Patents

Literature

41results about How to "Membrane surface smooth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Automobile bumper spraying process

InactiveCN105013685AImprove surface qualityMembrane surface smoothPretreated surfacesCoatingsControl parametersEngineering

The invention discloses an automobile bumper spraying process. The automobile bumper spraying process includes the specific processes of workpiece transfer, shielding, piece feeding, surface wiping, workpiece grinding, electrostatic dust removal on primer, primer spraying, primer airing, primer grinding, electrostatic dust removal on colored paint, colored paint spraying, colored paint airing, varnish spraying, varnish airing, drying, forced cooling, ornamenting and grinding, ornamenting and polishing, checkout and storage. By controlling parameters and operation of all procedures, the surface quality of a sprayed automobile bumper can be high, a film face where colored paint is sprayed is smooth, high in brightness, uniform in film face, capable of reaching the preset color and luster degree and not prone to color fading, and the product quality of the bumper can be ensured.

Owner:WUHU GUOFENG PLASTIC TECH

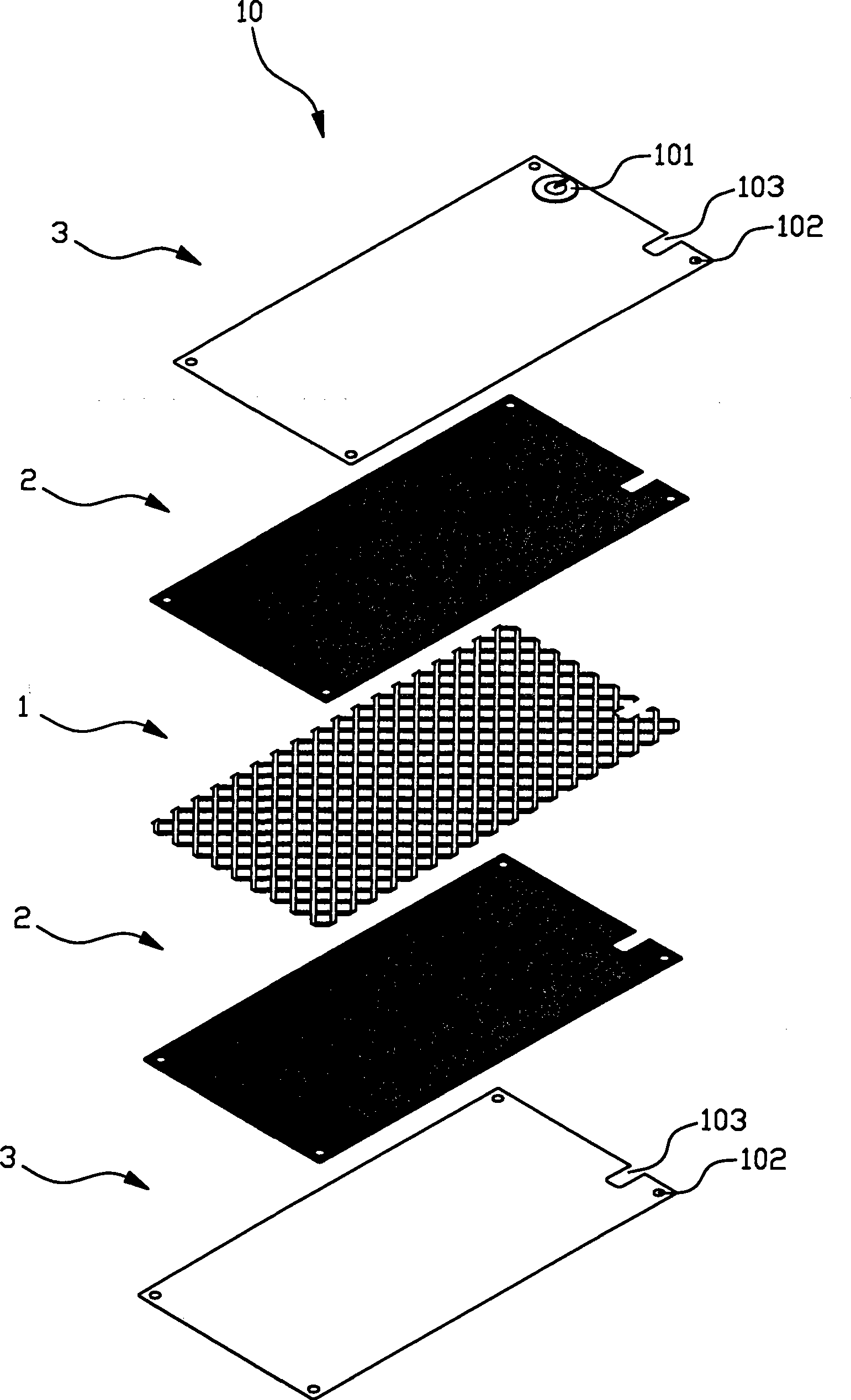

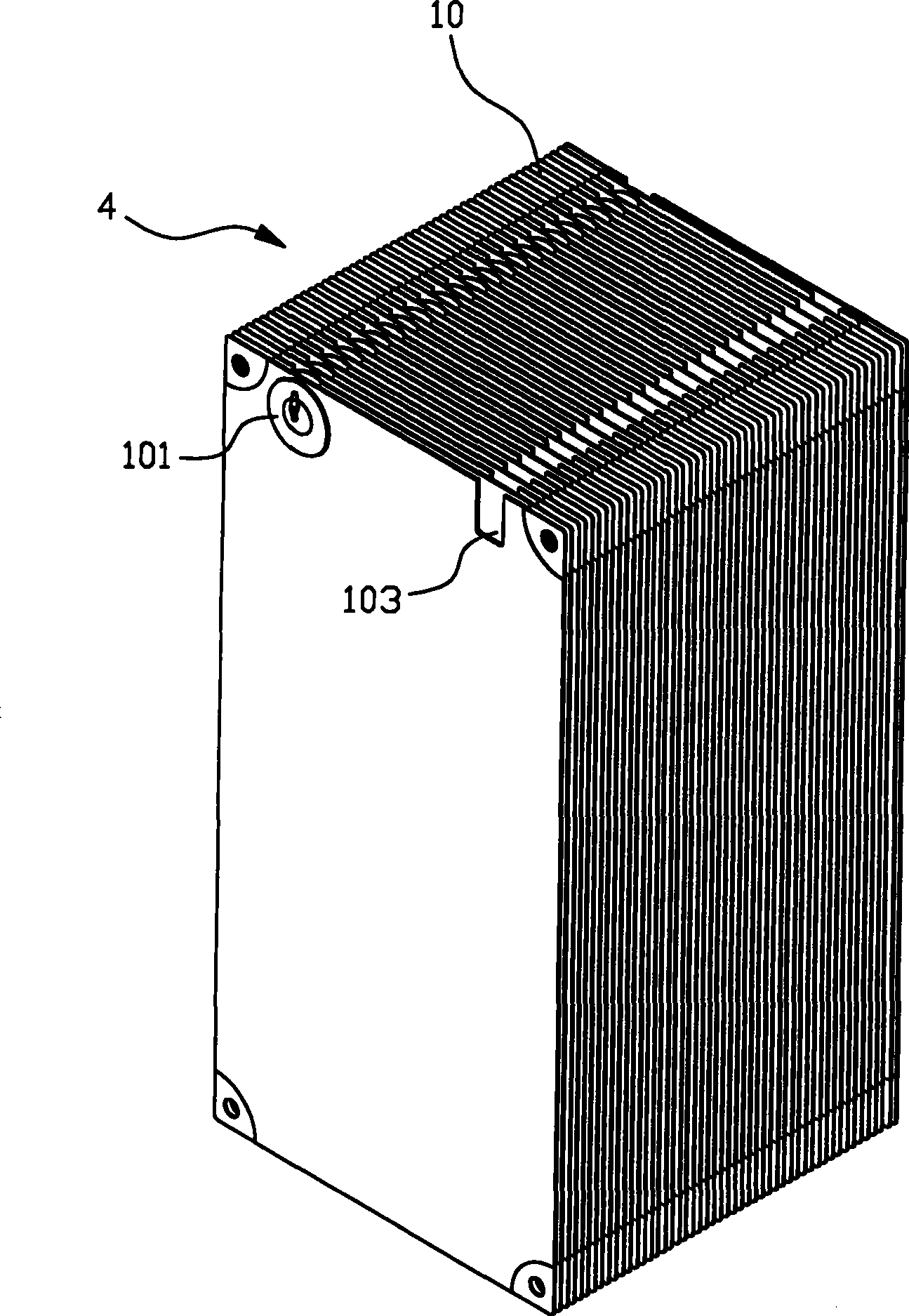

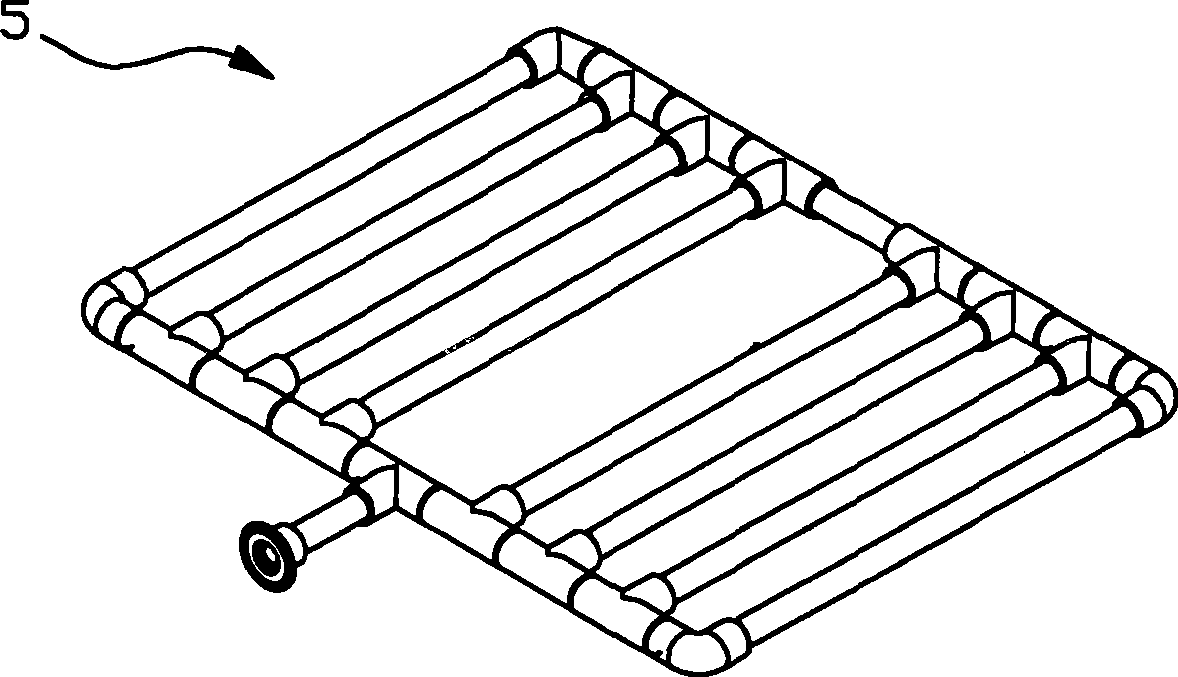

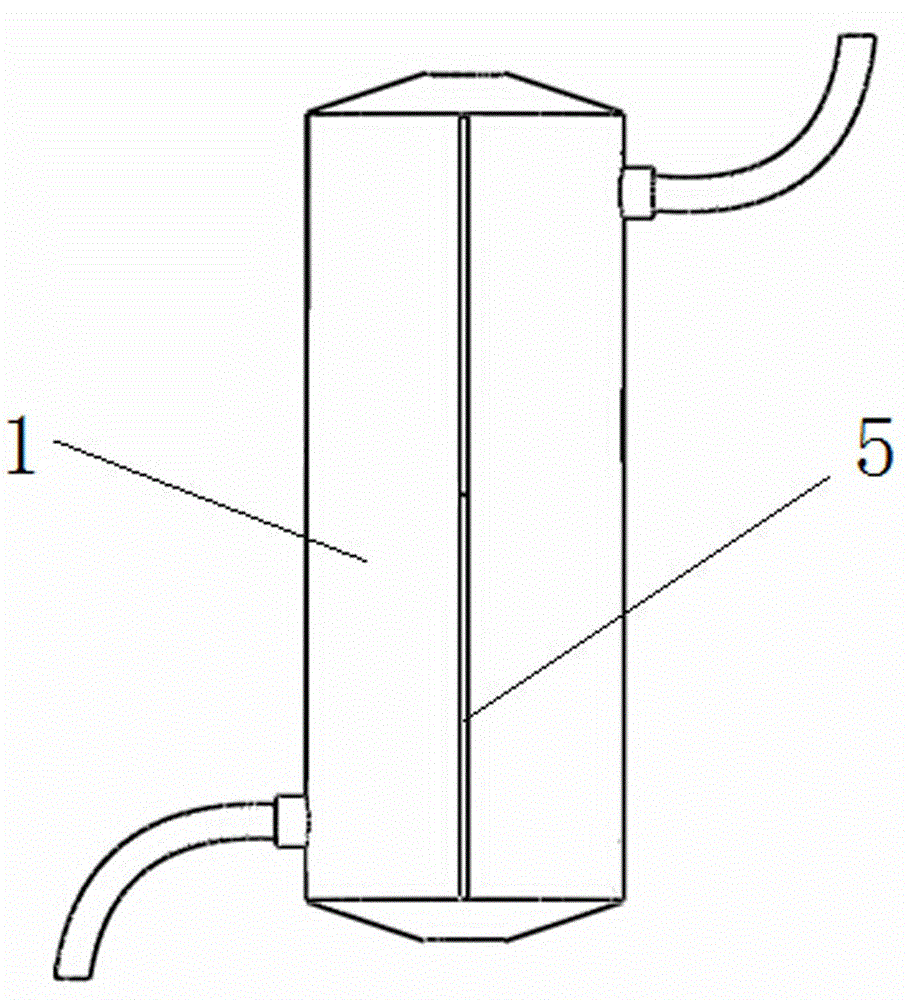

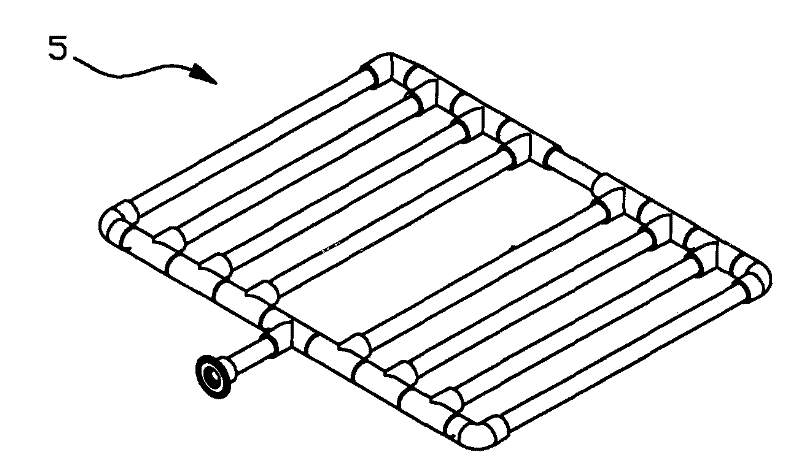

Filtering film bag and film bioreactor using the filtering film bag

ActiveCN101371971AMembrane surface smoothNot easy to hide dirtSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisFiltration membraneMembrane surface

The present invention relates to a filtering membrane packet which consists of five layers of materials at least, wherein, the central layer is filtering support gridding; the two sides of the filtering support gridding are provided with filtering support cloth respectively; the outer side of the filtering support cloth is provided with a filtering membrane respectively; the five layers of materials form a membrane packet with an integral closed structure. The surface of the membrane packet is provided with at least one collecting port used for leading filtrate in the membrane packet out. The present invention also provides a membrane biological reactor which uses the filtering membrane packet. The membrane biological reactor comprises a membrane packet component, an aerator pipe component, a filtrate collecting pipe component and a frame fixing component used for fixing the components into a whole. The present invention uses five layers of materials of the filtering support gridding, the filtering support cloth and the filtering membranes to form the membrane packet, the membrane surface is flat and is not dirty easily; the membrane biological reactor using the membrane packet is simple for aerating and flushing and has the small size of membrane components, the high quality of produced water, strong anti-pollution capacity, long service life of the membrane, easy maintenance and low manufacturing cost; and the present invention requires the user to invest low cost so that the membrane biological reactor can be popularized and applied widely.

