Patents

Literature

41 results about "Perfluoroalkoxy alkane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Perfluoroalkoxy alkanes (PFA) are fluoropolymers. They are copolymers of tetrafluoroethylene (C₂F₄) and perfluoroethers (C₂F₃ORᶠ, where Rᶠ is a perfluorinated group such as trifluoromethyl (CF₃)). In terms of their properties, these polymers are similar to polytetrafluoroethylene (PTFE). Compared to PTFE, PFA have better anti-stick properties, higher chemical resistance on expense of a lesser scratch resistance. Other than in PTFE, the alkoxy substituents allow the polymer to be melt-processed. On a molecular level, PFA have a smaller chain length and higher chain entanglement than other fluoropolymers. They also contain an oxygen atom at the branches. This results in materials that are more translucent and have improved flow, creep resistance, and thermal stability close to or exceeding PTFE. Thus, PFA are preferred when extended service is required in hostile environments involving chemical, thermal, and mechanical stress. PFA offer high melt strength, stability at high processing temperatures, excellent crack and stress resistance, a low coefficient of friction. Similarly advantaged processing properties are found in fluorinated ethylene propylene (FEP), the copolymer of tetrafluoroethylene and hexafluoropropylene. However FEP is ten times less capable to withstand repeated bending without fracture than PFA.

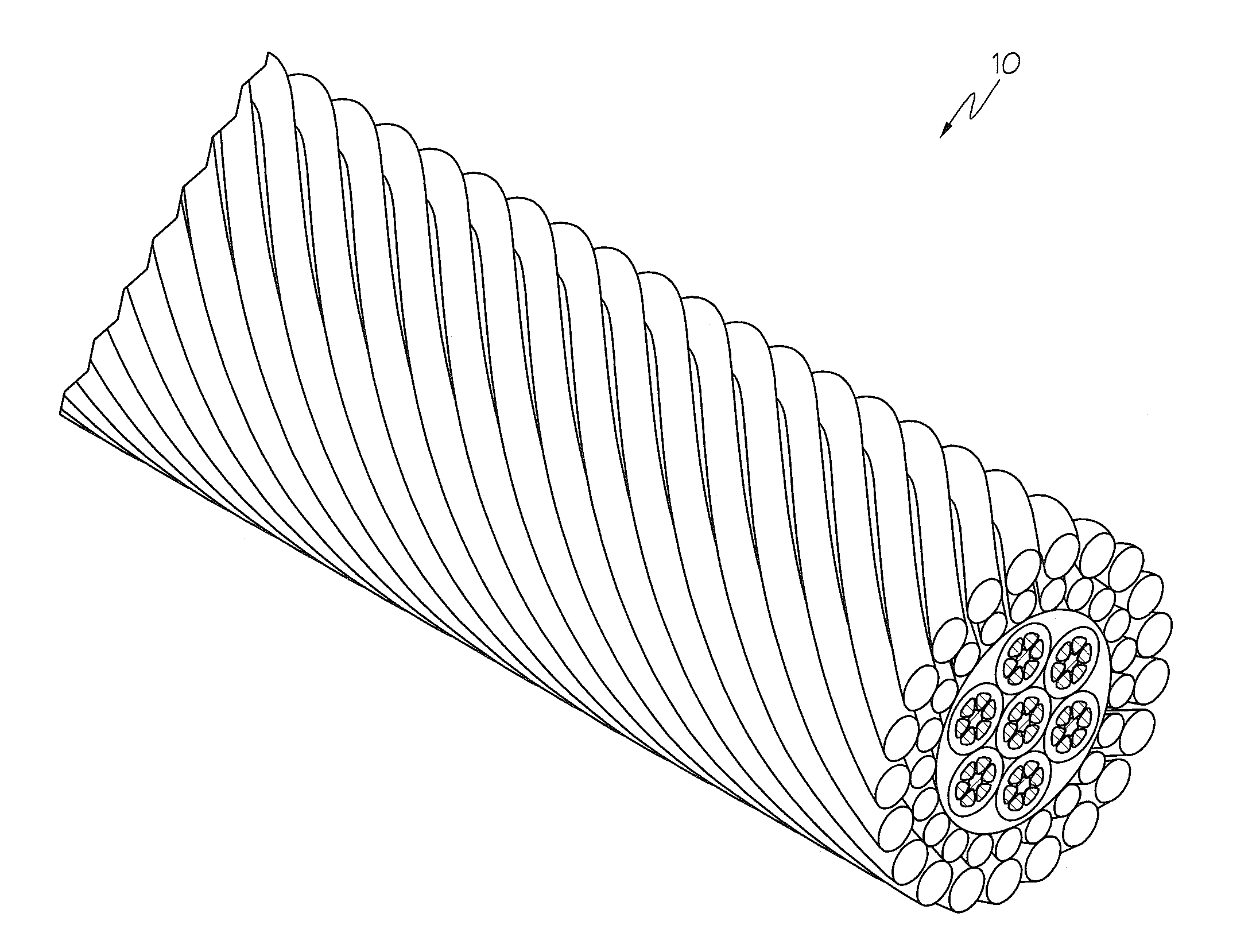

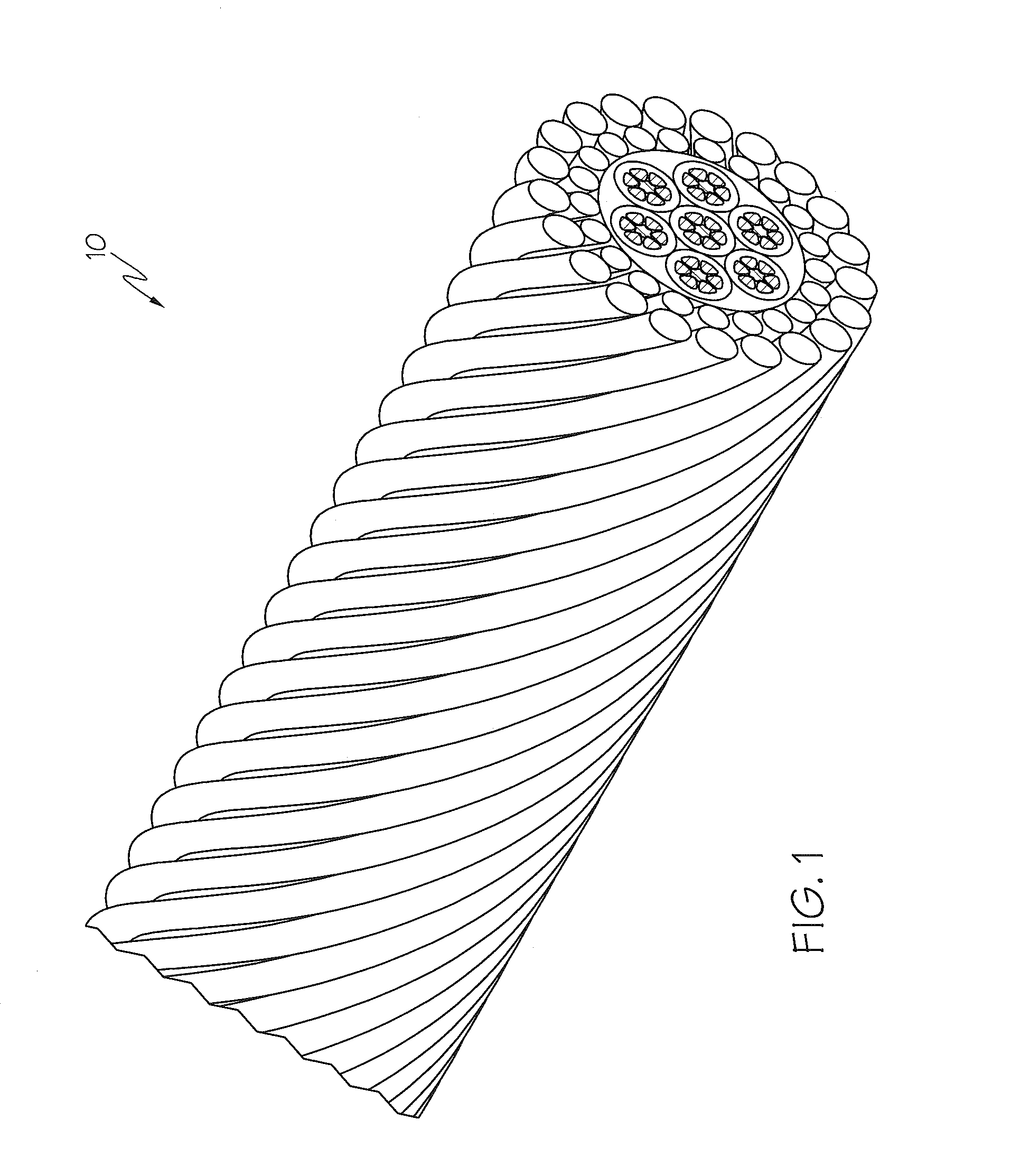

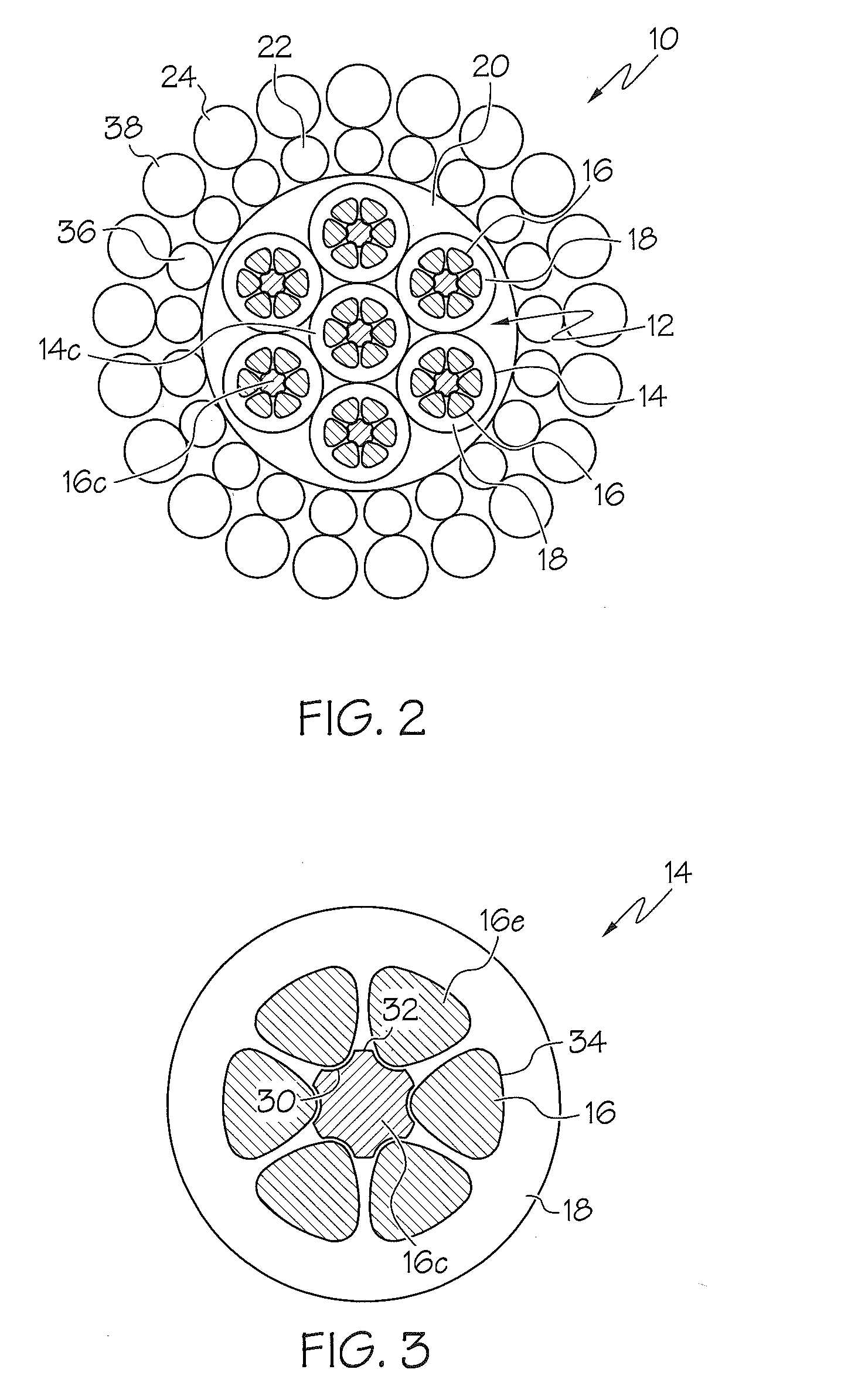

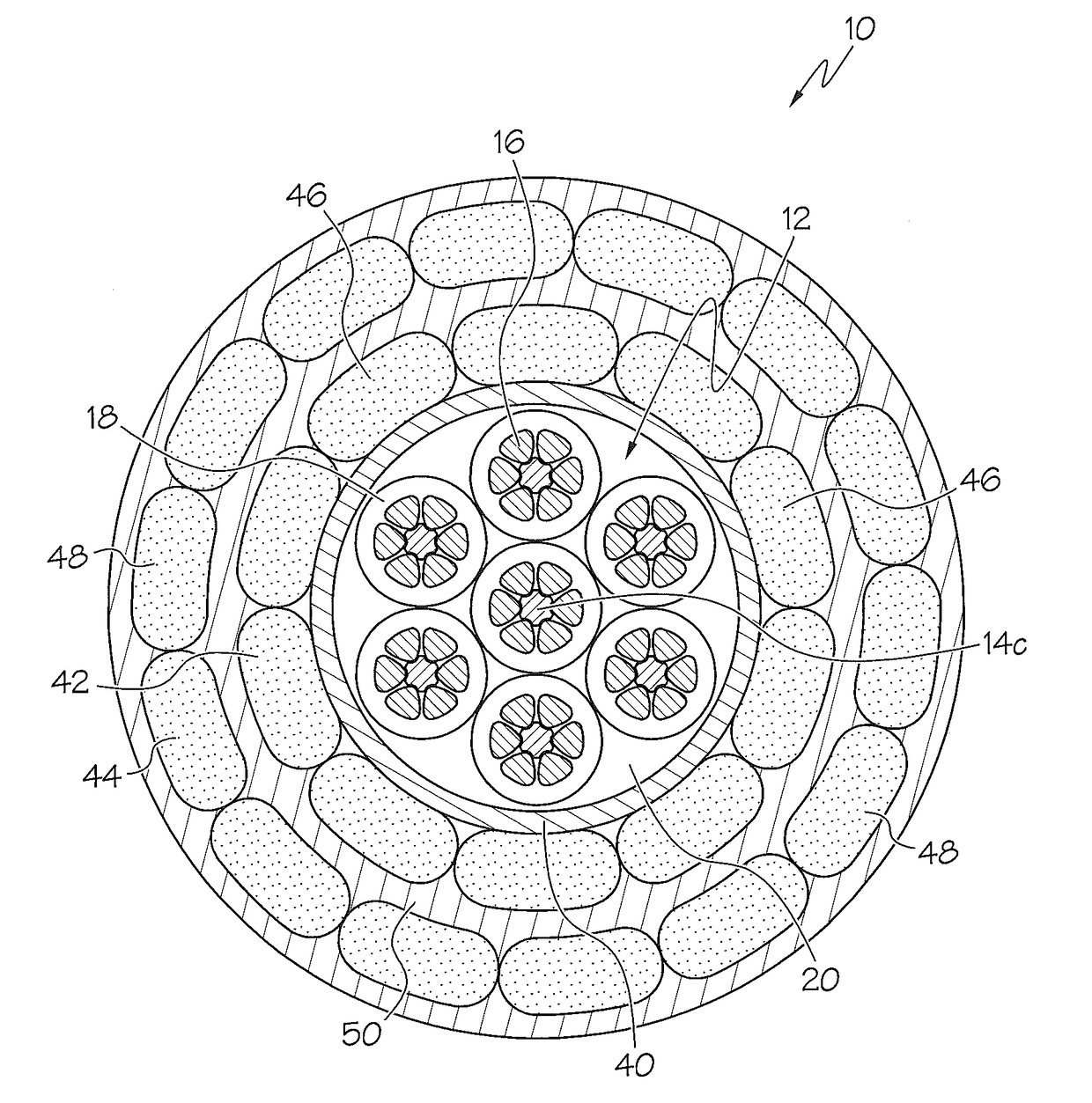

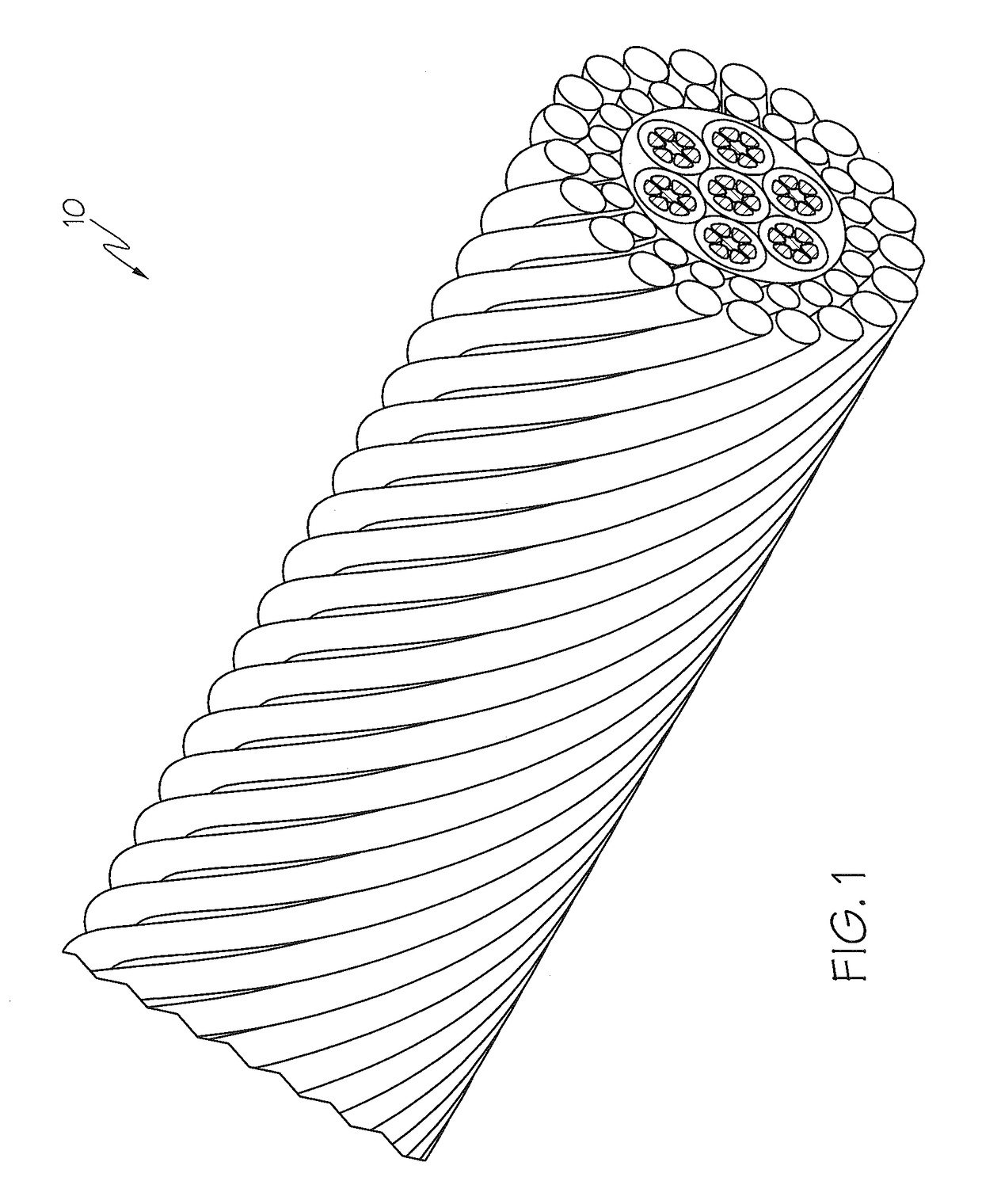

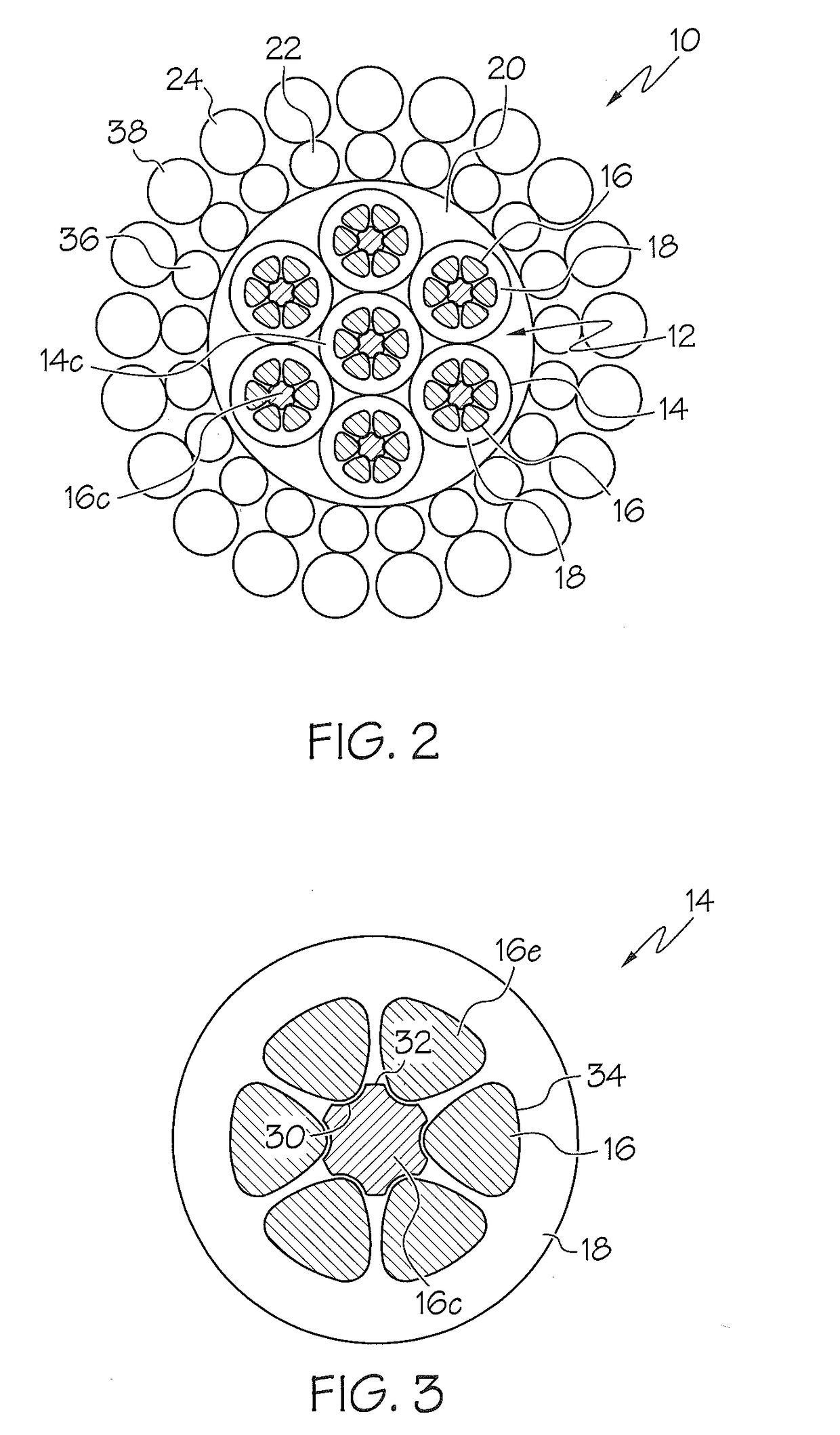

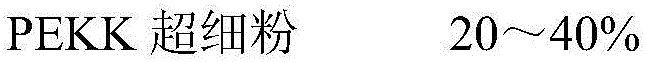

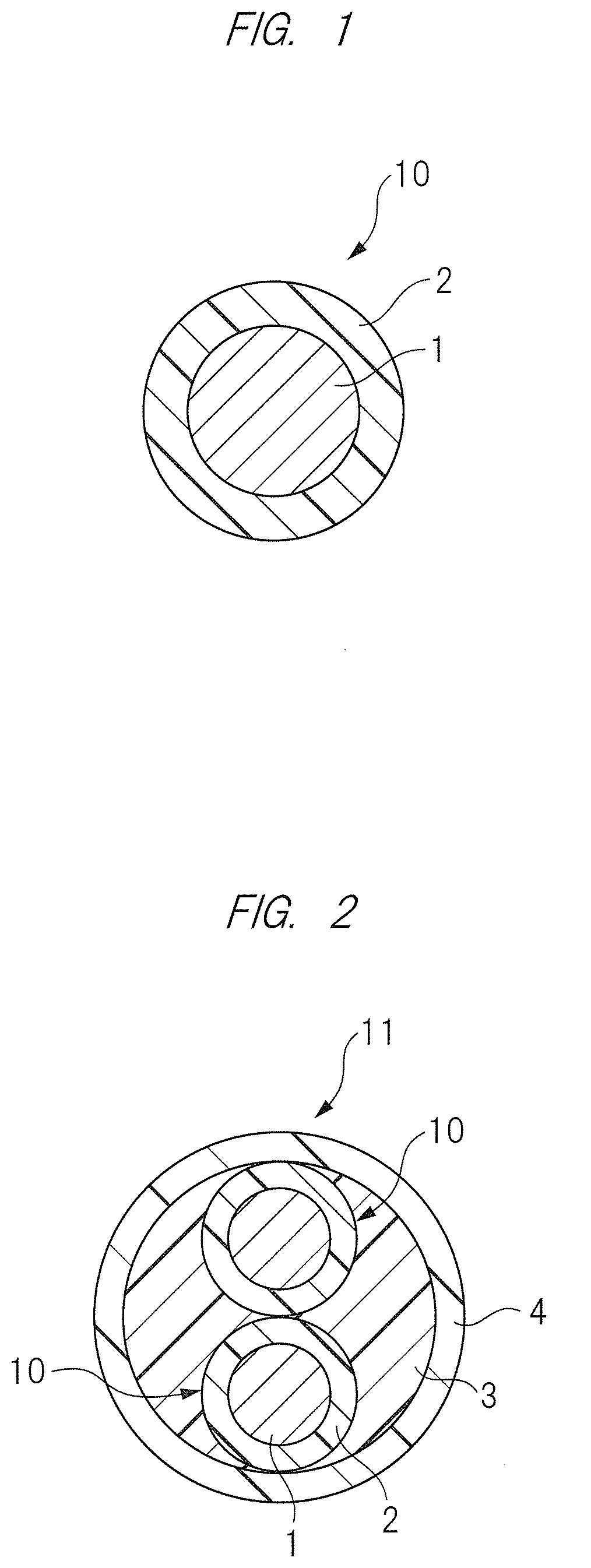

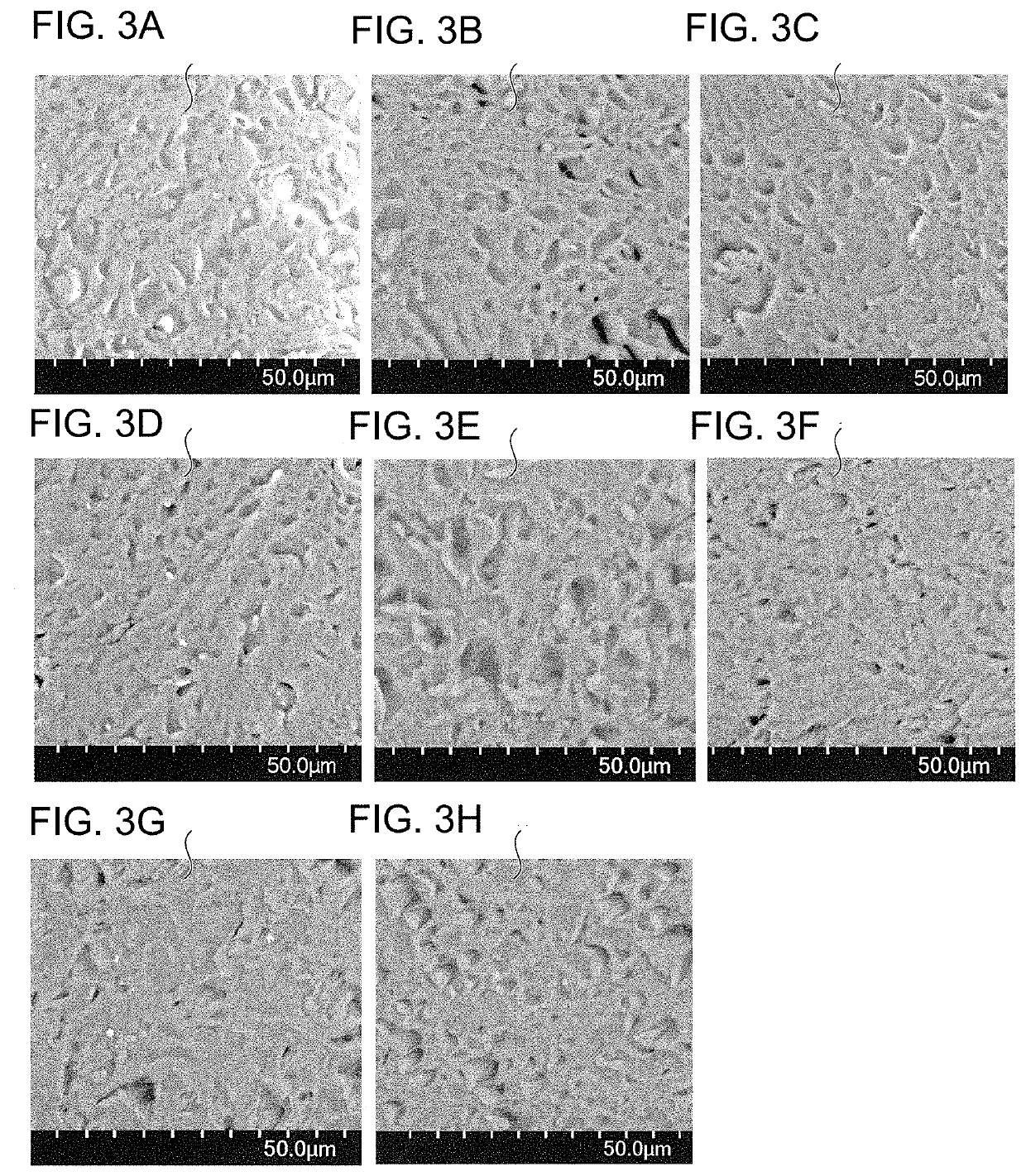

High-power low-resistance electromechanical cable

ActiveUS20140318858A1Power cables with screens/conductive layersInsulated cablesTetrafluoroethyleneElectrical conductor

