owner:SUZHOU WANLONG AUTO PARTS

Polyphenyl sulfone ketone copolymers

A polymer comprising sulfone groups, ketone groups and optionally substituted polyarylene groups, wherein the number of moles of sulfone groups over the number of moles of ketone groups ratio is greater than 1. A process for making such polymer, a composition comprising such polymer, and articles made therefrom.

Owner:SOLVAY ADVANCED POLYMERS LLC

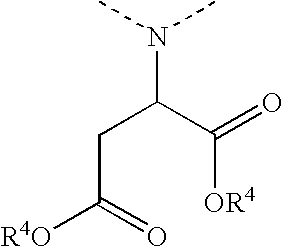

Polymer having network structure

InactiveUS6545118B1Low creepLow modulusSynthetic resin layered productsStands/trestlesIsocyanateChemistry

A series of polymeric compositions, methods of making the compositions and uses of the compositions are described. An exemplary composition is made by copolymerization of a trifunctional amine or hydroxy compound, a monofunctional amine or hydroxy compound and a polyisocyanate compound.

Owner:CHIEF OF NAVAL RES OFFICE OF COUNSEL GOVT OF THE UNITED STATES OF AMERICA DEPT OF THE NAVY THE

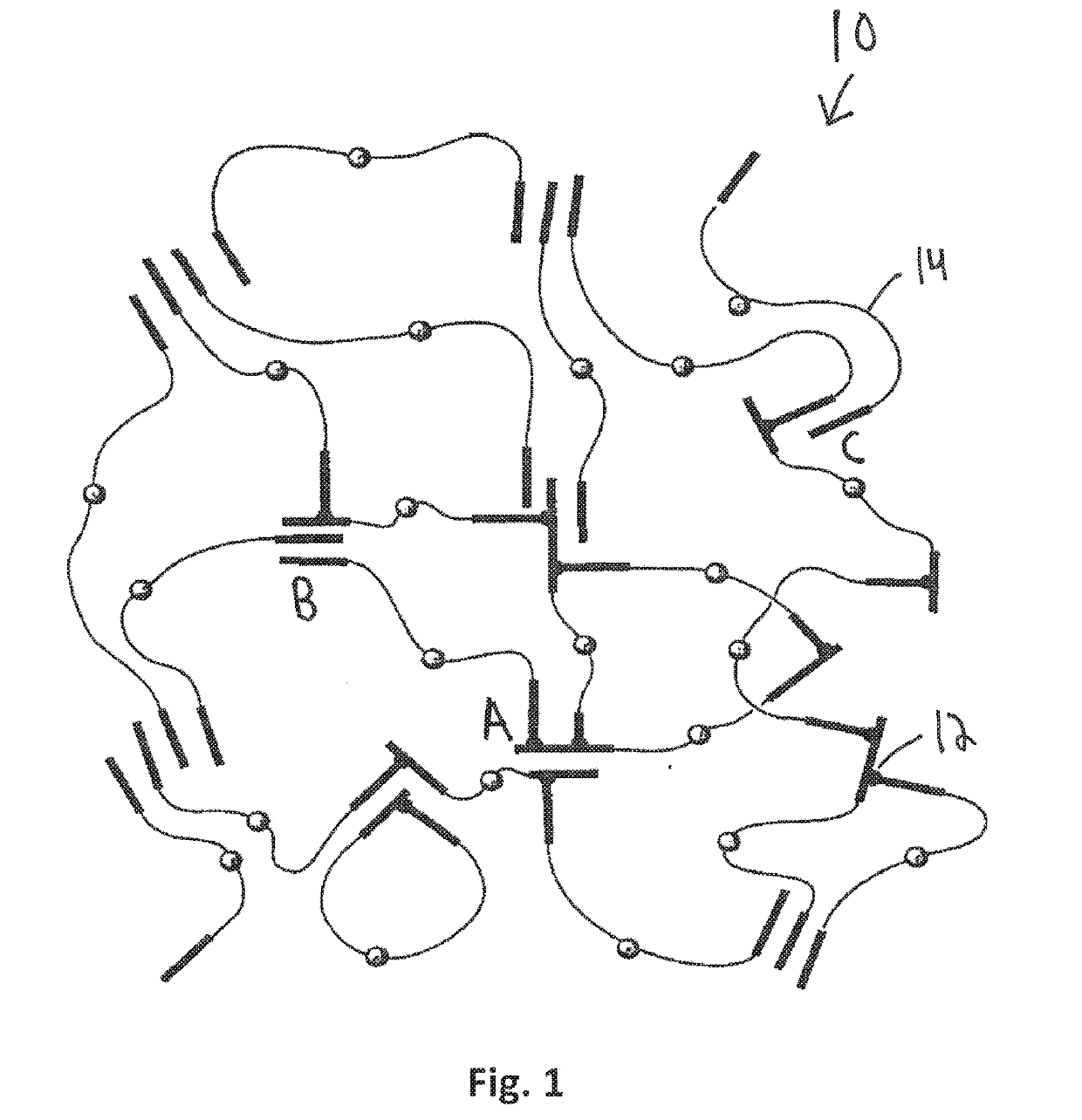

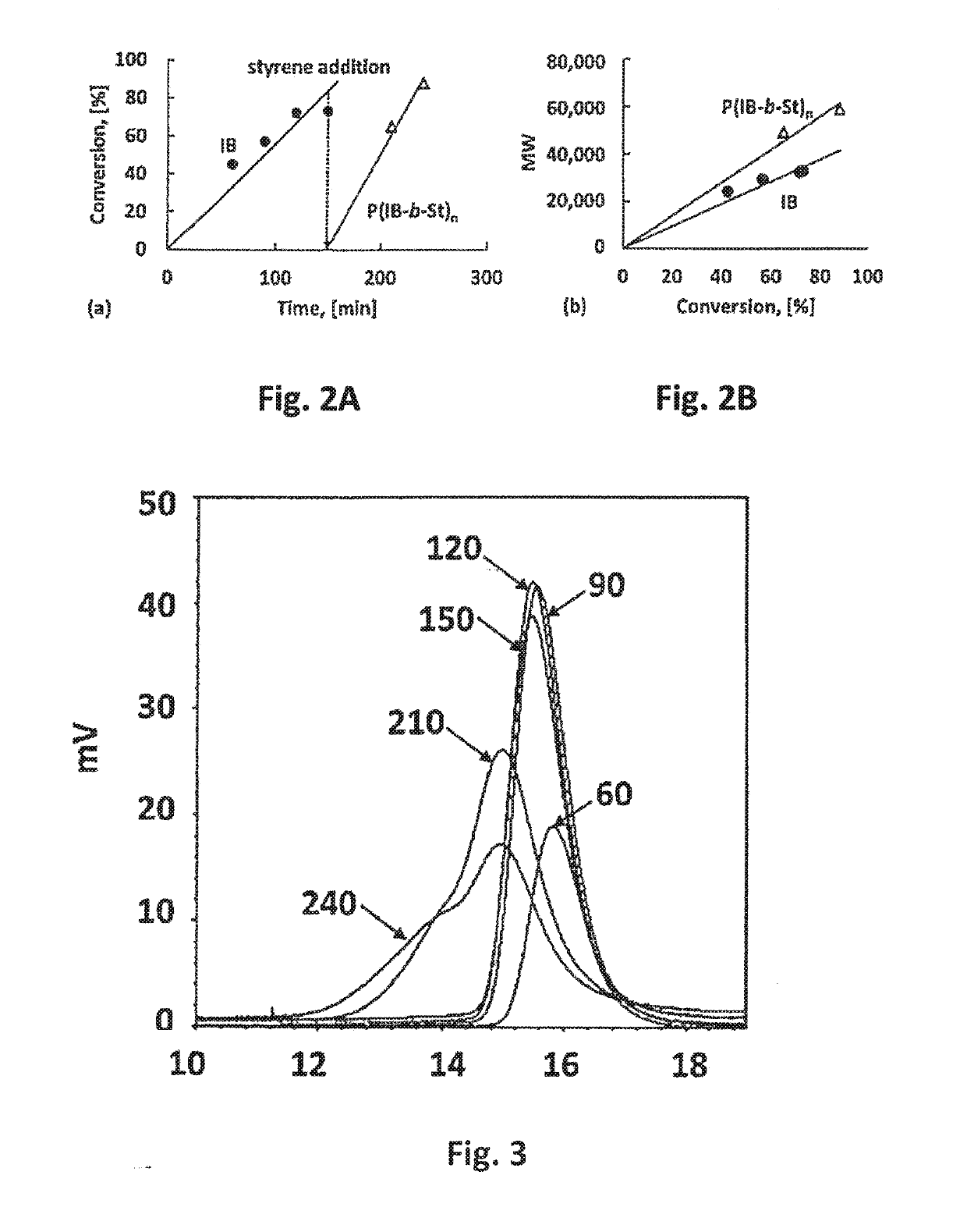