Owner:SANDA FILM SCI & TECH XIAMEN

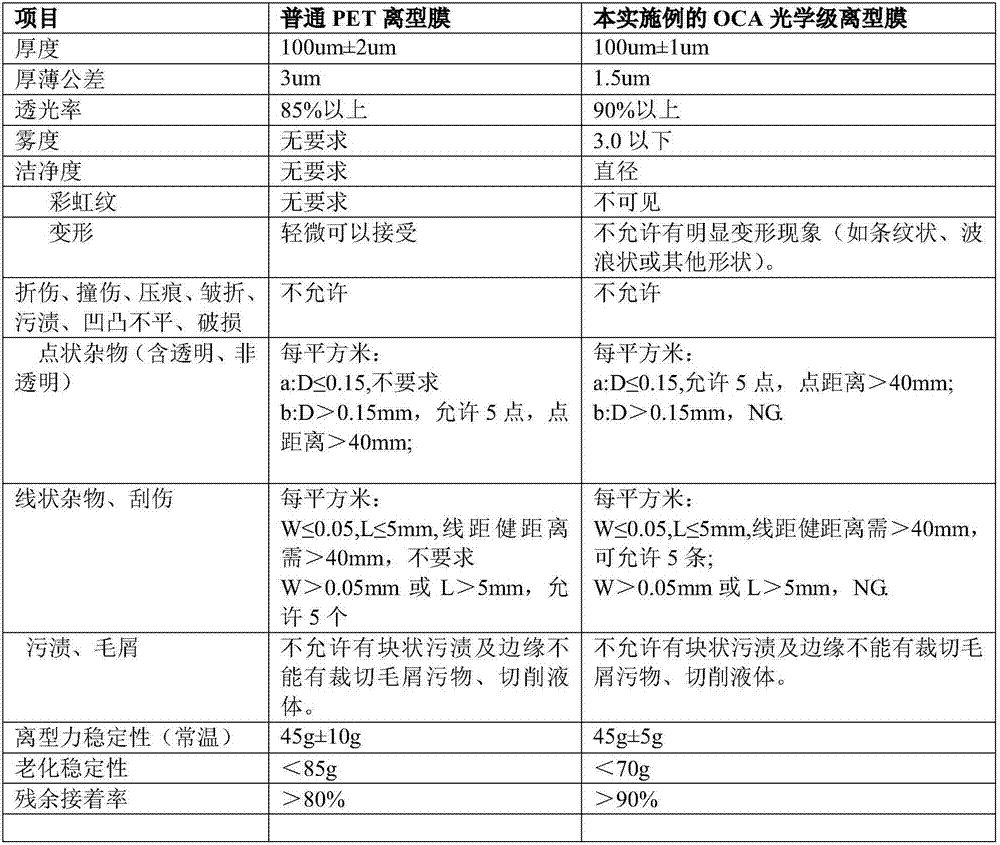

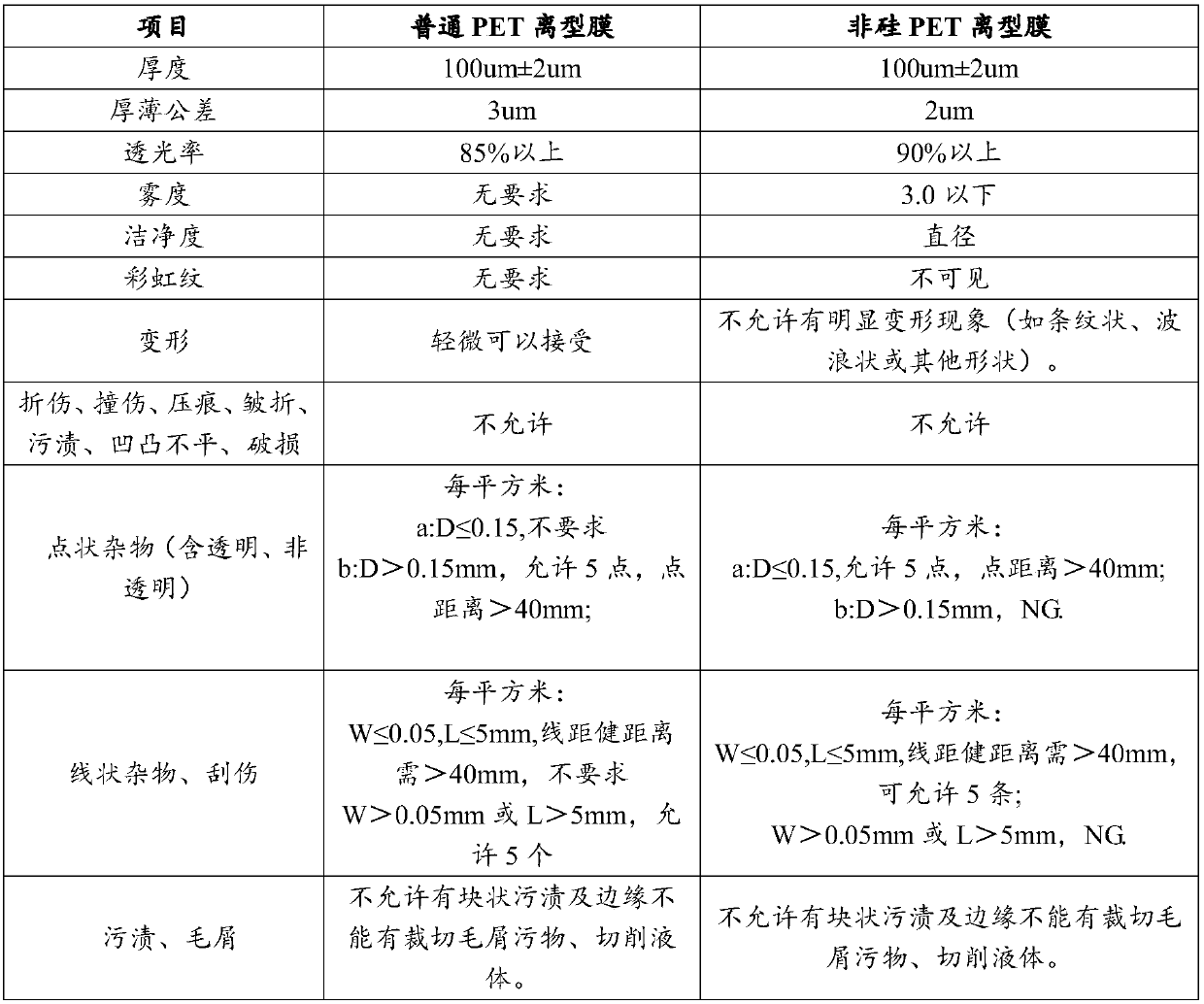

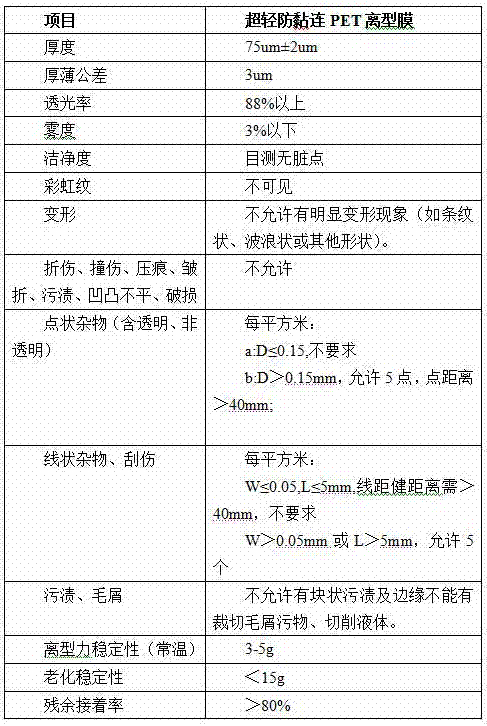

PET release film applied to OCA glue and production process thereof

The invention discloses a production process of a PET release film applied to OCA glue. The production process includes the steps that 1, a coating is prepared, wherein solvent oilD120, solvent oil D30, butanone and isopropanol are mixed to serve as a solvent; 2, a corona value is greater than 50 when a raw film is subjected to corona treatment, and a double-faced dust removal device is used for dust removal processing; 3, a precision coating mode is inverse coating, wherein the coating speed is 40 m / min; 4, drying and curing are performed; 5, material receiving and rolling are performed, wherein the tension during rolling is 230N, the taper is 50%, the pressure of a laminating roller is M: 0.4MPa / G: 0.4 MPa,the pressure of a traction roller is M: 0.2 MPa / G: 0.2 MPa; 6, post-curing treatment is performed at the temperature of 45 DEG C, and curing needs 48 hours. The light transmittance of the production process of the PET release film applied to the OCA glue is 90% or above, the haze is 3.0 or below, the release force stability (normal temperature) is 45 + / - 5 g, no visual particle nor foreign matter does not exist under a hundred times of a magnifying lens, a film surface is flat and free of longitudinal grains, water ripples, cross grains and obvious rainbow stripes, the aging stability is 70g or below, and the residual retention rate is 90% or above.

Owner:江阴华美光电科技有限公司

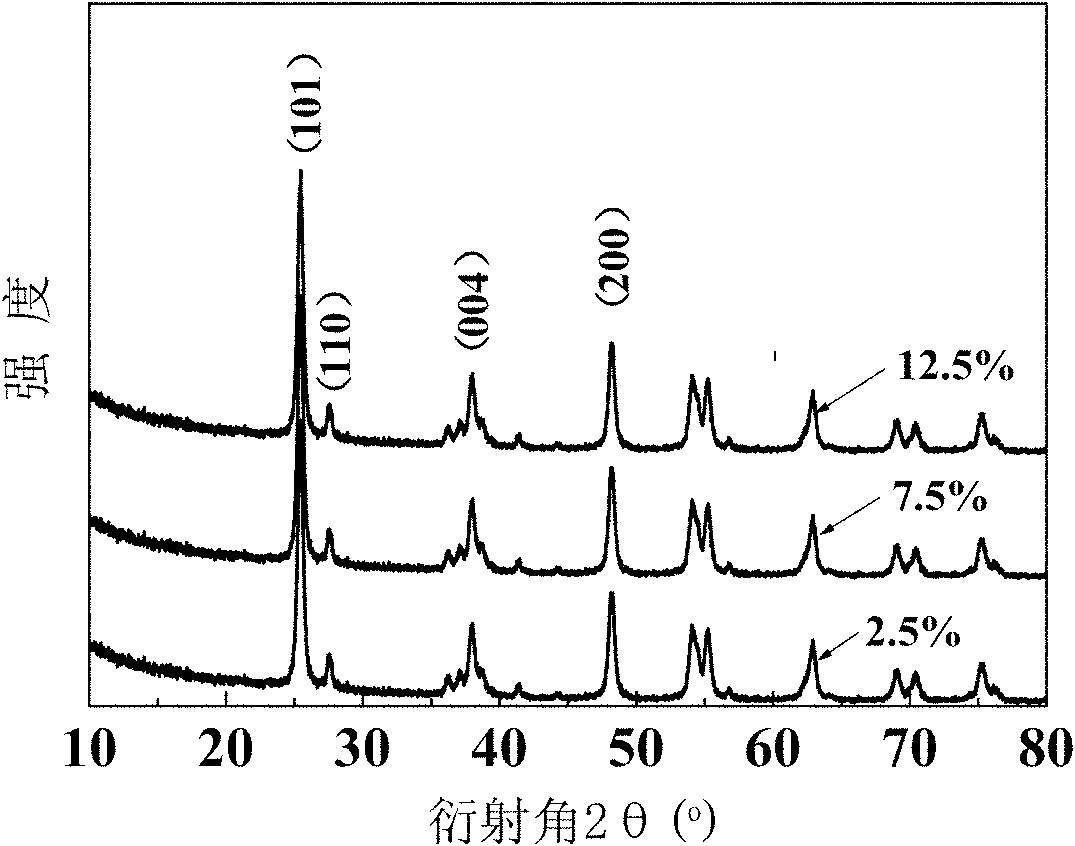

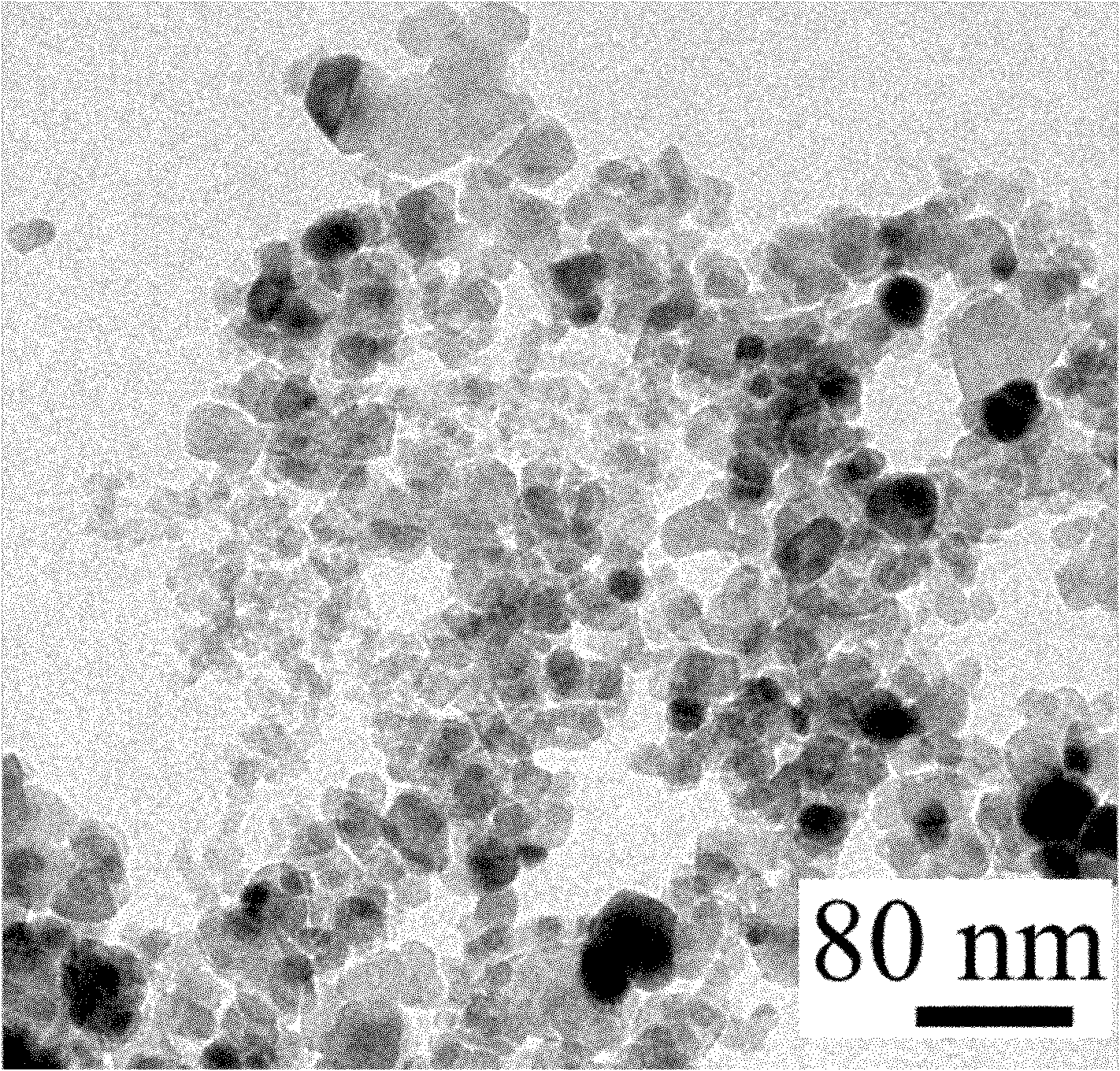

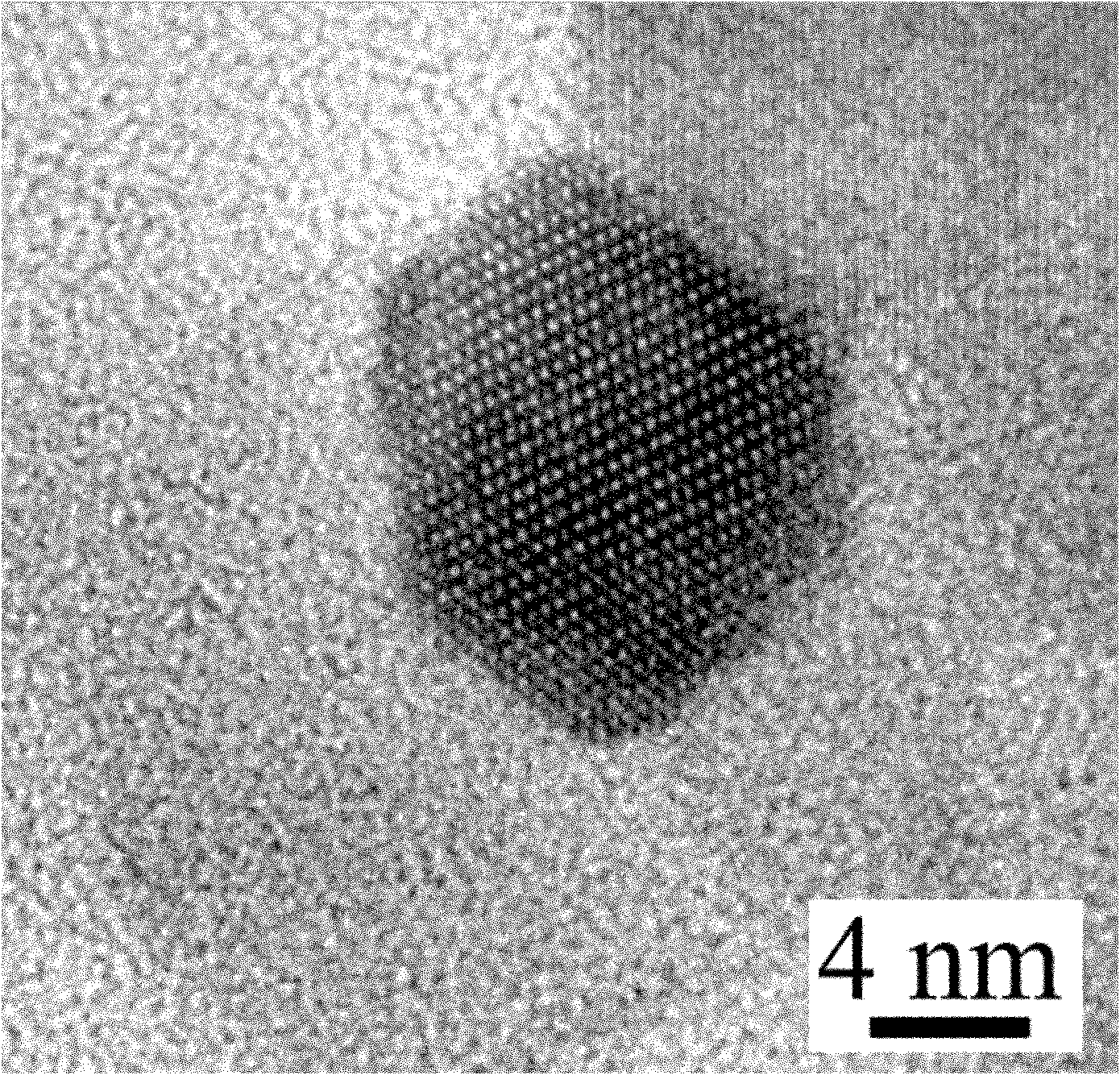

Doping dye sensitized solar cell photo anode, preparation method and application thereof

InactiveCN102074374AGood contactMembrane surface smoothLight-sensitive devicesSolid-state devicesPhotocatalysisNanocrystalline semiconductors

The invention discloses a doping dye sensitized solar cell photo anode, preparation method and application thereof, wherein the doping dye sensitized solar cell photo anode is divided into three layers in structure; the first layer is a common glass; the second layer is a SnO2 transparent conductive film doped with F; the third layer is a nanocrystalline porous composite film formed by doping the nano particle with mesoporous semiconductor at wide band with nanocrystalline semiconductor particles, wherein dyes are attached on the nanocrystalline porous composite film. The doping dye sensitized solar cell photo anode is used in doping dye sensitized solar cells. The doping dye sensitized solar cell photo anode of the invention can improve the photoelectric conversion performance of cells and increase the photoelectric conversion efficiency of solar cells well, and has the advantages of simple preparing technology, good repeatability and low cost; the doping dye sensitized solar cell photo anode not only can be used in dye sensitized solar cell materials, but also can be used in the fields of photocatalysis, gas sensitive material and the like.