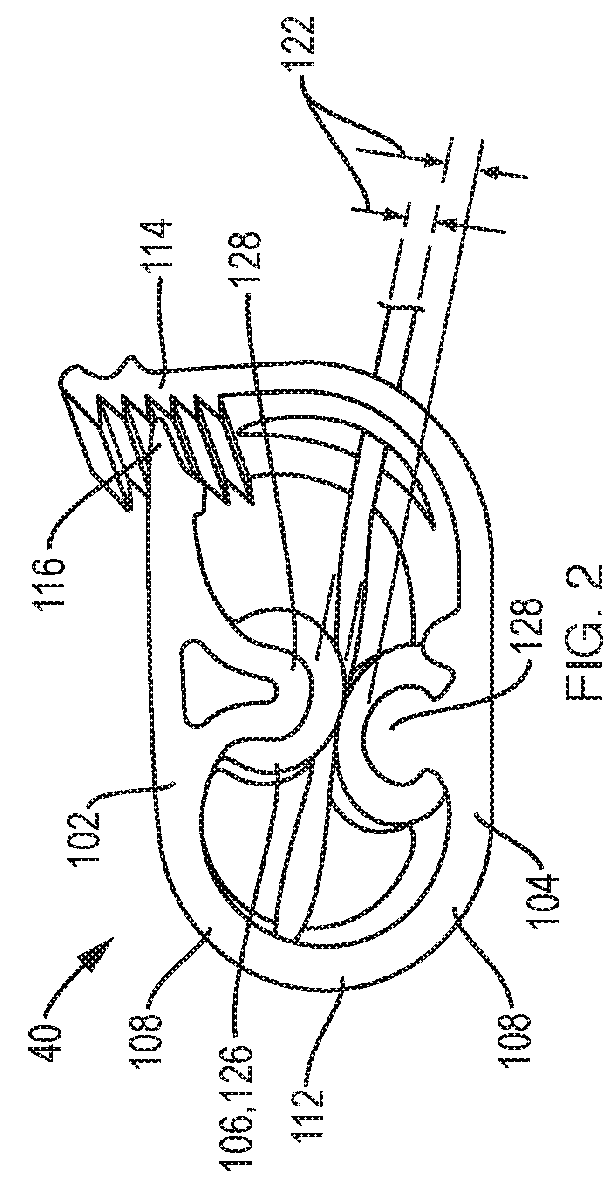

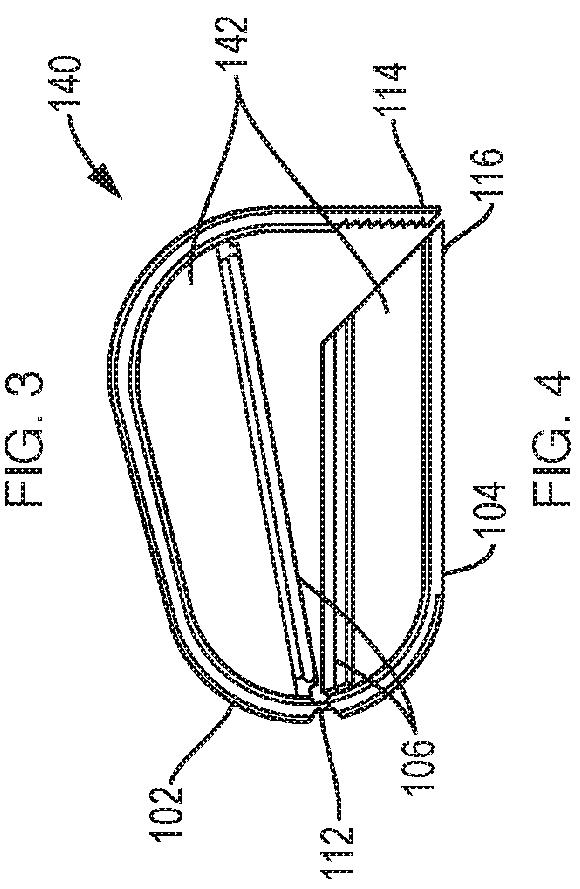

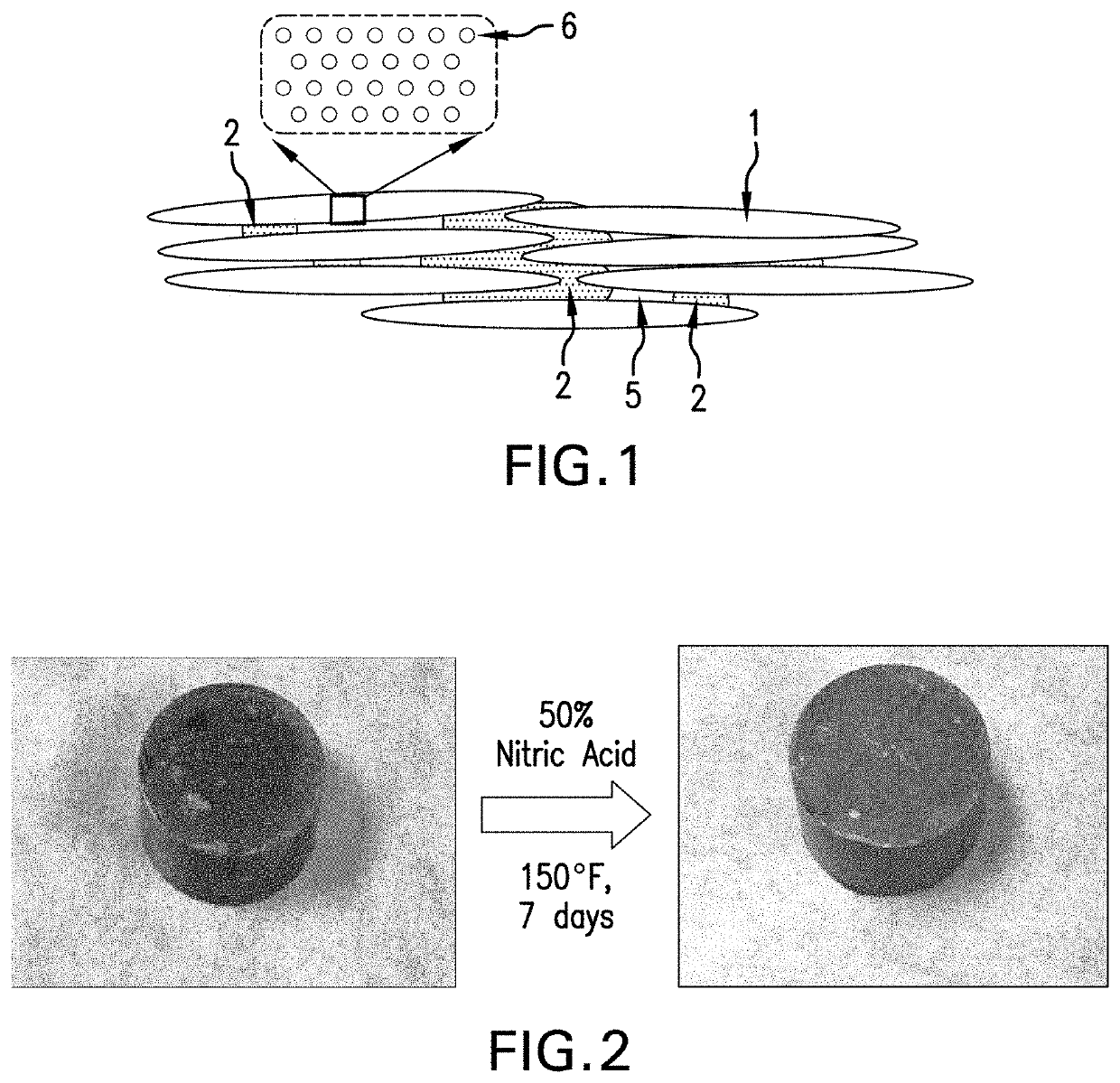

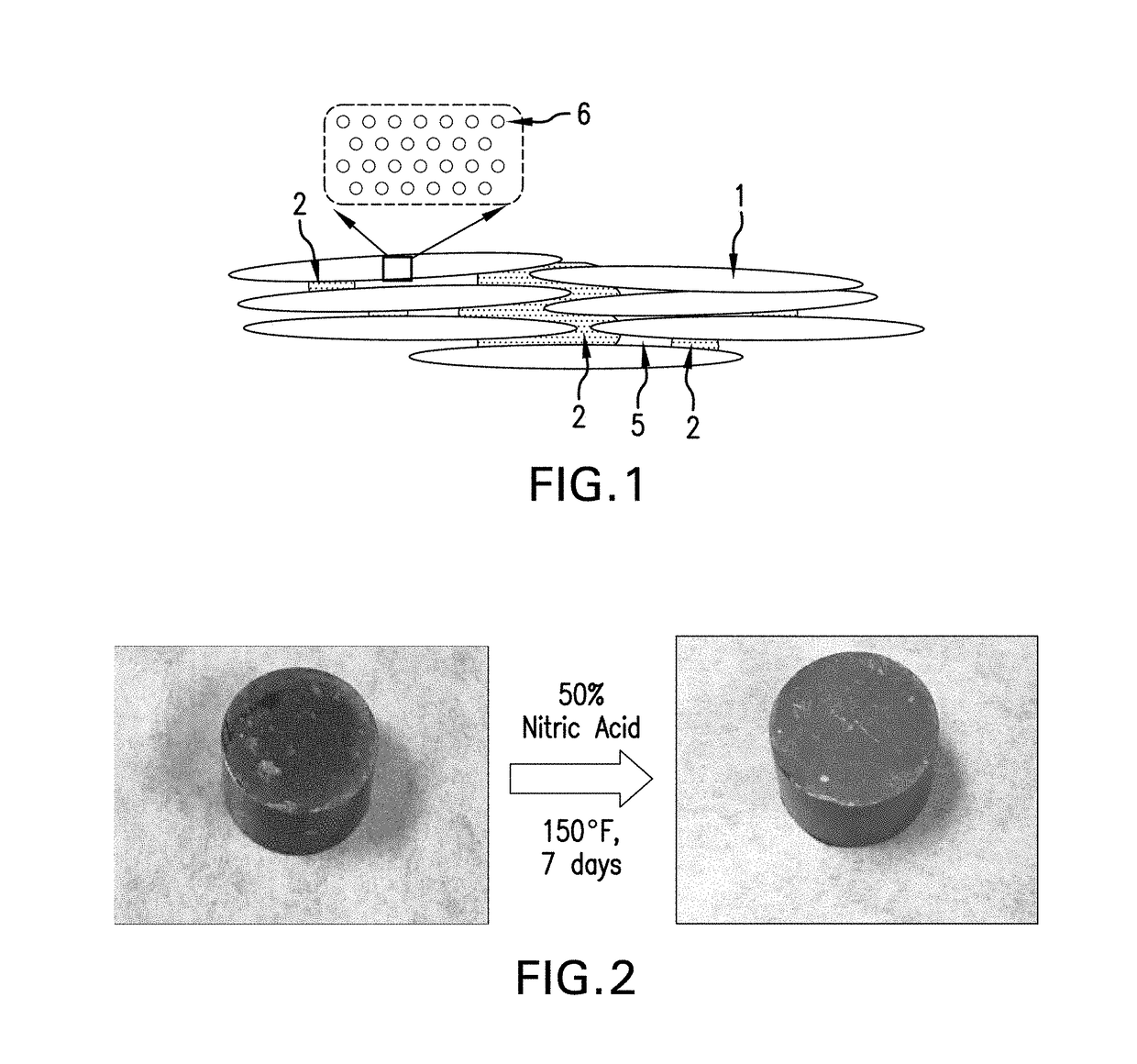

A high-power low-resistance electromechanical cable constructed of a conductor core comprising a plurality of conductors surrounded by an outer insulating jacket and with each conductor having a plurality of wires that are surrounded by an insulating jacket. The wires can be copper or other conductive wires. The insulating jacket surrounding each set of wires or each conductor can be comprised of ethylene tetrafluoroethylene, polytetrafluoroethylene, polytetrafluoroethylene tape, perfluoroalkoxyalkane, fluorinated ethylene propylene or a combination of materials. A first layer of a plurality of strength members is wrapped around the outer insulating jacket. A second layer of a plurality of strength members may be wrapped around the first layer of a plurality of strength members. The first and / or second layer of strength members can be made of single wires, synthetic fiber strands multi-wire strands, or rope. If either or both layers are made up of synthetic fiber, then the synthetic fibers may be surrounding and encapsulated by an additional insulating and protective layer.

Owner:WIRECO WORLDGROUP INC

High-power low-resistance electromechanical cable

ActiveUS9627100B2Communication cablesReduction of cables/conductors sizeElectrical conductorEngineering

A high-power low-resistance electromechanical cable constructed of a conductor core comprising a plurality of conductors surrounded by an outer insulating jacket and with each conductor having a plurality of wires that are surrounded by an insulating jacket. The wires can be copper or other conductive wires. The insulating jacket surrounding each set of wires or each conductor can be comprised of ethylene tetrafluoroethylene, polytetrafluoroethylene, polytetrafluoroethylene tape, perfluoroalkoxyalkane, fluorinated ethylene propylene or a combination of materials. A first layer of a plurality of strength members is wrapped around the outer insulating jacket. A second layer of a plurality of strength members may be wrapped around the first layer of a plurality of strength members. The first and / or second layer of strength members can be made of single wires, synthetic fiber strands multi-wire strands, or rope. If either or both layers are made up of synthetic fiber, then the synthetic fibers may be surrounding and encapsulated by an additional insulating and protective layer.

Owner:WIRECO WORLDGROUP INC

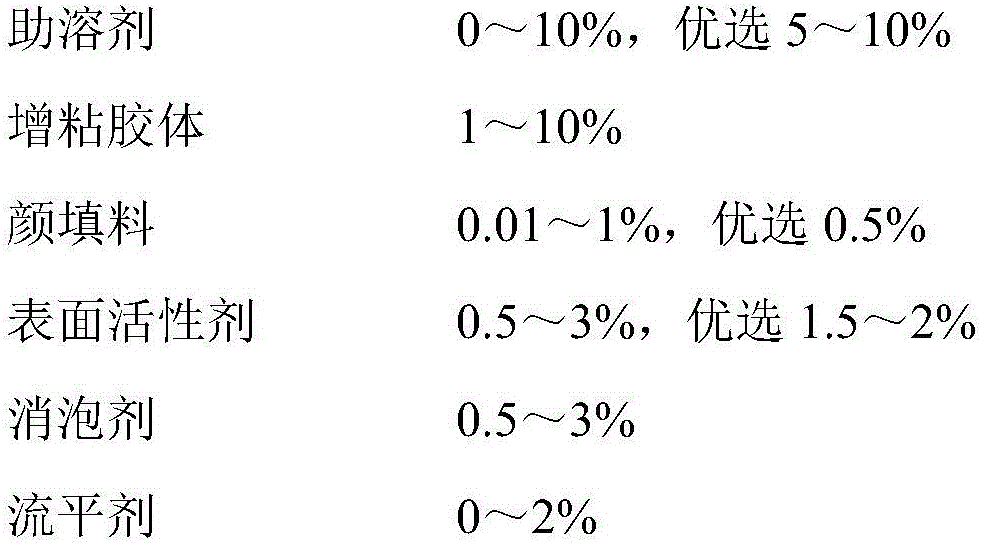

High-heat-conductivity vacuum-tolerant high-temperature-tolerant anticorrosion coating

ActiveCN106810964AImprove bindingFlat surfaceFireproof paintsLiquid surface applicatorsEngineering plasticSulfide

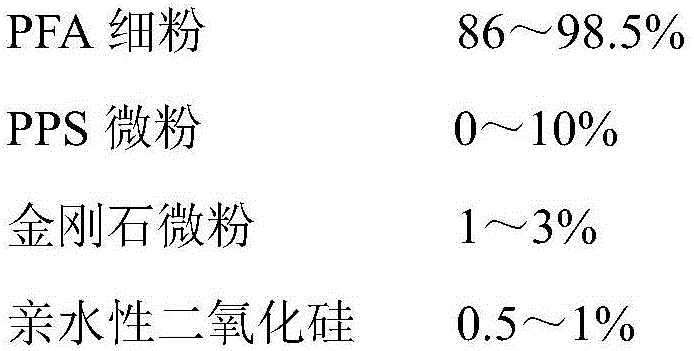

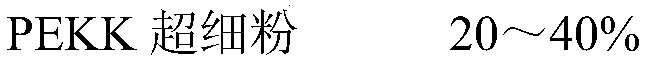

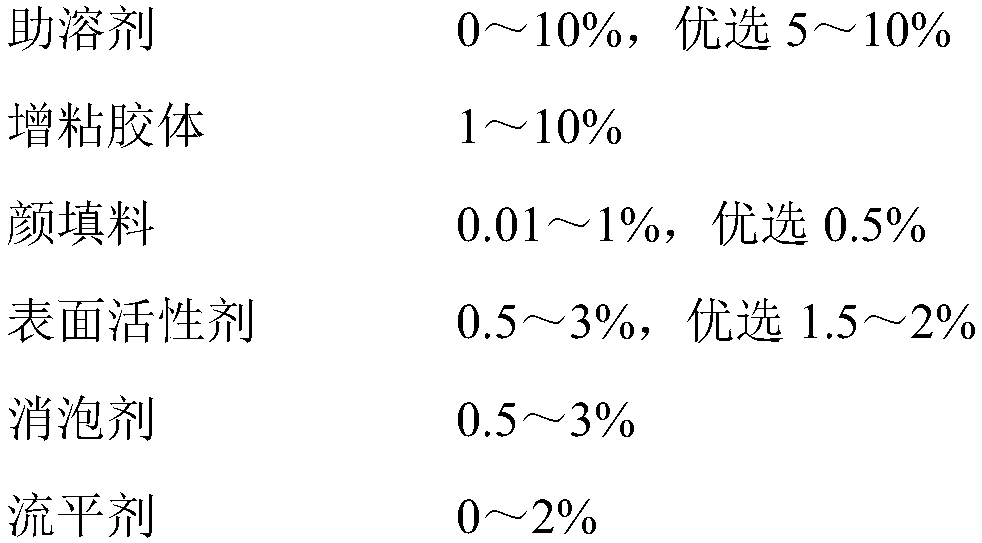

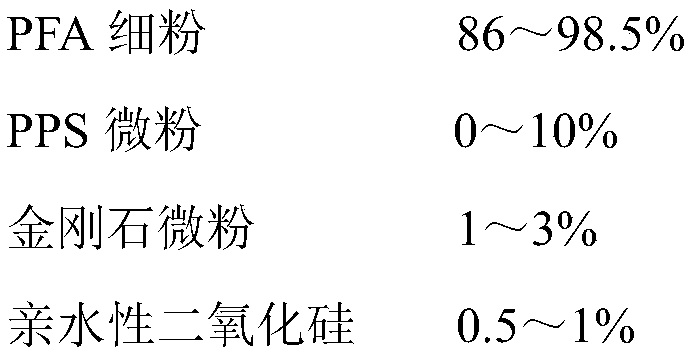

The invention relates to a high-heat-conductivity vacuum-tolerant high-temperature-tolerant anticorrosion coating and belongs to the technical field of macromolecular special engineering plastic; the high-heat-conductivity vacuum-tolerant high-temperature-tolerant anticorrosion coating comprises a bottom coating and a surface coating; the bottom coating is prepared from, by applying, by weight, 20-40% of PEKK (polyetherketoneketone) superfine powder, 0-10% of a cosolvent, 1-10% of tackified glue, 0.01-1% of pigment-filler, 0.5-3% of a surfactant, 0.5-3% of a defoaming agent, and 0-2% of a leveling agent; the surface coating is prepared from, by applying, by weight, 86-98.5% of PFA (perfluoroalkoxy alkane) fine powder, 0-10% of PPS (polyphenylene sulfide) micropowder, 1-3% of diamond micropowder, and 0.5-1% of hydrophilic silicon dioxide. The high-heat-conductivity vacuum-tolerant high-temperature-tolerant anticorrosion coating is very suitable for application in the field of high-temperature-tolerant anticorrosion coating requiring heat transfer, particularly high-heat-conductivity high-temperature-tolerant anticorrosion application for thin-walled devices, and has the advantages of high binding force, surface smoothness, and good heat conductivity.

Owner:SHANDONG KAISHENG NEW MATERIALS

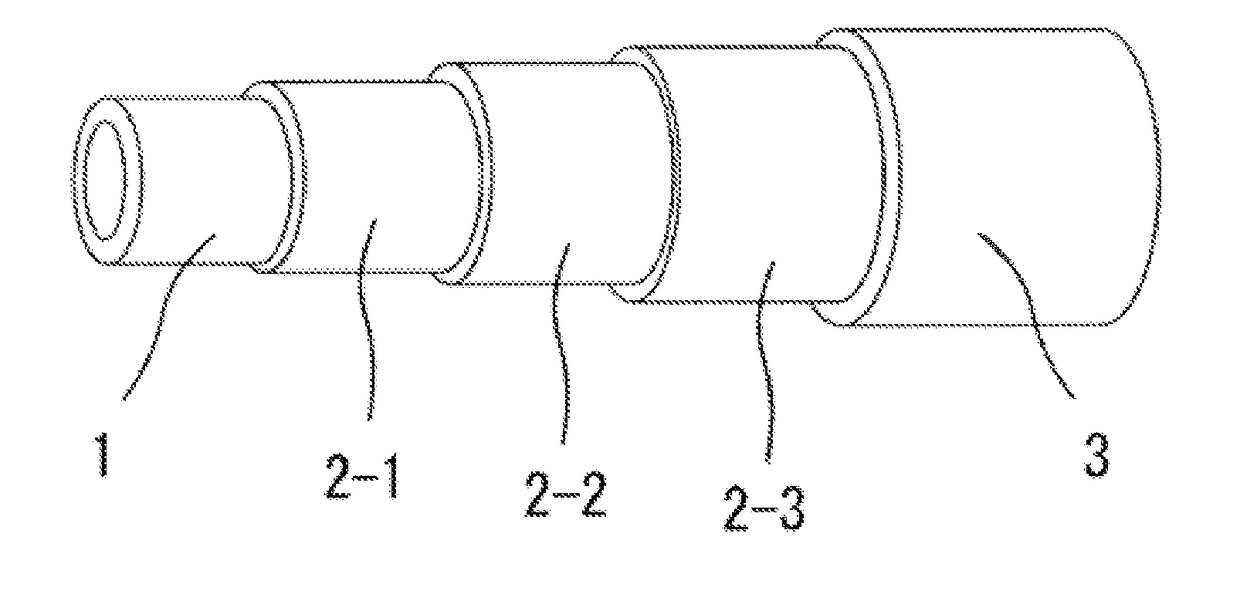

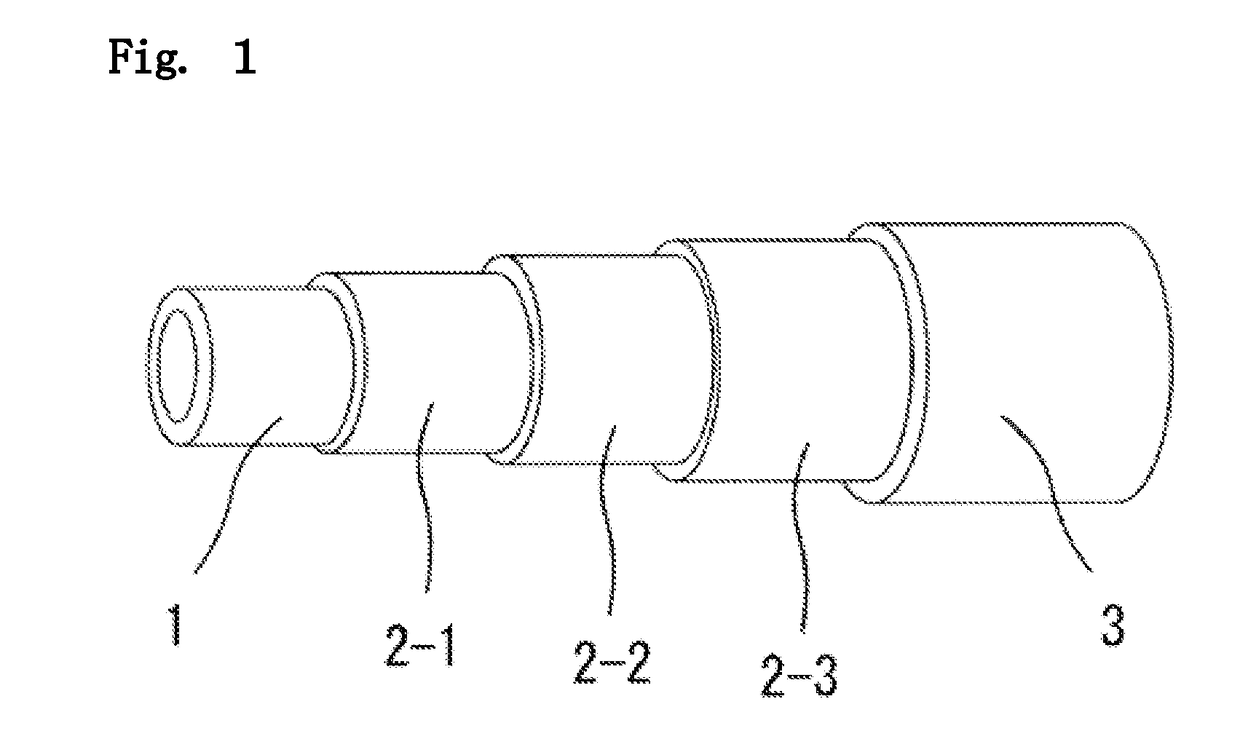

Ink supply tube

ActiveCN107614271AGood solvent resistanceImprove bending performanceFlexible pipesPrintingElastomerTetrafluoroethylene

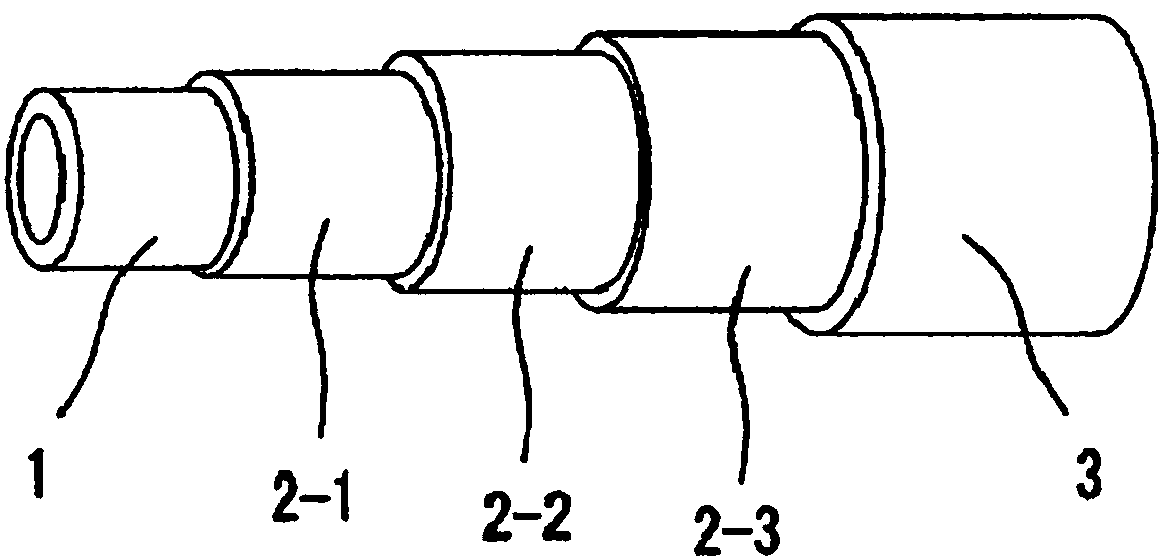

This ink supply tube comprises an inner layer that makes contact with ink, an intermediate layer comprising at least three layers, and an outer layer, and is characterized in that: the intermediate layer includes a first intermediate layer, a second intermediate layer and a third intermediate layer; the inner layer comprises any of an ethylene-tetrafluoroethylene copolymer resin, a tetrafluoroethylene-perfluoroalkoxy alkane copolymer resin, or a modified perfluoroalkoxy resin, which have solvent resistance, oxygen barrier properties and low moisture permeability; the first intermediate layer comprises a polyamide resin, which is fusible with the inner layer or the second intermediate layer; the second intermediate layer comprises an ethylene-vinyl alcohol copolymer resin, which has oxygenbarrier properties; the third intermediate layer is fusible with the second intermediate layer or the outer layer and comprises an adhesive polyolefin resin, which has low moisture permeability; and the outer layer comprises a thermoplastic resin or elastomer. Due to this configuration, the present invention provides an ink supply tube for ink jet printers, which has excellent solvent resistance and flexibility, and which is superior in terms of oxygen barrier properties and low moisture permeability.

