Lithium ion battery composite separation membrane and lithium ion battery containing lithium ion battery composite separation membrane

A technology for lithium-ion batteries and composite diaphragms, applied in the field of composite diaphragms and the preparation of said composite diaphragms, can solve the problems of low glass transition temperature, gel formation or swelling, heat shrinkage resistance not maintained in liquid electrolyte, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

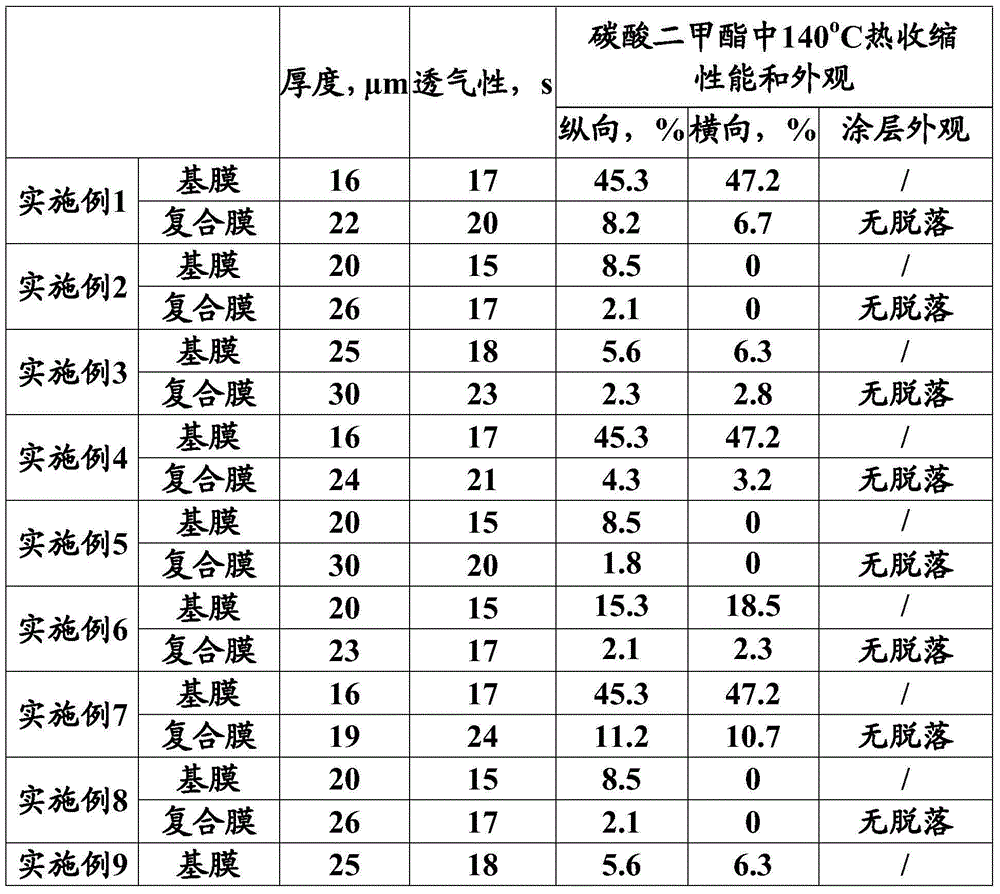

Embodiment 1

[0060]At room temperature, after fully dissolving 10 parts of polyetherimide (GE, Ultem1000) with 90 parts of N-methylpyrrolidone under stirring conditions, slowly add isopropanol to the resulting solution at room temperature until the solution just appears cloudy , to obtain a suspension, and continue to stir and mature the resulting suspension for 12h. Weigh out 85 parts of alumina with an average particle size of 0.3 μm, and add linoleic acid glyceride to the aged polyetherimide suspension according to 2.5% by weight of the alumina. After stirring and dispersing evenly, add 85 parts of aluminum oxide weighed into the obtained dispersion, and disperse by ball milling to form a stable suspension with a solid content of 30%, which is the coating solution.

[0061] A polyethylene single-layer diaphragm with a thickness of 16 μm and a porosity of 40% prepared by a wet method is immersed in the obtained coating solution, and a wire bar coater is used on both sides to control the ...

Embodiment 2

[0063] At room temperature, take 7 parts of polym-phenylene isophthalamide (DuPont, Nomex) and fully dissolve it with a mixed solution of 100 parts of N,N-dimethylacetamide and 5 parts of lithium chloride under stirring conditions , slowly add water to the obtained solution at room temperature until the solution just becomes turbid to obtain a suspension, and continue to stir and mature the obtained suspension for 12 hours. Weigh out 50 parts of silicon dioxide with an average particle diameter of 0.012 μm, and add triethyl phosphate to the aged polym-phenylene isophthalamide suspension according to 5% by weight of the silicon dioxide. After stirring and dispersing evenly, add 50 parts of silicon dioxide weighed to the obtained dispersion, and at the same time add 15 parts of micronized polyethylene wax with a melting point of 85°C, and disperse with a ball mill to form a stable suspension with a solid content of 25%. , which is the coating solution.

[0064] Immerse a uniaxi...

Embodiment 3

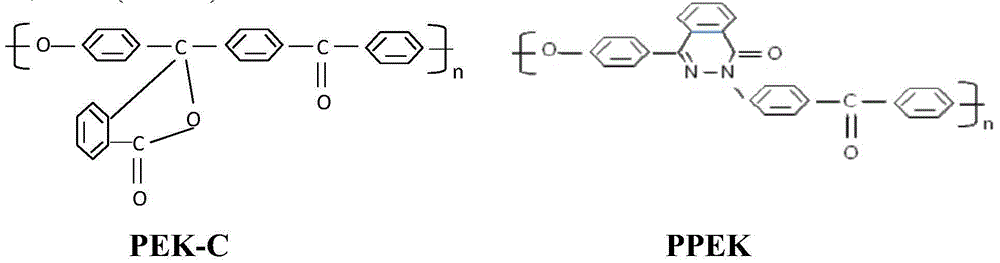

[0066] At room temperature, take 20 parts of phenolphthalein polyaryletherketone (Changchun Institute of Chemical Engineering, PEK-C) and fully dissolve it with 100 parts of tetrahydrofuran under stirring conditions, then slowly add ethanol to the resulting solution at room temperature until the solution just appears cloudy, A suspension was obtained, and the obtained suspension was continued to be stirred and matured for 12 h. Weigh out 90 parts of barium sulfate with an average particle size of 0.8 μm, and add castor oil to the aged polyaryletherketone suspension at 1.5% by weight of the barium sulfate. After stirring and dispersing evenly, add 90 parts of barium sulfate weighed into the obtained dispersion, and add 5 parts of polypropylene wax with a melting point of 145 °C at the same time, and disperse with a ball mill to form a stable suspension with a solid content of 40%, which is Coating fluid.

[0067] The resulting coating solution is sprayed to form a layer of uni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com