Ink supply tube

A technology for ink supply tubes and intermediate layers, applied in the direction of hoses, tubes, tubes/pipe joints/fittings, etc., which can solve problems such as poor ejection, adverse effects on printing quality, and nozzle clogging of print heads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

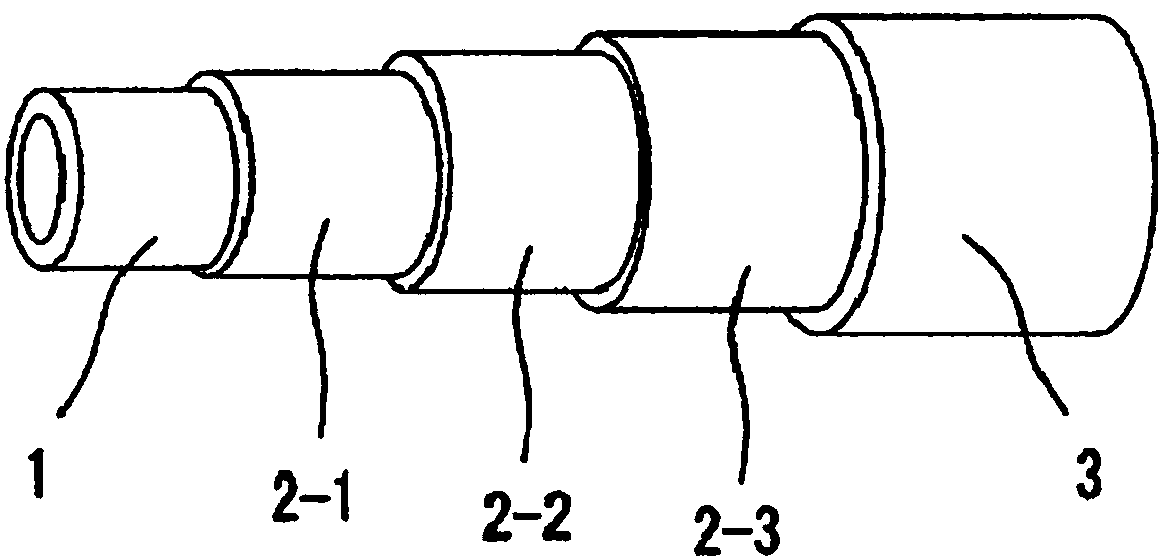

[0057] Will figure 1 Each layer in the film was made into the following component composition, and the ink supply tube of Example 1 was manufactured.

[0058] Inner layer 1: Fluorine resin (manufactured by Asahi Glass Co., Ltd.; ethylene-tetrafluoroethylene copolymer resin (ETFE-based resin); layer thickness: 50 μm)

[0059] First intermediate layer 2-1: polyamide resin (manufactured by Ube Industries, Ltd. (Ube Industries, Ltd.); polyamide 12; layer thickness: 30 μm)

[0060] Second intermediate layer 2-2: Ethylene-vinyl alcohol copolymer resin (EVOH resin) (manufactured by Kuraray Co., Ltd. (Kurare Co., Ltd.); ethylene-vinyl alcohol copolymer resin; layer thickness: 30 μm)

[0061] Third intermediate layer 2-3: adhesive polyolefin resin (manufactured by Mitsubishi Chemical Corporation; acid-modified polyethylene; layer thickness: 30 μm)

[0062] Outer layer 3: Ethylene-based polymer (manufactured by Mitsui DuPont Chemical Co., Ltd.; Ethylene-based polymer; layer thickness:...

Embodiment 2

[0065] The ink supply tube of Example 2 was produced in the same manner as in Example 1, except that the outer layer 3 had the following composition.

[0066] Outer layer 3: polyolefin-based elastomer (manufactured by Prime Polymer Co., Ltd.; linear low-density polyethylene (L-LDPE); layer thickness: 260 μm).

Embodiment 3

[0068] The ink supply tube of Example 3 was produced in the same manner as in Example 2, except that the second intermediate layer 2-2 had the following component composition. In addition, polyester resin was compounded as a modifier in consideration of stress-crack resistance.

[0069] Second intermediate layer 2-2: ethylene-vinyl alcohol copolymer resin (EVOH resin) / polyester resin=80 / 20 (layer thickness: 30 μm)

[0070] EVOH resin: (manufactured by Kuraray Co., Ltd. (Kurare Co., Ltd.); ethylene-vinyl alcohol copolymer resin)

[0071] Polyester resin: (manufactured by Mitsubishi Chemical Corporation; polyester-based thermoplastic elastomer)

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com