Owner:HAKKO CO LTD

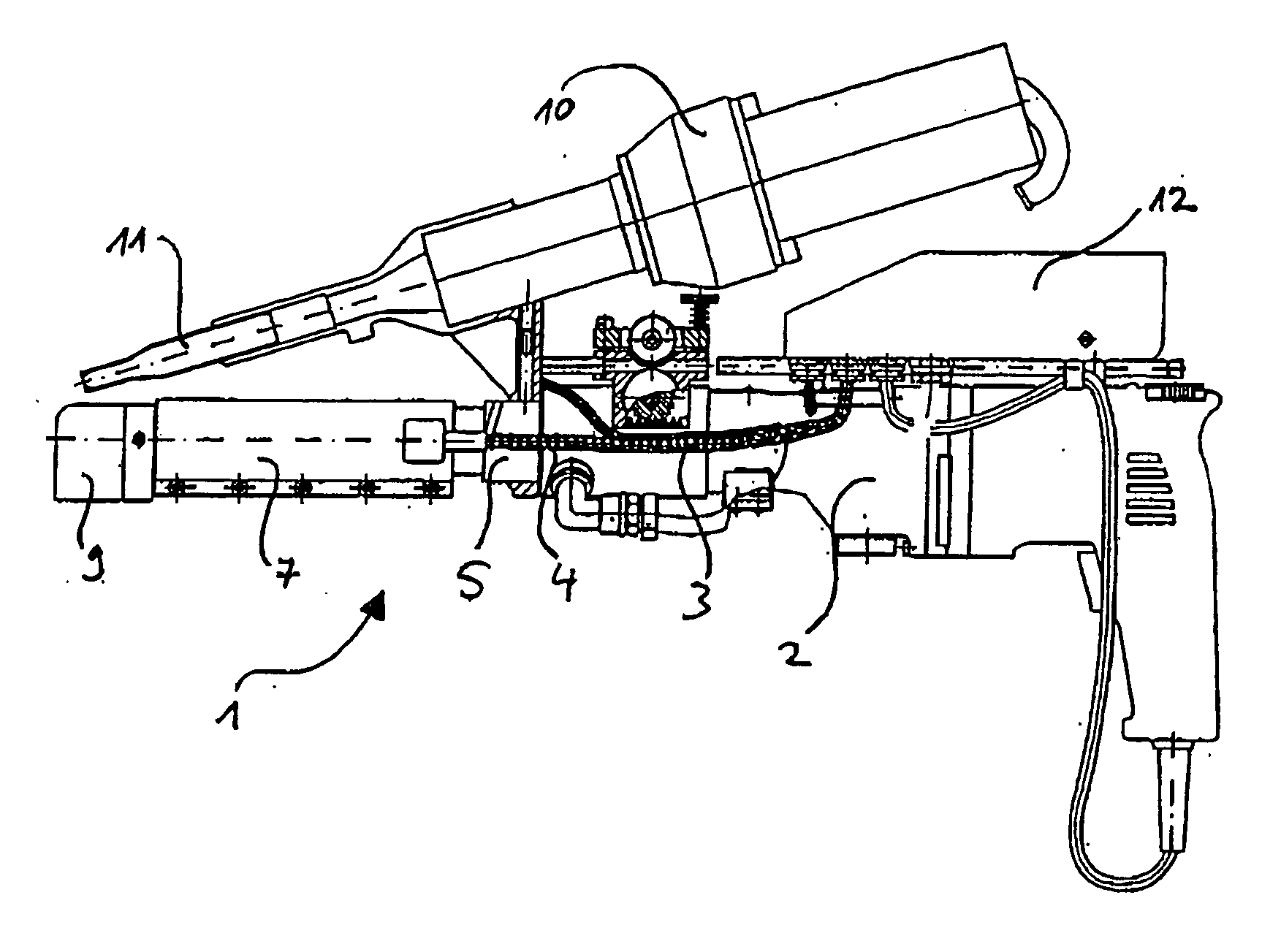

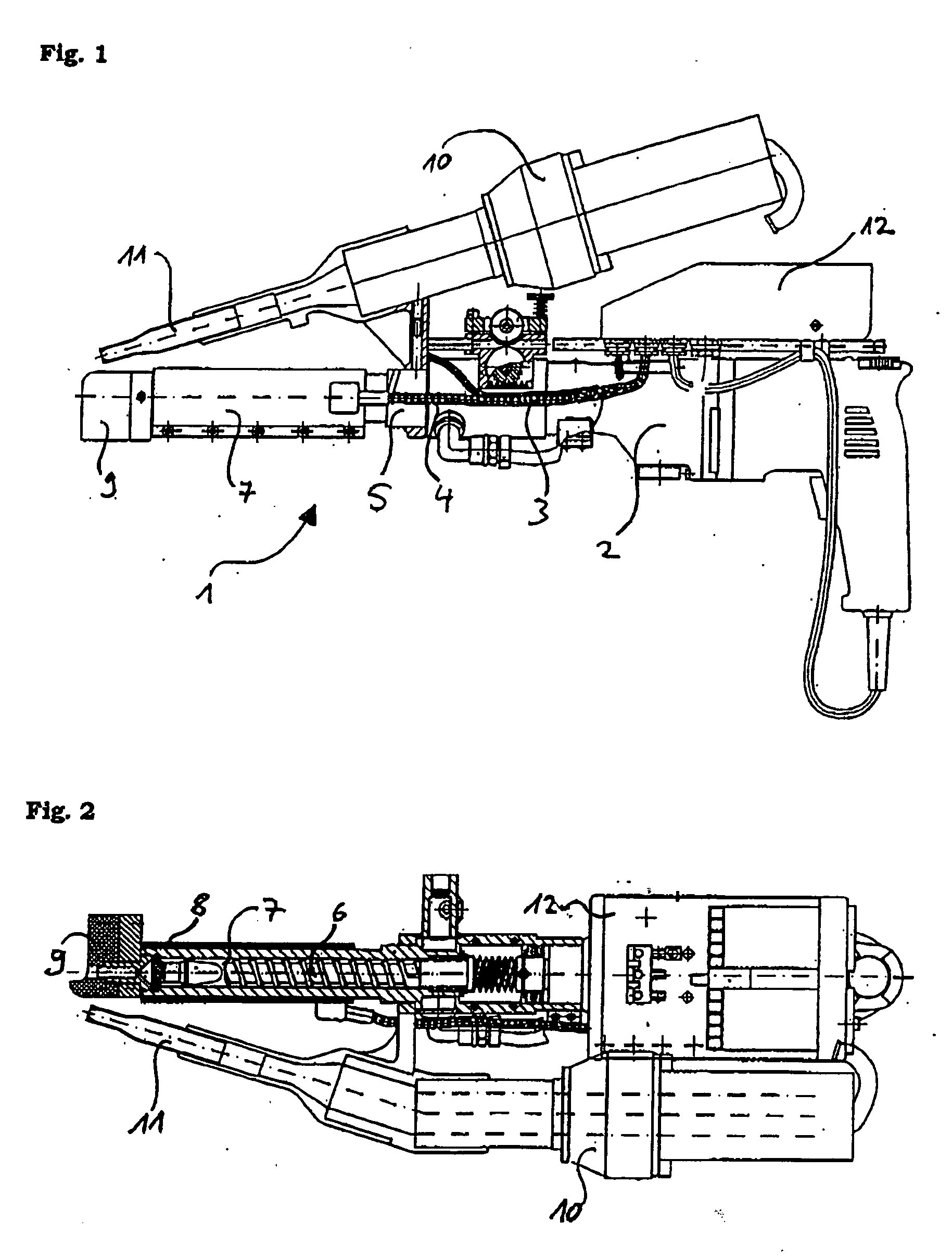

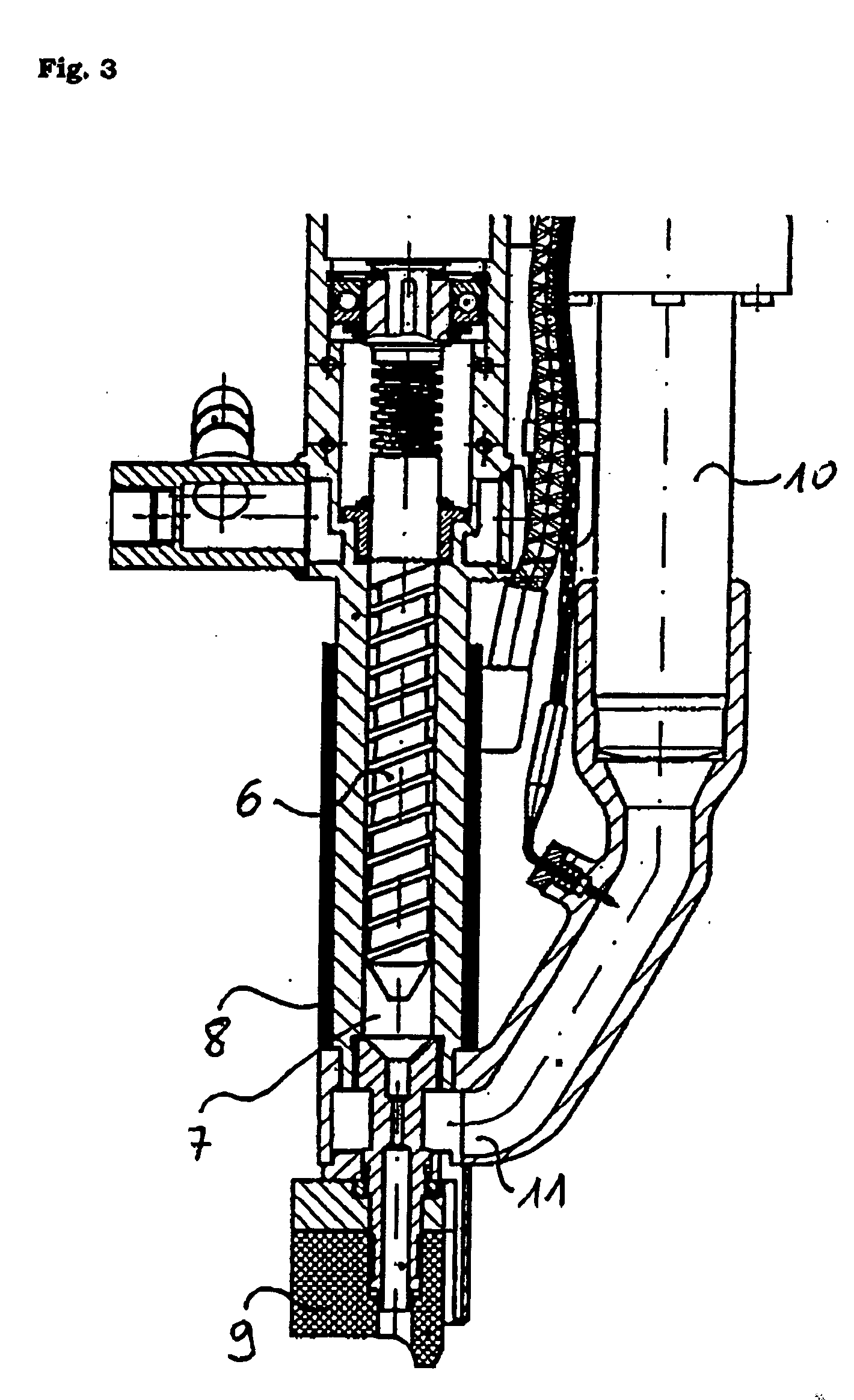

Welding shoe, plastic welding shoe extruder, method for producing a plastic welded seam

InactiveUS20060078635A1Increase composition temperatureAvoid pollutionCeramic shaping apparatusPerfluoroalkoxy alkaneWeld seam

A welding shoe, a plastic welding extruder, which has a conveying device, a housing for the conveying device, a melting chamber, a welding shoe and / or a nozzle device, and a method for producing a plastic welded seam by means of a plastic welding extruder wherein a ceramic is used at least partly as a material of construction, as a result of which contamination of the melted material and wear are avoided and an increase in the temperature of the composition becomes possible, so that highly fluorinated plastics (PTFE (Teflon), FEP (hexafluoropropylene copolymer), PFA (perfluoroalkoxyalkane) or the like, high-tech plastics or the like can be processed.

Owner:HERZ FRANZ JOSEF

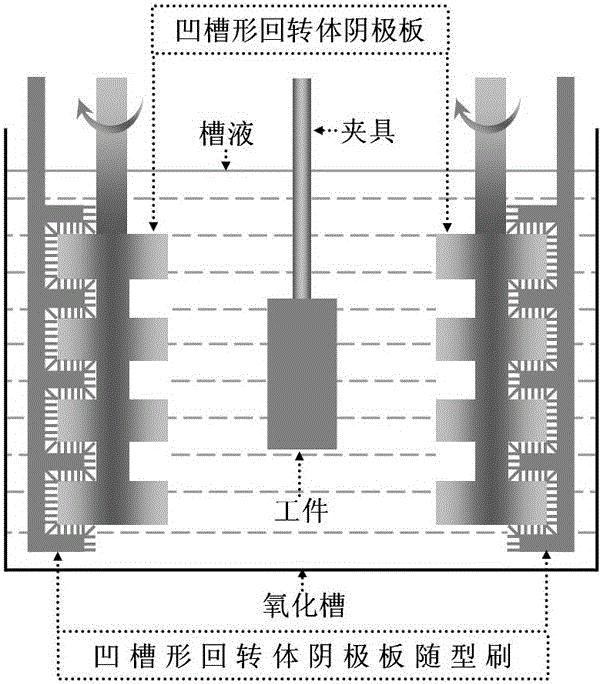

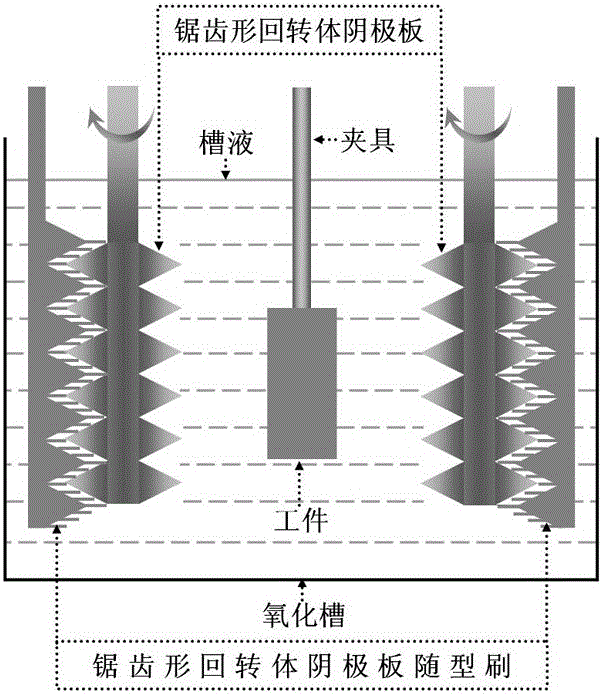

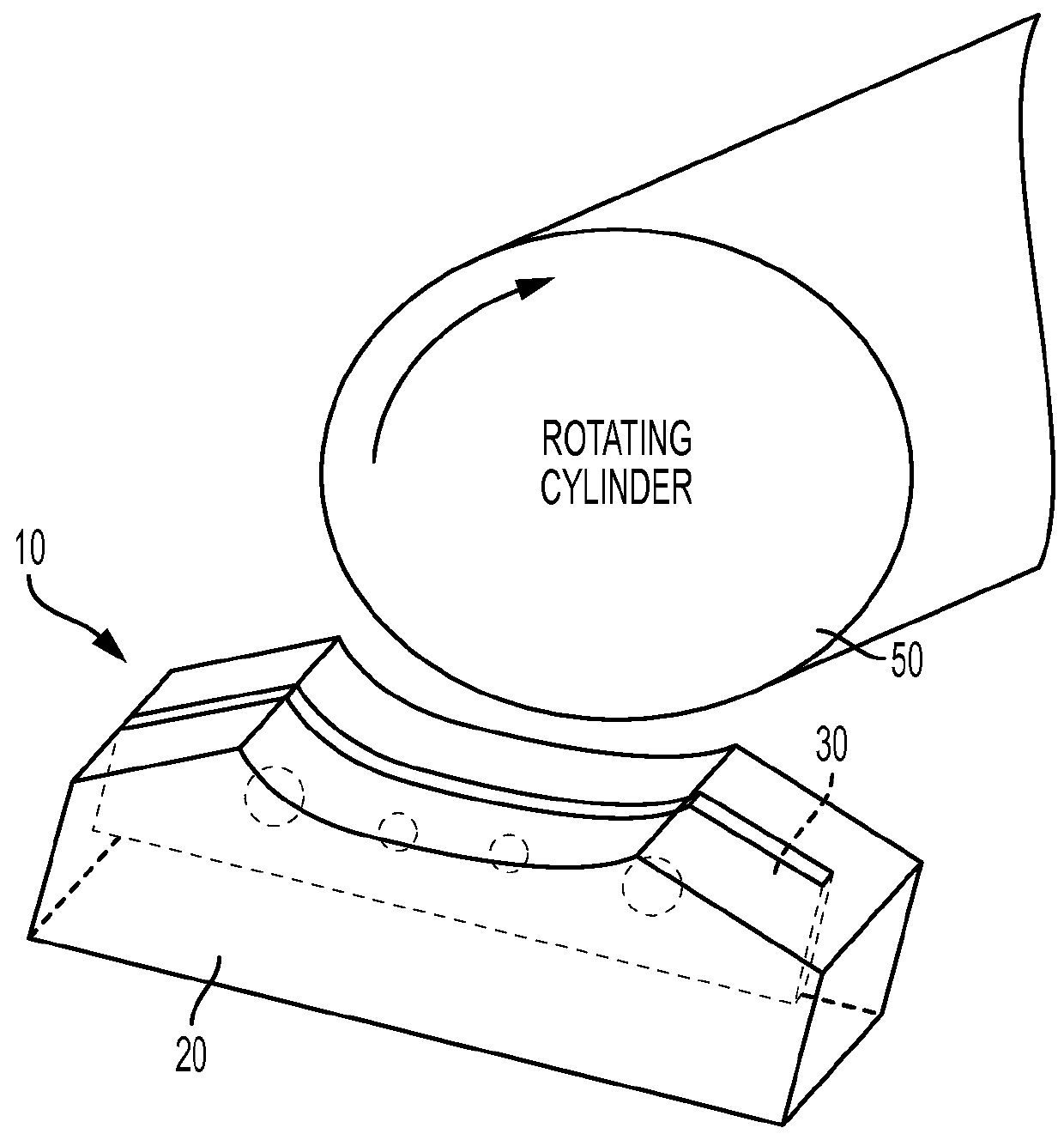

Innovation method of anodized negative plate

The invention relates to an innovation method of an anodized negative plate. The innovation method is characterized in that tops of bristles of an irregular rotary negative plate follow brush are attached to the surface of the negative plate, and the negative plate stably rotates in ananodizingbath solution at a constant speed; the shape of the negative plate is a groove-shaped rotary body, a sine wave rotary body or a sawtooth-shaped rotary body; the bristles of the follow brush are made of PTFE (polytetrafluoroethylene), PFA (perfluoroalkoxy alkane), PP (polypropylene), PE (polyethylene), PS (polystyrene), carbon fibers, glass fibers, basalt fibers, aramid fibers or polyester fibers; the rotating speed of the negative plate is 1-12 r / min. According to the innovation method, the area of the anodized negative plate is effectively increased, bubbles and impurities on the surface of the negative plate are reduced, so that the utilization rate of the negative plate is increased, current density of a workpiece is uniform, thickness and performance of an oxide film are uniform, and the service life of the negative plate is prolonged; the method is also suitable for micro-arc oxidation.

Owner:XIHUA UNIV

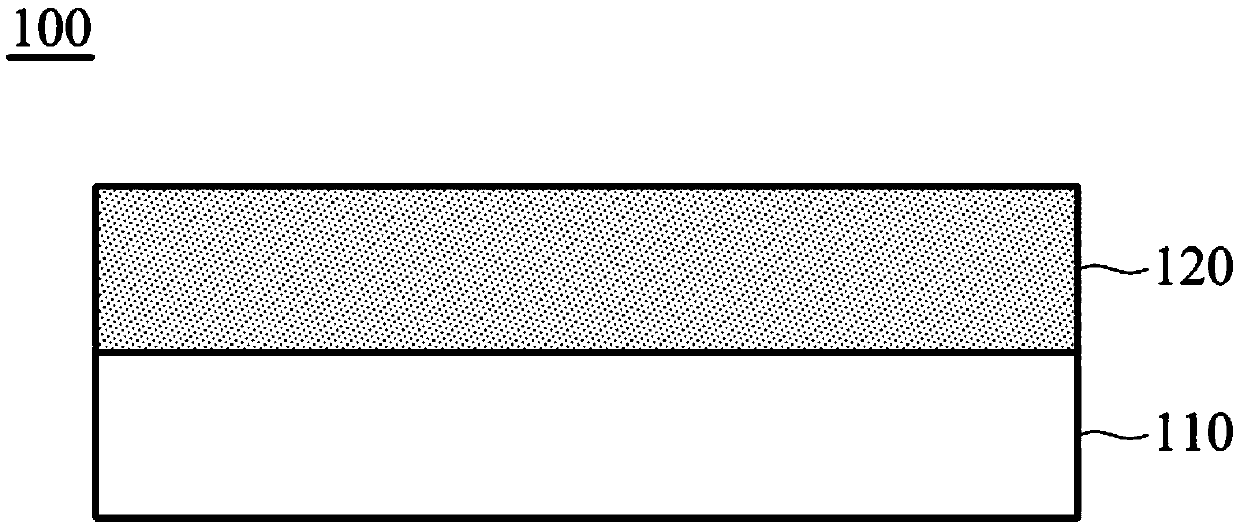

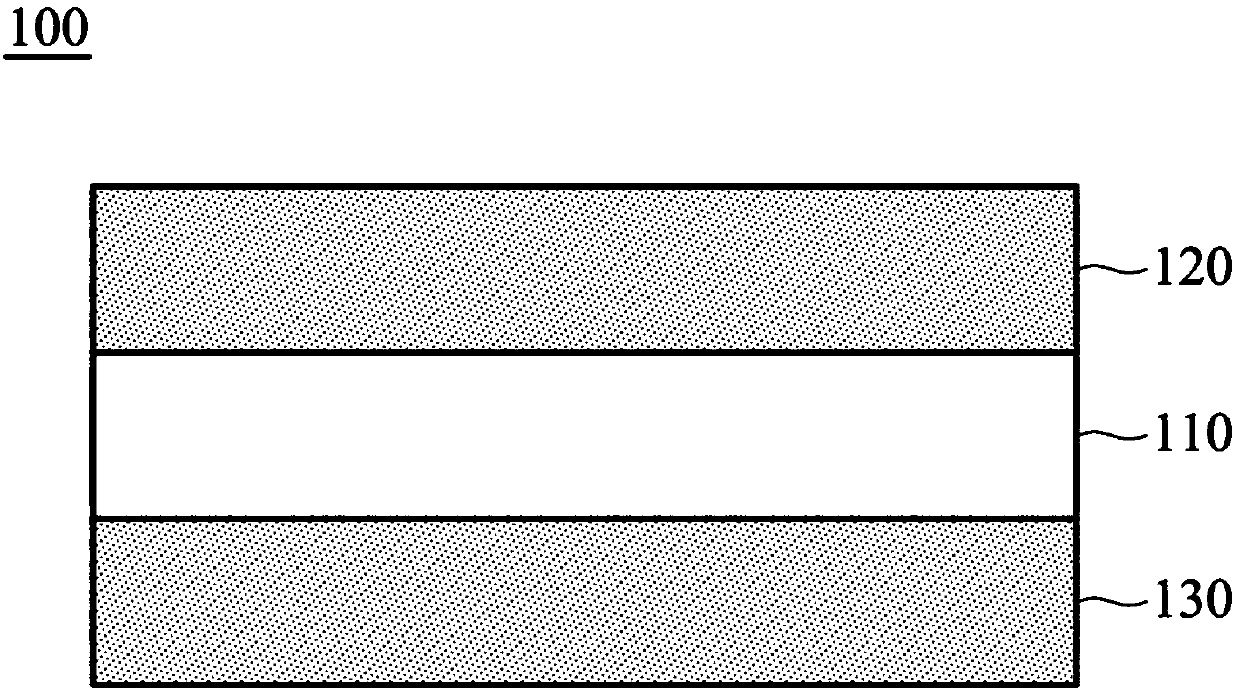

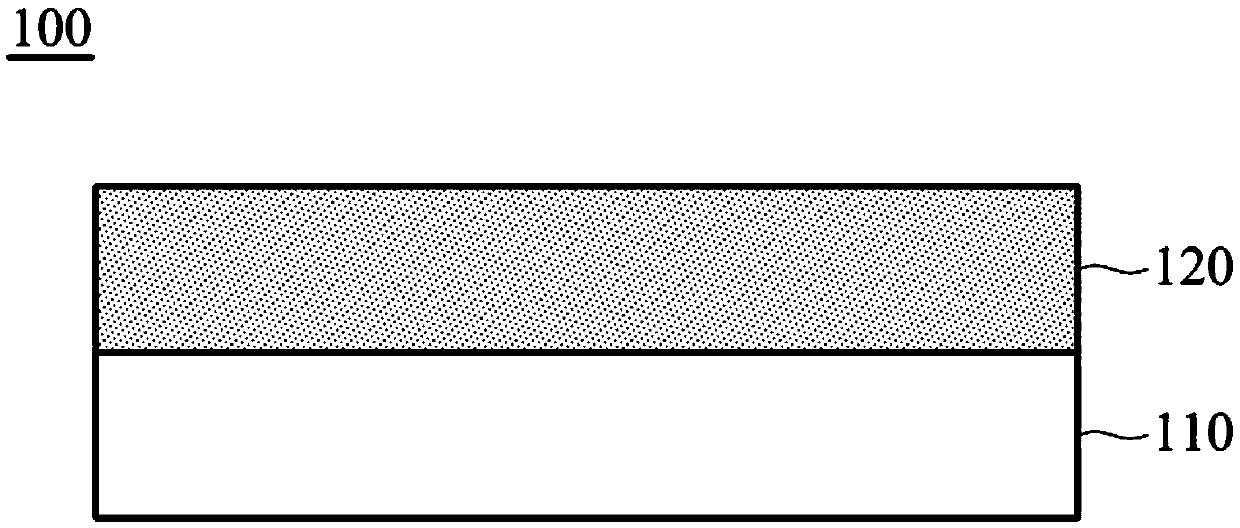

Substrate composition and substrate prepared therefrom

A substrate composition and a substrate prepared from the substrate composition are provided. The substrate composition includes 25-80 parts by weight of a polymer, 20-75 parts by weight of an inorganic filler, and 0.015-0.7 part by weight of a compound. The total weight of the polymer and the inorganic filler are 100 parts by weight. The polymer is selected from a group consisting of polytetrafluoroethylene (PTFE) and perfluoroalkoxy alkane (PFA). The compound has at least three terminal vinyl groups.

