Washable mask core fiber filter material and preparation method thereof

A water-washable, fiber filtration technology, used in fiber processing, textiles and papermaking, non-woven fabrics, etc., can solve the problems of uncontrollable membrane cross-linking process, easy peeling, weak single-layer membrane strength, etc., to solve the cross-linking process. uncontrollable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A core fiber filter material of a washable mask and a preparation method thereof, the steps are as follows:

[0031] (1) Polyurethane is dissolved in N,N-dimethylformamide and preparation concentration is the solution of 25wt%, wherein the concentration of crosslinking agent orthosilicate is 0.004wt%; Polyimide is dissolved in N simultaneously , in N-dimethylformamide, prepare a solution with a concentration of 20wt%, wherein the concentration of the crosslinking agent N,N'-1,4-phenylene bismaleimide is 0.002wt%.

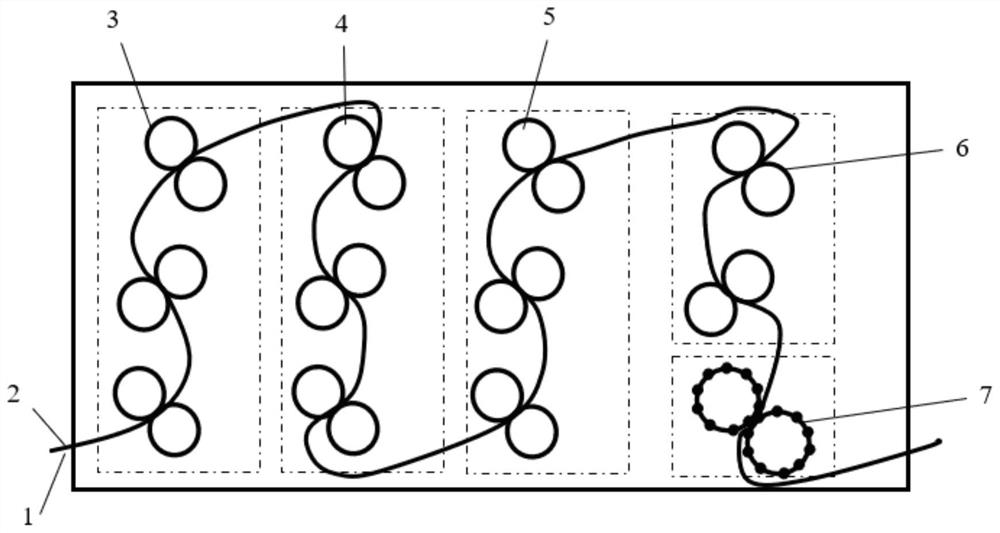

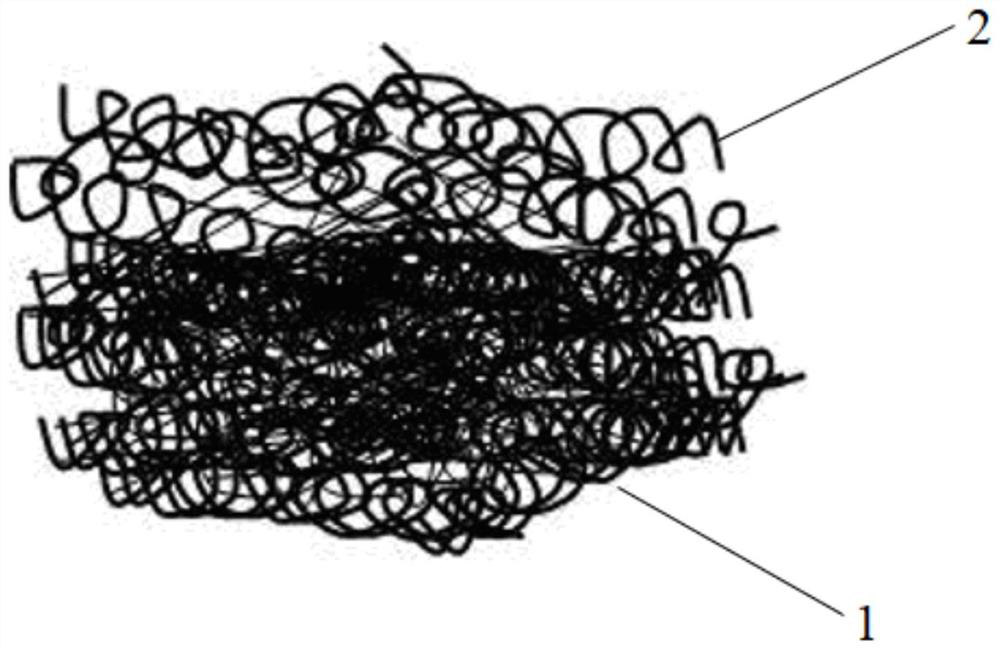

[0032] (2) Place the polyurethane spinning solution prepared in step 1 in the liquid supply device, adjust the electrospinning process parameters: voltage 40kV, spinning distance 40cm, spinning speed 1m / min, spinning ambient temperature 25°C, Humidity 30%; start the high-voltage power supply, start electrospinning, and deposit a dense layer of nanofibers on the receiving device, in which the diameter of the nanofibers is 0.3 μm, the pore size of the dense lay...

Embodiment 2

[0037] A core fiber filter material of a washable mask and a preparation method thereof, the steps are as follows:

[0038] (1) Dissolve polyacrylonitrile in dimethyl sulfoxide to prepare a solution with a concentration of 22wt%, wherein the concentration of the crosslinking agent orthosilicate is 0.005%; simultaneously dissolve polyimide in N, N - In dimethylformamide, prepare a solution with a concentration of 25 wt%, wherein the concentration of the cross-linking agent N,N'-1,4-phenylene bismaleimide is 0.01 wt%.

[0039] (2) Place the polyacrylonitrile spinning solution prepared in step 1 in the liquid supply device, and adjust the electrospinning process parameters: voltage 40kV, receiving distance 40cm, perfusion speed 1m / min, spinning temperature 25°C, relative environment Humidity 20%; start the high-voltage power supply, start electrospinning, and deposit a dense layer of nanofibers on the receiving device, wherein the diameter of the nanofibers is 0.04 μm, the pore s...

Embodiment 3

[0044] A core fiber filter material of a washable mask and a preparation method thereof, the steps are as follows:

[0045] (1) dissolving polyvinylidene fluoride in N,N-dimethylformamide to prepare a solution with a concentration of 18wt%, wherein the concentration of the crosslinking agent orthosilicate is 0.5wt%; Dissolved in dichloromethane to prepare a solution with a concentration of 22 wt%, in which the concentration of the crosslinker 2,2'-bis[4-(4-maleimidophenoxy)phenyl]propane was 0.6 wt% .

[0046] (2) Place the polyvinylidene fluoride spinning solution prepared in step 1 in the liquid supply device, adjust the electrospinning process parameters: voltage 50kV, receiving distance 45cm, perfusion speed 1.5m / min, spinning temperature 30°C, The relative humidity of the environment is 25%; start the high-voltage power supply, start electrospinning, and the dense layer of nanofibers is deposited on the receiving device. The diameter of the nanofibers is 0.03 μm, the por...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com