Production process of PET (polyethylene terephthalate) release film for coating by water used as solvent

A production process and release film technology, applied in coatings, conductive coatings, etc., can solve the problems of lowering physical properties, uneven distribution of PET film surface resistance, and damaged structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

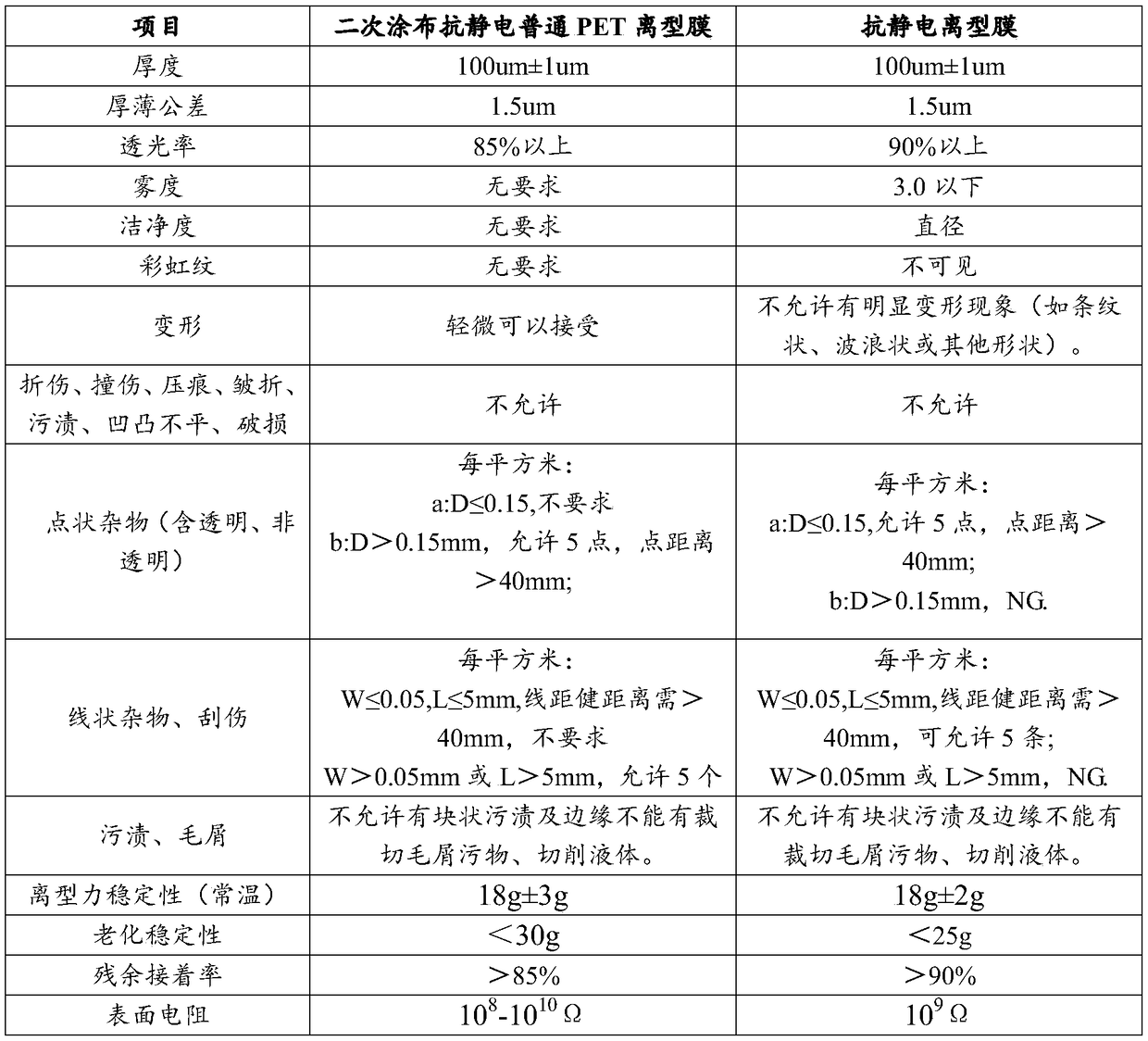

Image

Examples

Embodiment 1

[0024] A kind of production technology of the PET release film that water is used as solvent to carry out coating, comprises the following steps:

[0025] Step 1. Coating configuration: distilled water as a solvent, add silicone oil main agent, cross-linking agent, anchoring agent and antistatic agent in sequence and stir at 1200 rpm for 30 minutes, filter through a 200-mesh filter to obtain the slurry, and use it within 3 hours;

[0026] Step 2, original film treatment: including corona treatment and dust removal treatment; during corona treatment, the corona value is greater than 50, and the gap between any two points is guaranteed to be no more than 5, thereby enhancing the adhesion of the film surface;

[0027] Step 3, precision coating: use the slurry prepared in step 1 to apply glue, the traction tension of the glue is 230N, and the glue tension is 120N;

[0028] Step 4, drying and curing: the temperature of the oven in the oven is set to 100±2°C, 135±2°C, 150±2°C, 155±2...

Embodiment 2

[0036] A kind of production technology of the PET release film that water is used as solvent to carry out coating, comprises the following steps:

[0037] Step 1. Coating configuration: distilled water as a solvent, add silicone oil main agent, cross-linking agent, anchoring agent and antistatic agent in sequence and stir at 1200 rpm for 30 minutes, filter through a 200-mesh filter to obtain the slurry, and use it within 3 hours;

[0038] Step 2, original film treatment: including corona treatment and dust removal treatment; during corona treatment, the corona value is greater than 50, and the gap between any two points is guaranteed to be no more than 5, thereby enhancing the adhesion of the film surface;

[0039] Step 3, precision coating: use the slurry prepared in step 1 to apply glue, the traction tension of the glue is 230N, and the glue tension is 120N;

[0040] Step 4, drying and curing: the temperature of the oven in the oven is set to 100±2°C, 135±2°C, 150±2°C, 155±2...

Embodiment 3

[0048] A kind of production technology of the PET release film that water is used as solvent to carry out coating, comprises the following steps:

[0049] Step 1. Coating configuration: distilled water as a solvent, add silicone oil main agent, cross-linking agent, anchoring agent and antistatic agent in sequence and stir at 1200 rpm for 30 minutes, filter through a 200-mesh filter to obtain the slurry, and use it within 3 hours;

[0050]Step 2, original film treatment: including corona treatment and dust removal treatment; during corona treatment, the corona value is greater than 50, and the gap between any two points is guaranteed to be no more than 5, thereby enhancing the adhesion of the film surface;

[0051] Step 3, precision coating: use the slurry prepared in step 1 to apply glue, the traction tension of the glue is 230N, and the glue tension is 120N;

[0052] Step 4, drying and curing: the temperature of the oven in the oven is set to 100±2°C, 135±2°C, 150±2°C, 155±2°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com