Owner:IND TECH RES INST

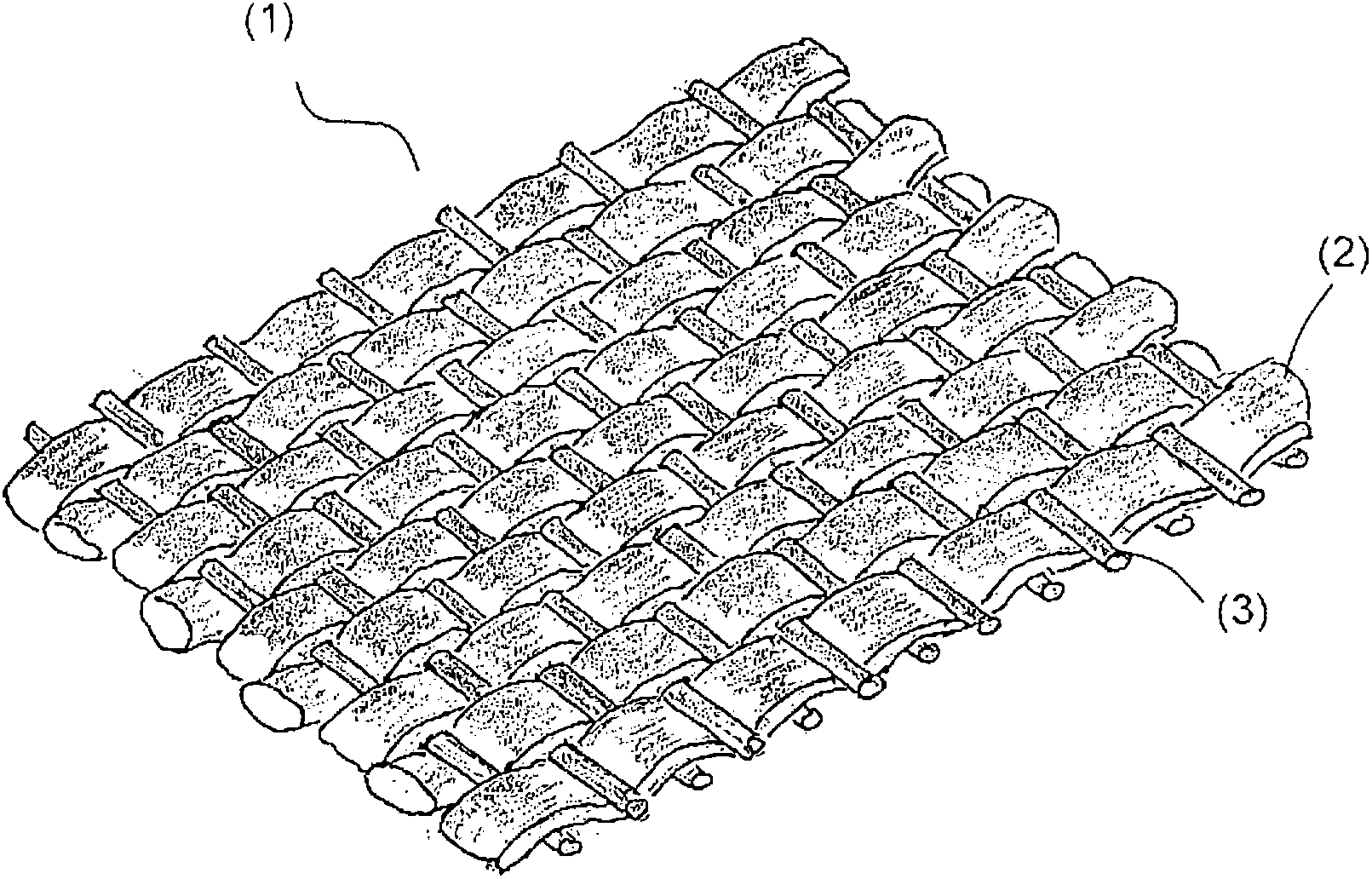

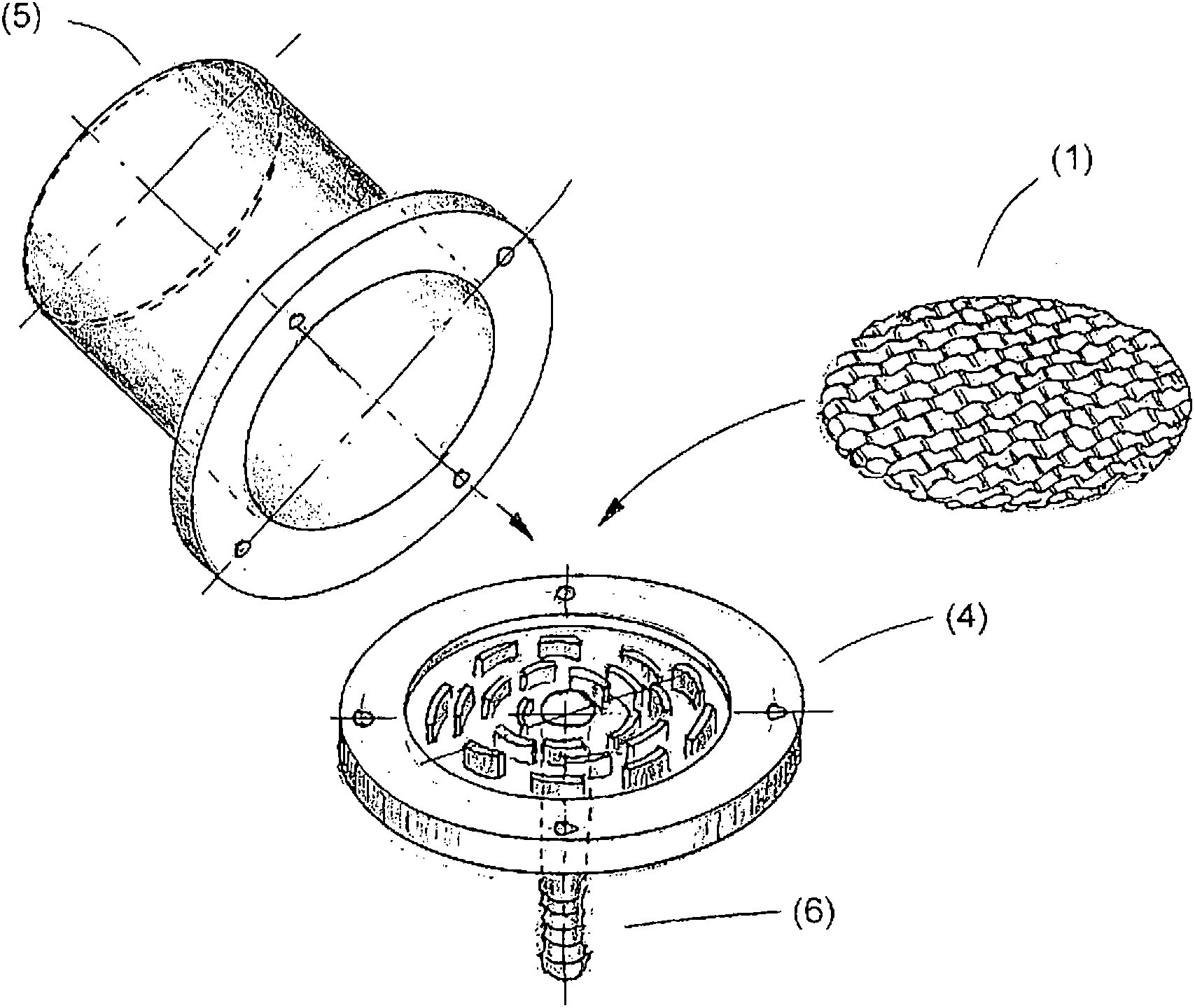

Woven filter fabric for a band filter

The present invention relates to a woven filter fabric for a band filter, wherein the air permeability of the woven filter fabric is 100 l / (min*dm2) to 350 l / (min*dm2) and the fibers of the woven filter fabric have a fiber thickness of 25 [mu]m to 35 [mu]m and contain from 50 wt.-% to 100 wt.-% perfluoroalkoxyl alkane (PFA). The woven filter fabric comprises 25 to 35 warp threads (3) and 15 to 25 weft threads (2) per 1 cm.

Owner:SMS DEMAG AG

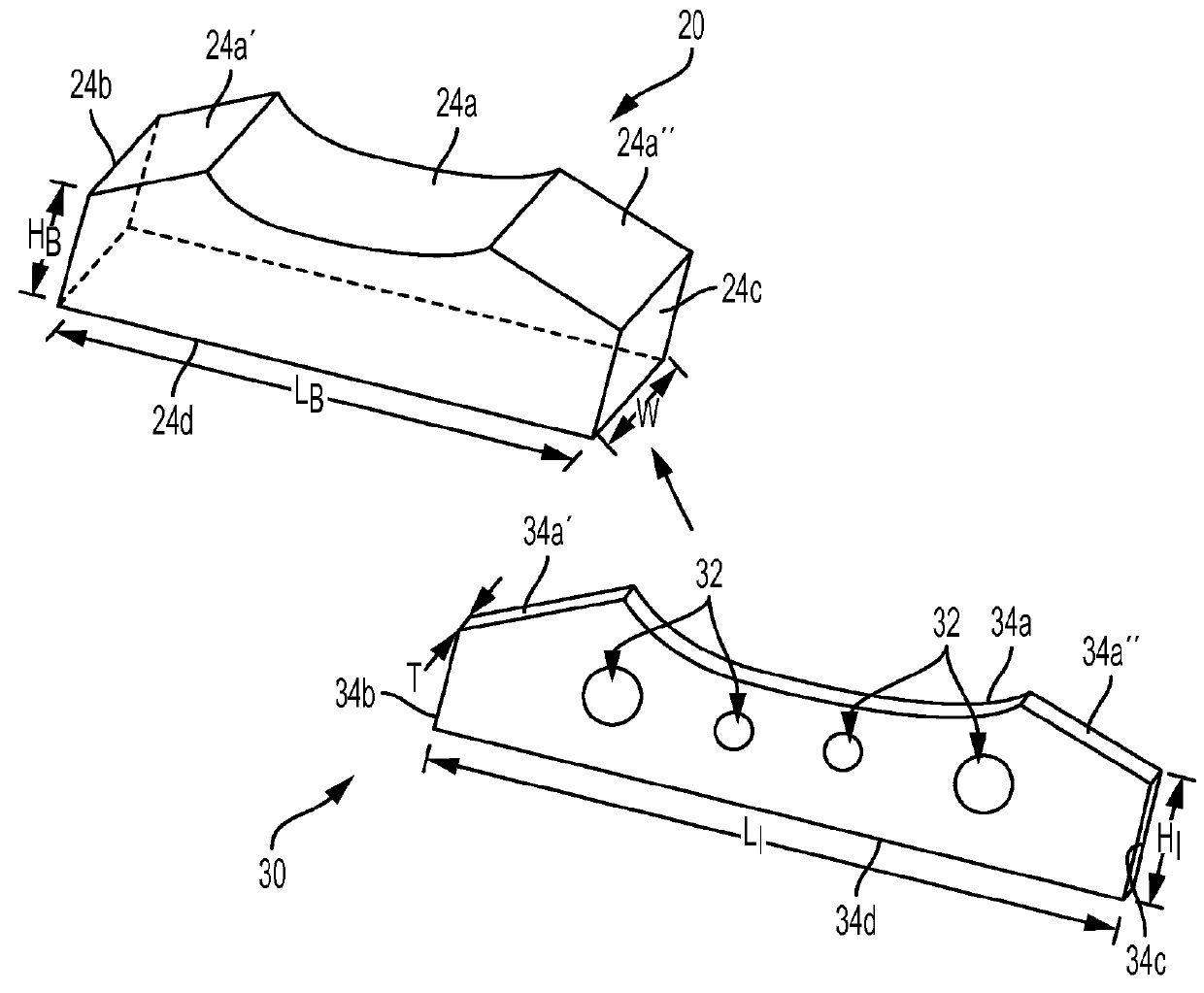

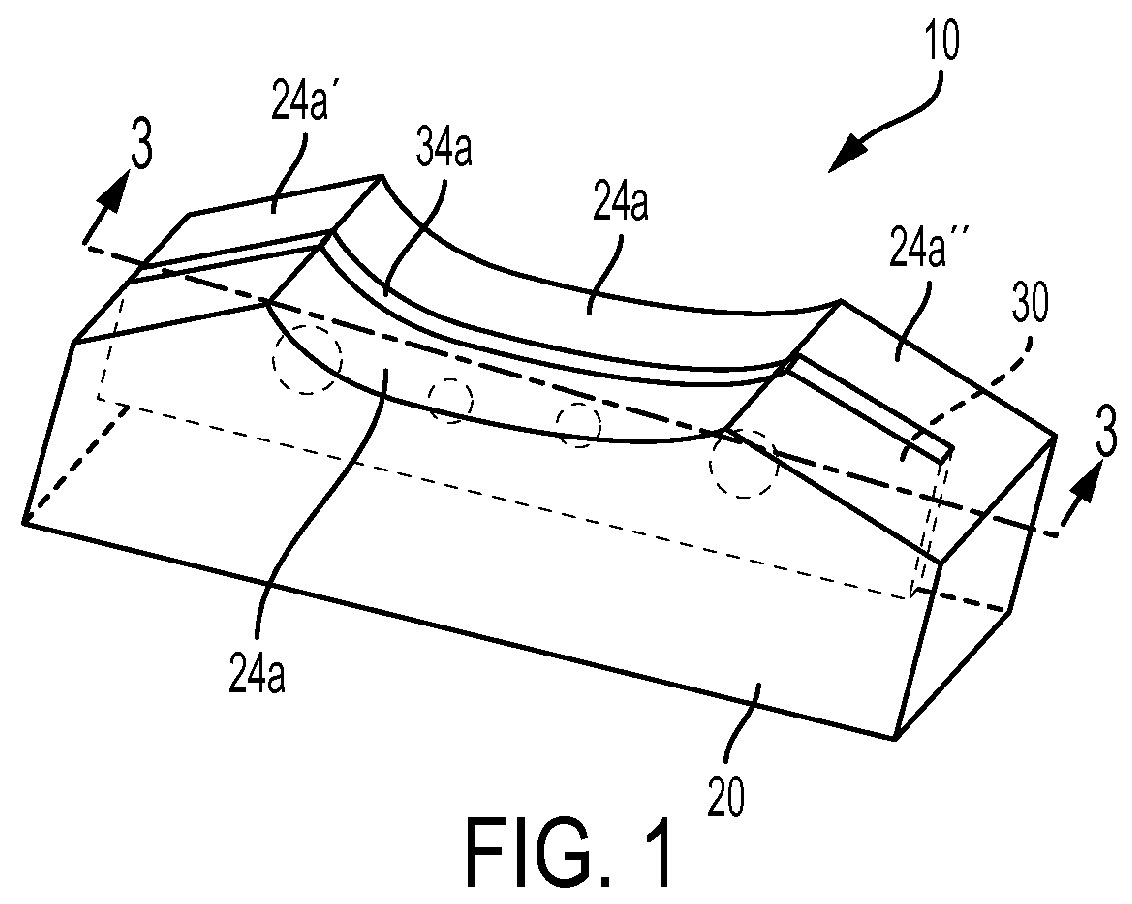

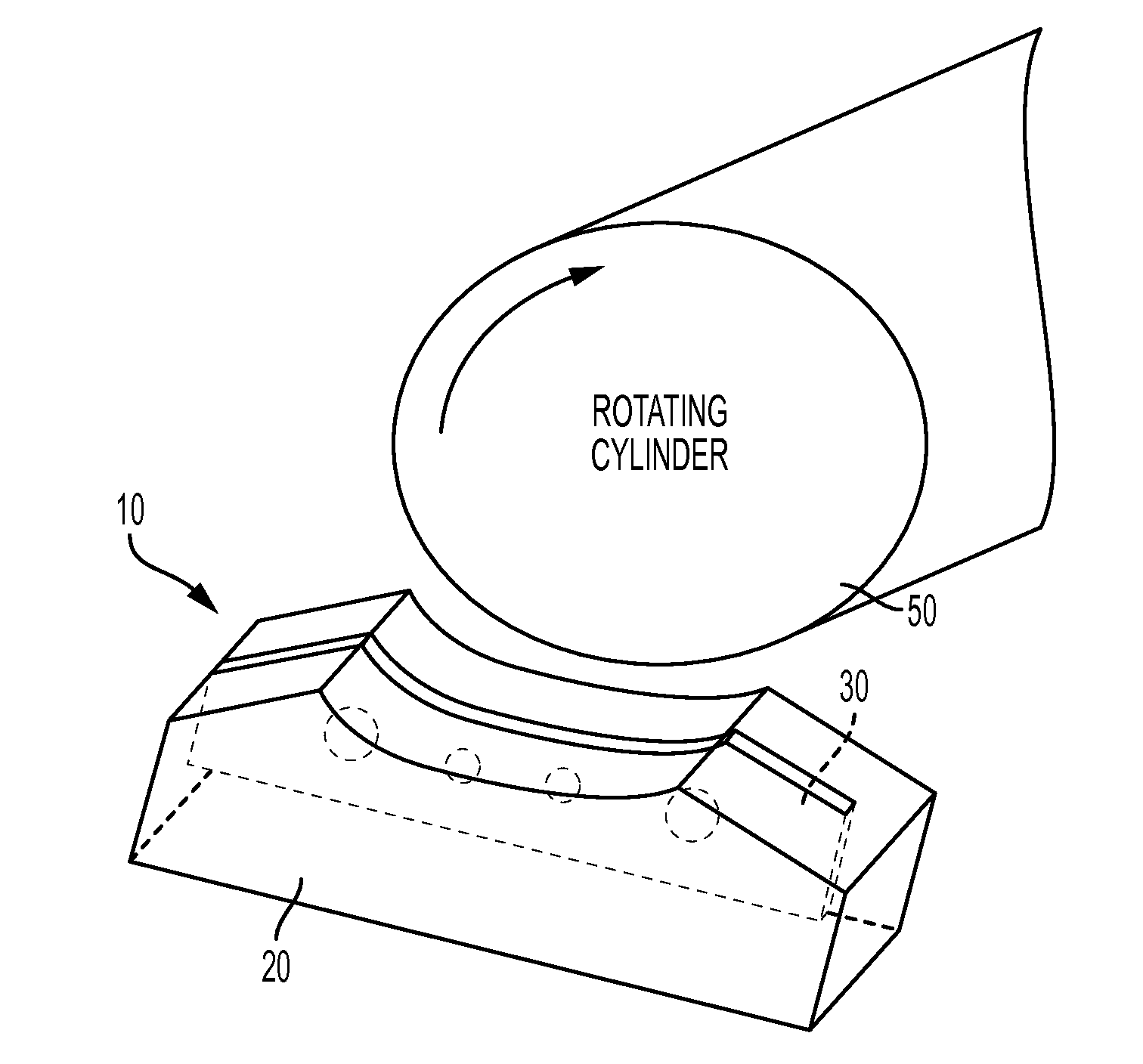

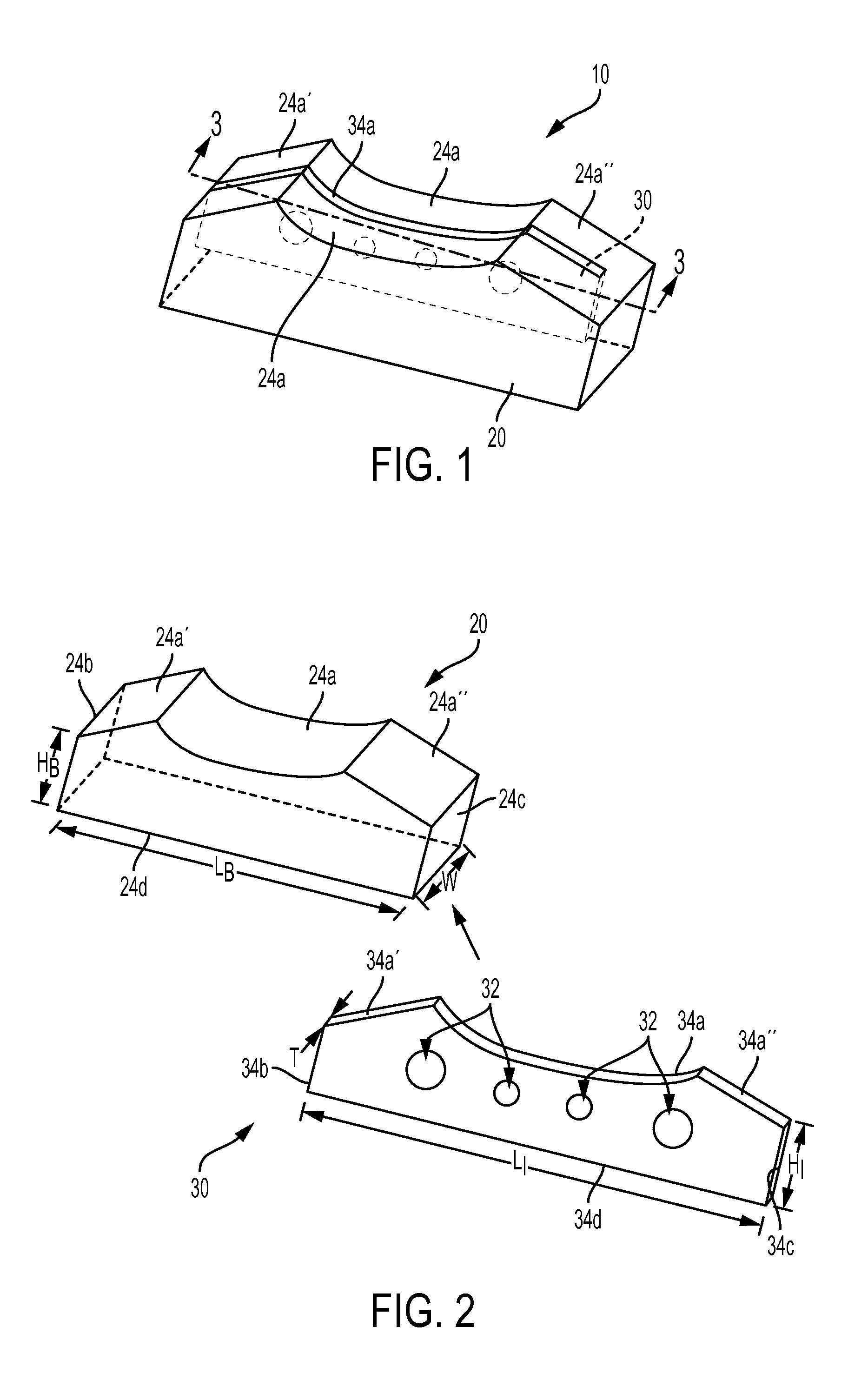

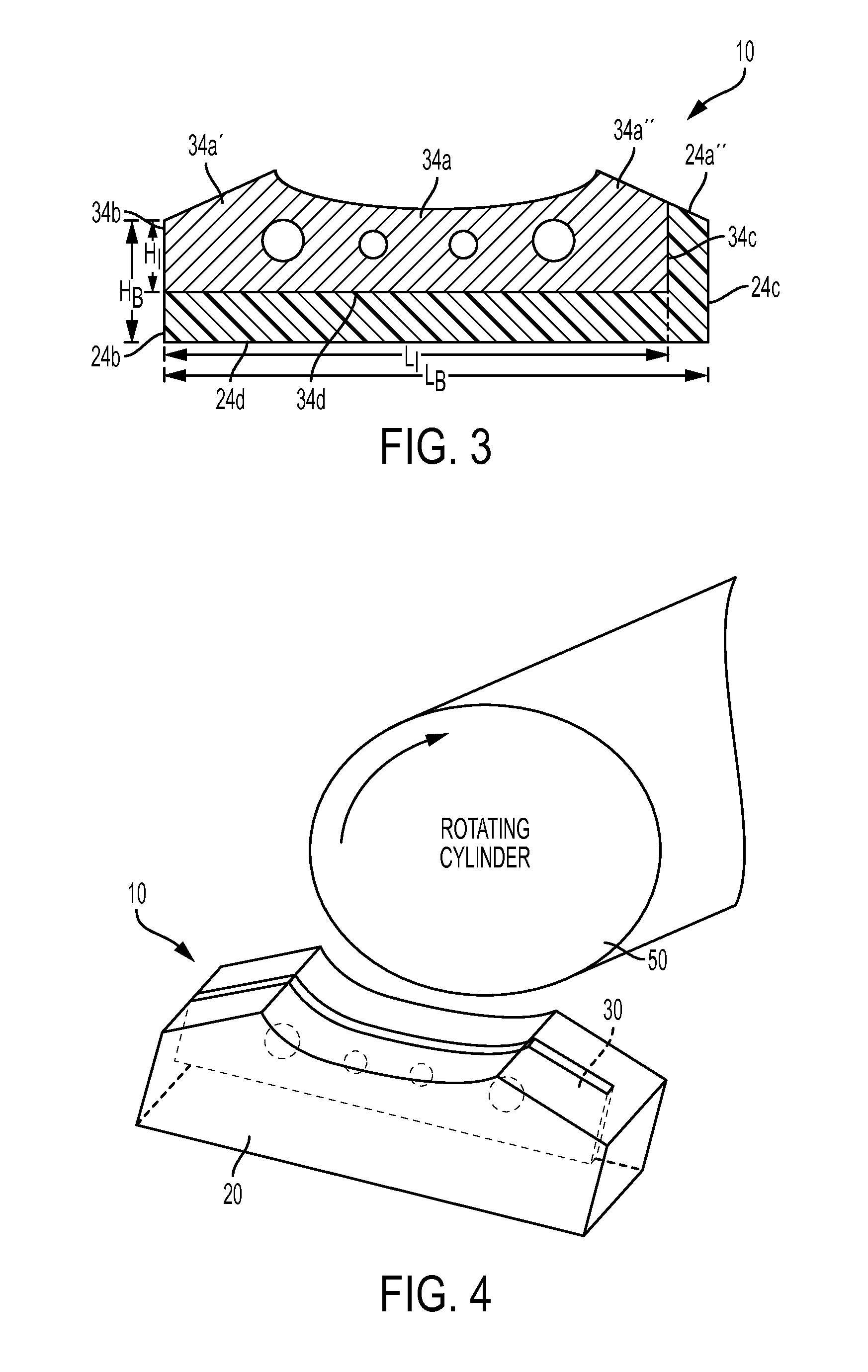

End seal with insert for chambered doctor blade assembly

ActiveUS9250566B2Improves Structural IntegrityImprove sealingElectrographic process apparatusPrinting press partsEngineeringMechanical engineering

An end seal for removable attachment to a doctor blade assembly is provided. The end seal comprises a seal body having a bottom wall, opposite first and second sidewalls and a top edge configured to include a radius adapted to seal against a roller surface. At least one abrasion resistant insert is integrally secured within the seal body. The insert includes a bottom wall, opposite first and second sidewalls and a top edge configured to coincide with the body top edge so as to seal against the roller surface. The abrasion resistant insert may further include one or more holes wherein the seal body impregnates the holes. One or both of the opposite first and second insert sidewalls and / or the insert bottom wall may reside within and be encapsulated by the seal body. The abrasion resistant insert may be constructed of polytetrafluoroethylene, a perfluoroalkoxy alkane or fluorinated ethylene propylene.