Owner:HEFEI UNIV OF TECH

An aqueous ceramic/PVDF mixed coating slurry, a preparation method and an application thereof

ActiveCN109065804AEvenly dispersedReduce crystallinityFinal product manufactureCell component detailsWater basedHexafluoropropylene

A method for prepare an aqueous ceramic / PVDF mixed coat slurry comprises uniformly mixing high-purity water, perfluoroalkyl dispersant, tert-butyl hydrogen peroxide and acetone, continuously introducevinylidene fluoride and hexafluoropropylene gas to obtain aqueous PVDF emulsion; The ceramic material and the first dispersant are dispersed in deionized water, then thickener and adhesive, water-based PVDF emulsion and wetting agent are added, and the slurry is obtained after being uniformly mixed. The water-based ceramic / PVDF mixed coating slurry prepared by the invention is coated on a polyethylene diaphragm to obtain a wet film; A water-based ceramic / PVDF mix coating membrane is obtain by drying. The invention aims at remarkably improving the dispersion uniformity of ceramic / PVDF blend slurry, improving the uniformity of ceramic / PVDF blend coating separator coating, combining the characteristics of ceramic material and PVDF material, and remarkably improving the comprehensive performance of lithium ion battery separator.

Owner:湖南烁普新材料有限公司

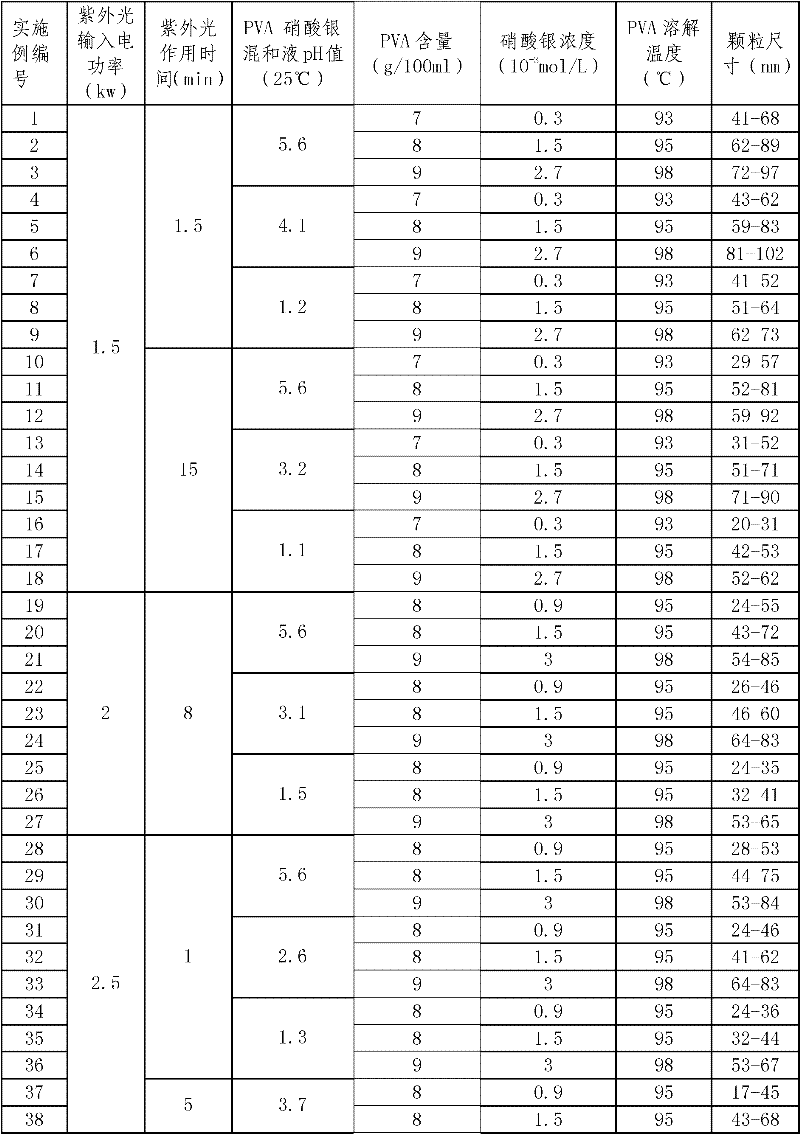

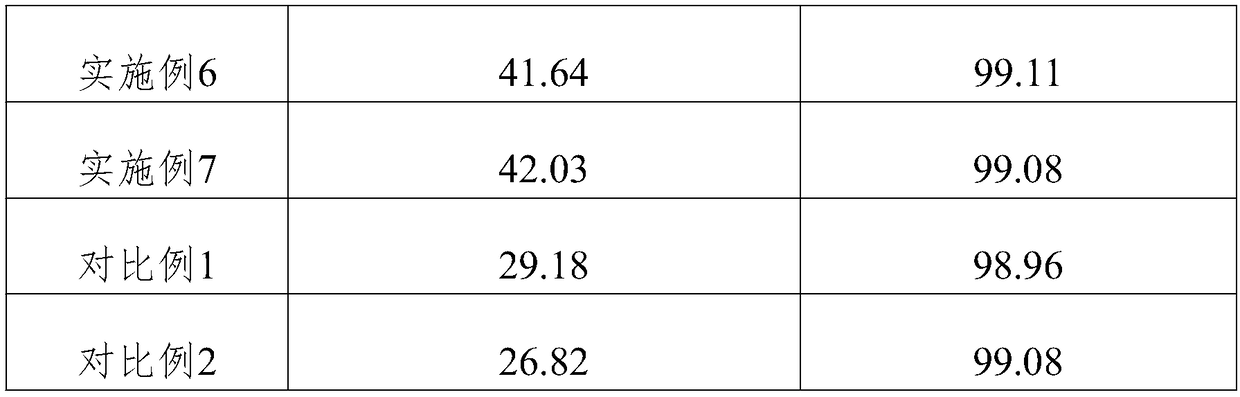

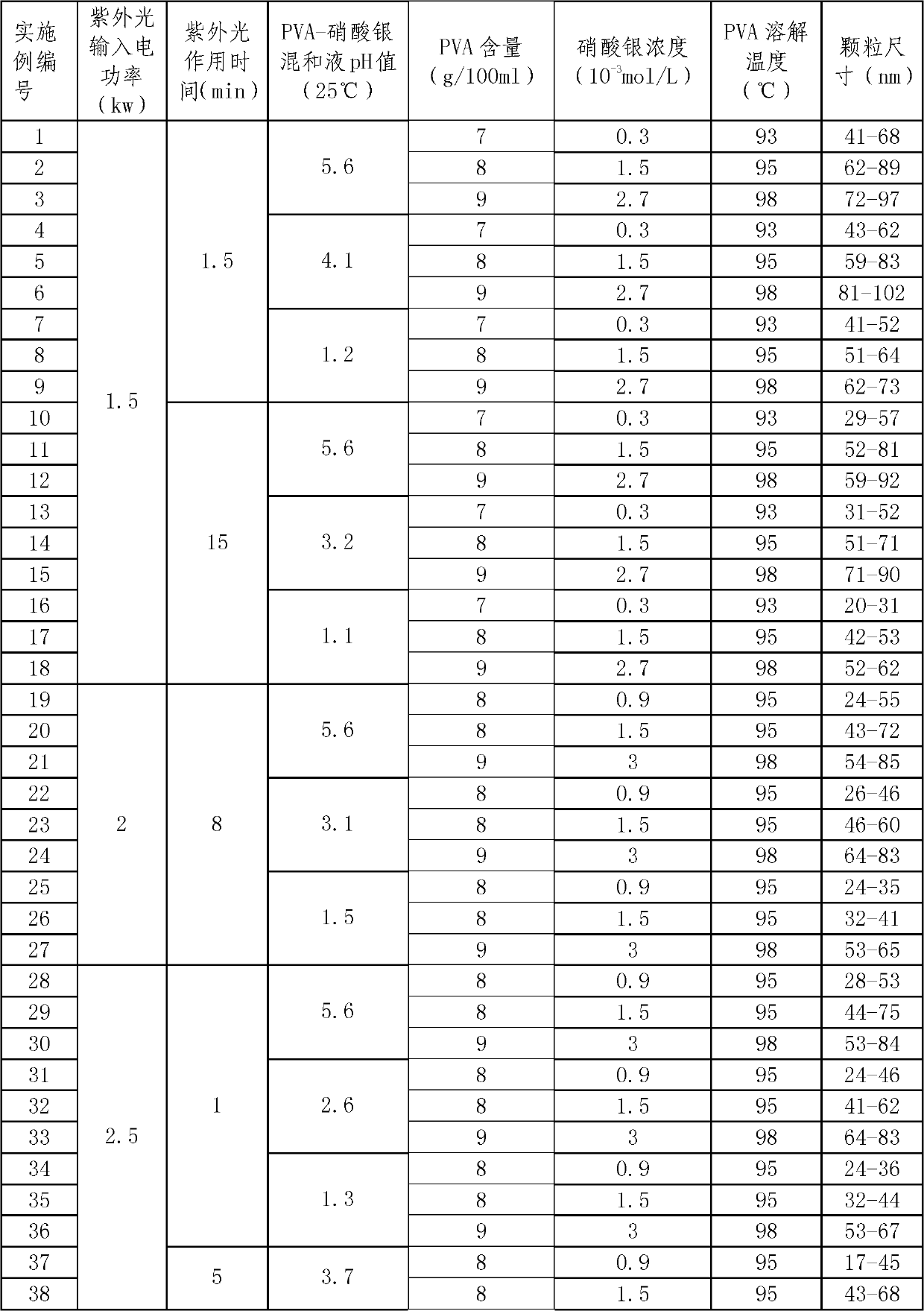

Preparation method of polyvinyl alcohol composite film with embedded silver-wrapped nanoparticles

The invention discloses a preparation method of a polyvinyl alcohol composite film with embedded silver-wrapped nanoparticles, comprising the following steps: (1) preparing a polyvinyl alcohol-silver nitrate solution; (2)preparing a polyvinyl alcohol-silver nitrate film by using spin coating method or casting film method; and (3) irradiating the polyvinyl alcohol-silver nitrate film with ultraviolet light. The prepared composite film has the characteristics of uniform metal nanoparticle size distribution, controllable dimension, uniform shape, and uniform dispersion.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Antibacterial and pollution-resistant composite reverse osmosis membrane and production method thereof

InactiveCN109012240AStrong antibacterial and pollution resistanceIncrease water fluxMembranesReverse osmosisReverse osmosisAntibacterial property

The invention relates to the technical field of reverse osmosis composite membranes, and concretely relates to an antibacterial and pollution-resistant composite reverse osmosis membrane and a production method thereof. Silver nitrate and a stabilizer 3-aminopropyltrimethoxysilane (APS) are introduced into a membrane casting solution, the silver nitrate and DMF undergo a redox reaction in the dissolving and stirring process of a high-molecular polymer in order to form nano-silver particles, the nano-silver particles form a nano-silver stable dispersion under the action of APS, and the nano-silver stable dispersion is firmly embedded in a porous support layer to make the membrane have a certain antibacterial property; and triaminoguanidine hydrochloride (TAGH) is introduced into an aqueousphase solution, and the TAGH, m-phenylenediamine and trimesoyl chloride (TMC) undergo an interfacial polymerization reaction to form a polyamide desalting layer, so the membrane surface of the polyamide desalting layer is smooth and highly hydrophilic. The anti-adhesion property and the organic pollution resistance of the reverse osmosis membrane are greatly improved. Additionally, the "structuralfragmentation" effect of an guanidino group is used to activate water molecules, so the water permeability is enhanced, and the water flux is improved without sacrificing the salt rejection rate.

Owner:VONTRON MEMBRANE TECH CO LTD

Internal-wall tempering coating

InactiveCN1472265AGood resistance to chlorine bleachingReduce dosageCoatingsHigh resistancePolyvinyl alcohol

A hardening paint for internal paint is prepared from polyvinyl alcohol, fluorescent whitening agent, titanium oxide ashed calcium, urea and water. Its advantages are high film hardness, adhesion and smoothness, high resistance to acid and alkali corrosions, and low cost.

Owner:周华海

Quantum dot ink and electroluminescence device

ActiveCN110172274AUniform film formationMembrane surface smoothSolid-state devicesSemiconductor/solid-state device manufacturingSolventQuantum dot

The invention discloses a quantum dot ink and an electroluminescence device. The quantum dot ink comprises quantum dots and a mixed solvent, the mixed solvent comprises a first solvent and a second solvent, the surface tension of the mixed solvent is 25-35 mN / m, and the difference value of the surface tension of the first solvent and the second solvent is within 0.5-3 mN / m. By selecting solvents different in surface tension, ink droplets can be quickly and naturally dried into a film in an atmospheric environment, film formation is even, the film face is flat, and the phenomenon of a coffee ring is effectively inhibited.

Owner:SUZHOU XINGSHUO NANOTECH CO LTD

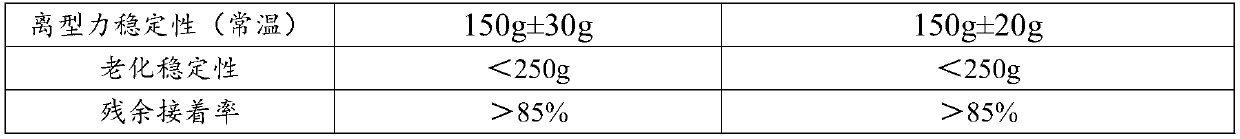

Amorphous PET release film as silica gel roll protective film and production technology of amorphous PET release film

The invention discloses an amorphous PET release film as a silica gel roll protective film and a production technology of the amorphous PET release film. The amorphous PET release film comprises a PETbasic film, and a functional coating layer is arranged on one surface of the PET basic film; the functional coating layer comprises, by weight, 3-8 parts of solvent naphtha D120, 3-8 parts of solventnaphtha D30, 4-8 parts of butanone, 0.5-2 parts of isopropanol, 0.05-0.2 part of amorphous release agent, 0.18-0.45 part of methylbenzene, 0.2-0.6 part of heavy stripping additive, 0.05-0.09 part ofcrosslinking agent, 0.01 part of anchoring agent and 0.02 part of catalyst. The light transmittance of the produced amorphous PET release film is above 90%, the haze is below 3.0, and under normal temperature, release force stability is 150 g+ / -20 g; through one hundred times of magnification of a magnifying lens, no visible particles or foreign matter exists, the surface of the film is flat and free of longitudinal grains, water ripples, transverse grains and obvious rainbow grains, the ageing stability is smaller than 250 g, and the residual adhesive power is larger than 85%.

