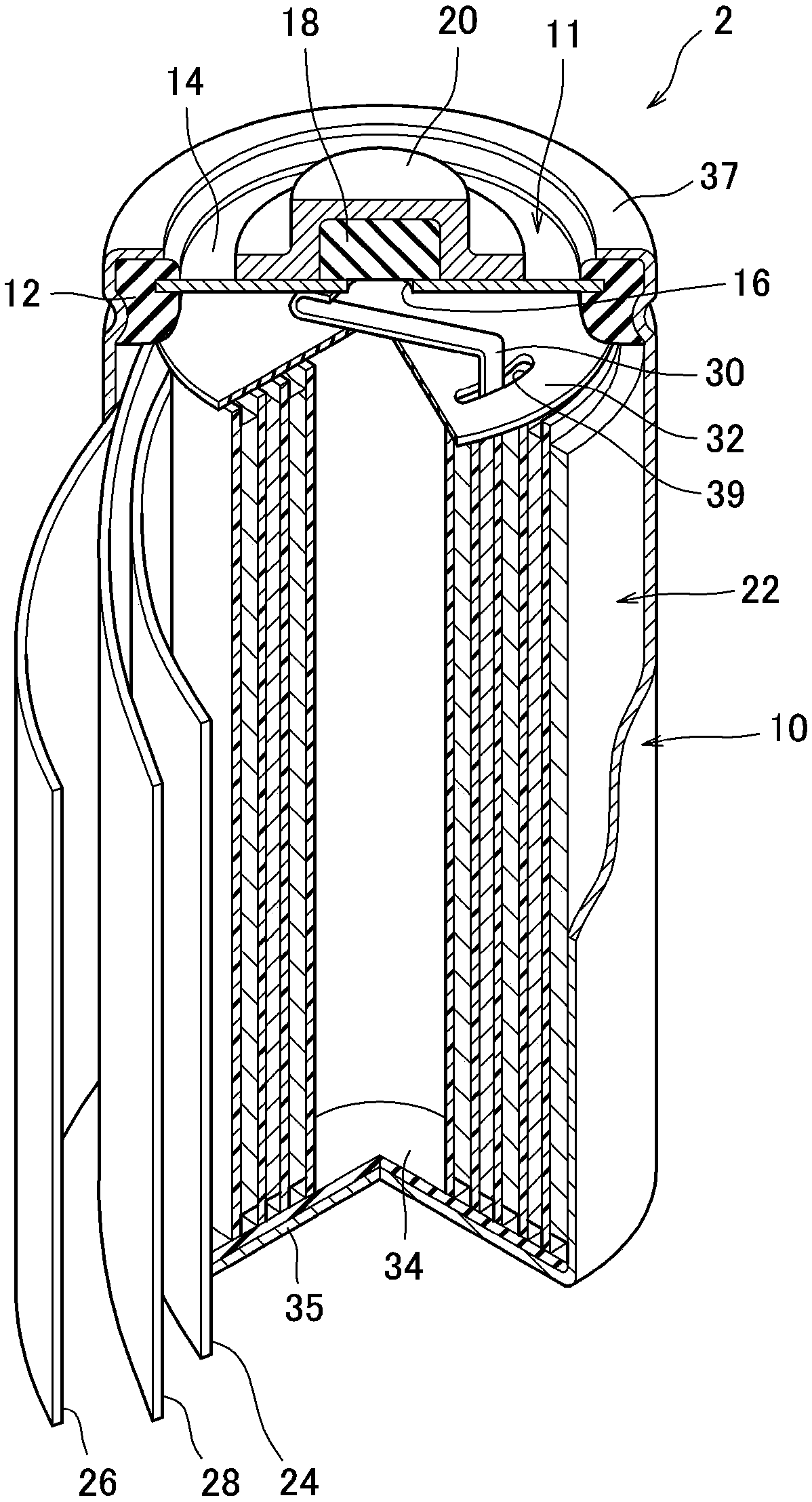

Negative electrode for nickel hydrogen secondary battery, and nickel hydrogen secondary battery including the negative electrode

A technology of secondary battery and negative electrode, applied in the direction of nickel battery, battery electrode, alkaline battery electrode, etc., can solve the problems of rising internal pressure of battery, failure of oxygen absorption reaction to proceed smoothly, and insufficient oxygen absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] (1) Manufacturing of positive electrode

[0070] Nickel sulfate, zinc sulfate, and cobalt sulfate were weighed under the conditions that zinc reached 2.5% by mass and cobalt reached 1.0% by mass relative to nickel, and added them to a 1N sodium hydroxide aqueous solution containing ammonium ions to prepare a mixed aqueous solution. While stirring the resulting mixed aqueous solution, a 10N sodium hydroxide aqueous solution was slowly added to the mixed aqueous solution to make it react, and the pH during the reaction was stabilized at 13-14, and a solid nickel hydroxide was produced. Matrix particles in which zinc and cobalt are dissolved.