Owner:FOLEY ANTHONY

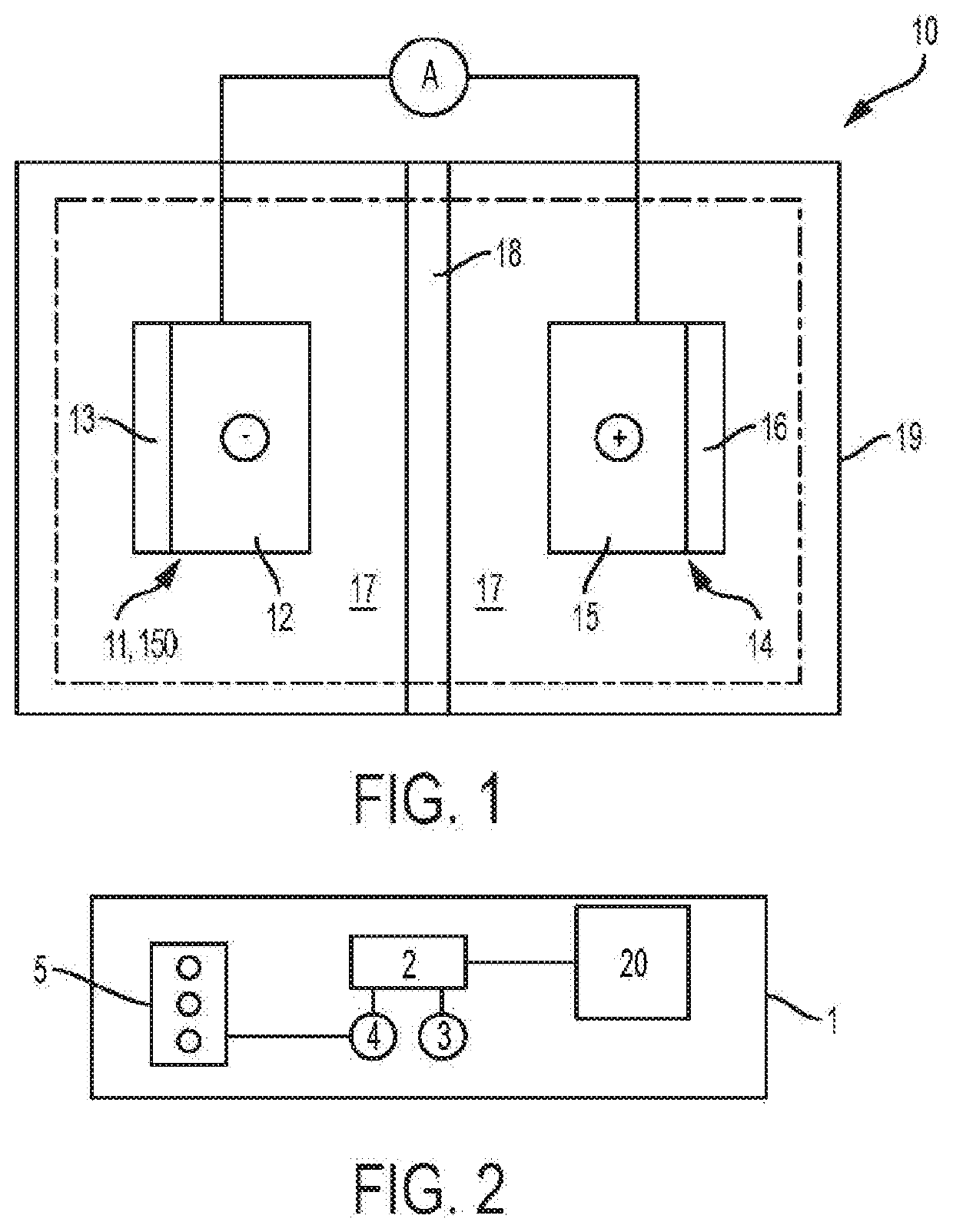

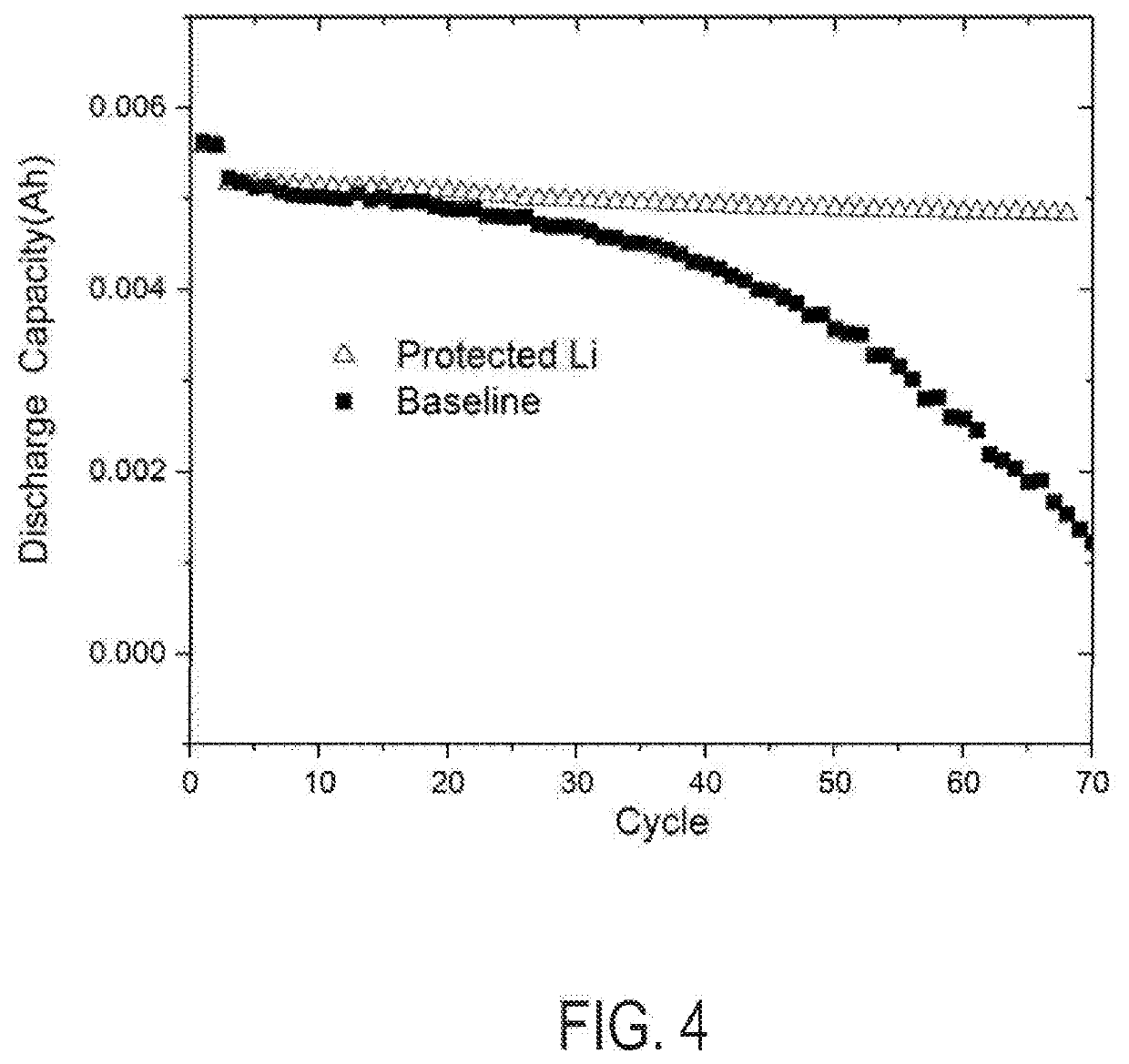

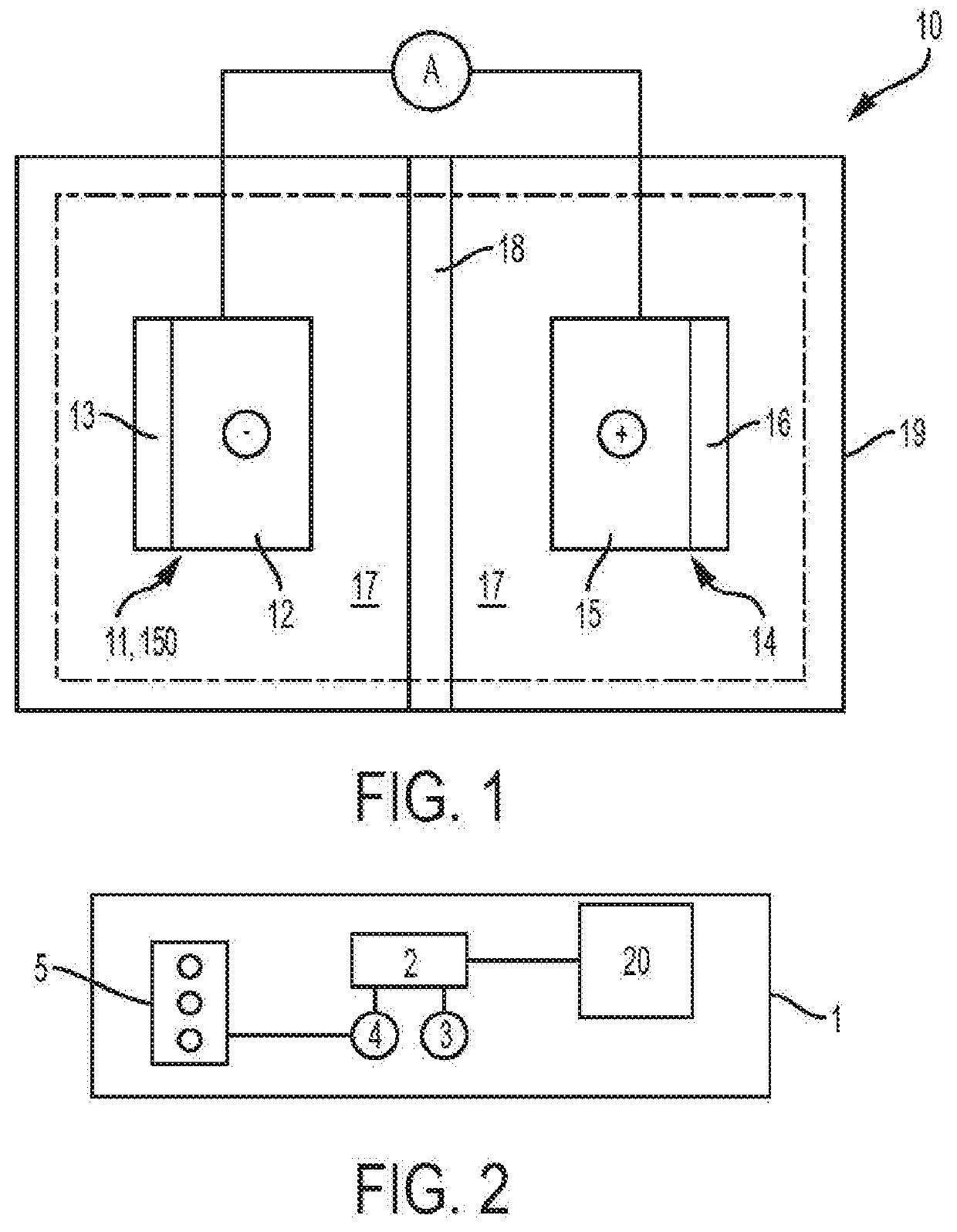

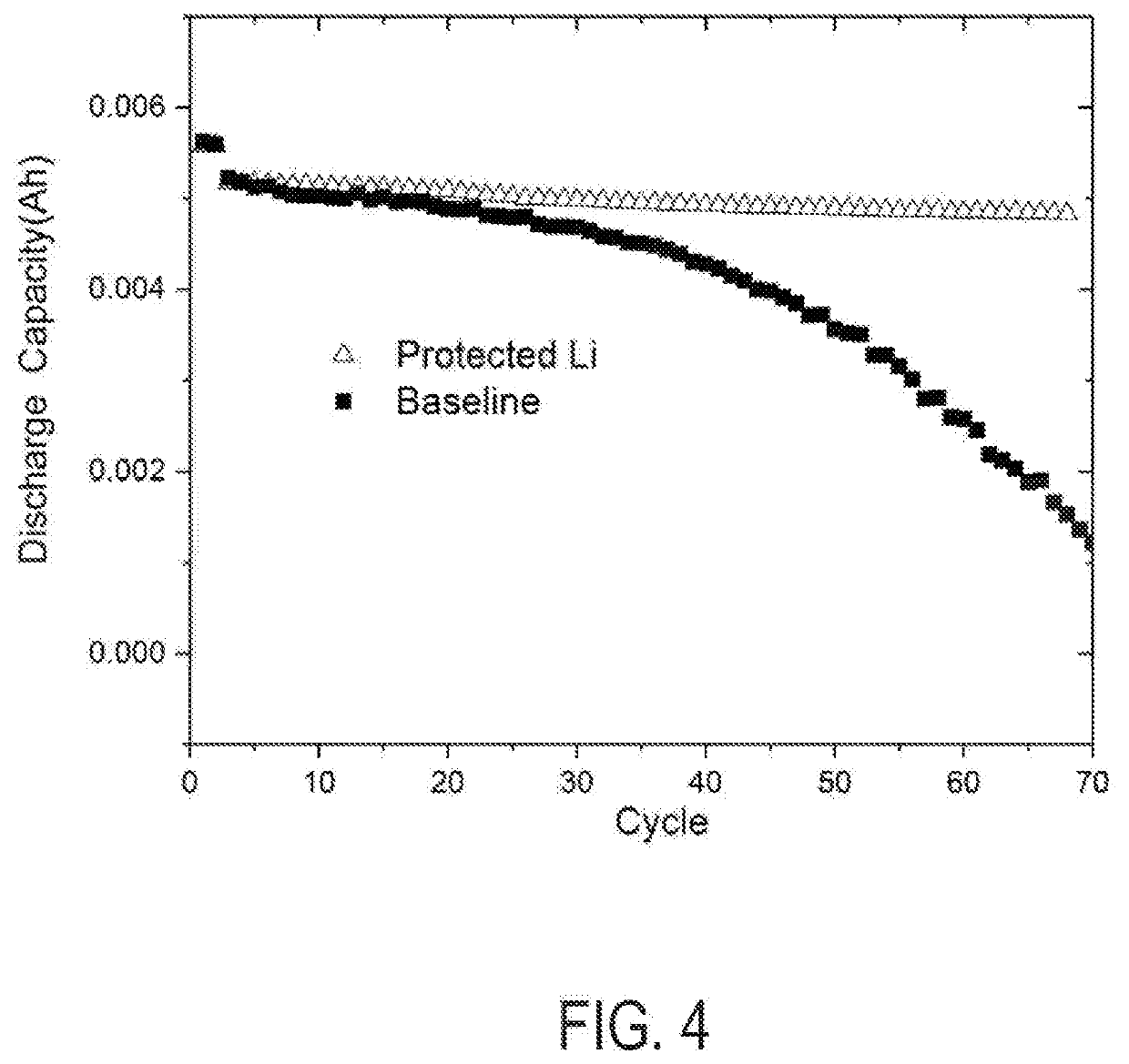

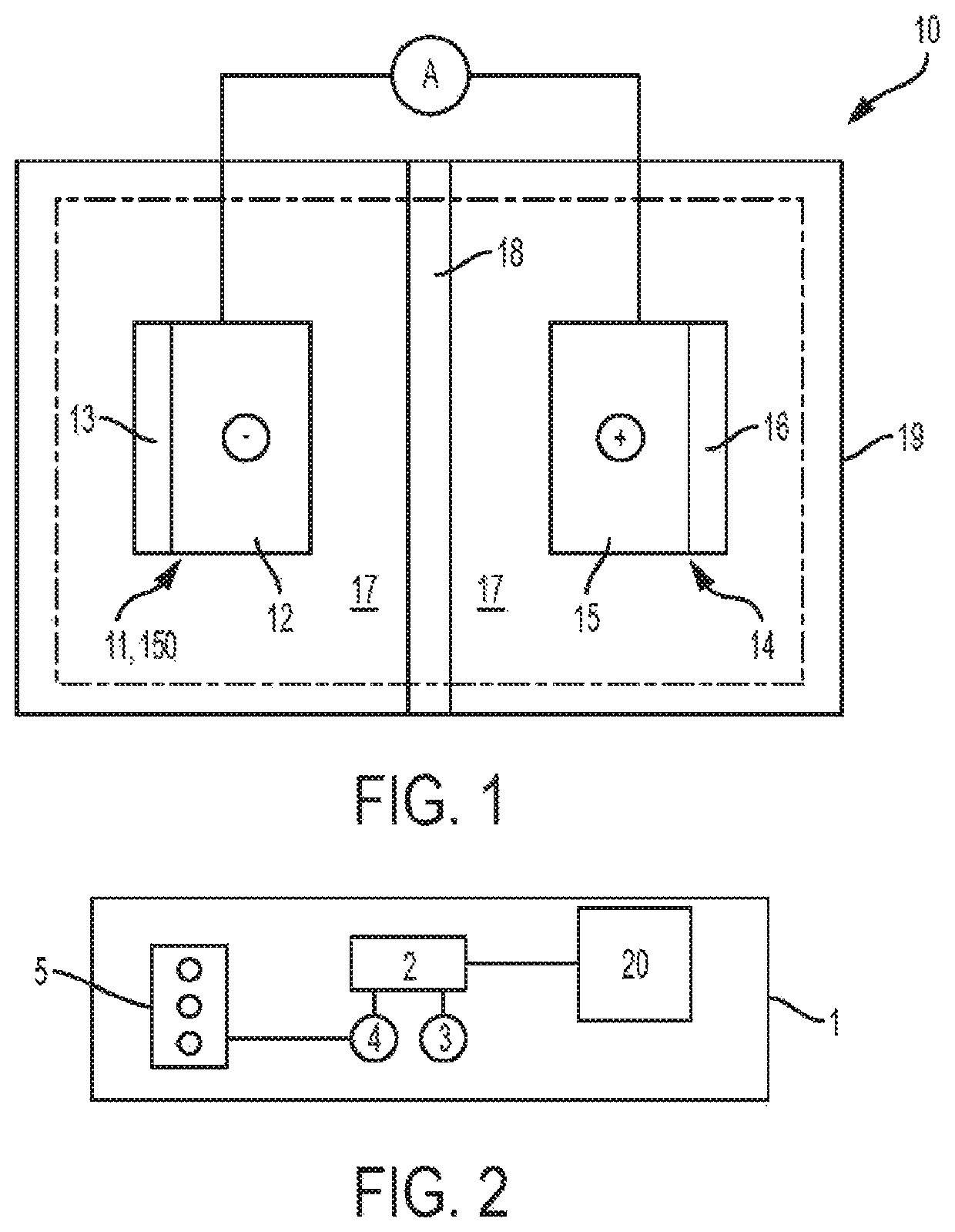

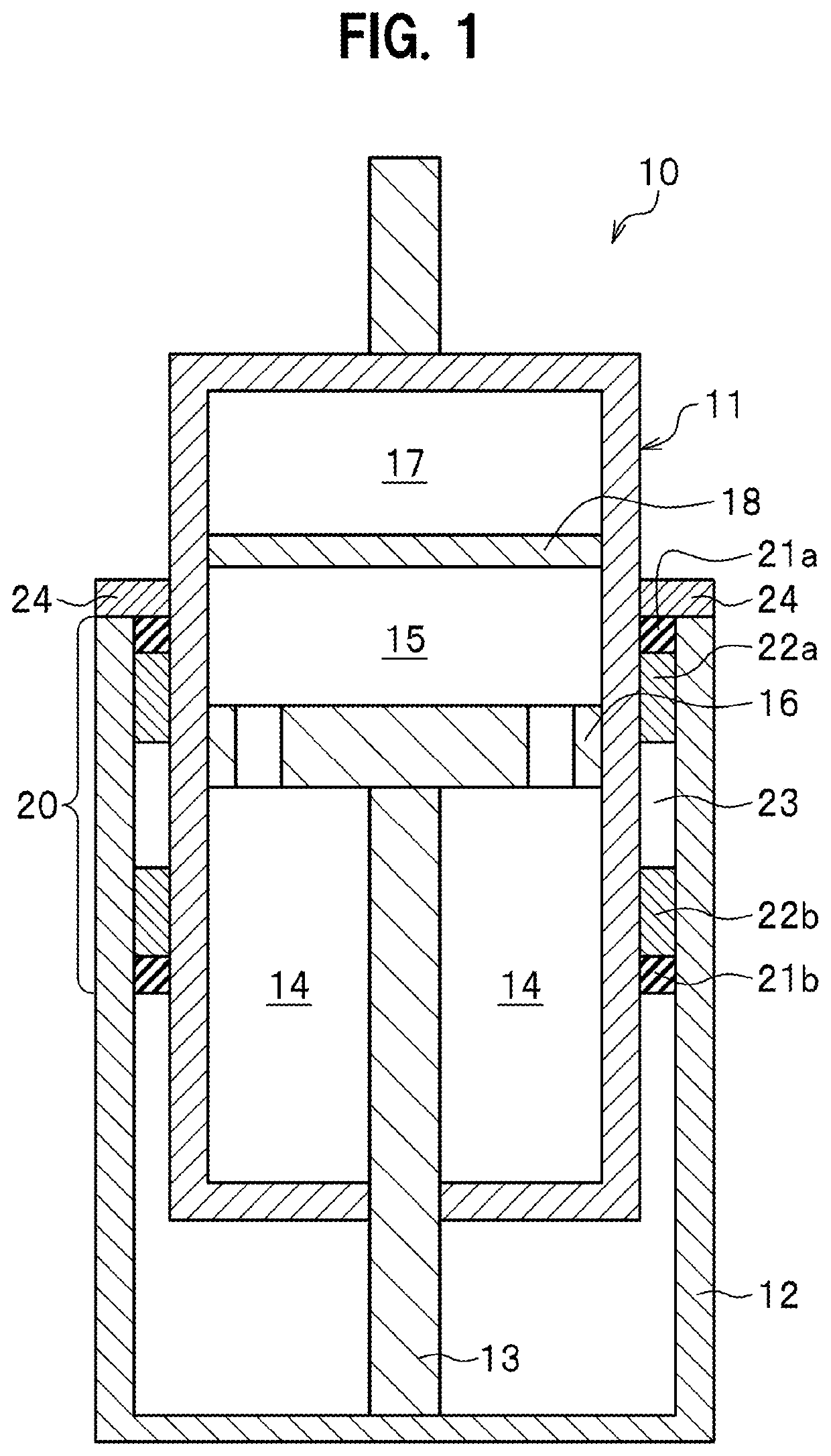

Electrodes including fluoropolymer-based solid electrolyte interface layers and batteries and vehicles utilizing the same

InactiveUS20200321617A1Promote sportsIncrease energy densityHybrid vehiclesFinal product manufactureVinyl etherAlkane

Electrodes include a lithium-based host material with a solid electrolyte interface (SEI) layer including a polymer matrix including fluoropolymers, and LiF imbedded within the matrix. The SEI layer comprises about 5 wt. % to about 75 wt. % LiF. The LiF can be present within the polymer matrix as nanocrystals with an average diameter of about 5-500 nm. The one or more fluoropolymers can include and / or are the defluorination products of one or more of fluorinated ethylene propylene, perfluoroalkoxy alkanes, vinylidenefluoride, and copolymers of perfluoromethylvinylether and tetrafluoroethylene. The —CF3 functional groups of the one or more defluorinated fluoropolymers can be at least about 3 wt. % of the SEI layer. The lithium-based host material can include at least 50 wt. % lithium. The lithium-based host material can include a lithium-aluminum alloy, a lithium-silicon alloy, a lithium-tin alloy, a lithium-zinc alloy, or a lithium-germanium alloy. Battery cells and electric vehicles can utilize such electrodes.

Owner:GM GLOBAL TECH OPERATIONS LLC

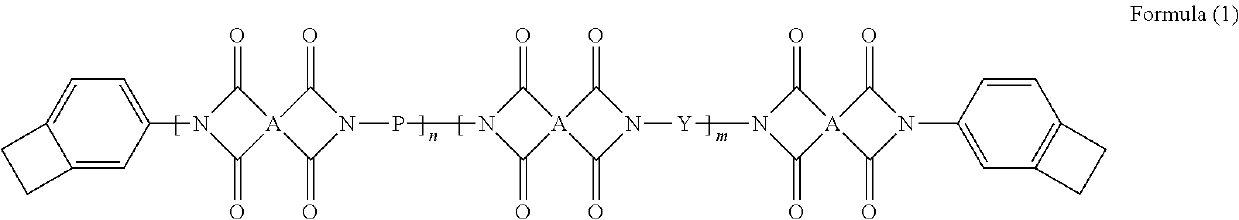

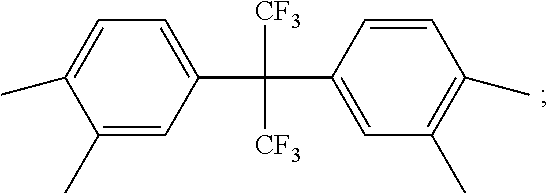

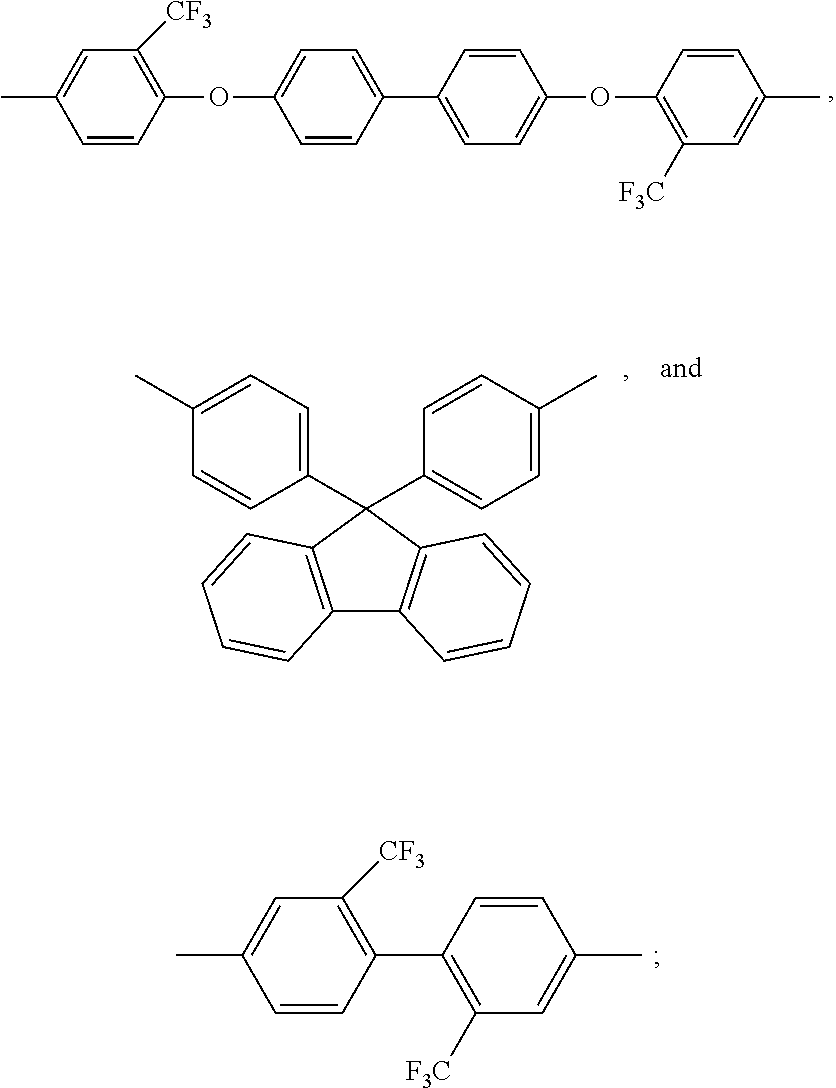

Benzocyclobutene-containing polyimide resin and its composition, manufacturing method, redistribution layer, polyimide film, and use

ActiveUS20210261777A1High glass transition temperatureImprove suppression propertiesPolymer scienceRedistribution layer

A benzocyclobutene-containing polyimide resin and a benzocyclobutene-containing polyimide resin composition are provided. The composition includes: (a) a filler:hollow silica, a perfluoroalkoxy alkane resin, or a combination thereof, and (b) a benzocyclobutene-containing polyimide resin with characteristics of high heat resistance, low dielectric property, low elastic modulus, and suitable for manufacturing a redistribution layer and a polyamide film of a semiconductor packaging material in a high-speed and high-frequency field.

Owner:CHIN YEE CHEM INDUSTRES

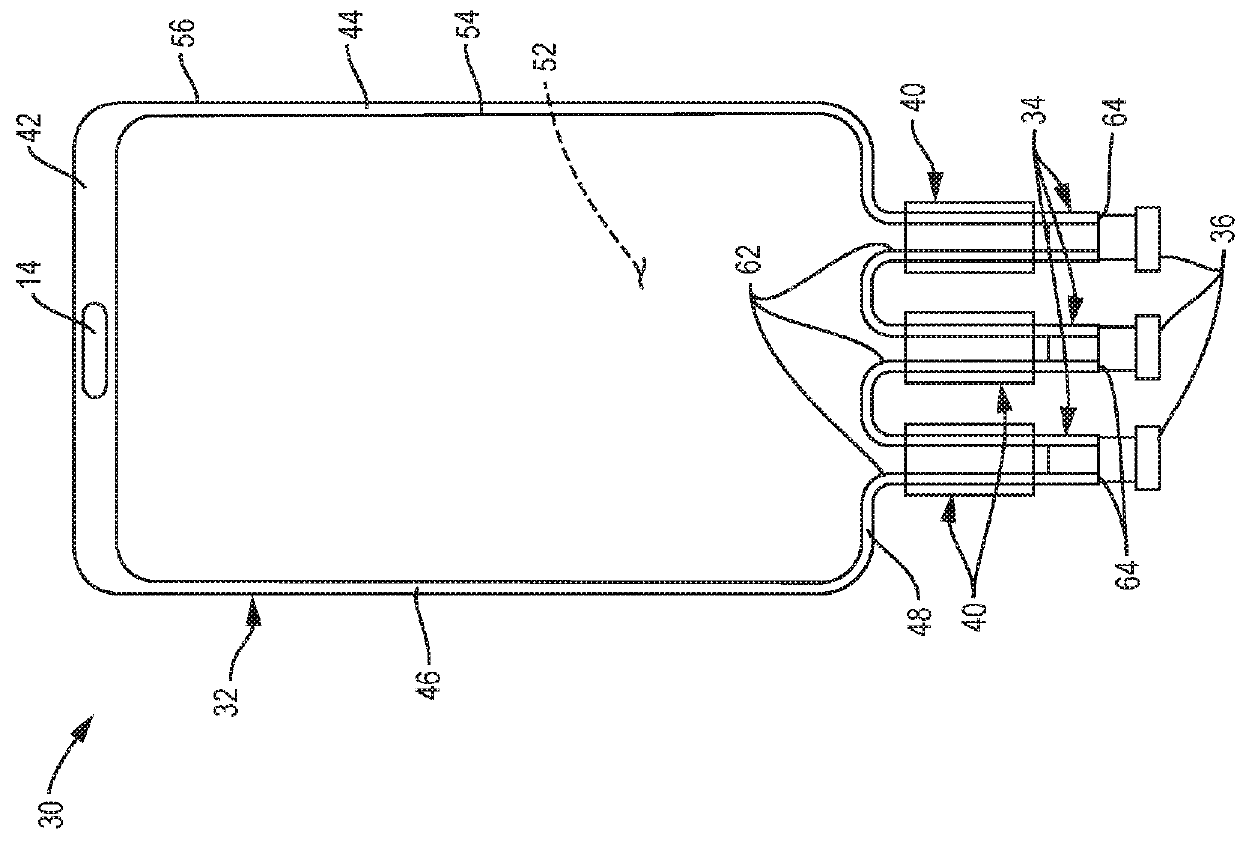

Dry sterilizable bag and clamp for storing liquid and frozen media and dispensing

InactiveUS20180104147A1Pharmaceutical containersBiochemistry apparatusEngineeringDry Heat Sterilization

A single-use bag (32) and dispensing system (30) for storage of liquid or frozen media and for dispensing the media are disclosed. A single-use bag (32) is composed of materials that can withstand the temperatures required for dry heat sterilization and, further, includes specialized clamps (40, 140) that accommodate the materials and construction techniques necessary for constructing the single-use bag (32) for restriction and isolation of flow from the single-use bag (32). The single-use bag (32) includes an inner film (76) defining a bag interior (52) and an outer film (78) overlying the inner film (76), the inner film (76) and the outer film (78) being heat bonded together, the inner film (76) being composed of perfluoroalkoxy alkane (PFA) and the outer film (78) being composed of polytetrafluoroethylene (PTFE), the single-use bag (32) defining at least one exit port (62) on a bottom edge (48) thereof; and at least one closeable exit passage (34) depending from the bottom edge (48) of the single-use bag (32), each of the at least one exit passage (34) being coupled to a respective one of the at least one exit port (62), the at least one exit passage (34) being in fluid communication with the bag interior (52).