Owner:江阴华美光电科技有限公司

Low-temperature cured ultra-light PET release film and preparation method thereof

InactiveCN110964220AReduce release forceImprove wear and weather resistanceCoatingsForeign matterMagnifying glass

The invention discloses a low-temperature cured ultra-light PET release film comprising the following components in parts by mass: 3-8 parts of 120 # solvent oil, 3-8 parts of D30 solvent oil, 5 to 12parts of ethyl acetate, 0.5 to 1.5 parts of isopropanol, 0.8 to 1.5 parts of Shin-Etsu KS-3755 silicone oil main agent, 0.001 to 0.002 part of silicon dioxide, 0.002 to 0.005 part of polyoxysilane and 0.001 to 0.0015 part of an organic platinum compound. A preparation method comprises the following process: 1) preparing a coating; 2) treating an original film; 3) carrying out precision coating; 4) drying and curing; and 5) carrying out material receiving and coiling. According to the low-temperature cured ultra-light PET release film prepared through the method, the curing temperature does not exceed 130 DEG C, and the release force is 5 g / in in 20 min; under one hundred times of the magnifying lens, no visible particles or foreign matters exist, the film surface is smooth, no longitudinal lines, water ripples, transverse lines or obvious rainbow lines exist, the 24-hour normal-temperature release force and the aging release force are close to 20 min release force, and the residual adhesion rate is larger than or equal to 75%.

Owner:江阴华美光电科技有限公司

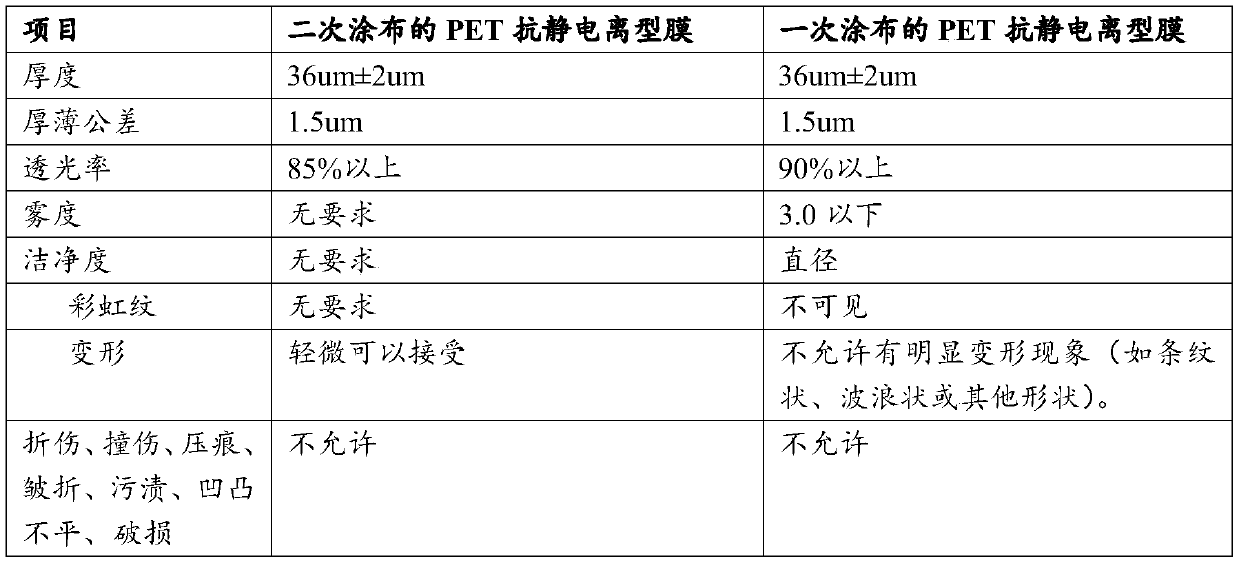

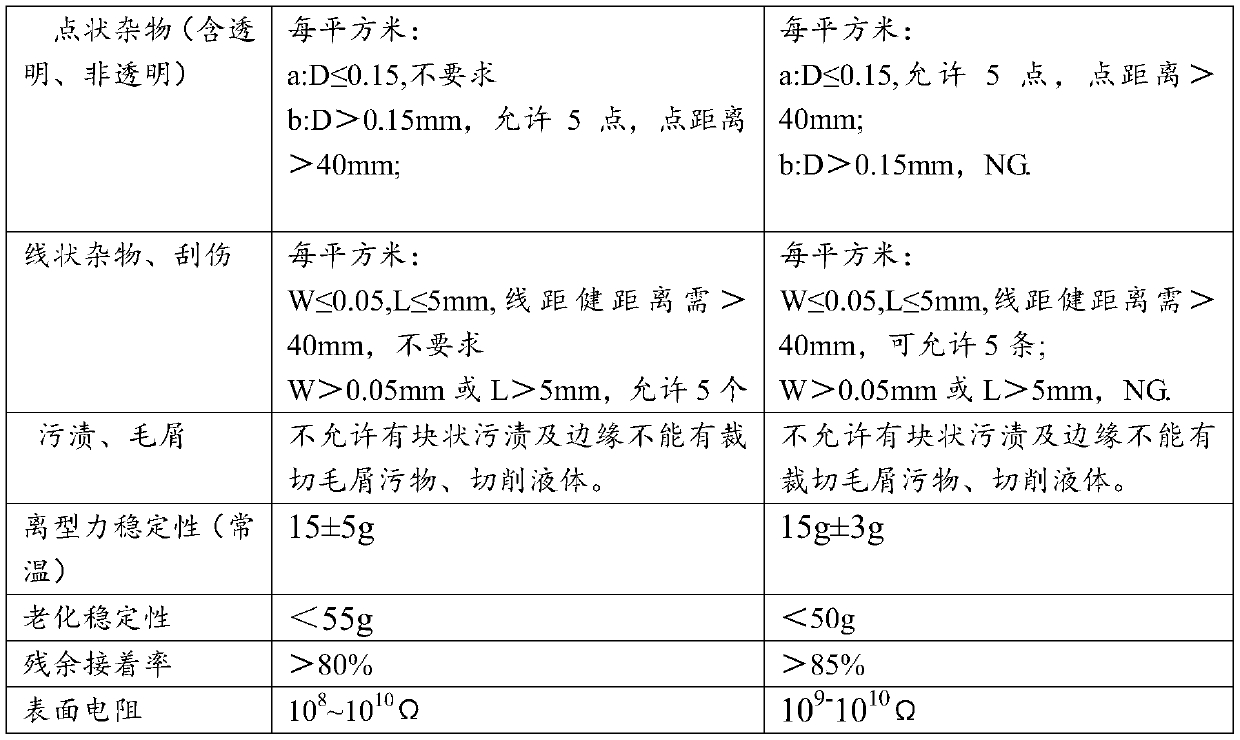

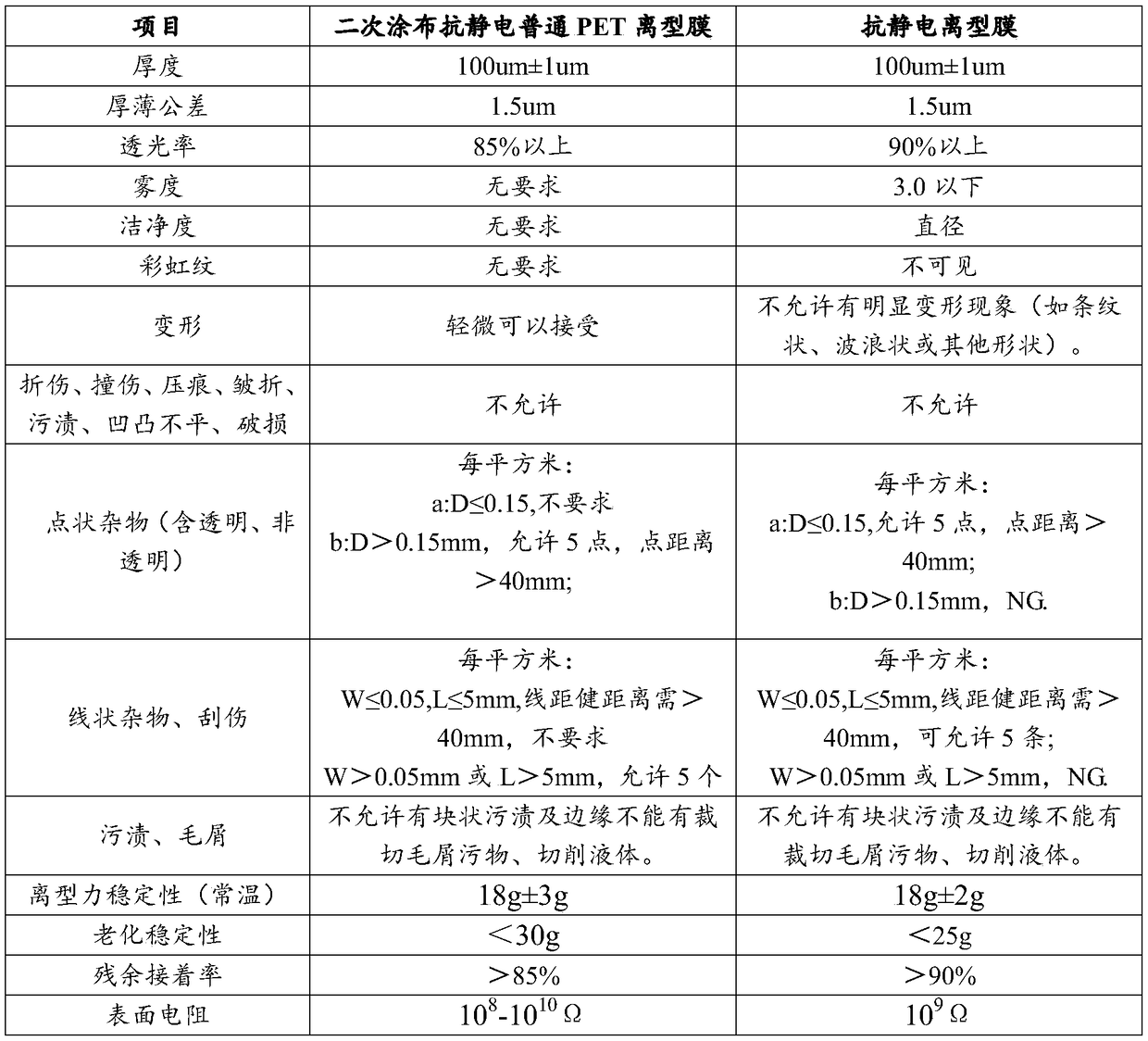

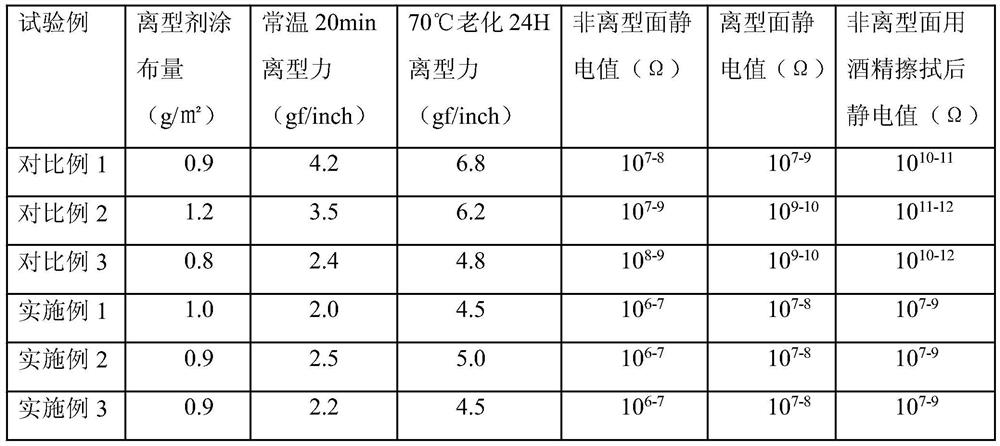

Once-coated PET antistatic release film and preparation method thereof

InactiveCN110922622AMembrane surface smoothElectrically-conductive paintsForeign matterPolymer science

The invention discloses a preparation method of a once-coated PET antistatic release film. The preparation method comprises the following steps: 1) preparing a coating: mixing 120 #, methylbenzene, butanone and isopropanol to serve as a solvent; 2) controlling the original film corona treatment value to be higher than 50 during corona treatment, and adopting a double-sided dust removal device fordust removal treatment; 3) adopting reverse coating in precision coating, and controlling the coating speed to be 40 m / min; (4) drying and curing; (5) carrying out material receiving and winding, wherein the tension during winding is 175 N, the taper is 60%, the laminating roller pressure is M: 0.4 MPa / G: 0.4 MPa, the traction roller pressure is M: 0.2 MPa / G: 0.2 MPa. The once-coated PET antistatic release film provided by the invention has a light transmittance of 90% or more, a haze degree of 3.0 or less, and a release force stability of 15 g + / -3 g; and the resistance value is 109-1010 ohms, no visible particles or foreign matters exist under one hundred times of the magnifying lens, the film surface is flat, no longitudinal lines, water ripples, transverse lines or obvious rainbow lines exist, the aging stability is less than 50 g, and the residual adhesion rate is more than 85%.

