Implant and method for manufacturing mandibular implant with PEKK (polyetherketoneketone) supporting and fixing units and tissue engineering growth unit

A technology of fixation unit and support unit, applied in bone implants, prostheses, additive manufacturing, etc., can solve problems such as insufficient consideration of occlusal reconstruction, increase of new trauma in the donor area, excessive elastic modulus, etc., and restore oral chewing Function, improve the success rate of repair, the effect of low elastic modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described below in conjunction with the accompanying drawings.

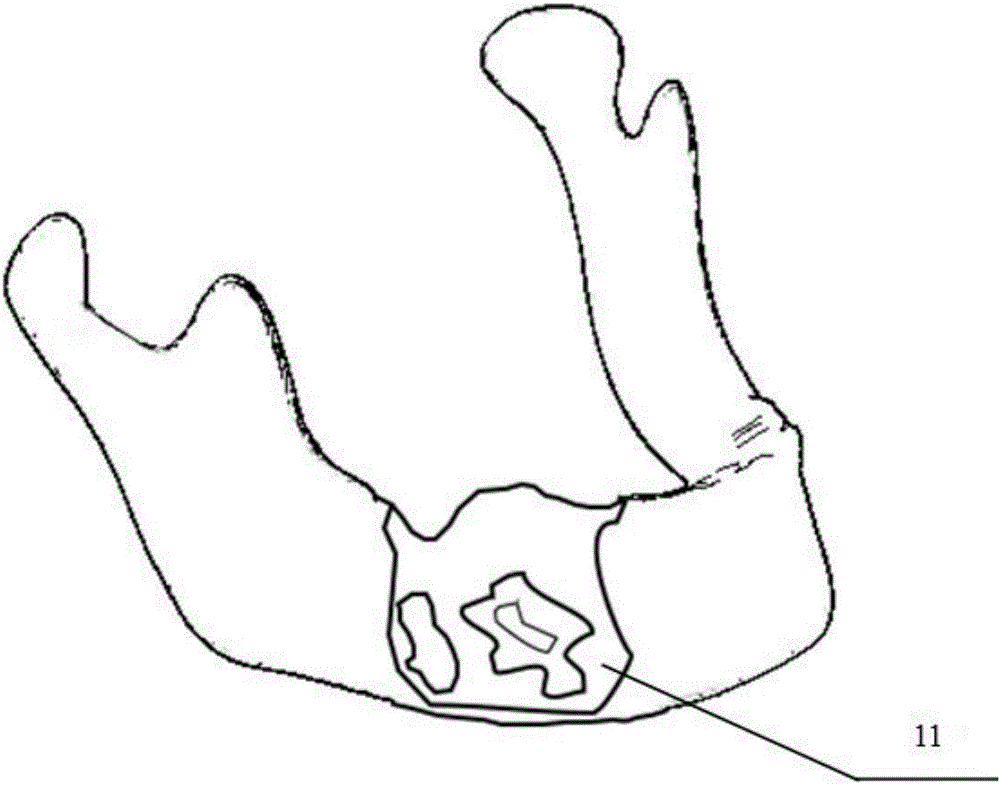

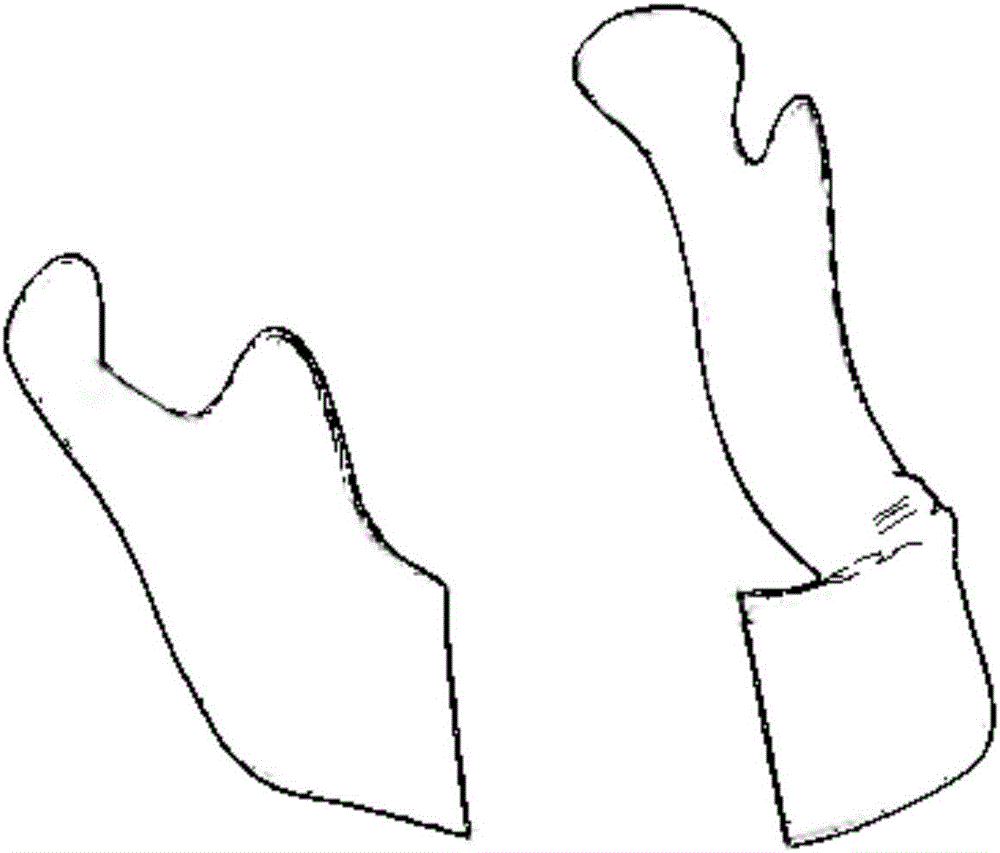

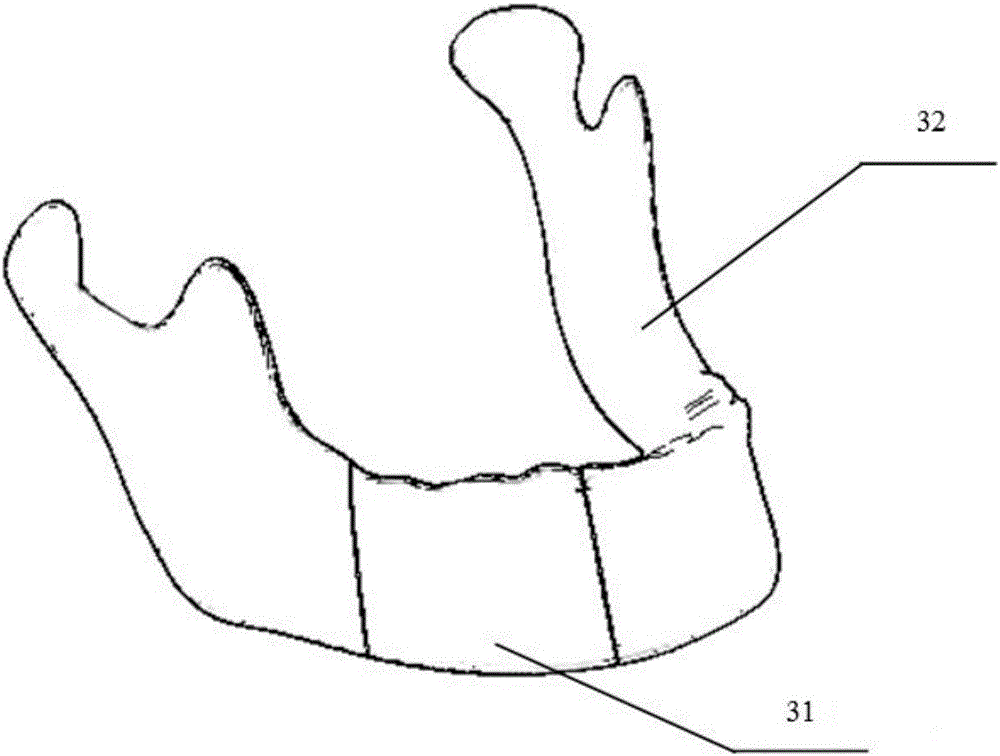

[0055] refer to Figure 1 to Figure 15 A method for manufacturing a mandibular implant with a PEKK support fixation unit and a tissue engineering growth unit comprises the following steps:

[0056] 1) Image acquisition and 3D model establishment:

[0057] ① Collect image data of the patient's mandible. The data can be collected by CT / MRI and other means. Taking CT as an example, spiral CT thin-slice scanning can be used, and the tomographic data can be stored in a storage device in DICOM format after scanning.

[0058] ②Reconstruct the mandible model of the patient. Import the image data of the patient's mandible into medical image processing software, such as Mimics software from Materlise Company, to perform 3D reconstruction of the mandible model, and reconstruct important anatomical structures such as tooth roots and mandibular nerve canal, etc. to analyze and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com