Owner:ENTEGRIS INC

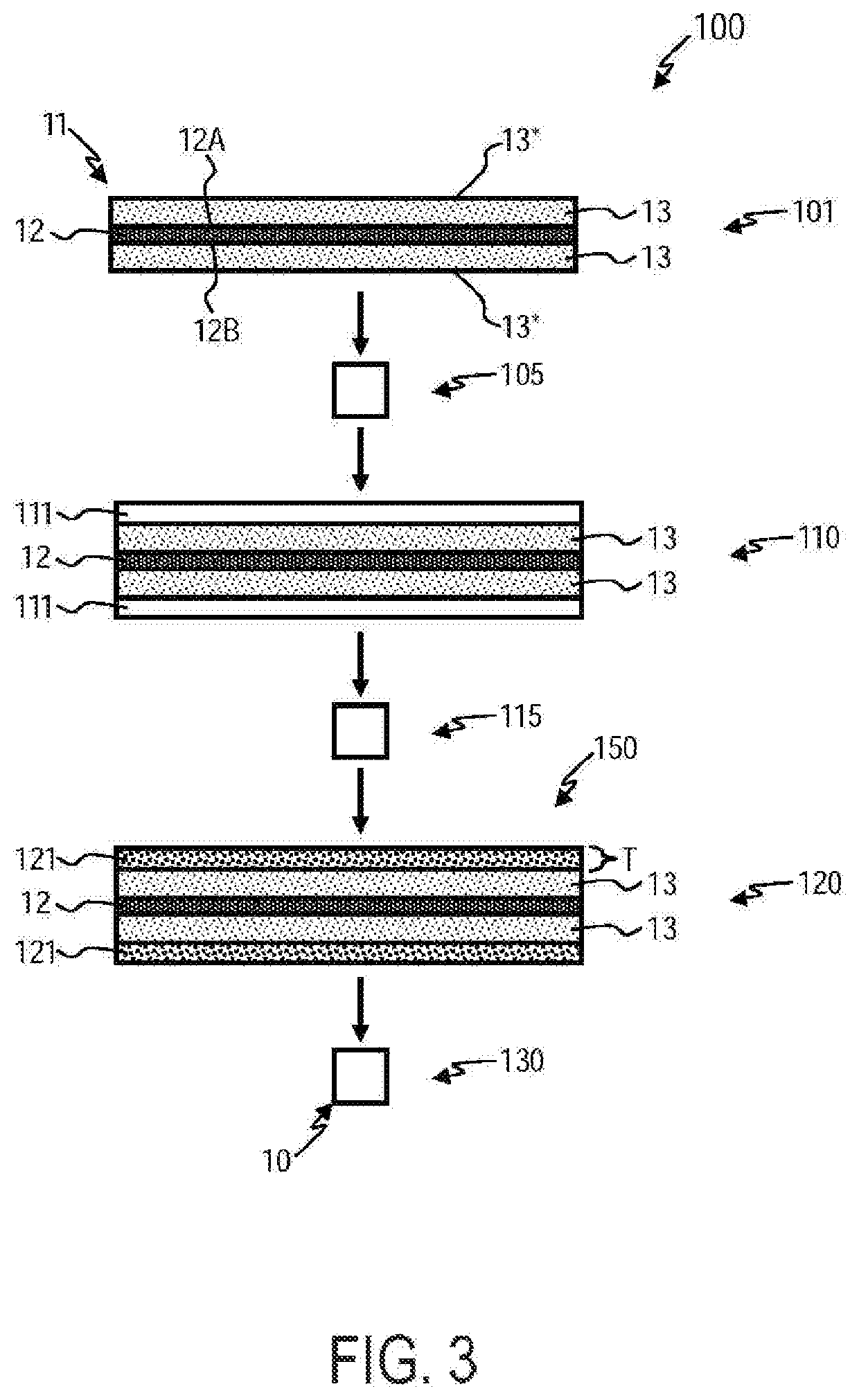

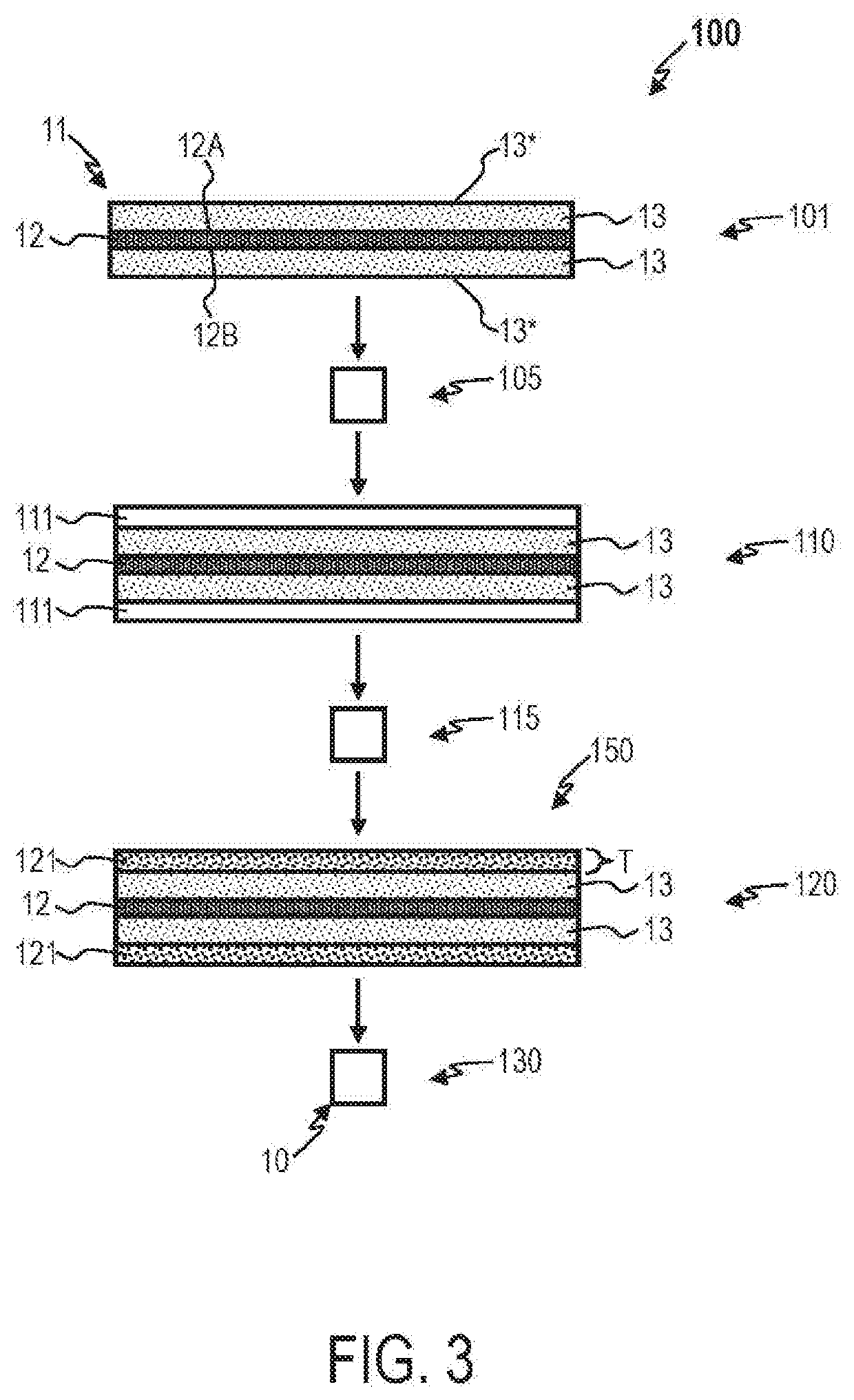

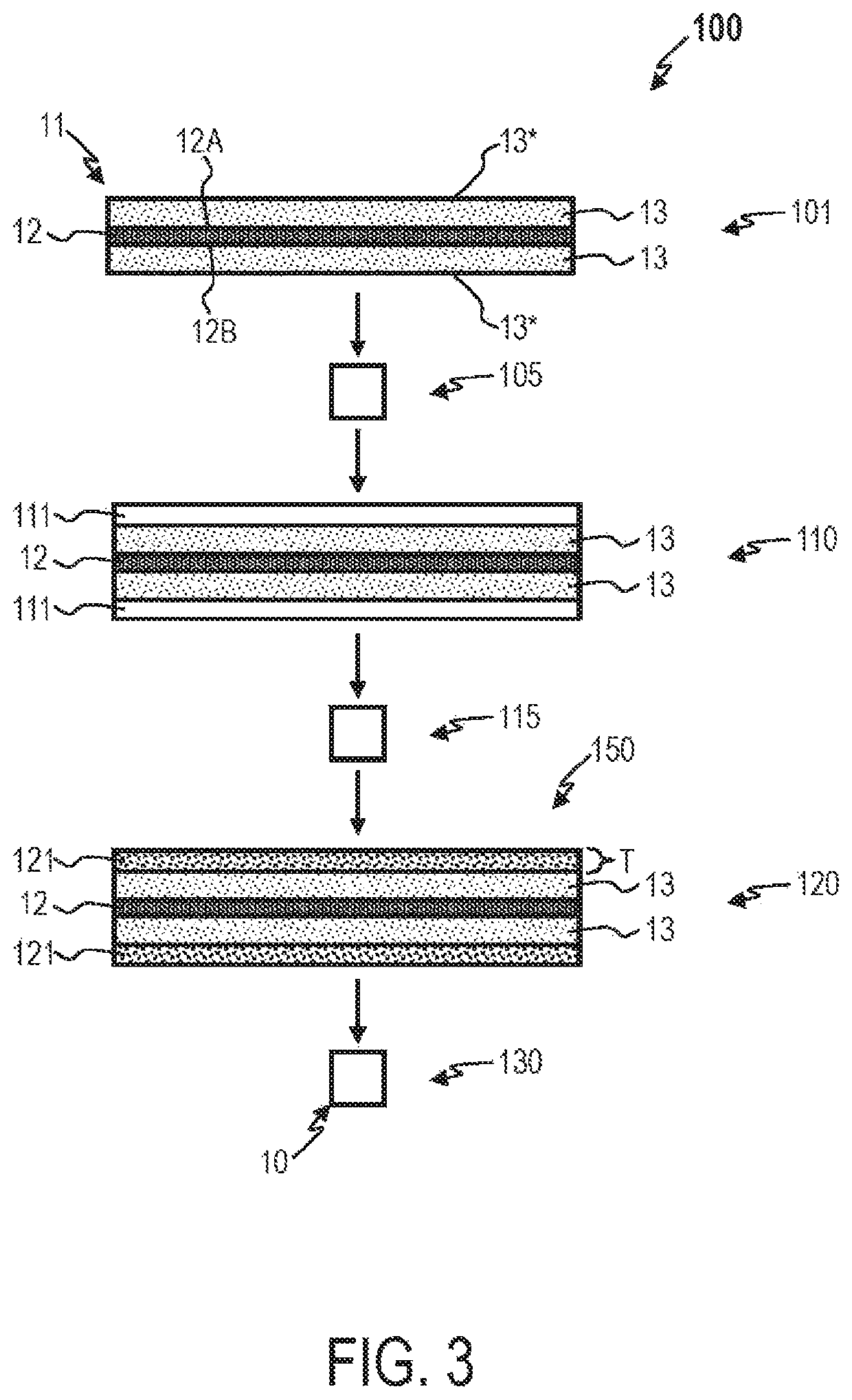

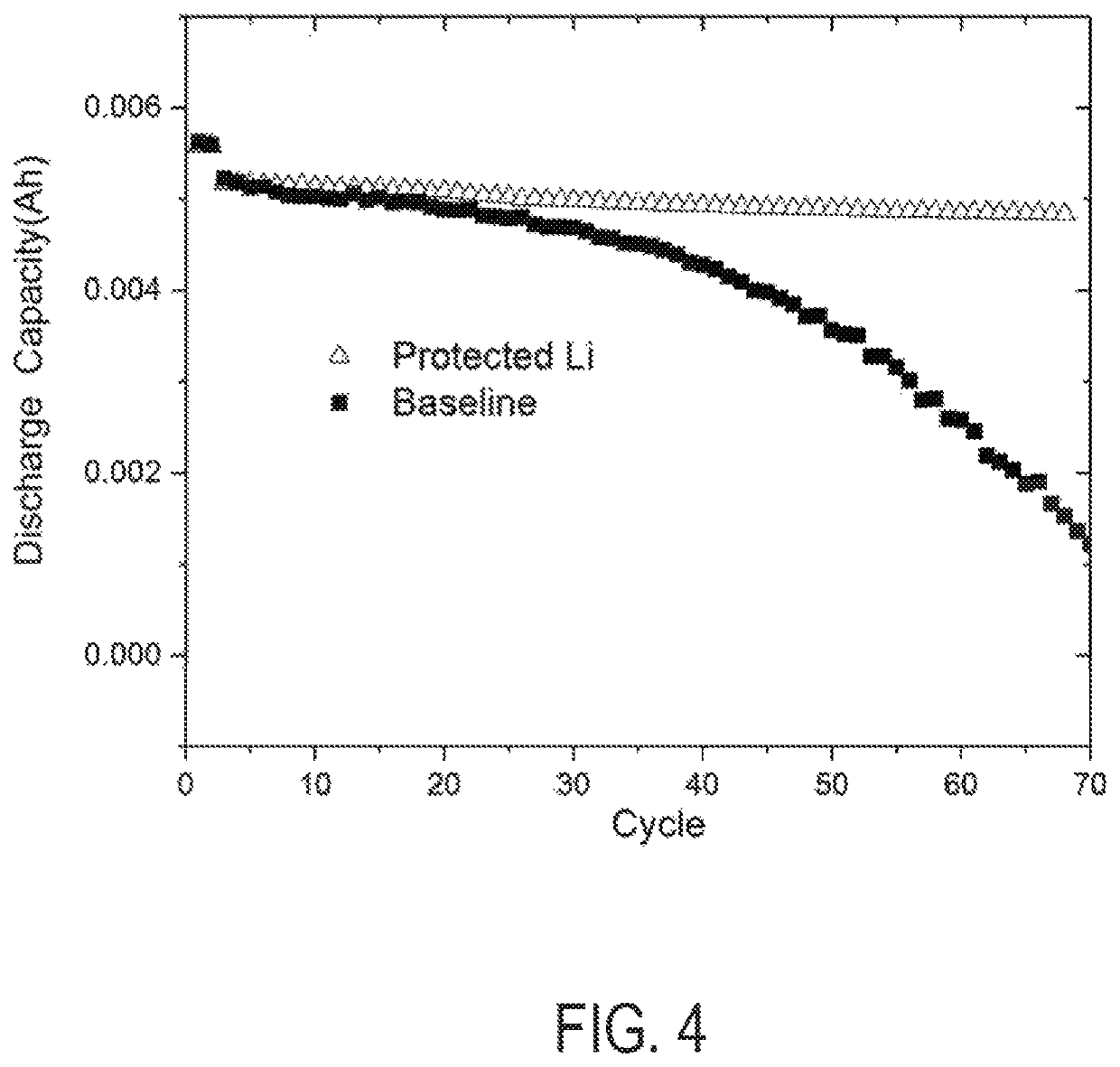

Methods for manufacturing electrodes including fluoropolymer-based solid electrolyte interface layers

ActiveUS20200321603A1Promote sportsIncrease energy densityElectrode thermal treatmentFinal product manufactureVinyl etherAlkane

Methods for manufacturing electrodes include applying a fluoropolymer film to a lithium-based host material, defluorinating the fluoropolymer film by heating to produce a lithium electrode having a solid electrolyte interface (SEI) layer including defluorinated fluoropolymers and at least about 5 wt. % LiF. The fluoropolymers can include one or more of fluorinated ethylenepropylene, perfluoroalkoxy alkanes, vinylidenefluoride, and copolymers of perfluoromethylvinylether and tetrafluoroethylene. The fluoropolymers can include one or more fluorinated monomers, including hexafluoropropylene, tetrafluoroethylene, ethylene-tetrafluoroethylene, perfluoroethers, and vinylidene fluoride. The —CF3 functional groups of the defluorinated fluoropolymers can be about 3 wt. % to about 10 wt. % of the SEI layer. The SEI layer can include about 30 wt. % to about 50 wt. % LiF. The method can include assembling a battery cell by disposing a battery separator between a cathode and the electrode, and disposing the battery separator, the cathode, and the electrode in an electrolyte.