Owner:江阴华美光电科技有限公司

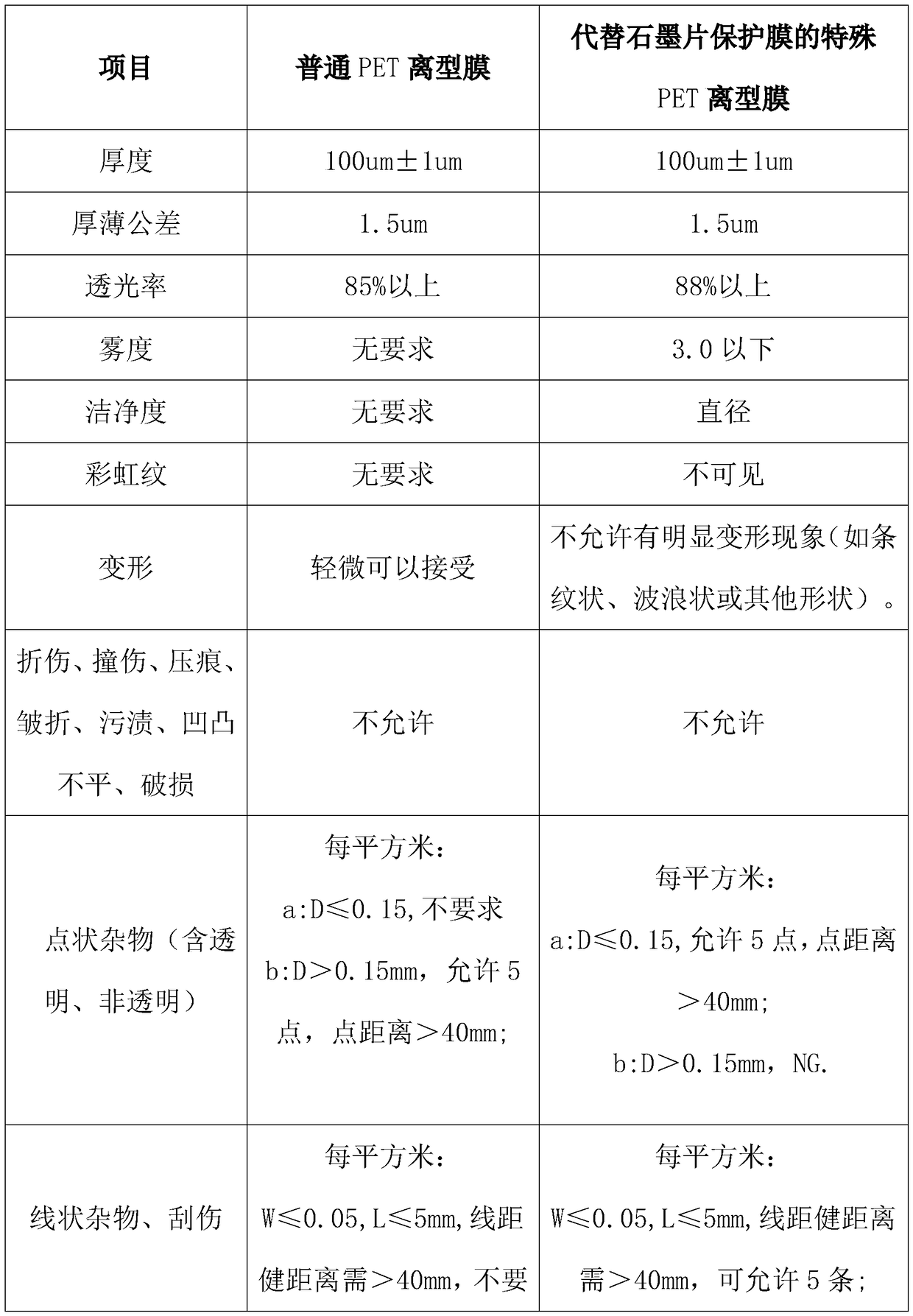

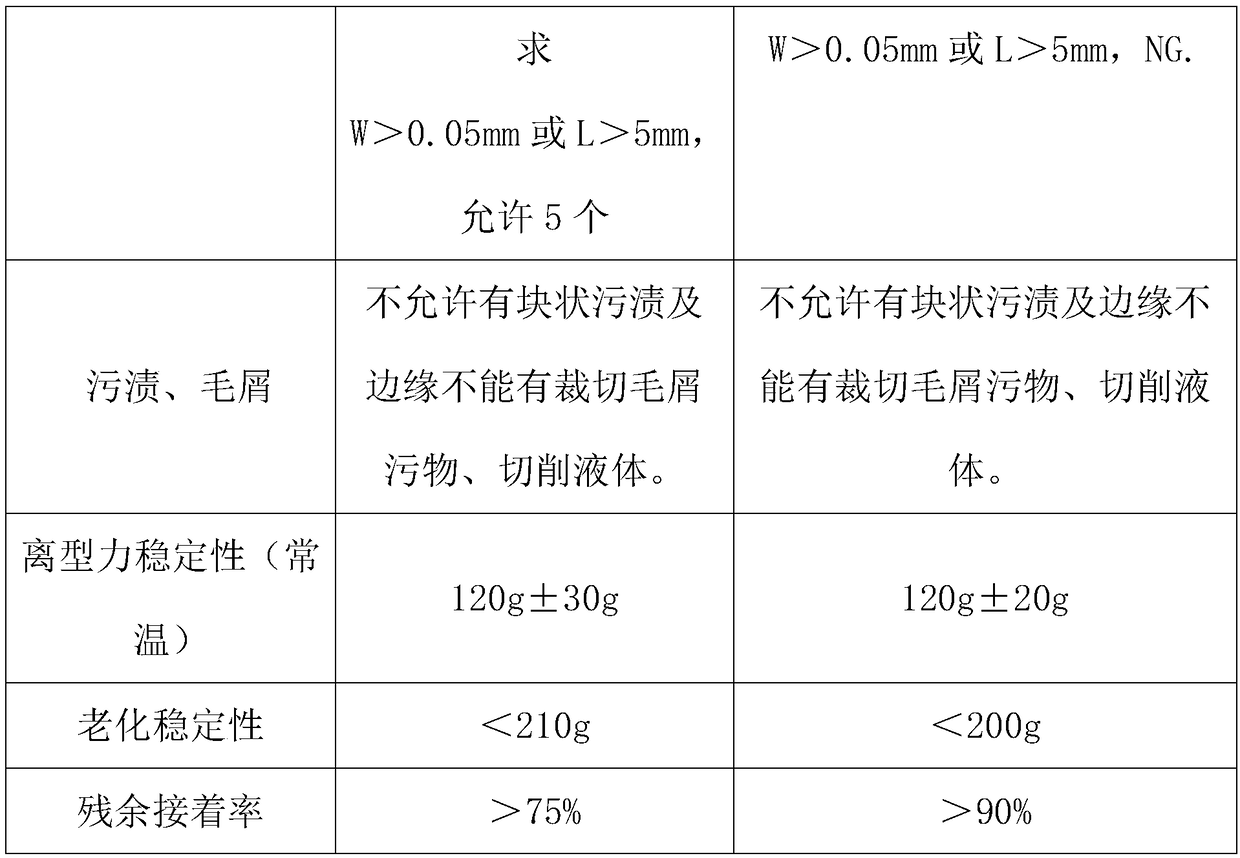

Polyethylene terephthalate (PET) release film replacing graphite sheet protective film and production process thereof

InactiveCN108822328ASimple production processEasy to operateCoatingsForeign matterTectorial membrane

The invention discloses a production process of a polyethylene terephthalate (PET) release film replacing a graphite sheet protective film. The production process comprises the following steps: 1) coating preparation: mixing D120 solvent oil, toluene and isopropanol as a solvent; 2) original membrane treatment: performing corona treatment under the condition of a corona value is larger than 50; performing dust removal treatment with a double-sided dust removal device; 3) precision coating, wherein the gluing traction tension, gluing tension is 100N; 4) drying for curing; 5) receiving and winding, wherein the tension in winding is 200N, and the taper is 50%. The light transmittance of the PET release film applied to the graphite sheet protective film is 88% or more, the mist is 3.0 or lower, and the stability of release force (at room temperature) is 120 g plus or minus 20 g. Under the magnifying glass 100 times, no visible particles or foreign bodies exist, no longitudinal line, waterripple, transverse line and no obvious rainbow line are found, and the film surface is smooth, the aging stability is smaller than 200 g, and the residual adhesion rate is larger than 80%.

Owner:江阴华美光电科技有限公司

High-glossiness metal anti-rust coating used for machinery

InactiveCN108485390AImprove rust resistanceImprove impact resistanceAnti-corrosive paintsEpoxyAcrylic resin

The invention relates to the technical field of metal rust prevention, and in particular relates to a high-glossiness metal anti-rust coating used for machinery. The coating includes the following components: a styrene-acrylic emulsion, an acrylic resin emulsion, iron oxide red, barium sulfate, wax powder, a defoaming agent, modified titanium dioxide, an corrosion-resistant auxiliary agent, a pigment, a film-forming auxiliary agent, aluminum triphosphate, deionized water, a dispersant and a coupling agent, wherein the barium sulfate has 700-800-mesh fineness; the defoaming agent is polydimethylsiloxane or tributyl phosphate; the film-forming auxiliary agent is 2-butoxy ethanol or 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate; the pigment is an ST-2 composite anti-rust pigment; the dispersant is a polyisobutylene diacid salt; and the coupling agent is epoxy silane coupling agent KH-560. The anti-rust coating provided by the invention has excellent anti-oxidation performance, good protection performance and a good film-forming effect; and a protective coating layer has high glossiness and is very beautiful.

Owner:HEFEI ZEJUN ELECTRICAL EQUIP CO LTD

Ultra-light anti-adhesion release film preparation method

ActiveCN107338675AMembrane surface smoothConsistent air volumeSpecial paperPaper coatingFiltrationTransmittance

The present invention discloses an ultra-light anti-adhesion release film preparation method, which comprises: 1, mixing 3-4 parts of D120 solvent oil, 3-4 parts of D30 solvent oil, 4-5 parts of butanone, and 1-1.5 parts of isopropanol to obtain a mixture as a solvent, adding 1-1.2 parts of a 7458 silicone oil main agent, 0.1-0.2 part of a 7672 cross-linking agent, 0.02-0.03 part of a 297 anchoring agent, and 0.05-0.06 part of a 4000 catalyst, stirring for 30-40 min at a speed of 1200-1300 rotation / min, filtering with a 200-230 mesh filtration screen, using within 3-3.5 h, carrying out raw film treatment, precisely coating, carrying out drying curing, and carrying out material receiving winding; 2, mixing 2-2.5 parts of D120 solvent oil, 2-2.5 parts of D30 solvent oil, 2.5-3 parts of butanone and 0.8-1.2 parts of isopropanol to obtain a mixture as a solvent, adding 0.8-1 part of a 9106 silicone oil main agent, 0.1-0.2 part of a 7672 cross-linking agent, 0.02-0.03 part of a 297 anchoring agent, and 0.06 part of a 4000 catalyst, stirring for 30-40 min at a speed of 1200-1300 rotation / min, filtering with a 200-230 mesh filtration screen, using within 3-3.5 h, carrying out raw film treatment, precisely coating, carrying out drying curing, and carrying out material receiving winding; and 3, carrying out post-curing treatment. According to the present invention, the produced release film has the light transmittance of more than 88%, has the mist degree of less than 3, and has the peel force stability (normal temperature) of 3-5 g.

Owner:江阴华美光电科技有限公司

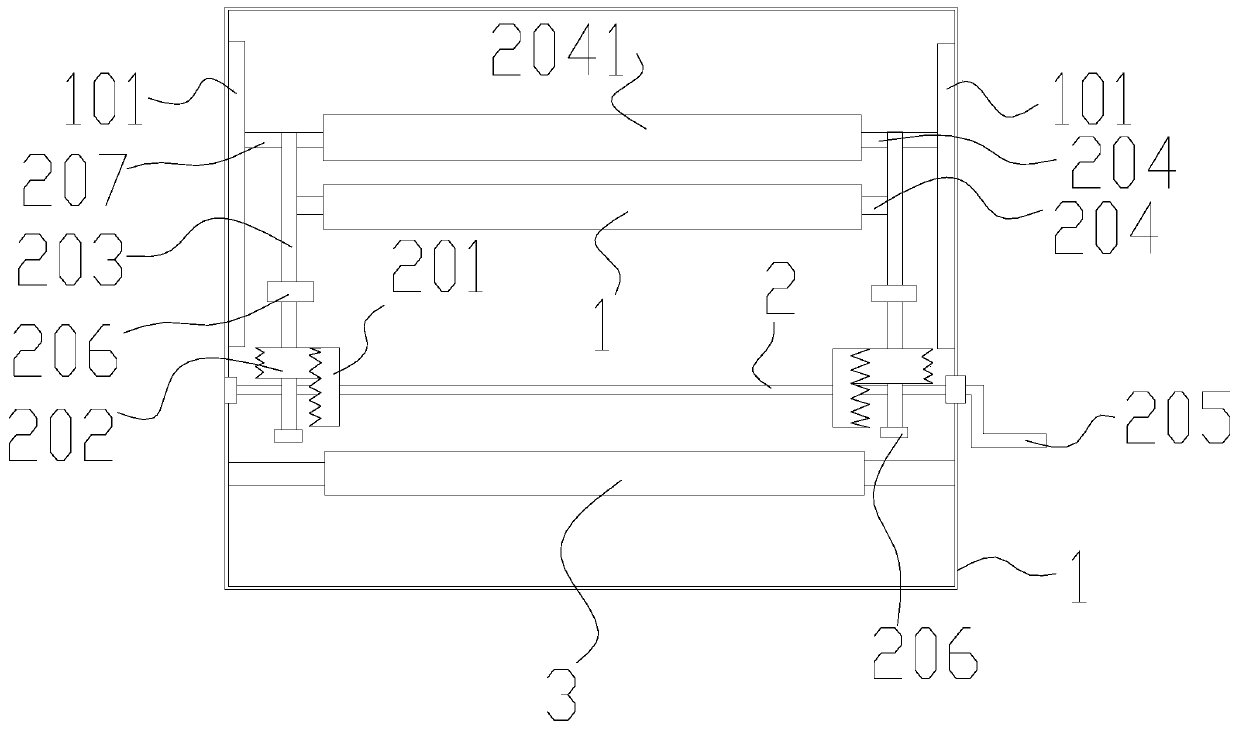

Plastic film cooling solidification device

The invention discloses a plastic film cooling solidification device. The plastic film cooling solidification device comprises a shell frame and a rotary shaft rod. The plastic film cooling solidification device is characterized in that contrate gears are disposed at the two ends of the rotary shaft rod correspondingly; lead screw gears are engaged with the contrate gears; lead screws are connected into the lead screw gears through screw threads; the lead screws at the two ends are connected with each other through at least one fixing rod; and each fixing rod is sleeved with a cooling roller.The lead screw gears are engaged with the contrite gears to drive the lead screws in the lead screw gears to perform parallel reciprocating movement, so that plastic film winded on the cooling rollersis subjected to cold drawing, the hardness of the plastic film is improved, the thickness requirement of the certain specification can be met, the cooling solidification device is additionally arranged on the back of a plate roller of equipment, the PET coating film is guided into the cooling solidification device immediately after PET coating film is subjected to high-temperature embossing, thePET coating film is rapidly transformed into cold-state solidification from the hot state, the flatness of the surface of the film is good, shrinkage is small, deformation does not occur, thus the product quality is improved, and loss is reduced.

Owner:湖南金时科技有限公司

Production process of PET (polyethylene terephthalate) release film for coating by water used as solvent

The invention discloses a production process of a PET (polyethylene terephthalate) release film for coating by water used as a solvent. The production process comprises the following steps: Step 1, coating preparation: adding a silicone oil main agent, a crosslinking agent, an anchoring agent and an anti-static agent into distilled water used as the solvent in sequence, stirring at 1,200 r / m for 30 min, filtering the mixture with a filter net of 200 meshes to obtain slurry, and using the slurry within 3 hours; Step 2, original film treatment; Step 3, precision coating; Step 4, drying and curing; Step 5, receiving and winding. The slurry obtained in the step 1 is prepared from the following components in parts by mass: 35 parts of water, 0.8 to 1.2 parts of the silicone oil main agent, 0.17to 0.21 part of a crosslining agent, 0.05 part of the anchoring agent and 24 to 25 parts of the anti-static agent. According to the production process, an organic solvent is directly replaced by thewater used as the solvent, and the PET film simultaneously has the release effect and the anti-static effect through one-time coating.