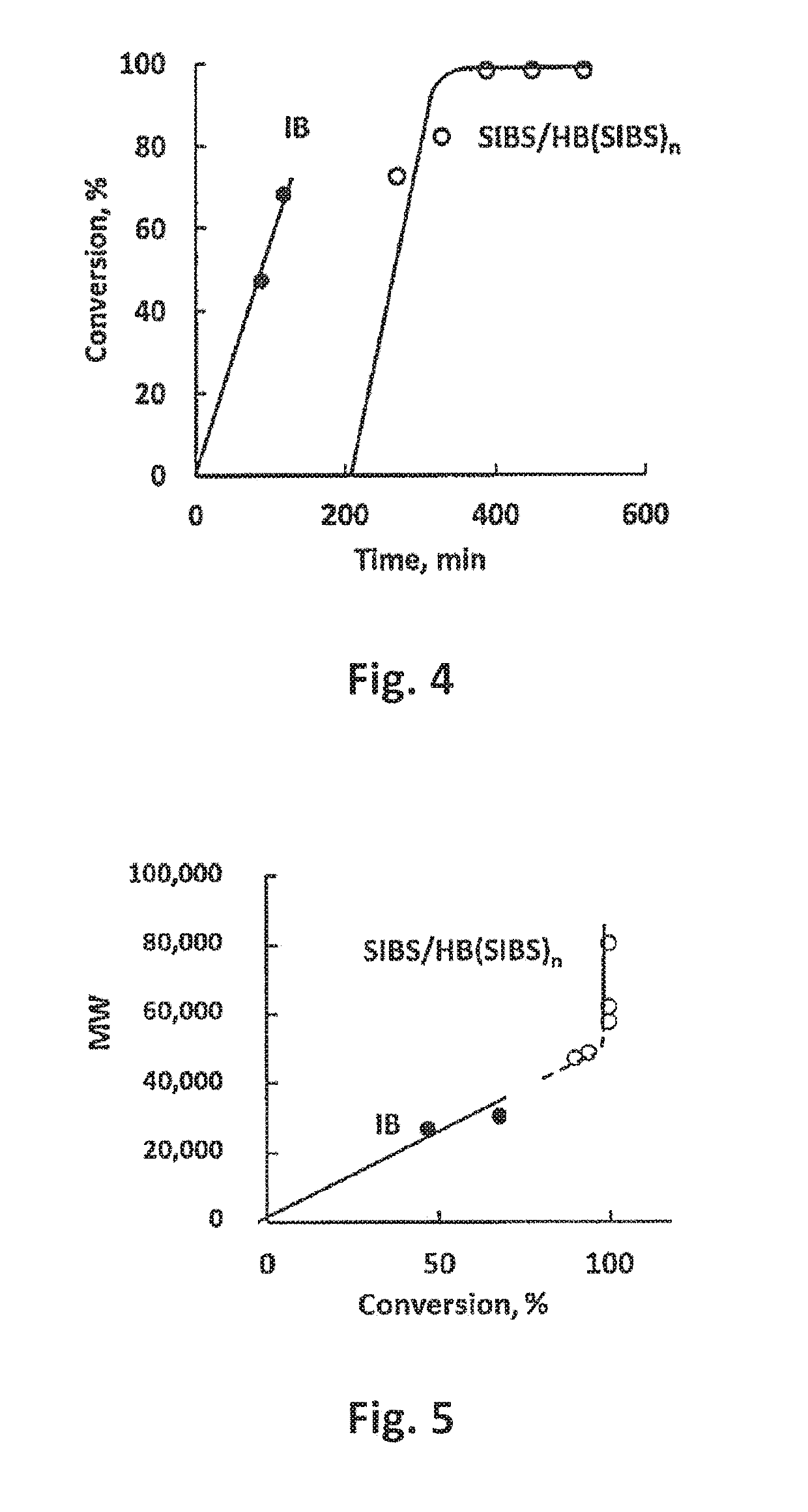

Styrenic block copolymer-hyperbranched styrenic block copolymer networks

A thermoplastic elastomeric network is taught. The thermoplastic elastomer network includes hyperbranched styrenic block copolymers and styrenic block copolymers physically crosslinked though aggregation. Additionally, the hyperbranched styrenic block copolymers of the thermoplastic elastomeric network are a plurality of styrenic block copolymers chemically crosslinked.

Owner:THE UNIVERSITY OF AKRON

Composite material and composite product

ActiveUS11034838B2Improved propertyLow creepWood treatment detailsThermal wood treatmentCellulosePolymer science

The present invention is directed to a composite material comprising a cellulosic material, high impact polystyrene (HIPS) and styrene maleic anhydride (SMA). The cellulosic material may be thermally modified prior to being incorporated into the composite material. The present invention is also directed to a composite product that comprises the composite material according to the invention.