[0071] After the obtained base particles were washed three times with a 10-fold amount of pure water, dehydration and drying were performed. The result of measuring the particle size of the prepared base particles by a laser diffraction scattering particle size distribution measuring device is that the average particle size of the base ...

Embodiment 2

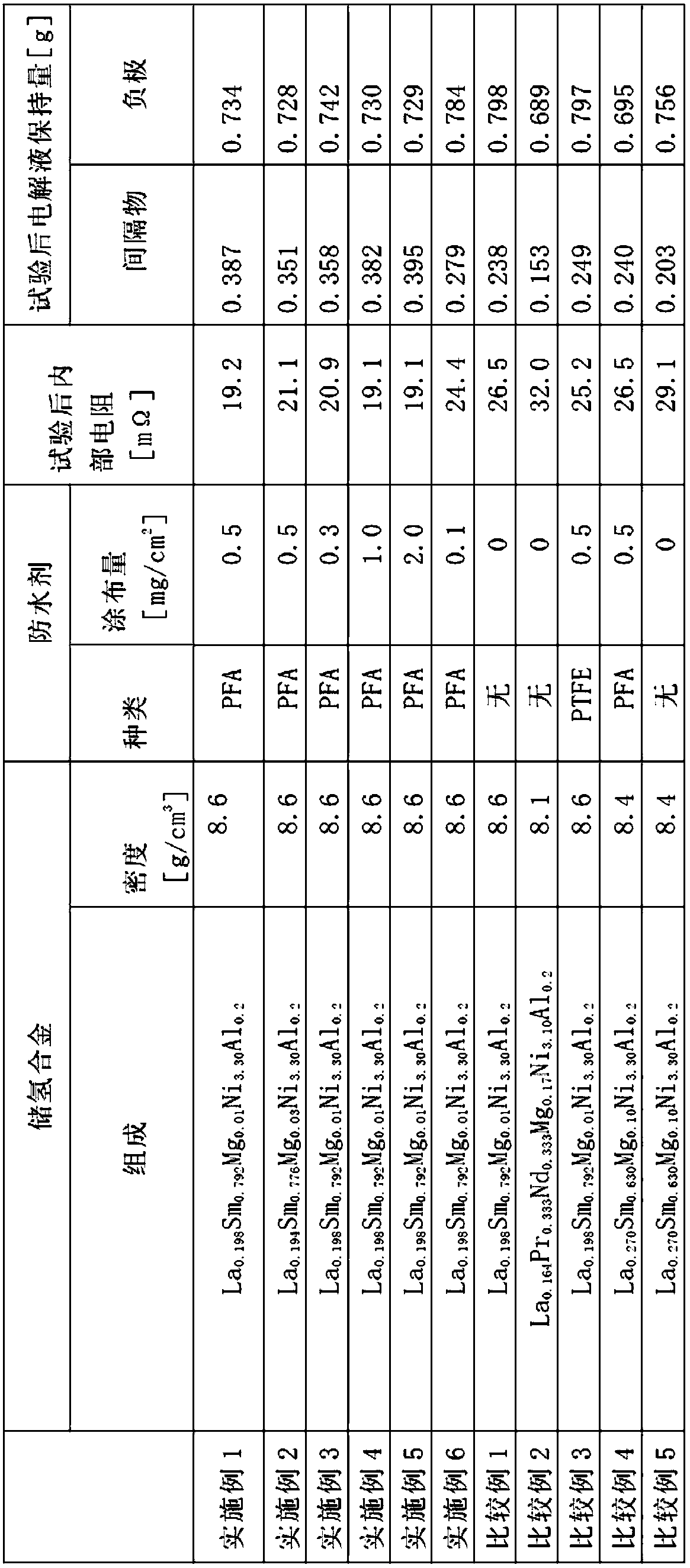

[0095] In addition to setting the composition of the hydrogen storage alloy to La 0.194 Sm 0.776 Mg 0.03 Ni 3.30 Al 0.2 Except this, in the same manner as in Example 1, a nickel-hydrogen secondary battery was produced. The density of the hydrogen storage alloy of Example 2 is 8.6g / cm 3 , The crystalline structure of the hydrogen storage alloy of Example 2 is A 2 B 7 type.

Embodiment 3

[0097] In addition to setting the mass of solid content per side of the PFA dispersion to 0.3 mg / cm 2 Except for coating the PFA dispersion on both sides of the intermediate product of the negative electrode, a nickel-hydrogen secondary battery was produced in the same manner as in Example 1. The density of the hydrogen storage alloy of Example 3 is 8.6g / cm 3 , The crystalline structure of the hydrogen storage alloy of Example 3 is A 2 B 7 type.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com