Owner:江阴华美光电科技有限公司

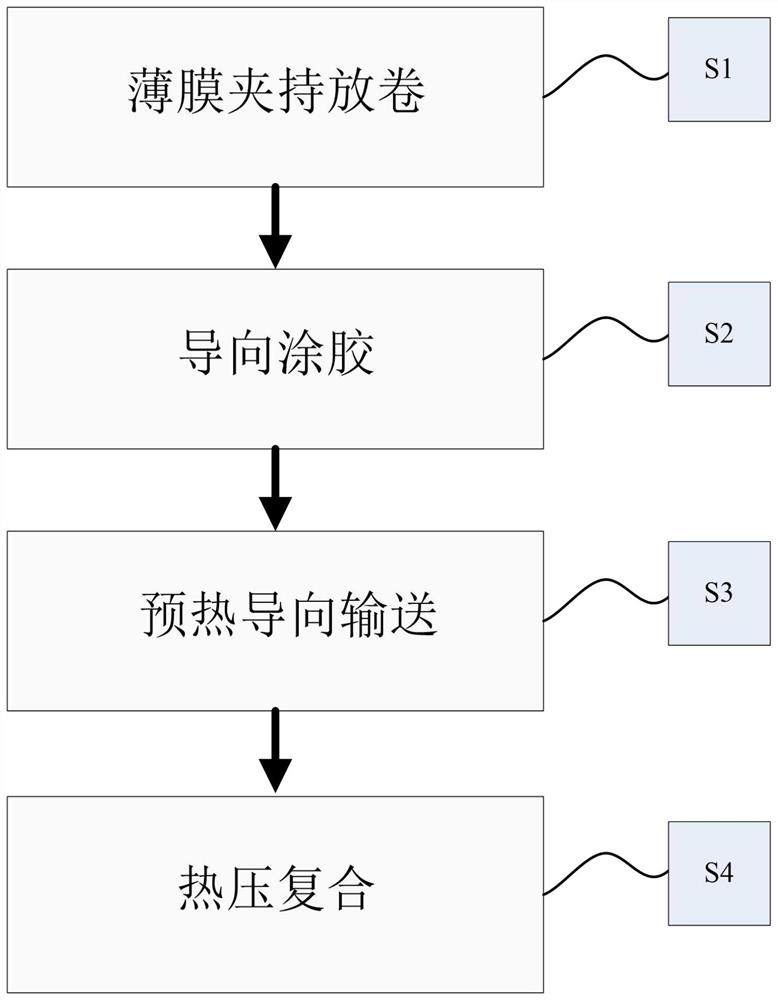

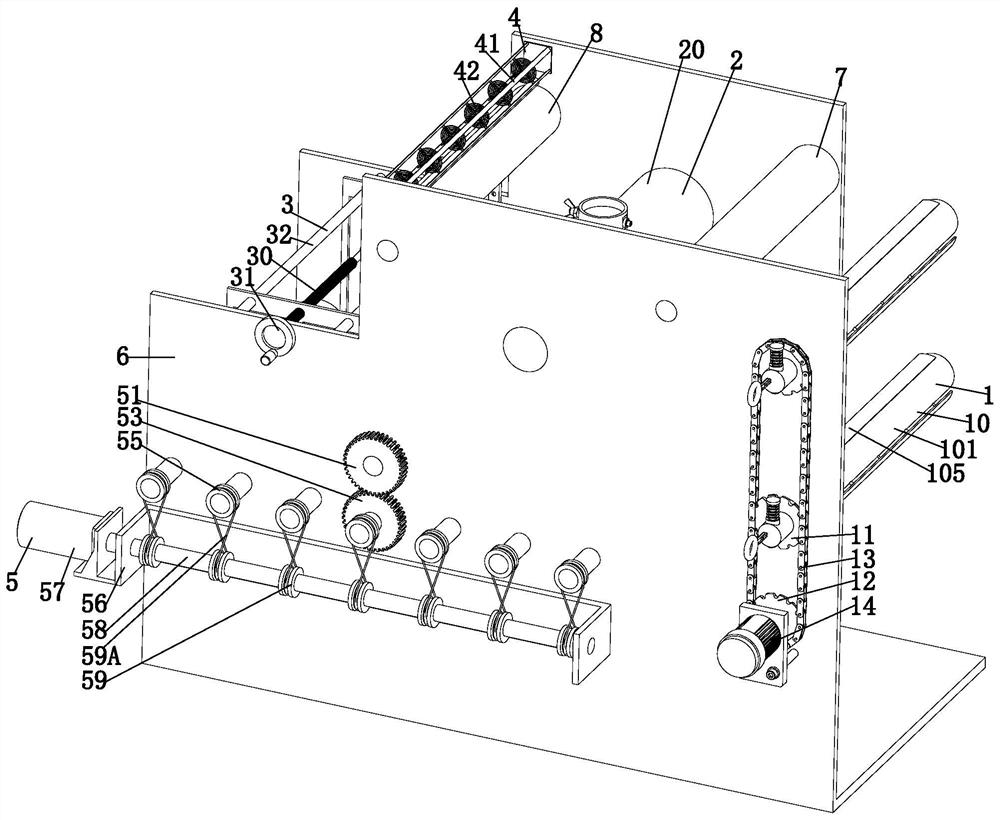

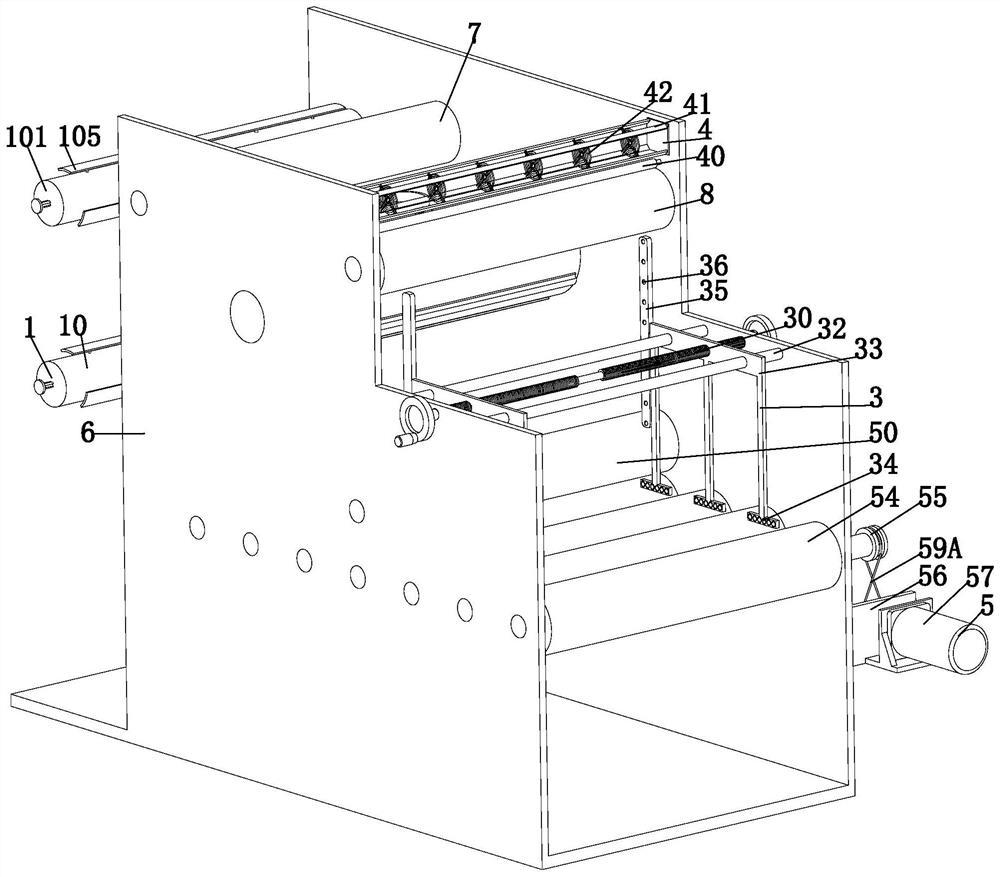

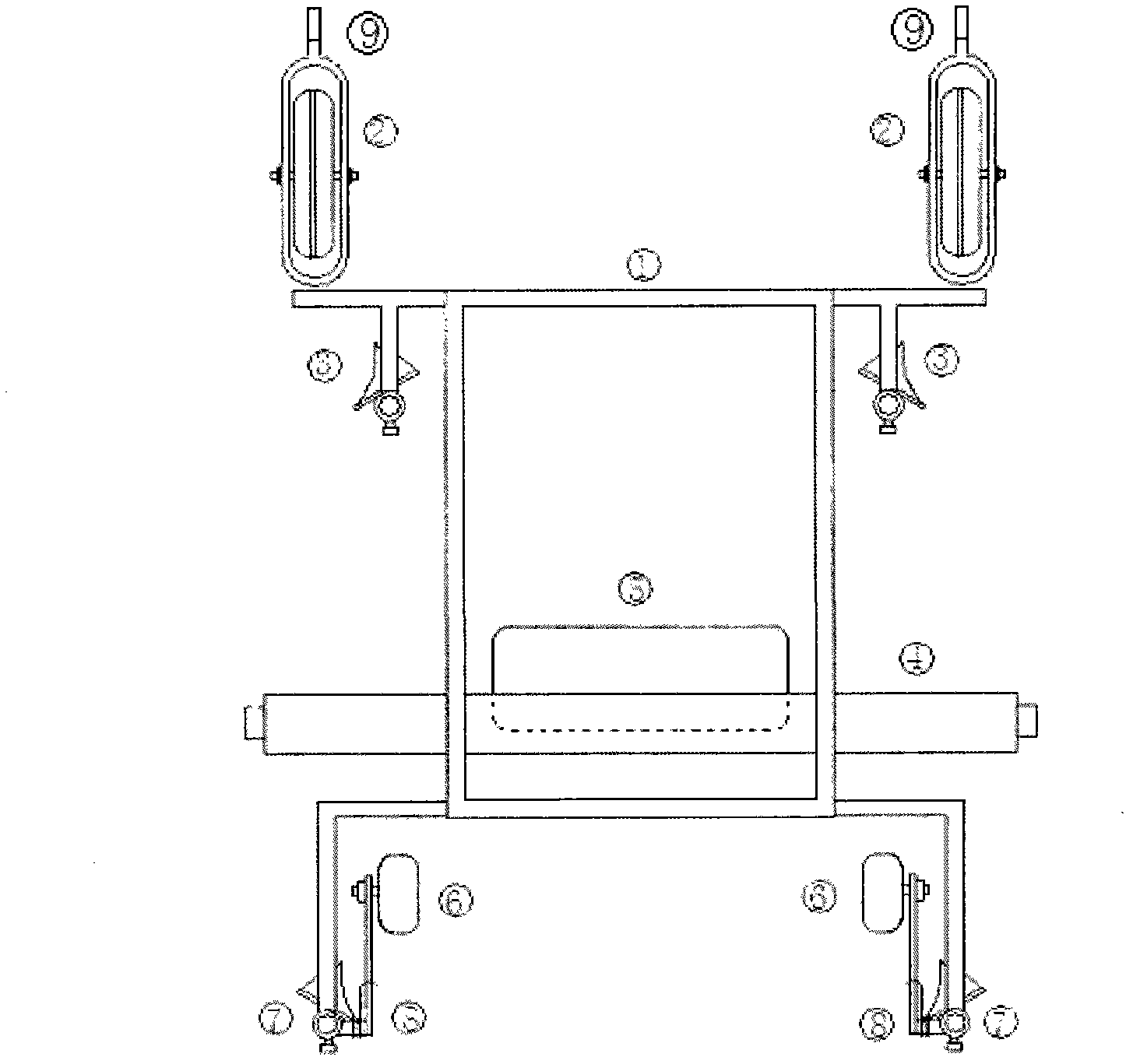

Film coating process for manufacturing packaging container

InactiveCN113500820ATension remains constantPrevent unbalanced transmission forcePaper-makingBox making operationsAdhesiveMechanical engineering

The invention provides a film coating process for manufacturing a packaging container. The film coating process comprises a winding mechanism, a coating mechanism, a guide mechanism, a drying mechanism, a conveying mechanism, a main beam plate frame, a guide roller I and a guide roller II. The film coating process solves the problems that clamping and fixing of an unwinding winding drum and a winding drum have limitation at present, and winding drums with different types and sizes cannot be clamped, so that the manufacturing of the film coating process is relatively single, and production and processing of film coating processes with different sizes cannot be realized; in the winding and unwinding processes, the execution actions cannot be synchronized, the tension in the film coating process is influenced to be constant, the film transmission stress is unbalanced, and the film is wrinkled or torn; no guide motion track exists for the transmission of paper printed matters and films, the deviation condition is easily caused after the films and the paper printed matters are compounded, and the film coating quality is influenced; and the coating of an adhesive on the surfaces of the films cannot be uniformly controlled, the coating flow speed of the adhesive cannot be controlled, and the film coating process is influenced.

Owner:武汉众诚科技有限公司

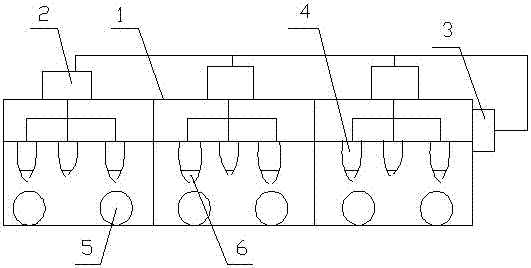

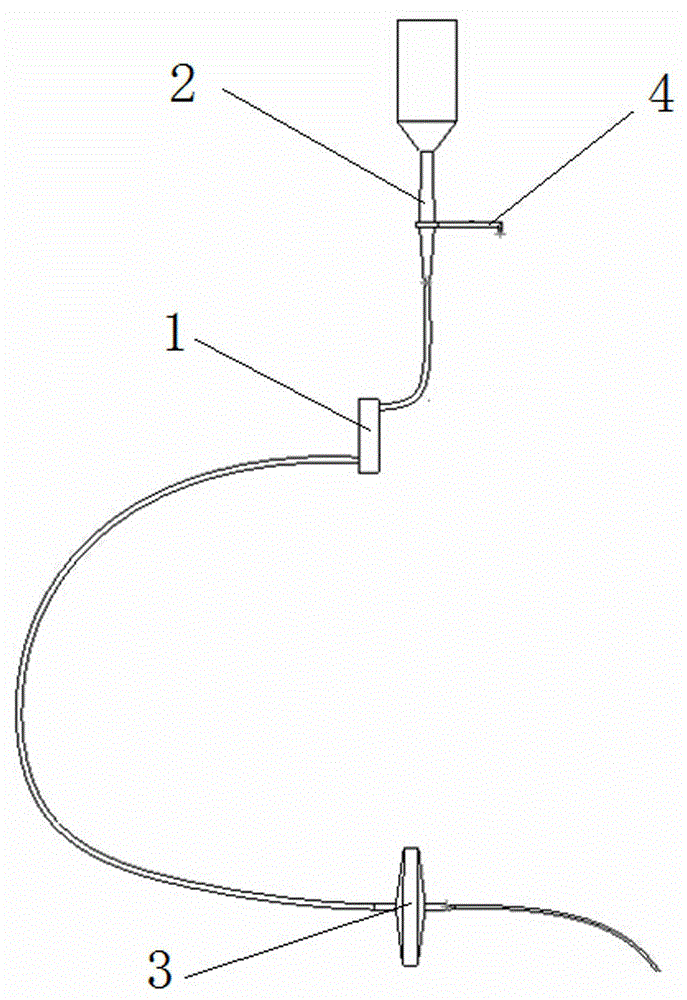

High-efficiency and low-resistance impurity particle filter system for venous transfusion

The invention particularly discloses a high-efficiency and low-resistance impurity particle filter system for venous transfusion, solving the problem that an existing venous transfusion filter system is unreasonable in structure design and poor in filter effect, thus causing potential safety hazards. The high-efficiency and low-resistance impurity particle filter system for venous transfusion comprises a murphy's dropper, wherein the murphy's dropper is provided with an air filter and a liquid medicine filter which are communicated with the murphy's dropper; the air filter is communicated with the right side of the upper part of the murphy's dropper, and the opening of an air inlet pipe of the air filter is downward; the liquid medicine filter is communicated with the left side of the lower part of the murphy's dropper; each of the murphy's dropper and the liquid medicine filter is internally provided with composite filter cloth which is vertically placed; the two pieces of composite filter cloth respectively divide the murphy's dropper and the liquid medicine filter from left to right; each composite filter cloth is made by bonding woven filter cloth and a polydimethylsiloxane filter membrane, and the end part of the air inlet pipe of the air filter is provided with horizontally placed composite filter cloth. The filtering effect of the venous transfusion is improved by the high-efficiency and low-resistance impurity particle filter system, and then the potential safety hazards are completely eradicated.

Owner:ZHONGBEI UNIV

Filtering film bag and film bioreactor using the filtering film bag

ActiveCN101371971BMembrane surface smoothNot easy to hide dirtSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisMembrane surfaceEngineering

Owner:SANDA FILM SCI & TECH XIAMEN

Preparation method of alkyd resin coating capable of forming flat surface

InactiveCN107868590AStrong compactnessImprove compactnessPolyurea/polyurethane coatingsPolyester coatingsGas phasePolyamide

The invention discloses a preparation method of an alkyd resin coating capable of forming flat surfaces. The method comprises the steps as follows: polyvinyl alcohol and bamboo charcoal powder are stirred, a silane coupling agent is added, grinding is performed, agarose is added, ultrasonic treatment is performed, and a first material is obtained; fumed silica, wollastonite powder, vermiculite powder, nano talcum powder, acetic ether, the first material and water are mixed, ultrasonic treatment is performed, and a second material is obtained; phenolic aldehyde modified alkyd resin, acrylic acid modified alkyd resin, diethylene glycol methyl ether acetate, ethylene glycol, waterborne polyurethane resin, polyamide polyamine epoxy chloropropane resin and oxidized polyethylene wax are uniformly stirred, the second material, polyoxypropylene glycerol ether, hydroxyl silicone oil, sodium lauryl sulfate, a wetting agent and a preservative are added, the mixture is stirred continuously, and the alkyd resin coating capable of forming the flat surfaces is obtained. The method is simple, and the obtained coating has good base material adhesion and film compactness, is not prone to peeling offand has good heat and damp resistance and temperature change resistance.

Owner:合肥林邦门业有限公司

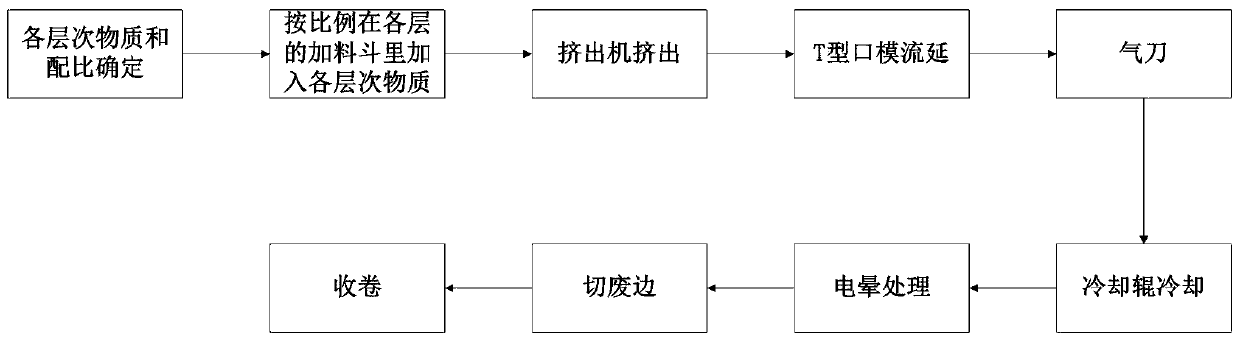

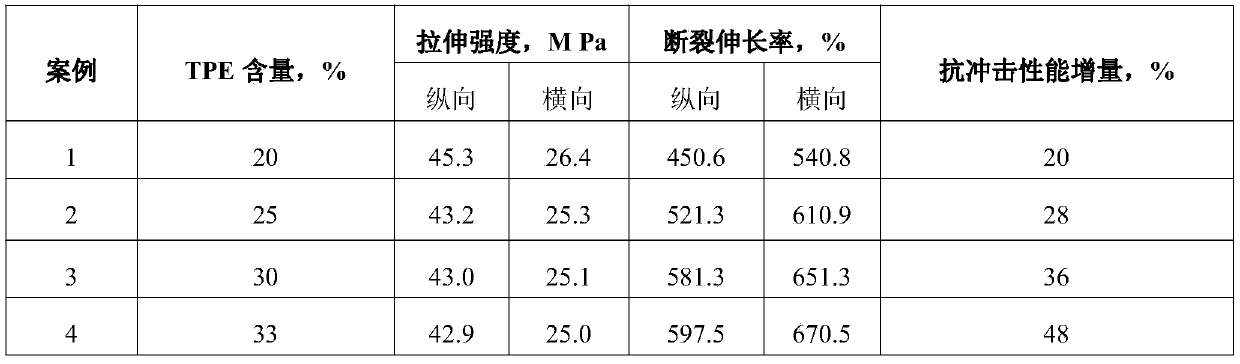

Agricultural high-toughness VMCPP aluminum laminated film and preparation method thereof

InactiveCN110948986AImprove performanceExtend the life cycleAgricultural articlesSynthetic resin layered productsThin membranePolypropylene

The invention discloses an agricultural high-toughness VMCPP aluminum laminated film and a preparation method thereof. The film comprises an aluminum layer and a CPP base film layer, wherein the CPP base film layer is sequentially provided with an aluminized layer, namely a corona layer, a middle layer and a heat sealing layer from bottom to top, the thickness of the aluminum layer is in a range of 380 angstroms to 450 angstroms, the thickness ratio of the aluminized layer is in a range of 15% to 20%, the thickness of the middle layer is in a range of 50% to 70%, the thickness of the heat sealing layer is in a range of 15% to 30%, the middle layer is composed of homo-polypropylene and TPE, and the TPE accounts for 20-33 parts by weight of the middle layer. According to the agricultural high-toughness VMCPP aluminum laminated film disclosed by the invention, the TPE is added into the middle layer of the CPP base film, so that the film is excellent in comprehensive performance and long in service life.