Owner:STORA ENSO OYJ +1

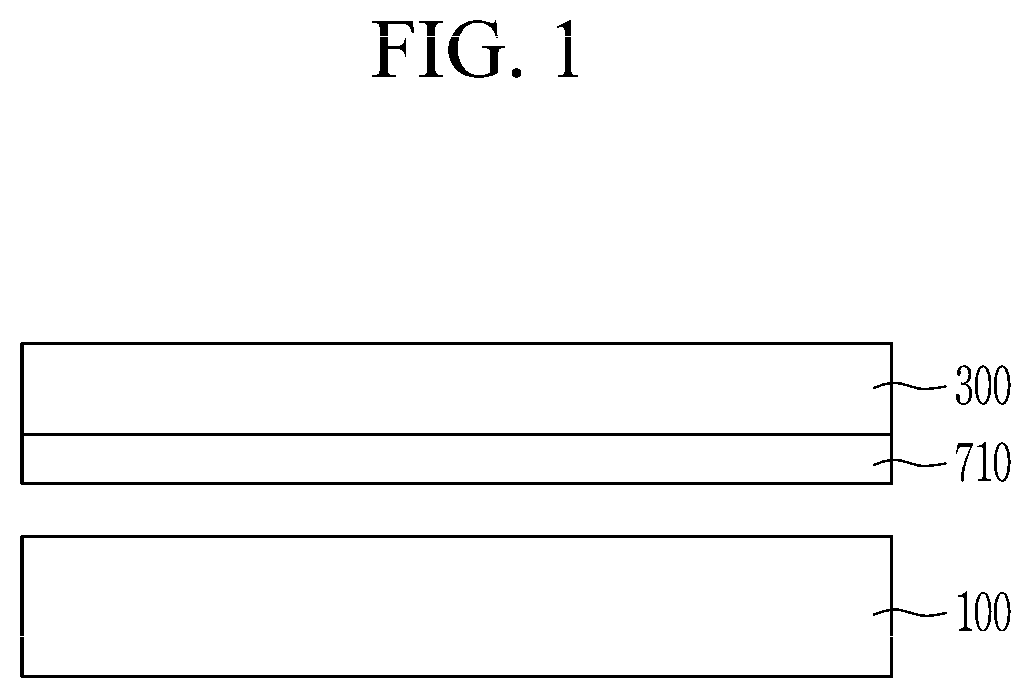

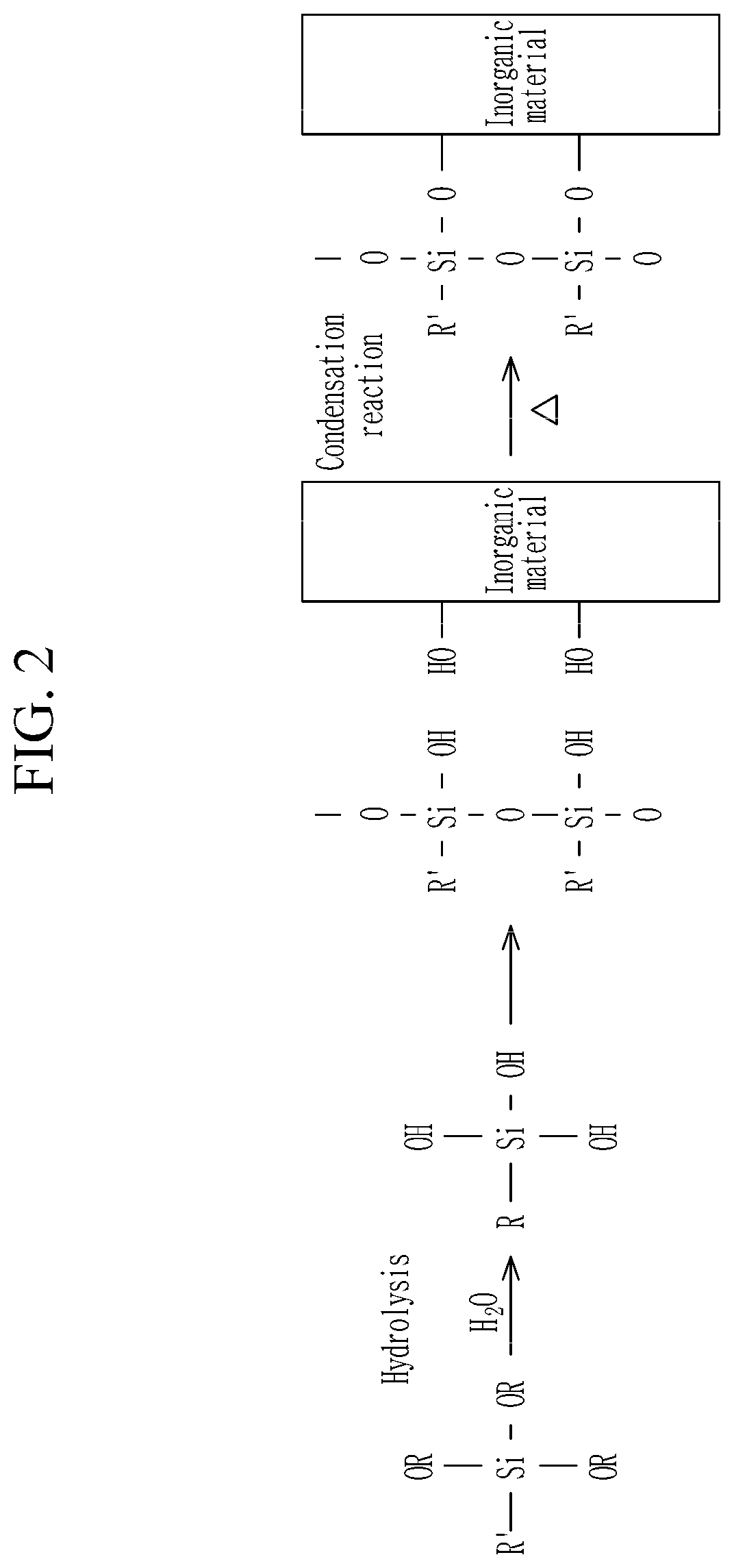

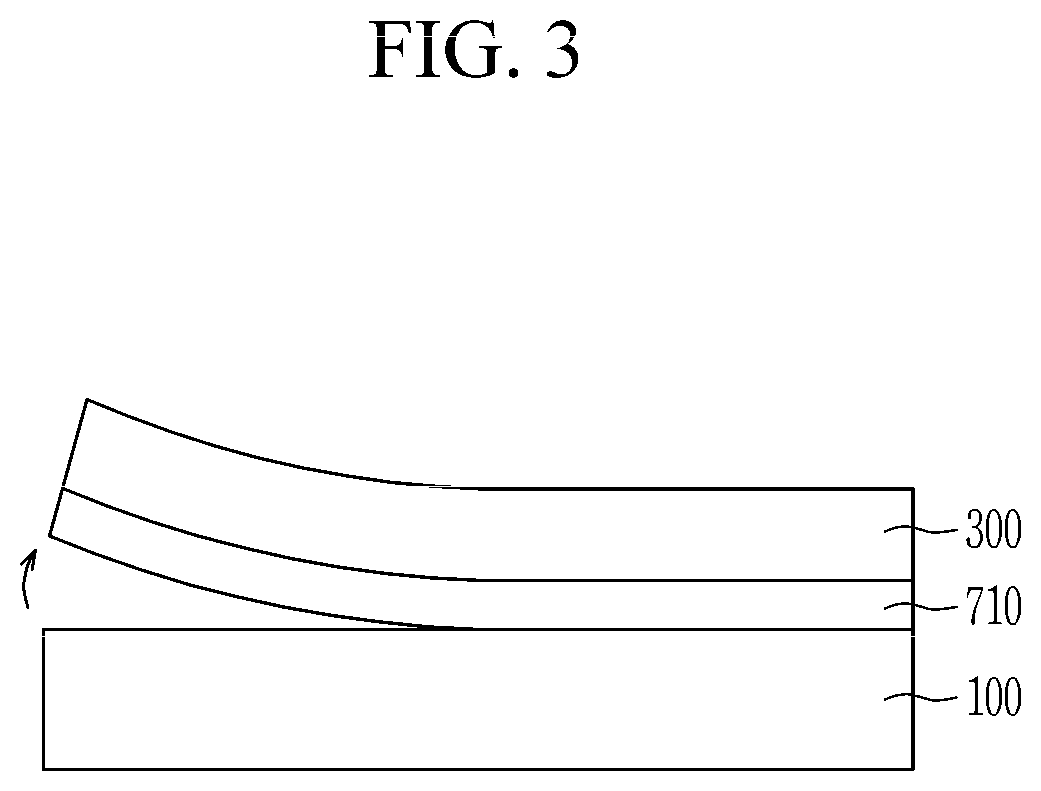

Display device

PendingUS20220105706A1Improve reliabilityLow creepCasings with display/control unitsSynthetic resin layered productsDisplay deviceEngineering

The present disclosure relates to a display device including a display panel, a protection layer on the display panel, and a first adhesive layer between the display panel and the protection layer. The first adhesive layer may contain 0.05 wt % to 1 wt % of a silane coupling agent, and the first adhesive layer may have creep of 20% or less at 60° C.

Owner:SAMSUNG DISPLAY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com