Owner:GM GLOBAL TECH OPERATIONS LLC

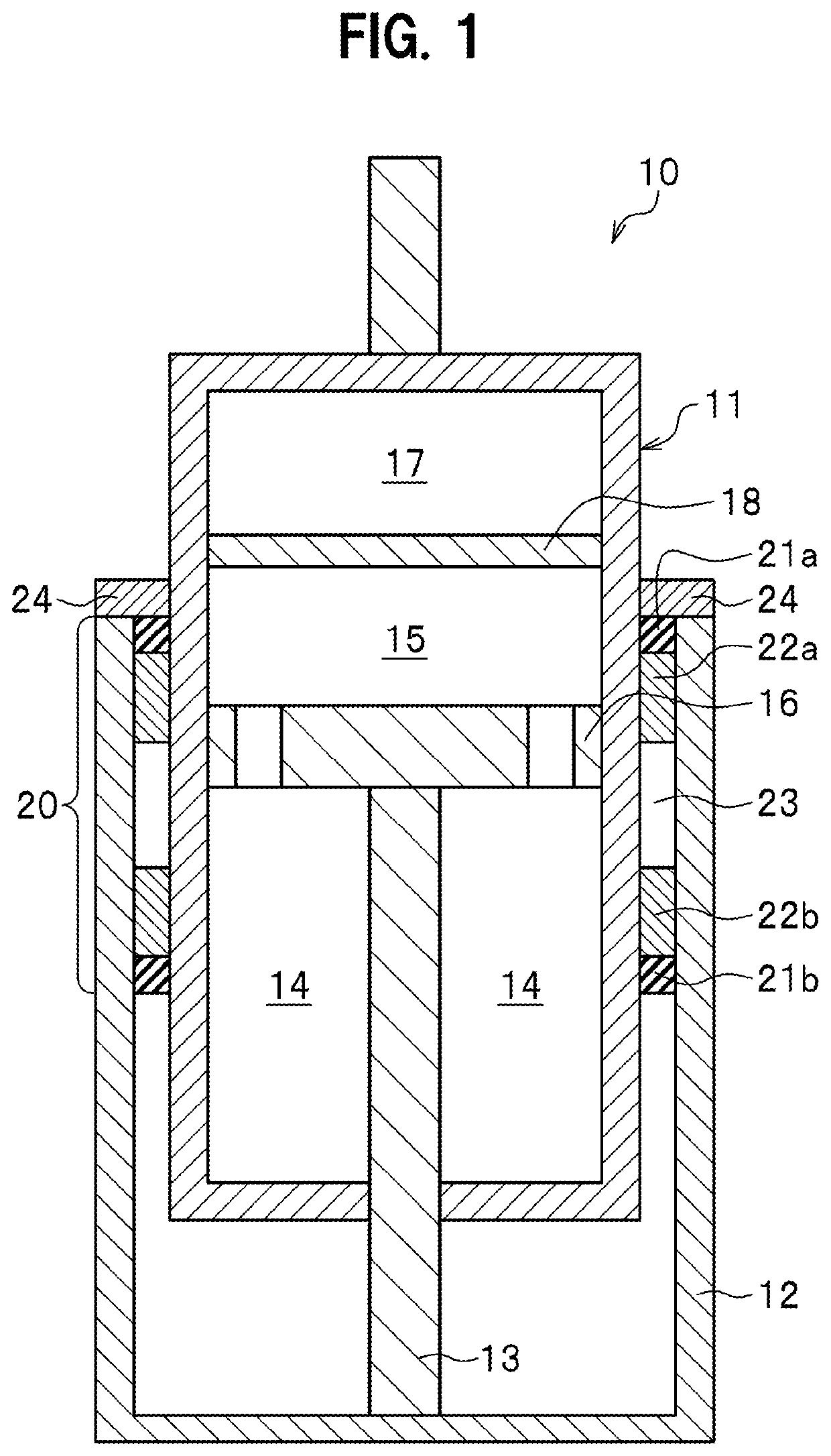

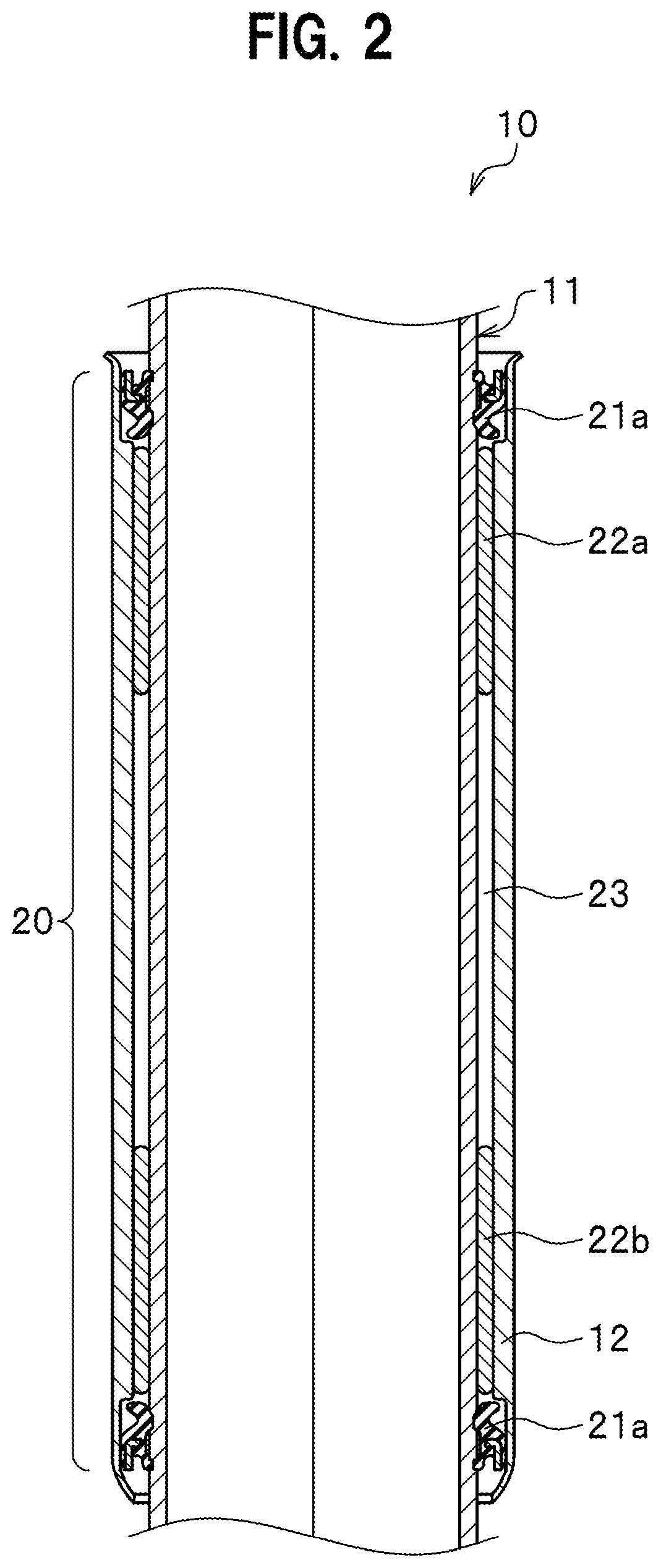

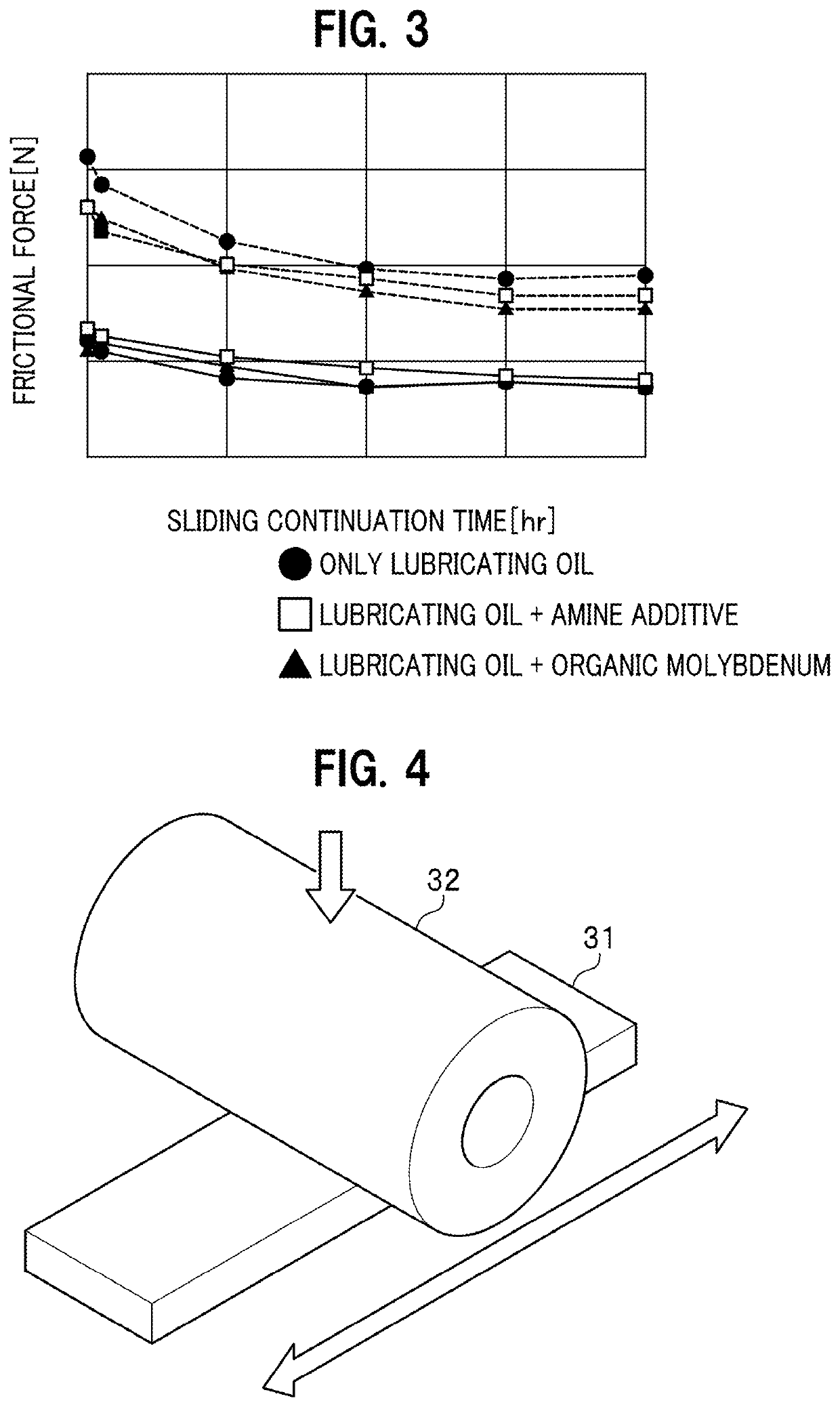

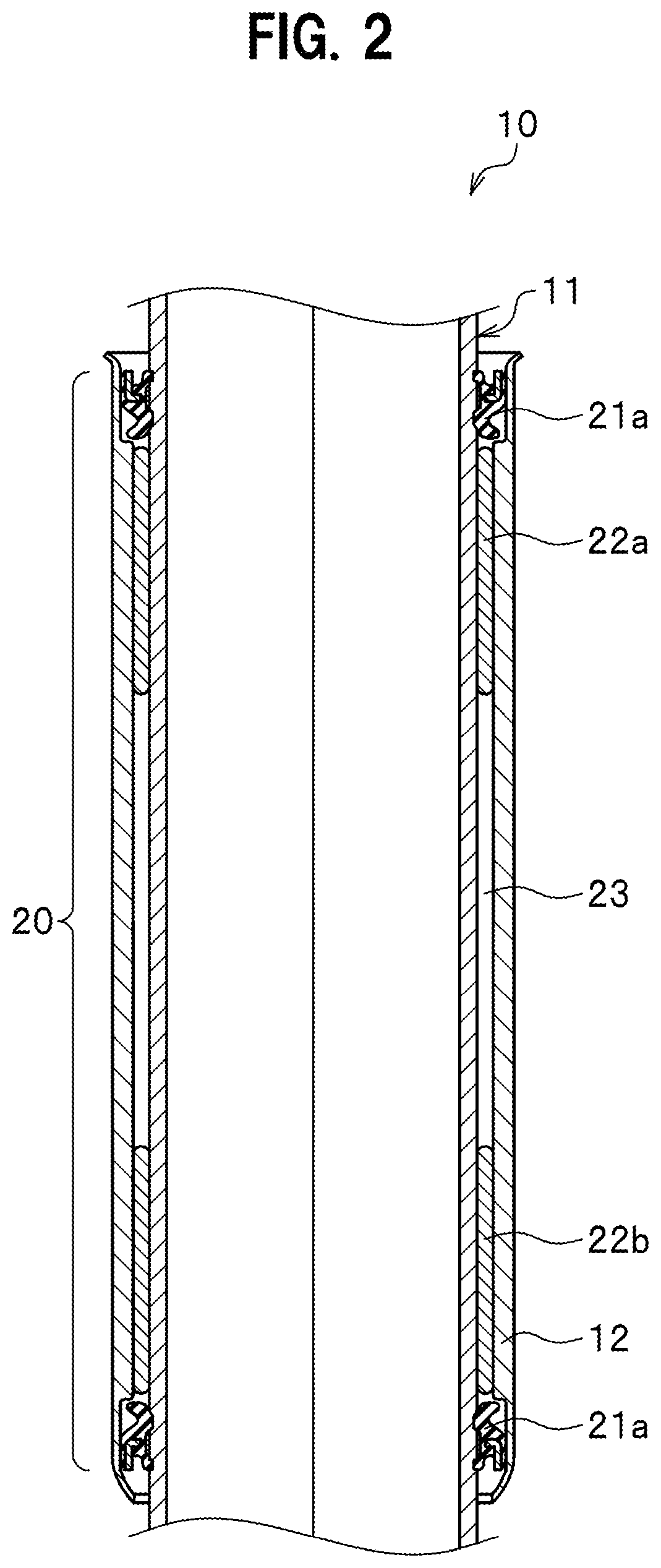

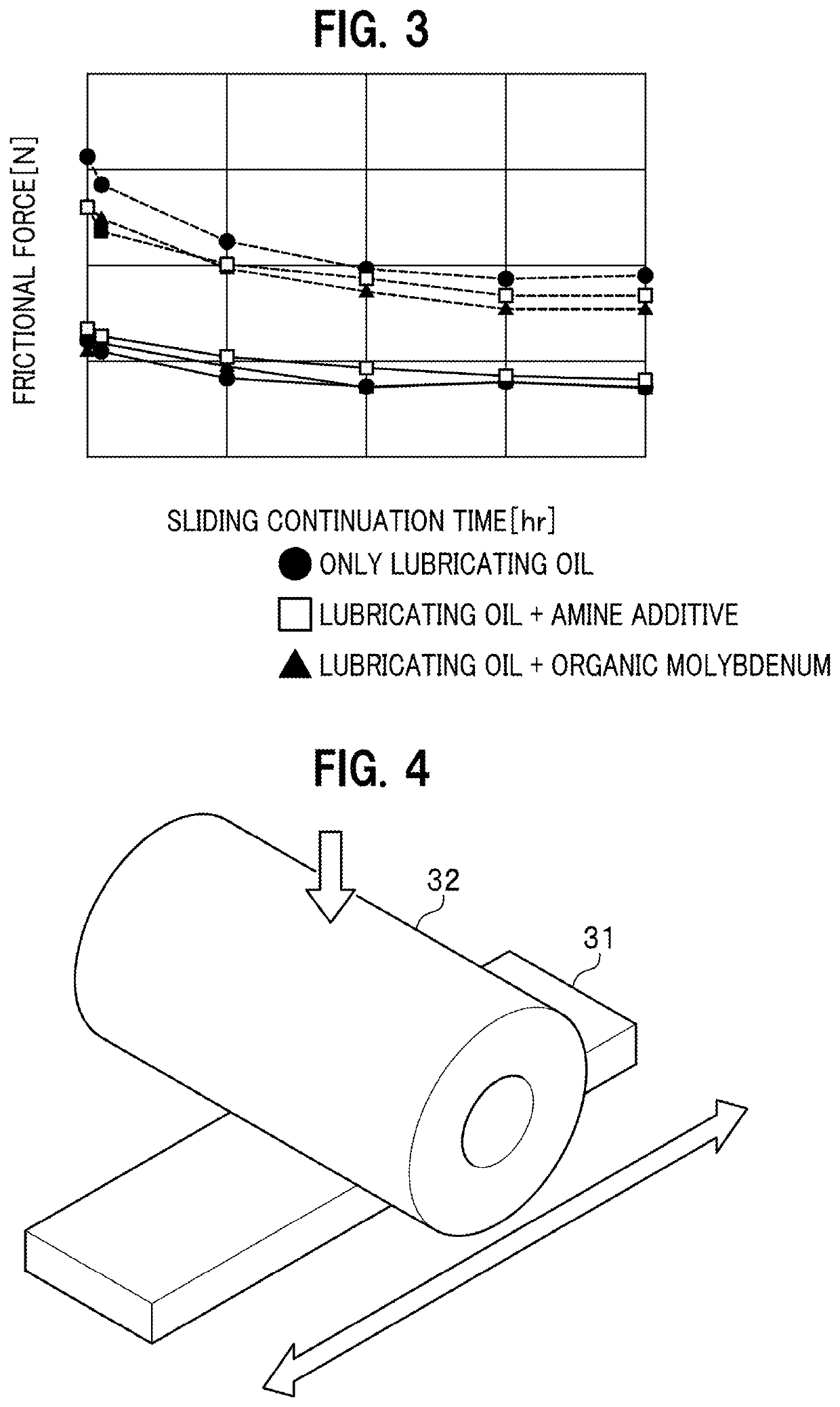

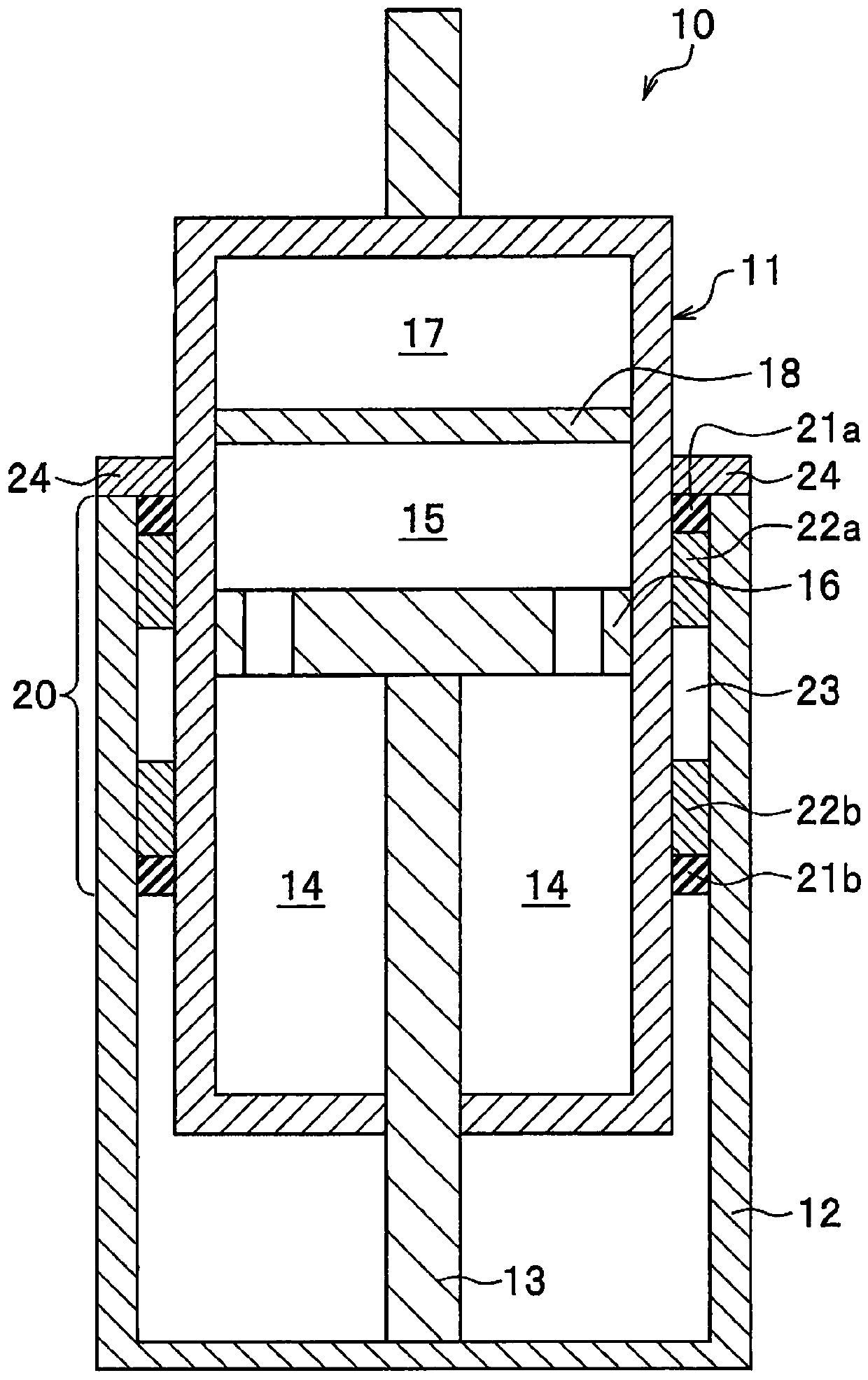

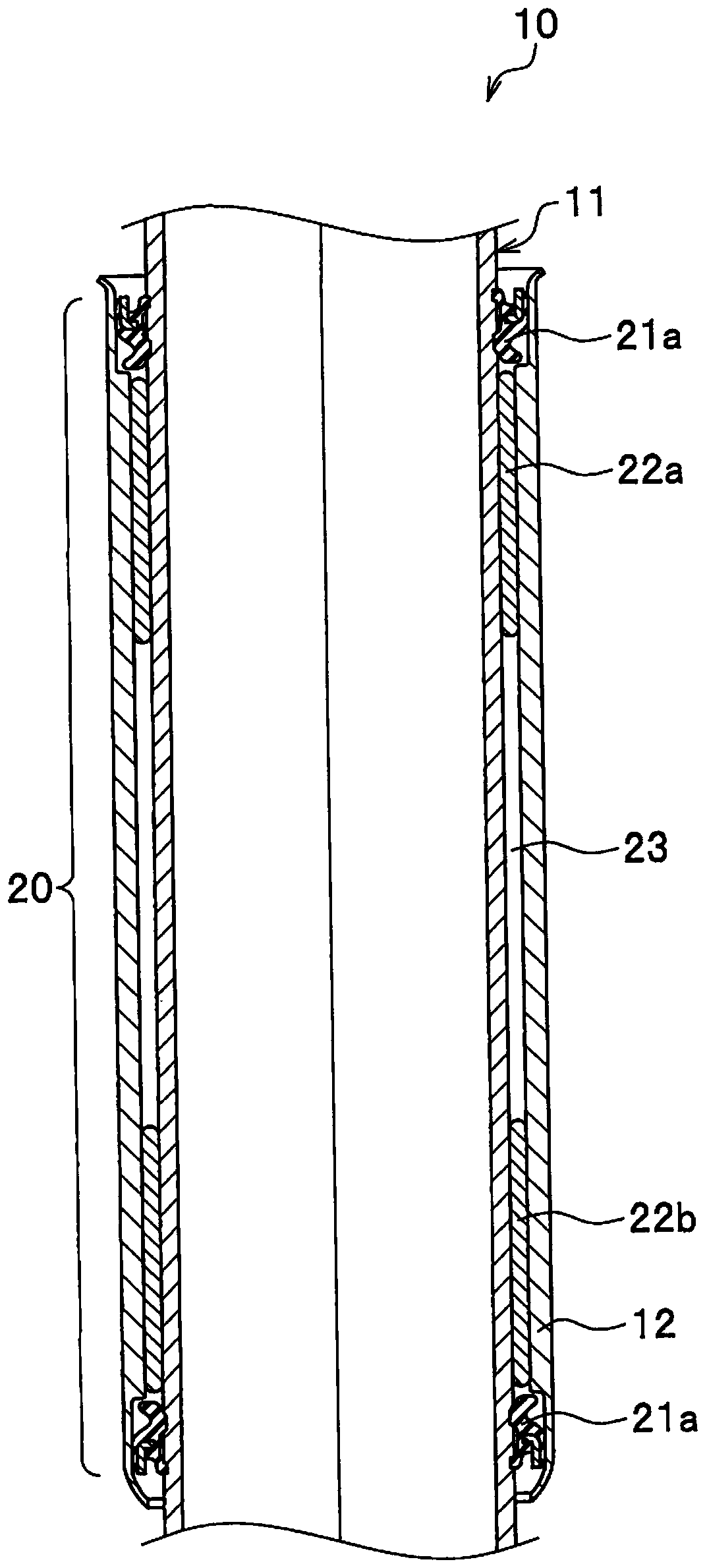

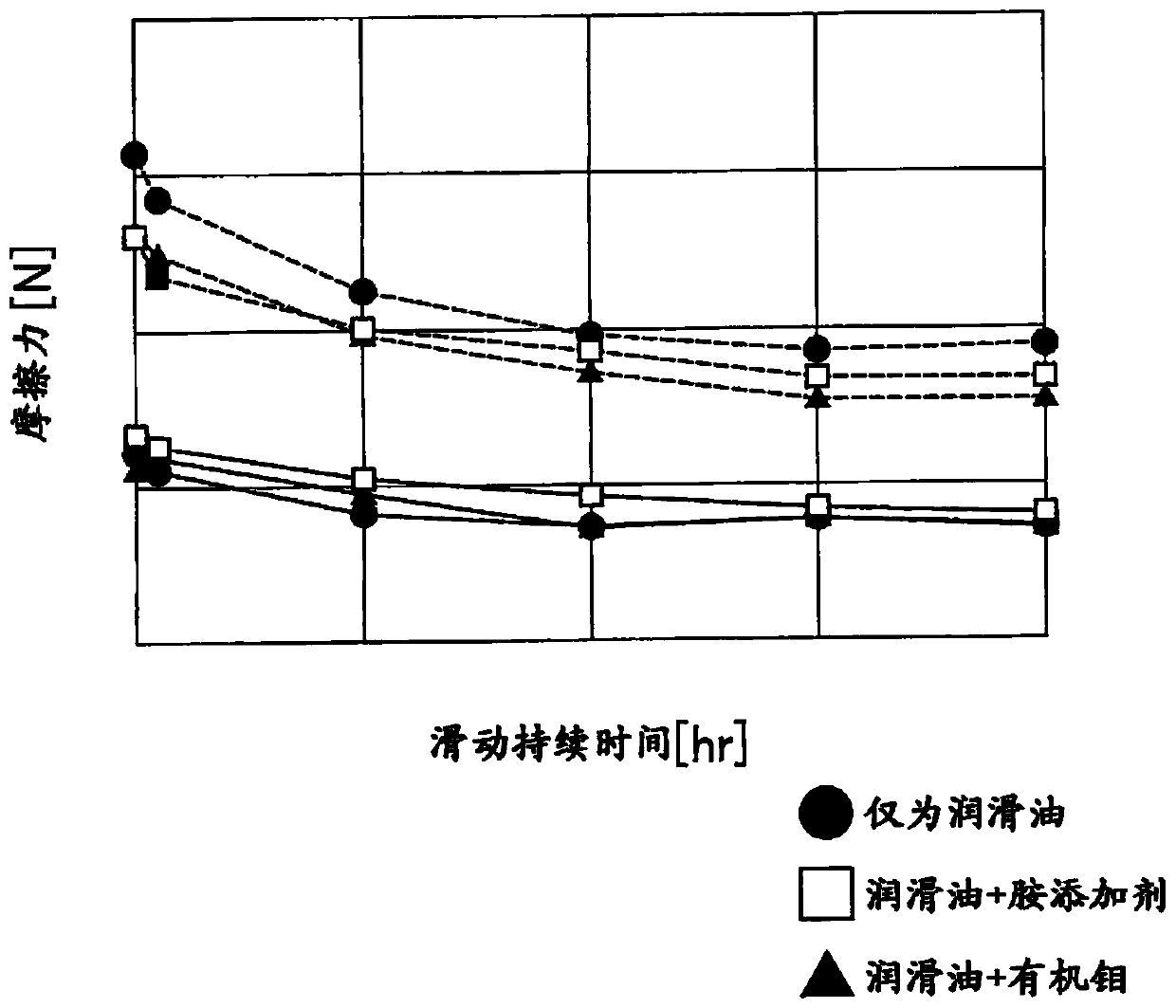

Vibration damping device of inverted structure

ActiveUS20200018375A1Reduce frictionReduced bearing wearSpringsSprings/dampers design characteristicsAlkaneClassical mechanics

A vibration damping device of an inverted structure includes a cylinder, a rod capable of protruding and retracting in the cylinder, an outer cylinder coupled to the rod and inserted over the outer periphery of the cylinder, and a bush slidably inserted between the outer cylinder and the cylinder. A gap between the outer cylinder and the cylinder is filled with lubricating oil. The bush contains polytetrafluoroethylene and perfluoro alkoxy alkane. The lubricating oil contains an organic molybdenum additive.

Owner:HONDA MOTOR CO LTD

Methods for manufacturing electrodes including fluoropolymer-based solid electrolyte interface layers

ActiveUS11217781B2Promote sportsIncrease energy densityElectrode thermal treatmentFinal product manufactureVinyl etherAlkane

Methods for manufacturing electrodes include applying a fluoropolymer film to a lithium-based host material, defluorinating the fluoropolymer film by heating to produce a lithium electrode having a solid electrolyte interface (SEI) layer including defluorinated fluoropolymers and at least about 5 wt. % LiF. The fluoropolymers can include one or more of fluorinated ethylenepropylene, perfluoroalkoxy alkanes, vinylidenefluoride, and copolymers of perfluoromethylvinylether and tetrafluoroethylene. The fluoropolymers can include one or more fluorinated monomers, including hexafluoropropylene, tetrafluoroethylene, ethylene-tetrafluoroethylene, perfluoroethers, and vinylidene fluoride. The —CF3 functional groups of the defluorinated fluoropolymers can be about 3 wt. % to about 10 wt. % of the SEI layer. The SEI layer can include about 30 wt. % to about 50 wt. % LiF. The method can include assembling a battery cell by disposing a battery separator between a cathode and the electrode, and disposing the battery separator, the cathode, and the electrode in an electrolyte.

Owner:GM GLOBAL TECH OPERATIONS LLC

Vibration damping device of inverted structure

ActiveUS10989265B2Reduce frictionReduced bearing wearSpringsSprings/dampers design characteristicsAlkaneClassical mechanics

A vibration damping device of an inverted structure includes a cylinder, a rod capable of protruding and retracting in the cylinder, an outer cylinder coupled to the rod and inserted over the outer periphery of the cylinder, and a bush slidably inserted between the outer cylinder and the cylinder. A gap between the outer cylinder and the cylinder is filled with lubricating oil. The bush contains polytetrafluoroethylene and perfluoro alkoxy alkane. The lubricating oil contains an organic molybdenum additive.

Owner:HONDA MOTOR CO LTD

End seal with insert for chambered doctor blade assembly

ActiveUS20150286161A1Improves Structural IntegrityImprove sealingElectrographic process apparatusPrinting press partsEngineeringMechanical engineering

An end seal for removable attachment to a doctor blade assembly is provided. The end seal comprises a seal body having a bottom wall, opposite first and second sidewalls and a top edge configured to include a radius adapted to seal against a roller surface. At least one abrasion resistant insert is integrally secured within the seal body. The insert includes a bottom wall, opposite first and second sidewalls and a top edge configured to coincide with the body top edge so as to seal against the roller surface. The abrasion resistant insert may further include one or more holes wherein the seal body impregnates the holes. One or both of the opposite first and second insert sidewalls and / or the insert bottom wall may reside within and be encapsulated by the seal body. The abrasion resistant insert may be constructed of polytetrafluoroethylene, a perfluoroalkoxy alkane or fluorinated ethylene propylene.

Owner:FOLEY ANTHONY

Ink supply tube

InactiveUS20180141342A1Excellent oxygen barrier propertiesLow moisture permeabilityFlexible pipesPrintingTetrafluoroethyleneElastomer

An ink supply tube of the present invention comprising an inner layer to come into contact with ink, a middle layer having at least three layers, and an outer layer, wherein the middle layer includes a first middle layer, a second middle layer, and a third middle layer, the inner layer comprises one of an ethylene-tetrafluoroethylene copolymer resin, a tetrafluoroethylene-perfluoroalkoxy alkane copolymer resin, and a modified perfluoroalkoxy-based resin, each having a solvent resistance, an oxygen barrier property, and a low moisture permeability, the first middle layer comprises a polyamide resin having a fusibility with the inner layer or the second middle layer, the second middle layer comprises an ethylene-vinyl alcohol copolymer resin having an oxygen barrier property, the third middle layer comprises an adhesive polyolefin resin having a fusibility with the second middle layer or the outer layer, and having a low moisture permeability, and the outer layer comprises a thermoplastic resin or elastomer. Accordingly, an ink supply tube for an inkjet printer is provided that has a more excellent oxygen barrier property and a more excellent low moisture permeability in addition to an excellent solvent resistance and an excellent flexibility.

Owner:HAKKO CO LTD

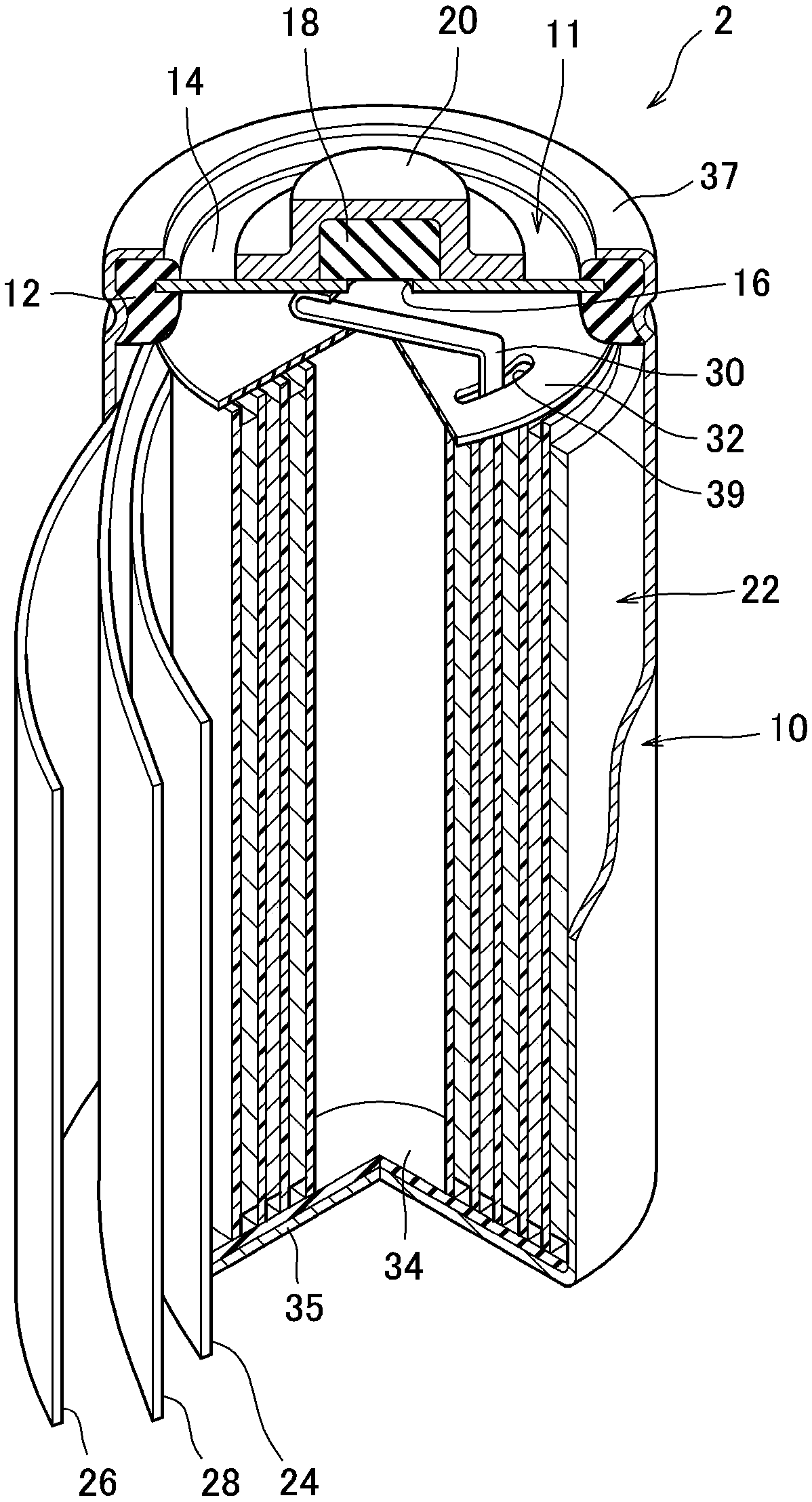

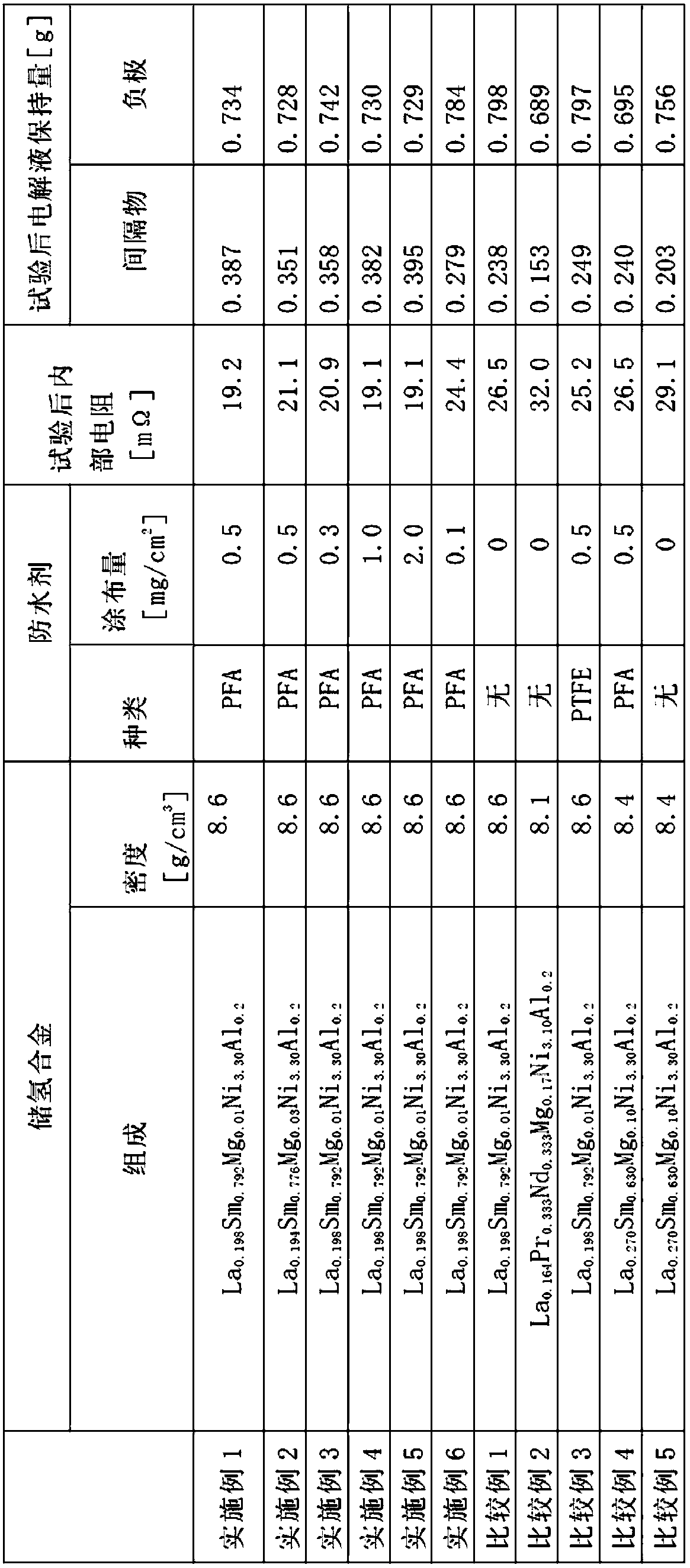

Negative electrode for nickel hydrogen secondary battery, and nickel hydrogen secondary battery including the negative electrode

ActiveCN109768225AGood three-phase interfaceExtend your lifeNegative electrodesAlkaline accumulator electrodesRare-earth elementElectrical battery

The nickel hydrogen secondary battery (2) has an electrode group (22) including a separator (28), a positive electrode (24) and a negative electrode (26), wherein the negative electrode (26) has a negative electrode core, and a negative electrode mixture held on the negative electrode core, wherein the negative electrode mixture contains a hydrogen absorbing alloy and a water repellent, wherein the hydrogen absorbing alloy has a composition represented by the general formula: Ln 1-x Mg x Ni y-a-b Al a M b (wherein Ln represents at least one element selected from rare earth elements, Ti and Zr;M represents at least one element selected from V, Nb, Ta, and the like; and the subscripts a, b, x and y satisfy relations represented by 0.05 <= a <= 0.30, 0 <= b <= 0.50, 0 <= x < 0.05 and 2.8 <=y <= 3.9, respectively), and has a structure of an A 2 B 7 type; and the water repellent comprises a perfluoroalkoxyalkane.

Owner:FDK CORP

Vibration damping device of inverted structure

The invention provides a vibration damping device of an inverted structure having a lower friction property. A low-friction lubricant and a low-friction sleeve are provided between the working cylinder and the outer cylinder. The vibration damping device of an inverted structure includes a cylinder, a rod capable of protruding and retracting in the cylinder, an outer cylinder coupled to the rod and inserted over the outer periphery of the cylinder, and a bush slidably inserted between the outer cylinder and the cylinder. A gap between the outer cylinder and the cylinder is filled with lubricating oil. The bush contains polytetrafluoroethylene and perfluoro alkoxy alkane. The lubricating oil contains an organic molybdenum additive.