Owner:嘉兴鹏翔包装材料有限公司

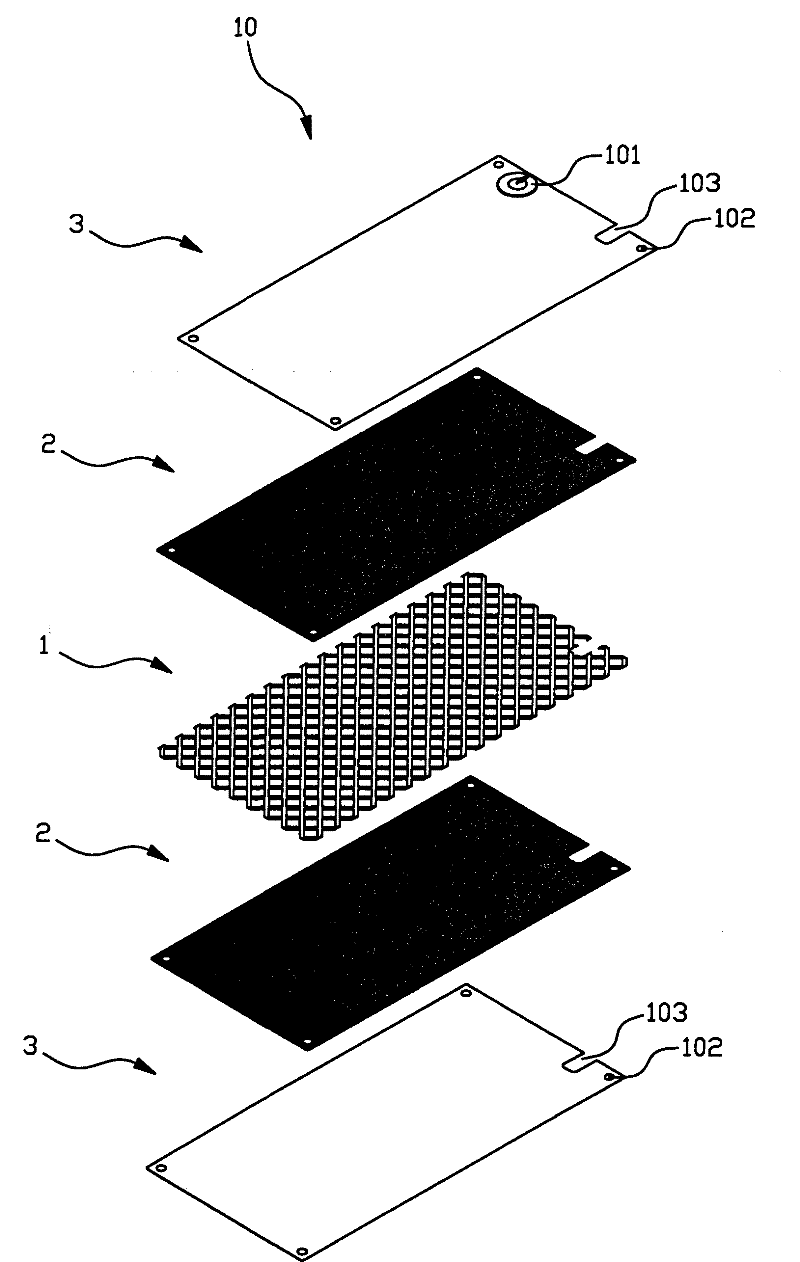

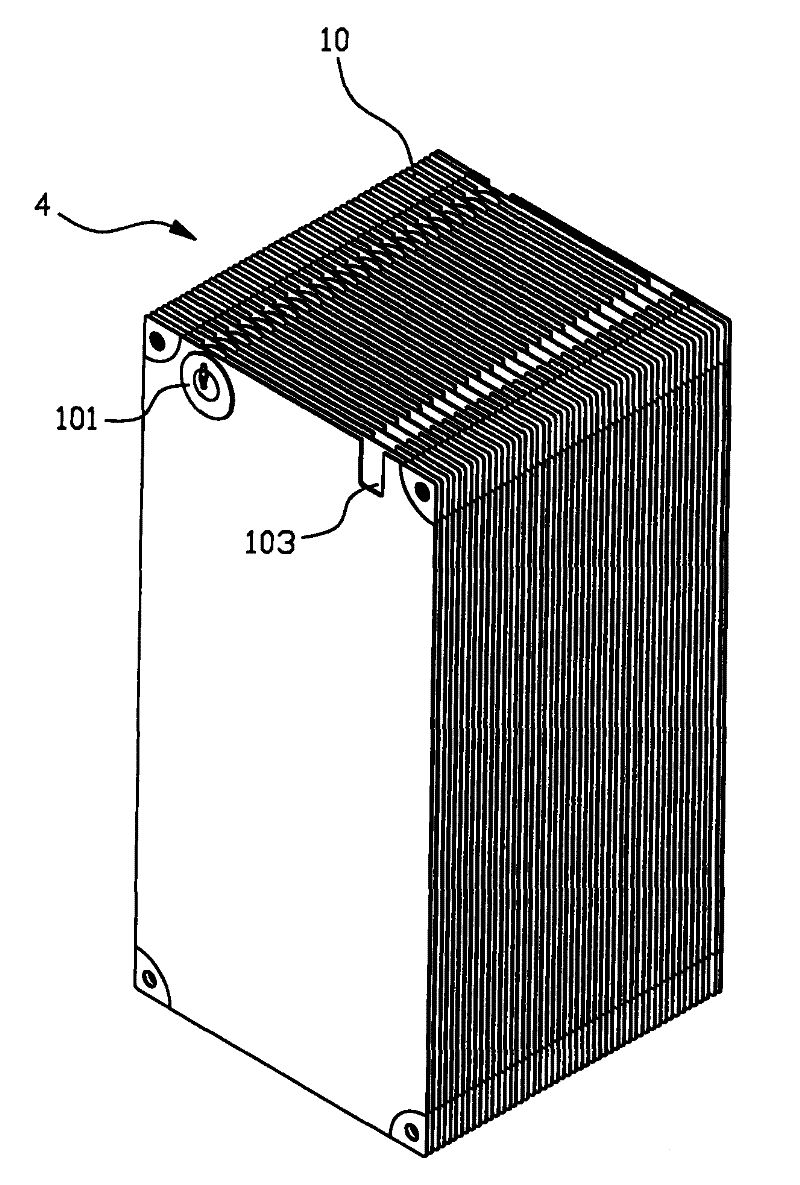

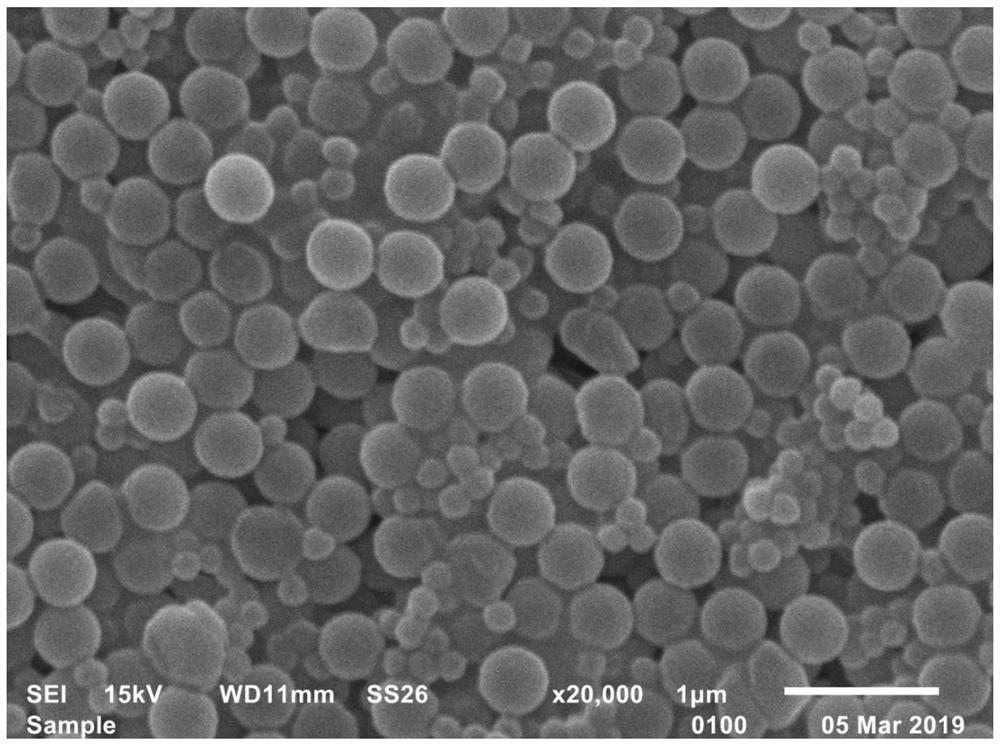

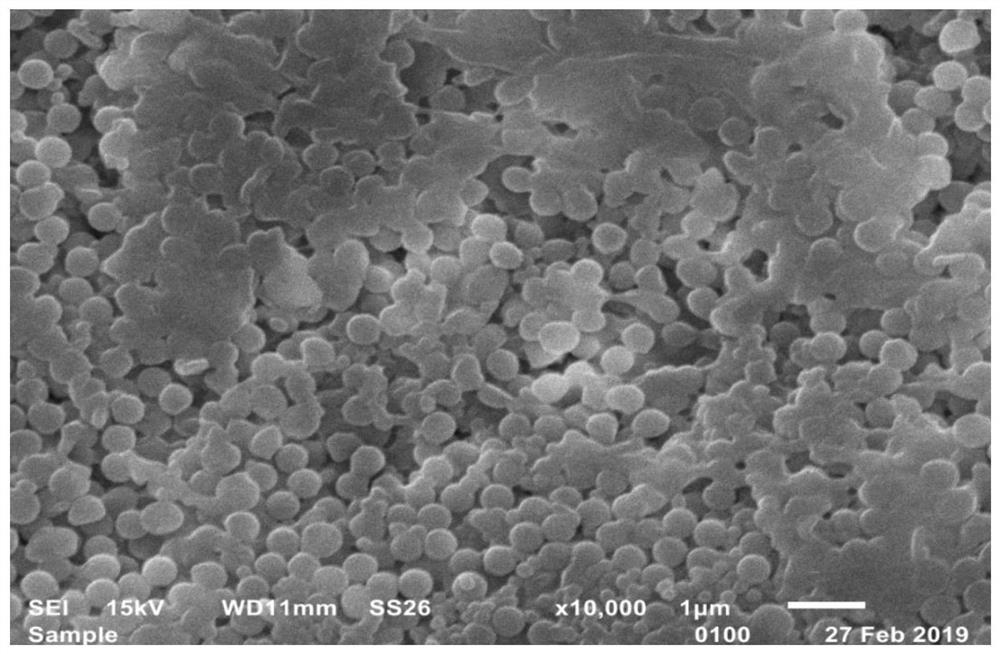

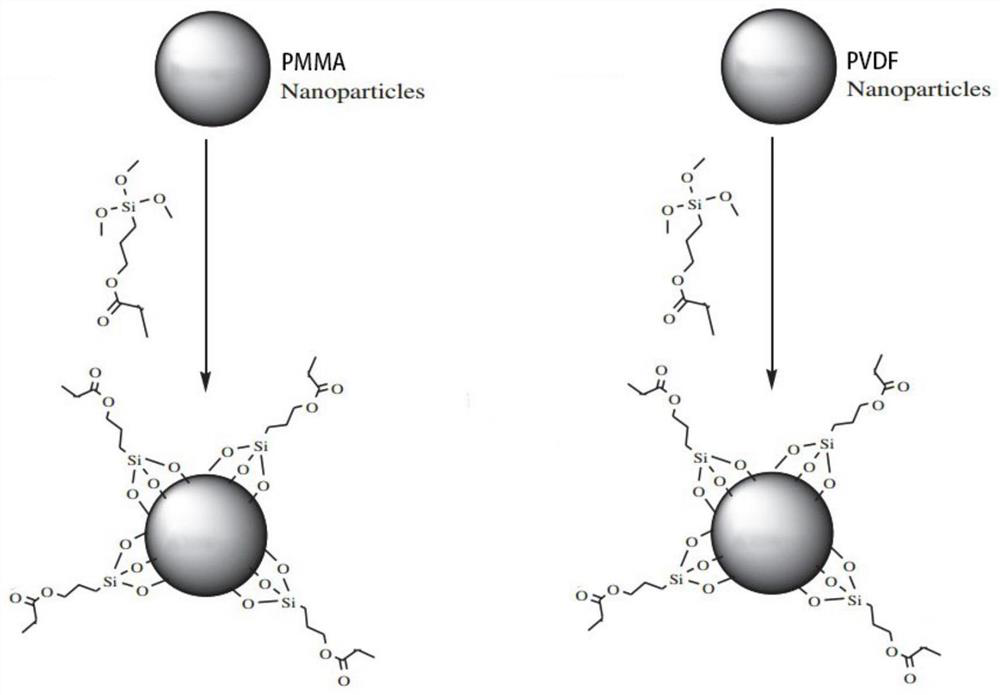

Surface modified pmma/pvdf hybrid coated lithium battery composite diaphragm and preparation method thereof

ActiveCN110048057BImprove specific surface energyMembrane surface smoothLi-accumulatorsCell component detailsElectrolytic agentIonic conductivity

The invention discloses a lithium battery composite diaphragm coated with a surface modified PMMA / PVDF mixture and a preparation method thereof; the lithium battery composite diaphragm comprises a battery diaphragm and a PMMA / PVDF mixed diaphragm coated on one side or both sides of the battery diaphragm Coating, the PMMA / PVDF hybrid coating comprises PMMA particles modified on the surface of the coupling agent and PVDF particles modified on the surface of the coupling agent. The present invention uses a coupling agent to modify the surface of PMMA and PVDF, which solves the problems of uneven mixing and easy sedimentation of PMMA and PVDF, makes the coated film surface smooth, and has a high yield rate, and effectively improves the mechanical properties and performance of the diaphragm. Adhesive, increased electrolyte absorption, improved ionic conductivity.

Owner:CHONGQING YUNTIANHUA NEWMI-TECH CO LTD

High bright leather transfer film process

The invention discloses a high bright leather transfer film process and relates to the technical field of leather transfer film processes. A manufacturing process mainly comprises the following steps: 1, manufacturing a PET basement membrane; 2, manufacturing a release layer; 3, manufacturing a coloring layer; 4, manufacturing an aluminum plating layer; and 5, manufacturing a back adhesive layer, wherein the PET basement membrane is a 23-micron high bright film; the release layer is prepared from LX-49M, butanone and cyclohexanone with the ratio of 10kg: 4kg: 1kg; the coloring layer is prepared through two kinds: 1, the coloring layer is prepared into golden and silver from PET-703, PET-703H, the butanone and the cyclohexanone according to the ratio of 2kg: 1kg: 1.5kg: 0.5kg, and 2, the coloring layer is prepared into deep color from the PET-703, the PET-703H, the butanone and the cyclohexanone according to the ratio of 2kg: 1kg: 1.5kg: 0.5kg; the aluminum plating layer adopts a vacuum coating machine; and the back adhesive layer is prepared from BJ-913AF, ethyl and toluene according to the ratio of 40kg: 3kg: 2kg. The high bright leather transfer film process has the beneficial effects of very good transparency, very good glossiness, fine, smooth and level film surface and good transfer effect and has the advantages of simple structure, reasonable design, low manufacturing cost and the like.