Owner:HONDA MOTOR CO LTD

Hermetic chip on board

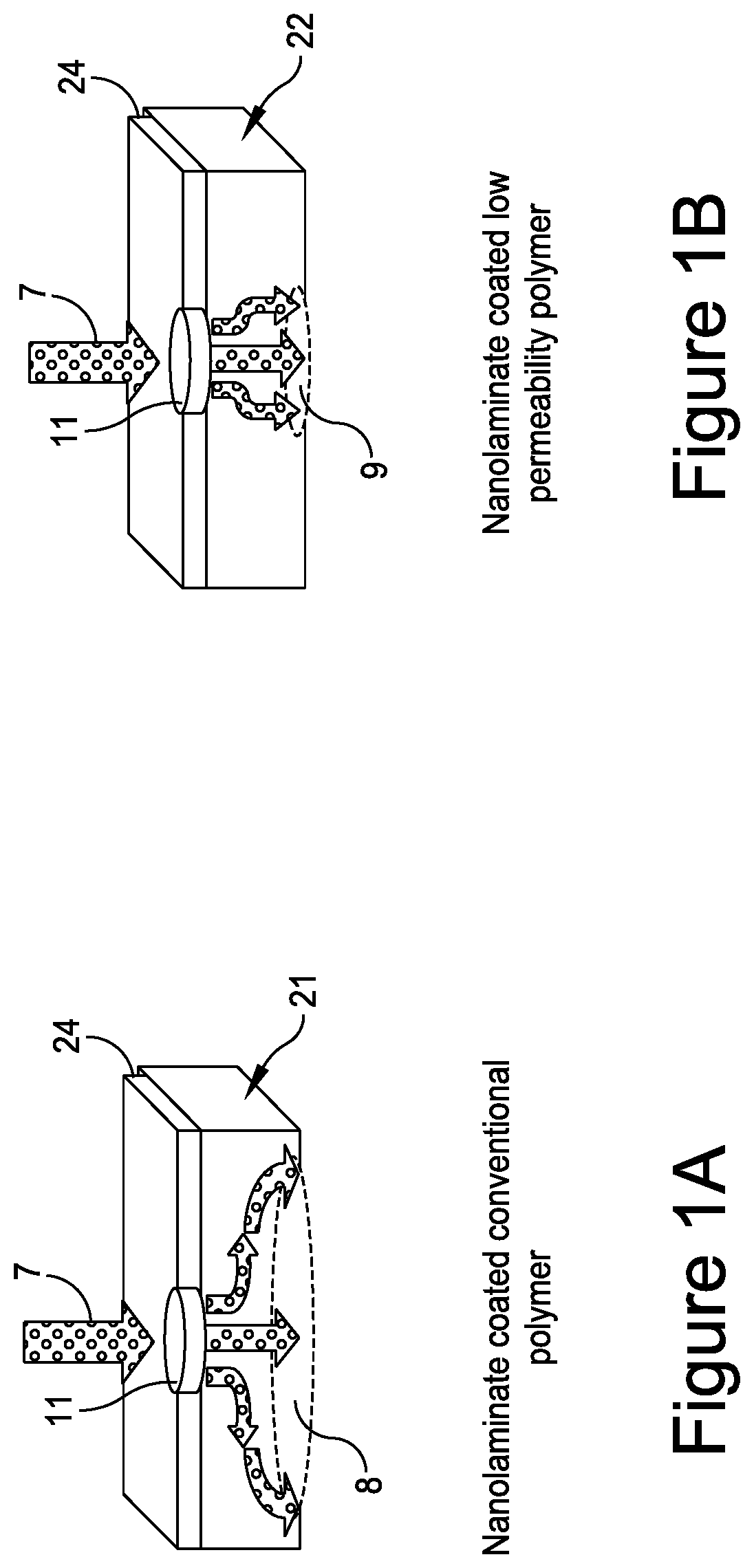

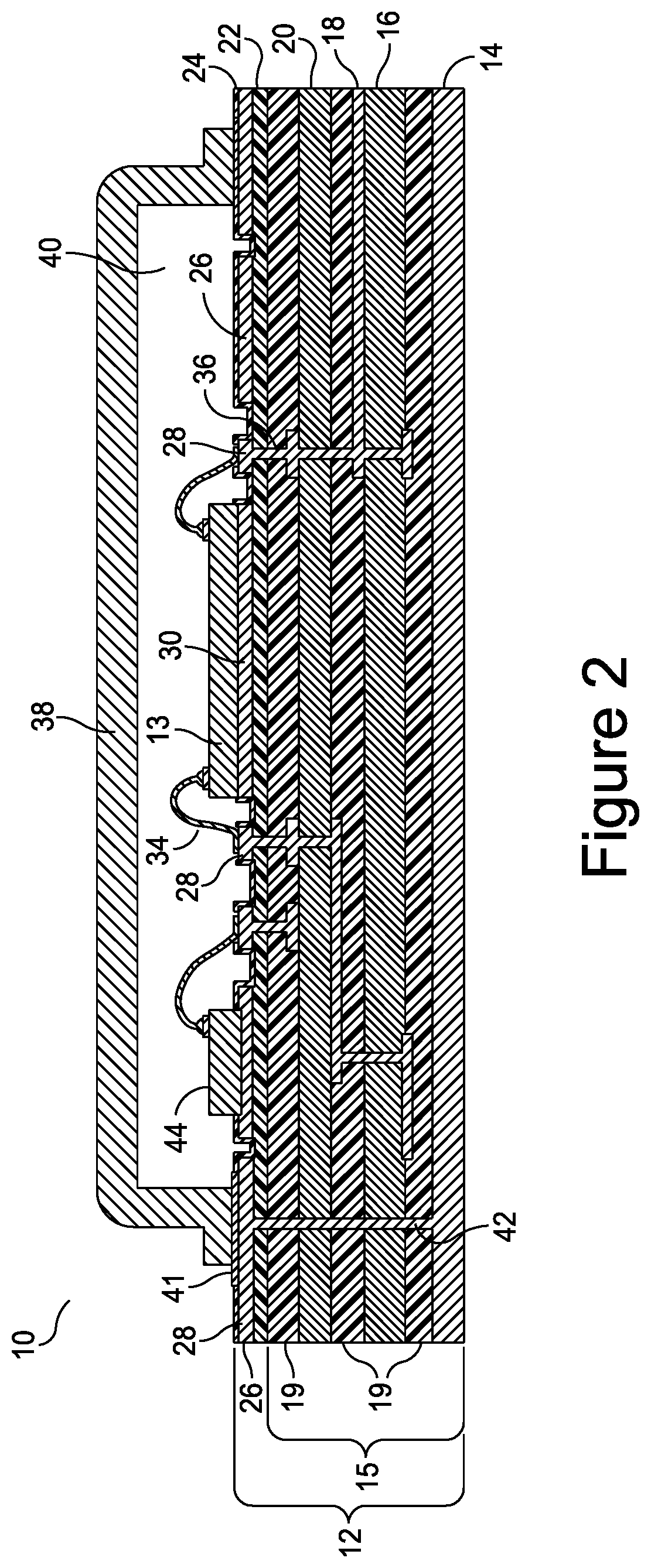

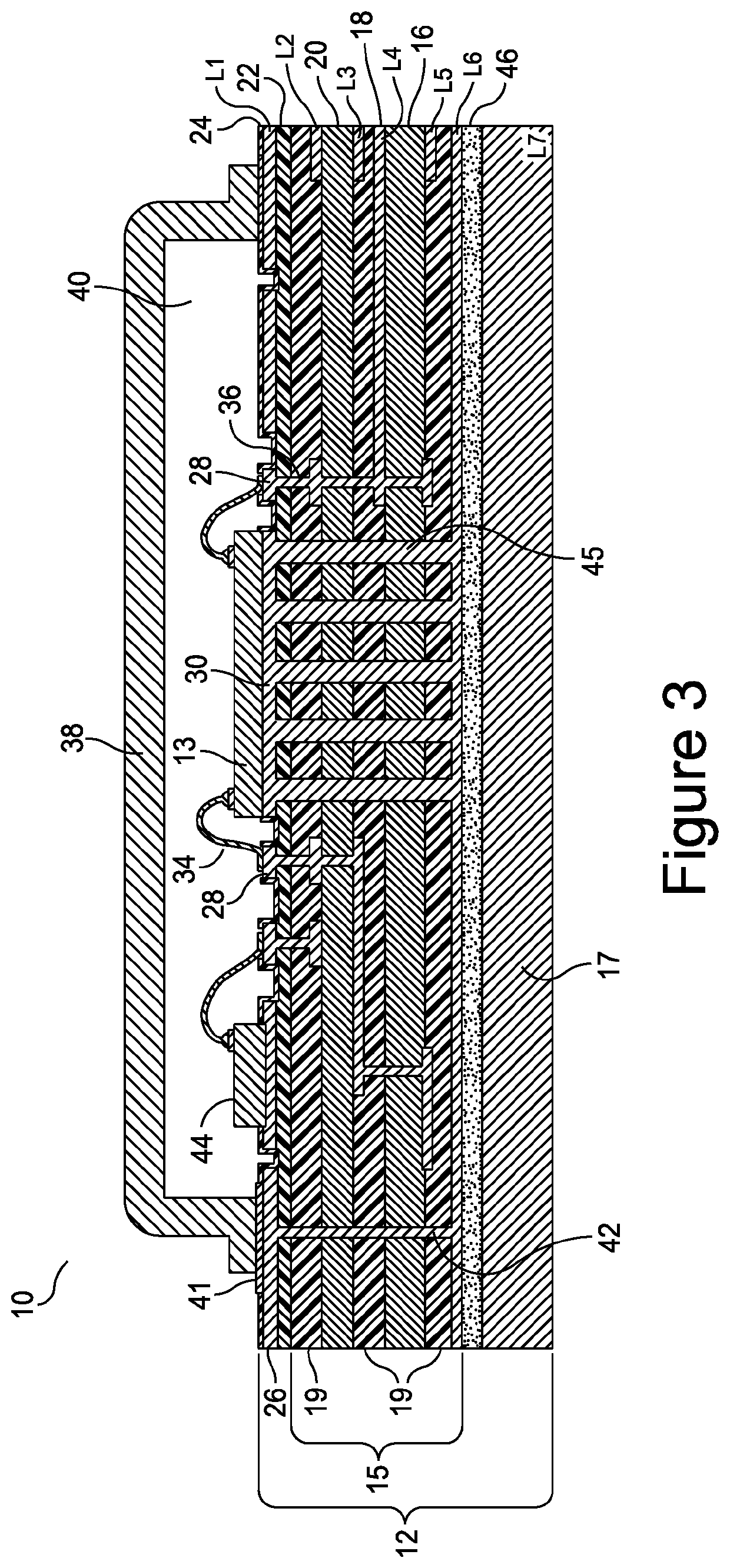

ActiveUS20200359506A1Reduce penetrationImprove permeabilitySemiconductor/solid-state device detailsSolid-state devicesAlkaneParylene

A low permeability laminate film includes one or more low moisture permeability homogeneous polymer films with a total thickness between 0.5 and ten mils without glass or ceramic fillers and with a moisture permeability measured at 37° C. and 100% RH of less than 2.6 E-05 atm·cc·mm / in2·sec of air. The polymer film includes one of polychlorotrifluoroethylene, polytetrafluorethylene, fluorinated ethylene propylene, and perfluoro alkoxy alkane. The low permeability laminate film further includes a nanolaminate including alternate combinations of nanolaminate material that is selected from the group consisting of alumina, titanium dioxide, zirconium oxide, beryllium oxide, hafnium oxide, titanium oxide, silicon nitride, tantalum nitride, silica, parylene F, parylene AF-4, parylene HT® and PTFE (polytetrafluoroethylene). A resulting coated nanolaminate film has a moisture permeability less than an equivalent standard leak rate per square inch of 3.0 E-08 atm·cc / in2·sec of air.

Owner:RAYTHEON CO

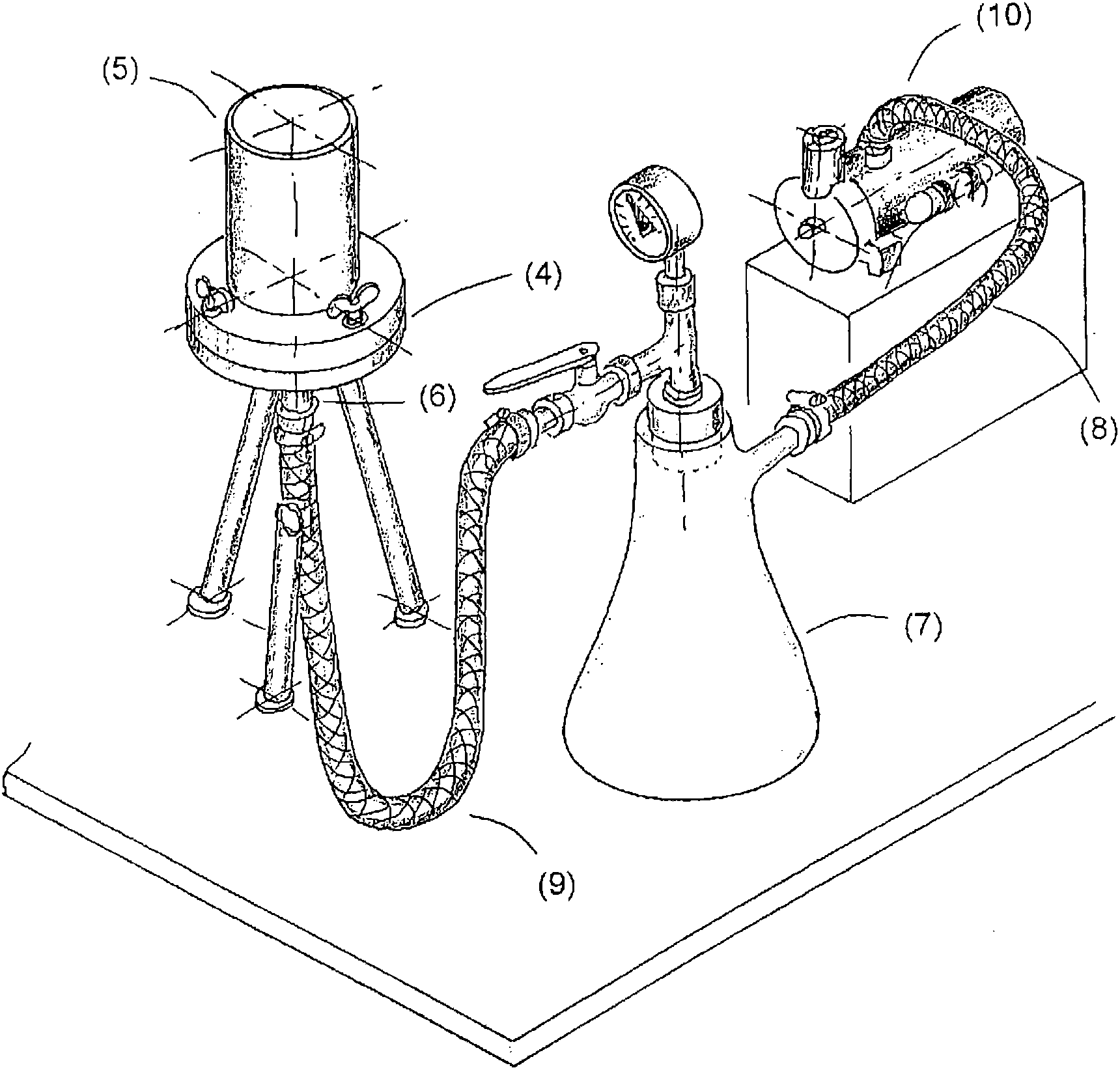

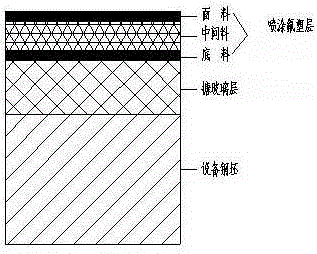

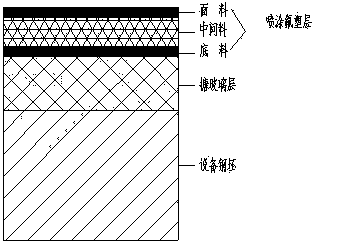

A method for manufacturing glass-lined workpieces by spraying fluorine plastic on the outside

ActiveCN104209251BImprove anti-corrosion performanceWide range of applicable mediaPretreated surfacesCoatingsSand blastingTemperature difference

The invention provides a manufacturing method for fluorine plastic injection outside a glass lining workpiece. The manufacturing method is characterized by comprising the following steps: step one, carrying out thorough clearing sand blasting on the surface of a metal blank body, and then enameling a ceramic glaze coating with uniform thickness on the surface; step two, uniformly spraying a fluorine plastic layer on the surface of the glass lining workpiece, and spraying on the surface of the glass lining workpiece in sequence, wherein the fluorine plastic layer is divided into a base material, a middle material and a surface material; step three, clearing the surface, and carrying out 20kv high-voltage discharge test to complete the preparation of the workpiece. The method for preparing the workpiece is wider in applicable medium, the surging range of temperature difference is improved, and the method has the obvious advantages of good medium permeability resistance, long service life, lower cost and the like; a PFA (Perfluoroalkoxy alkane) coating sprayed on the surface can compensate the defects of dark bubbles, pinholes and the like which are undetected by glass lining equipment; the temperature difference surging resistance of the equipment is further increased, and the risk of glass lining explosion caused by temperature difference surging is reduced.

Owner:NANJING ZHENGYUAN ENAMEL EQUIP MFG

Manufacturing method for fluorine plastic injection outside glass lining workpiece

ActiveCN104209251AImprove anti-corrosion performanceWide range of applicable mediaPretreated surfacesCoatingsSand blastingTemperature difference

The invention provides a manufacturing method for fluorine plastic injection outside a glass lining workpiece. The manufacturing method is characterized by comprising the following steps: step one, carrying out thorough clearing sand blasting on the surface of a metal blank body, and then enameling a ceramic glaze coating with uniform thickness on the surface; step two, uniformly spraying a fluorine plastic layer on the surface of the glass lining workpiece, and spraying on the surface of the glass lining workpiece in sequence, wherein the fluorine plastic layer is divided into a base material, a middle material and a surface material; step three, clearing the surface, and carrying out 20kv high-voltage discharge test to complete the preparation of the workpiece. The method for preparing the workpiece is wider in applicable medium, the surging range of temperature difference is improved, and the method has the obvious advantages of good medium permeability resistance, long service life, lower cost and the like; a PFA (Perfluoroalkoxy alkane) coating sprayed on the surface can compensate the defects of dark bubbles, pinholes and the like which are undetected by glass lining equipment; the temperature difference surging resistance of the equipment is further increased, and the risk of glass lining explosion caused by temperature difference surging is reduced.

Owner:NANJING ZHENGYUAN ENAMEL EQUIP MFG

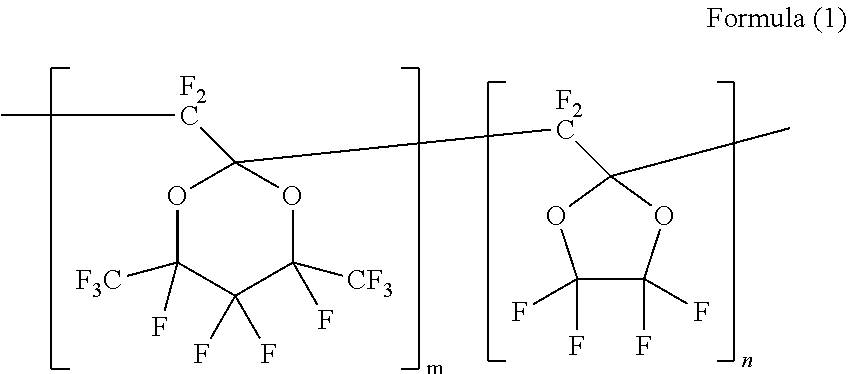

Resin composition and article made therefrom

A resin composition includes 100 parts by weight of a fluorine-containing compound and 1 part by weight to 15 parts by weight of a compound of Formula (1); in Formula (1), m and n are individually an integer of 10 to 100; and the fluorine-containing compound includes tetrafluoroethylene homopolymer, perfluoroalkoxy alkane or a combination thereof. Moreover, also provided is an article made from the resin composition, which comprises a prepreg, a resin film, a laminate or a printed circuit board, wherein the article achieves improvement in at least one of the following properties: dielectric constant, dissipation factor, Z-axis coefficient of thermal expansion, MIT bending resistance and tensile strength.

Owner:ELITE MATERIAL

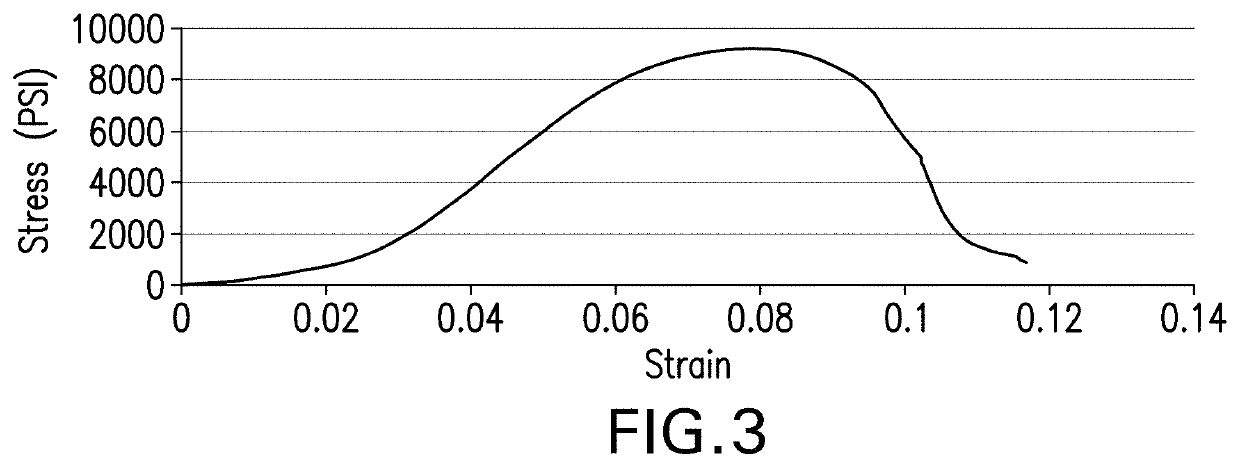

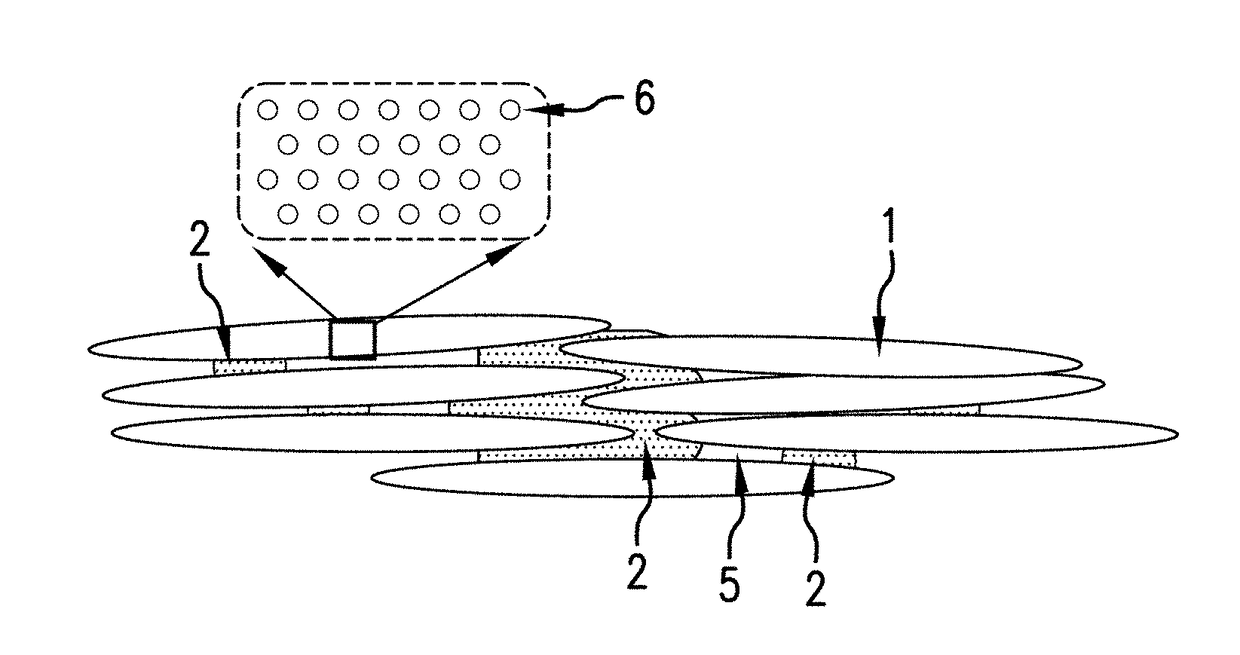

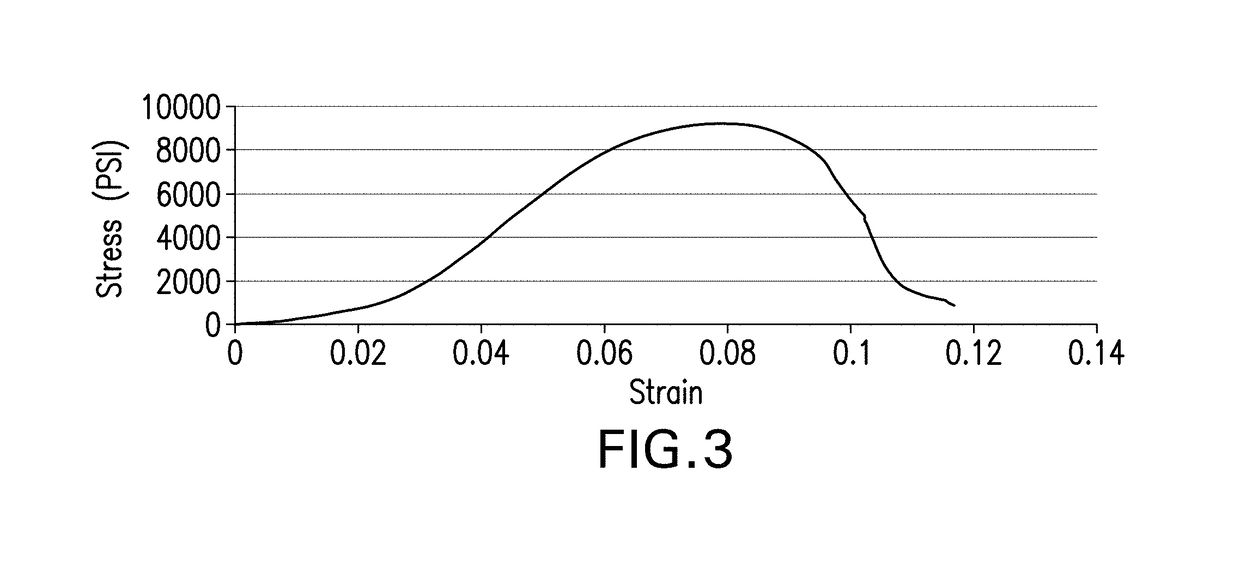

Acid resistant carbon composites, methods of manufacture, and articles formed thereof

An article comprising a carbon composite containing carbon microstructures having interstitial spaces among the carbon microstructures; and a binder disposed in at least some of the interstitial spaces; wherein the carbon microstructures comprise unfilled voids within the carbon microstructures; and the binder comprises one or more of the following: polytetrafluoroethylene; polyvinyl fluoride; polyvinylidene fluoride; polychlorotrifluoroethylene; perfluoroalkoxy alkane; fluorinated ethylene propylene; ethylene tetrafluoroethylene; ethylene chlorotrifluoroethylene; a peroxide cured copolymer of tetrafluoroethylene and propylene; a fluorocarbon rubber; perfluorocarbon rubber; or a perfluoropolyether.

Owner:BAKER HUGHES INC

Acid resistant carbon composites, methods of manufacture, and articles formed thereof

ActiveUS20180298158A1Overcome deficienciesEngine sealsWell/borehole valve arrangementsCarbon compositesPolymer science

An article comprising a carbon composite containing carbon microstructures having interstitial spaces among the carbon microstructures; and a binder disposed in at least some of the interstitial spaces; wherein the carbon microstructures comprise unfilled voids within the carbon microstructures; and the binder comprises one or more of the following: polytetrafluoroethylene; polyvinyl fluoride; polyvinylidene fluoride; polychlorotrifluoroethylene; perfluoroalkoxy alkane; fluorinated ethylene propylene; ethylene tetrafluoroethylene; ethylene chlorotrifluoroethylene; a peroxide cured copolymer of tetrafluoroethylene and propylene; a fluorocarbon rubber; perfluorocarbon rubber; or a perfluoropolyether.

Owner:BAKER HUGHES INC

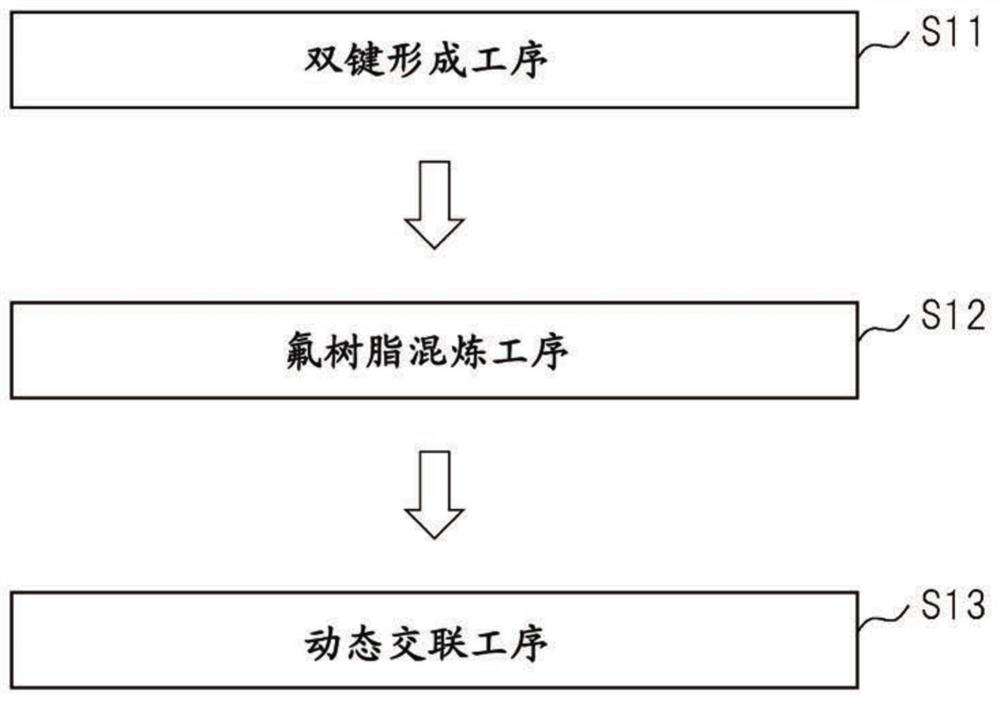

Thermoplastic Fluororesin Composition, Electric Wire and Cable

PendingUS20220145060A1Improve the heating effectMaintain good propertiesRubber insulatorsPlastic/resin/waxes insulatorsAlkanePolymer science

An electric wire uses a thermoplastic fluororesin composition as an insulating layer covering a periphery of a conductor. The thermoplastic fluororesin composition includes a fluororubber, a fluororesin and a compatibilizer. The fluororesin includes a first fluororesin constituted by perfluoroalkoxy alkane having a melting point of 280° C. or more and 290° C. or less, and the compatibilizer is a terpolymer of tetrafluoroethylene, hexafluoropropylene and vinylidene fluoride. A weight ratio (%) of the fluororubber to the fluororesin ranges from 20:80 to 60:40, and the fluororubbers are crosslinked to one another by dynamic crosslinking.

Owner:PROTERIAL LTD

Composite mechanical material and machining technology thereof

InactiveCN109434097ASimple preparation processLow costTransportation and packagingMetal-working apparatusGraphiteTitanium powder

The invention discloses a composite mechanical material and a machining technology thereof. The mechanical material is composed of the following components of, in parts by mass, 30-40 parts of calciumcarbonate, 10-20 parts of graphite powder, 5-10 parts of perfluoroalkoxy alkane resin, 5-10 parts of modified epoxy resin, 5-10 parts of tungsten carbide, 5-8 parts of titanium powder, 2-5 parts of trisodium phosphate, and the balance iron. The material has the beneficial effects that the preparation process is simple, the cost is low, the service life is long, the market requirements can be met,the industrial production is facilitated, and the material is suitable for popularization and application.

Owner:徐州特普勒金属科技有限公司

High thermal conductivity, vacuum resistance, high temperature resistance and anti-corrosion coating

ActiveCN106810964BImprove bindingFlat surfaceFireproof paintsLiquid surface applicatorsEngineering plasticSulfide

Owner:SHANDONG KAISHENG NEW MATERIALS

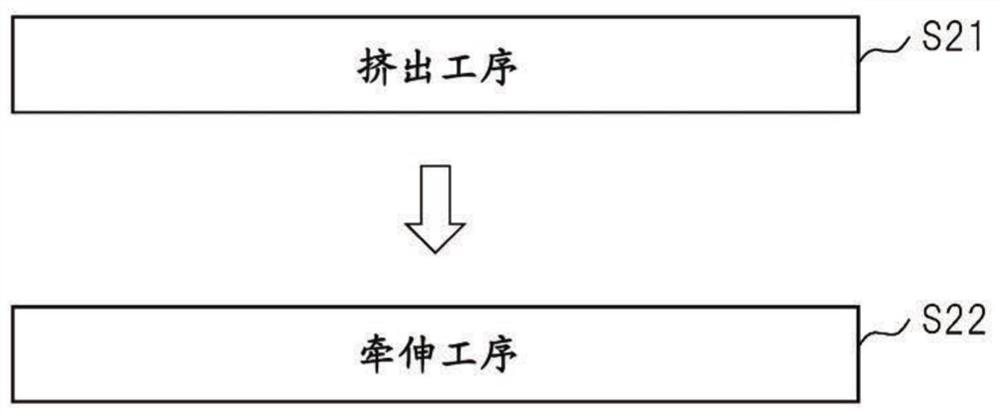

Electric wire manufacturing method and cable manufacturing method

InactiveCN111607178AExcellent mechanical propertiesImprove heat resistanceInsulating conductors/cablesAlkanePolymer science

The present invention provides an electric wire manufacturing method and a cable manufacturing method. A thermoplastic fluororesin composition is used, and the electric wire and the cable have excellent mechanical properties and heat resistance. The electric wire manufacturing method comprises (S21) a step for extruding the thermoplastic fluororesin composition so as to cover the periphery of a conductor, and (S22) a step for forming an insulating layer around the conductor by drawing the thermoplastic fluororesin composition extruded in the extrusion step (S21). The thermoplastic fluororesincomposition contains a fluororubber, a fluororesin and a compatibilizing agent, the fluororesin contains a perfluoroalkoxy alkane having a melting point of 300 DEG C or more and less than 310 DEG C, and the fluororubber is crosslinked by dynamic crosslinking in the thermoplastic fluororesin composition. The extrusion step (S21) is performed at a temperature equal to or higher than the melting point of the perfluoroalkoxy alkane and lower than the melting point + 10 DEG C.

Owner:HITACHI METALS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com