Owner:广西北流神通镭射装饰材料有限公司

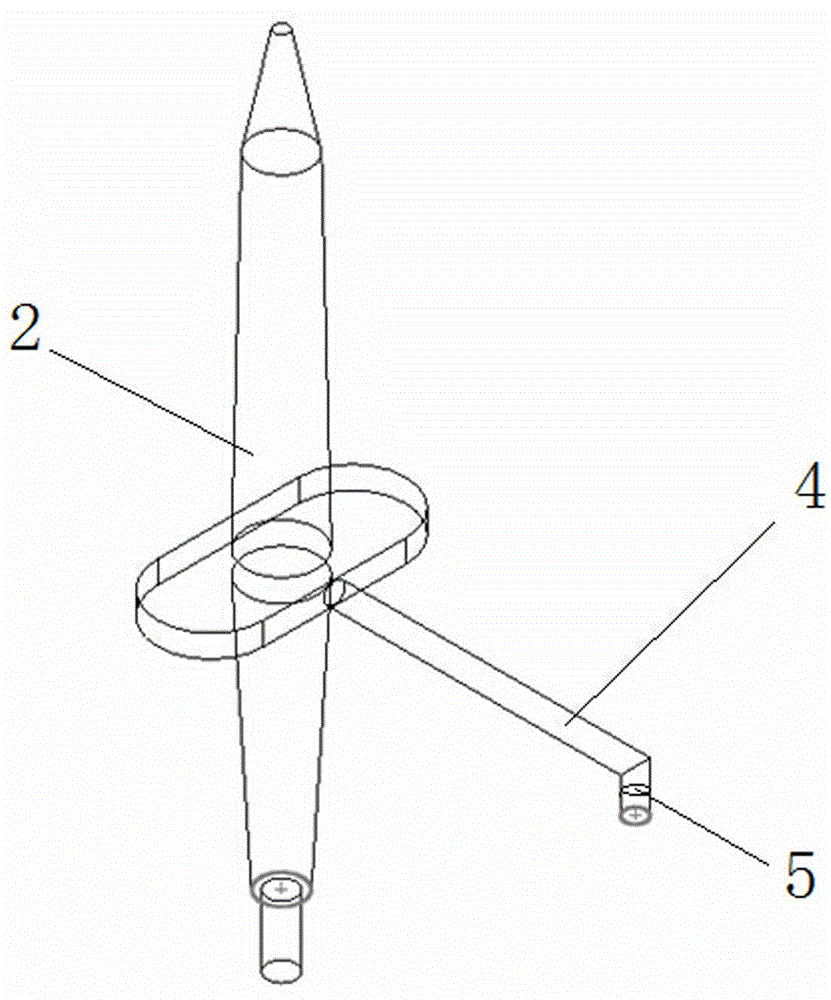

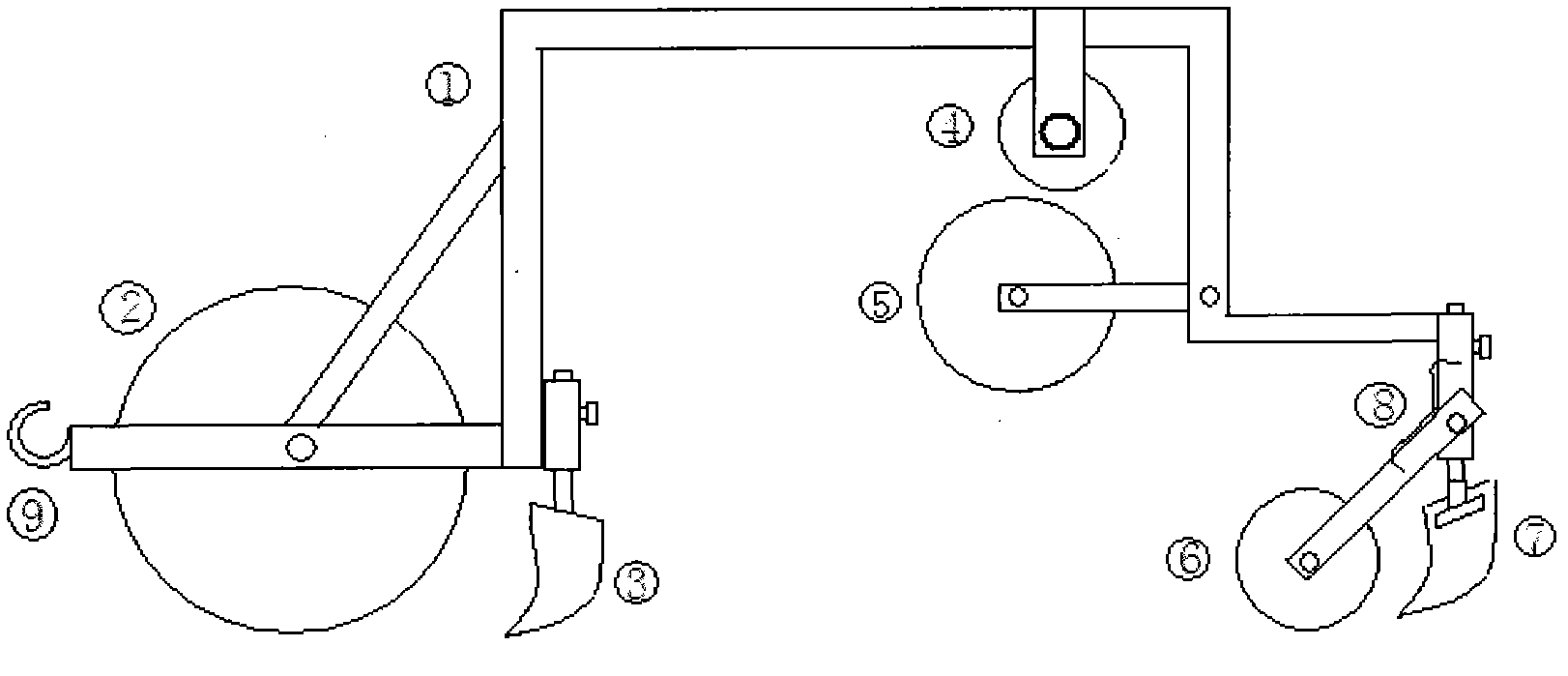

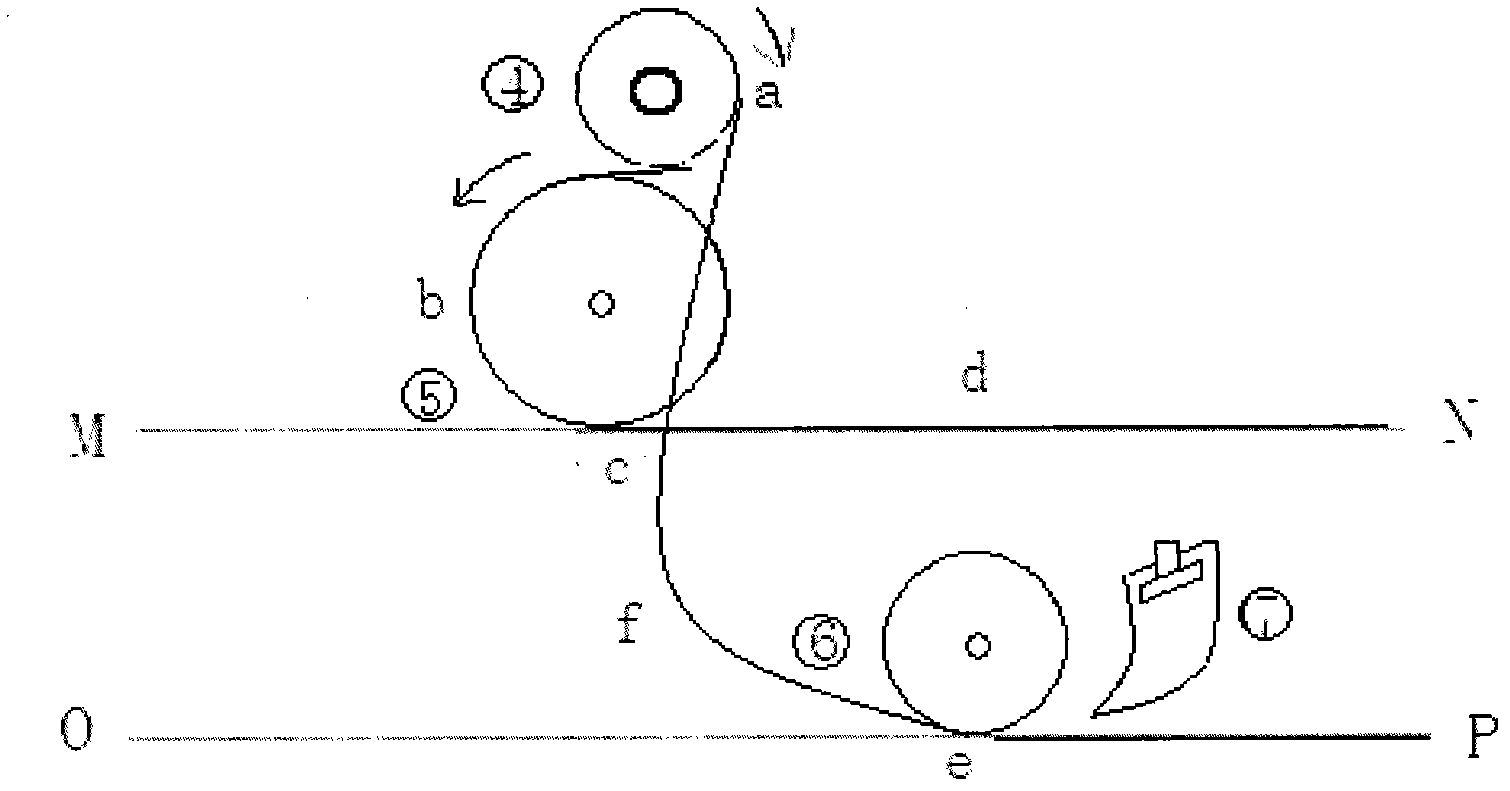

High ridge plastic film mulching machine

InactiveCN102577893ASmooth laminating operationMembrane surface smoothPlant protective coveringsSheet mulchingAgricultural engineering

The invention relates to agricultural machinery for mulching a plastic film on ridge culture crops. A draw hook (9) and a front bracket wheel (2) are arranged at the front end of a small-specification steel pipe bracket (1); an opener (3) is arranged at the rear of the small-specification steel pipe bracket (1); a film expansion mechanism is formed by a film bearing frame (4), a film expansion roller (5), a film pressing wheel (6) and a torsion spring (8); and finally a covering device (7) is arranged. Due to the adoption of the special film expansion mechanism, the operation can be smooth to carry out when the plastic film is mulched for the ridge culture crops such as potatoes, ridge culture peanuts and the like in a protected field, the soil is uniform to cover, the plastic film has proper tightness degree, and the film surface is flat like a mirror. The agricultural machinery for mulching the plastic film on the ridge culture crops needs small traction power and can be operated by both women and children.

Owner:时迎伟

Preparation method of ylate emulsion plant glue used for reflective membrane

The invention relates to a preparation method of an ylate emulsion plant glue used for a reflective membrane, which comprises the steps of pre-emulsion preparation, initiator aqueous solution preparation, reaction and the like. According to the invention, the ylate emulsion plant glue replaces a solvent type plant glue for reducing 40% of production cost; the aqueous plant glue and the base material enable excellent bonding performance, after the bonding, the membrane surface is flat and smooth, no leakage is generated, no capillary is generated; the technology is simple, the operation is convenient, the plant glue is easy to clean; the performance of the ylate emulsion plant glue is better than the performance of solvent type plant glue, and the plant glue of the invention has the advantages of small scent, low VOC content, health, safety, environmental protection, saved energy consumption and the like.

Owner:CHANGZHOU HUAWEI ADVANCED MATERIAL

Outdoor advertisement transfer membrane technology

The invention discloses an outdoor advertisement transfer membrane technology, and relates to the technical field of outdoor advertisement transfer membranes. The manufacturing technology mainly comprises the steps of manufacturing a PET base membrane, manufacturing a release layer, manufacturing a coloring layer, manufacturing an aluminum-coated layer and manufacturing a back glue layer. A 14-micrometer transfer membrane is adopted as the PET base membrane; the release layer is prepared from 1 kg of LX-185S, 3 kg of ethyl alcohol and 0.9 kg of water; the coloring layer is prepared from 2 kg of PET-703, 1 kg of PET-251, 1.5 kg of butanone and 0.5 kg of cyclohexanone; a vacuum coating machine is adopted to manufacture the aluminum-coated layer; the back glue layer is prepared from 2 kg of BJ-88, 0.6 kg of ethyl ester and 0.4 kg of methylbenzene. The outdoor advertisement transfer membrane technology has the advantages that the outdoor advertisement transfer membrane is excellent in glossiness, fine and smooth in membrane surface, level and good in effect; the structure is simple, the design is reasonable, and the manufacturing cost is low.

Owner:广西北流神通镭射装饰材料有限公司

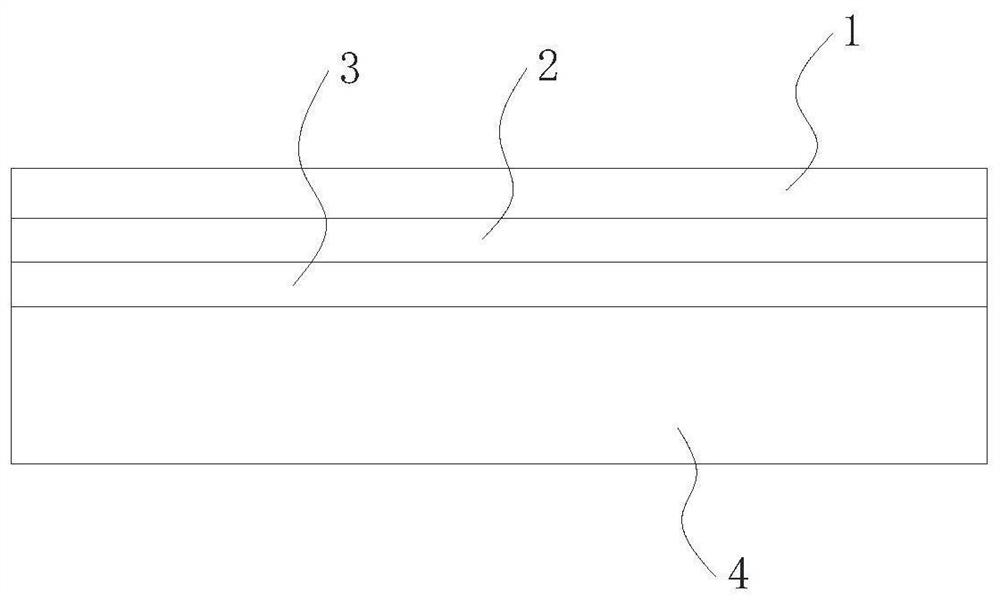

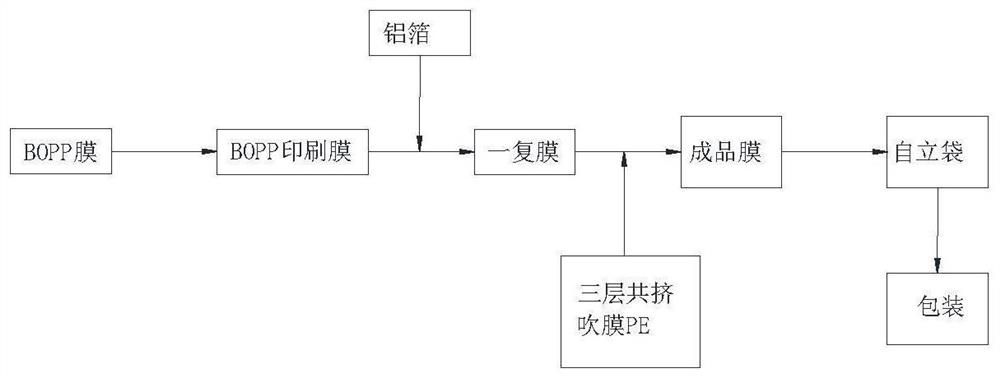

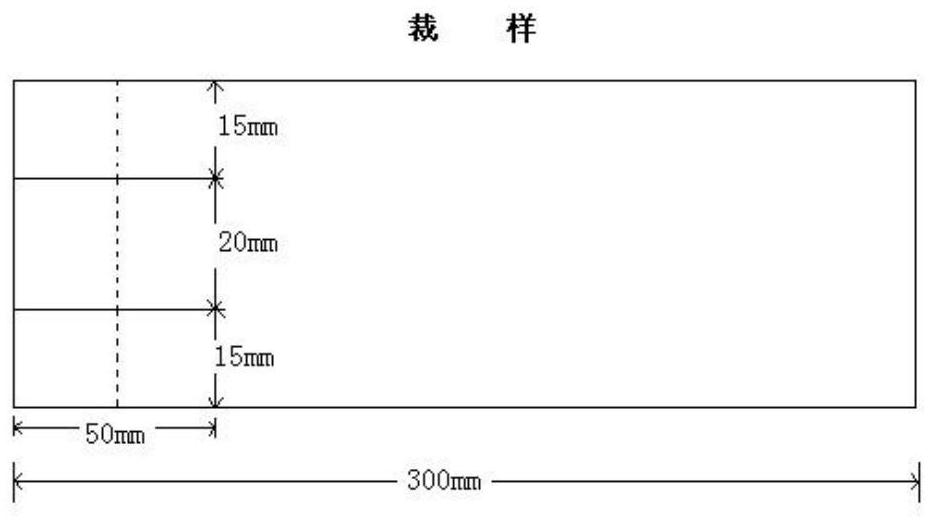

A self-supporting bag packaging material that can be opened by linear tearing and preparation method thereof

Owner:HUANGSHAN NOVEL

A kind of double-sided antistatic ultra-light PET release film and preparation method thereof

ActiveCN110527122BStable release forceStable peel forceLiquid surface applicatorsElectrically-conductive paintsCompound organicPolymer science

The invention discloses a double-sided antistatic ultra-light PET release film and a preparation method thereof. The release film includes a PET base film layer, and the PET base film layer is coated with an antistatic coating on both sides, and one side is coated with an antistatic coating. A release layer is coated on the layer, wherein the release agent used in the release layer comprises the following raw materials in parts by weight: 90-110 parts of methyl vinyl siloxane polymer, 20-30 parts of silicon dioxide dilution , non-reactive octamethylcyclotetrasiloxane polymer 25-35 parts, silane coupling agent 20-30 parts, composite organofunctional siloxane 12-20 parts, platinum catalyst and vinyl siloxane polymer 20-30 parts of the mixture and 350-500 parts of the organic solvent, the release layer of the present invention is evenly coated, the product has excellent antistatic effect, the release force and antistatic value are stable under normal temperature and high temperature conditions, and the product stability is better.

Owner:四川羽玺新材料股份有限公司

Preparation method of polyvinyl alcohol composite film with embedded silver-wrapped nanoparticles

The invention discloses a preparation method of a polyvinyl alcohol composite film with embedded silver-wrapped nanoparticles, comprising the following steps: (1) preparing a polyvinyl alcohol-silver nitrate solution; (2)preparing a polyvinyl alcohol-silver nitrate film by using spin coating method or casting film method; and (3) irradiating the polyvinyl alcohol-silver nitrate film with ultraviolet light. The prepared composite film has the characteristics of uniform metal nanoparticle size distribution, controllable dimension, uniform shape, and uniform dispersion.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com