Preparation method of polyvinyl alcohol composite film with embedded silver-wrapped nanoparticles

A technology of silver nanoparticles and polyvinyl alcohol, which is applied in the field of composite material preparation of metal nanoparticles prepared by ultraviolet light reduction method, can solve the problems of surface passivation of nanoparticles, deterioration of mechanical properties of polymer matrix, side reactions, etc., and achieve Relieve oxidation and agglomeration, avoid side reactions, uniform size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

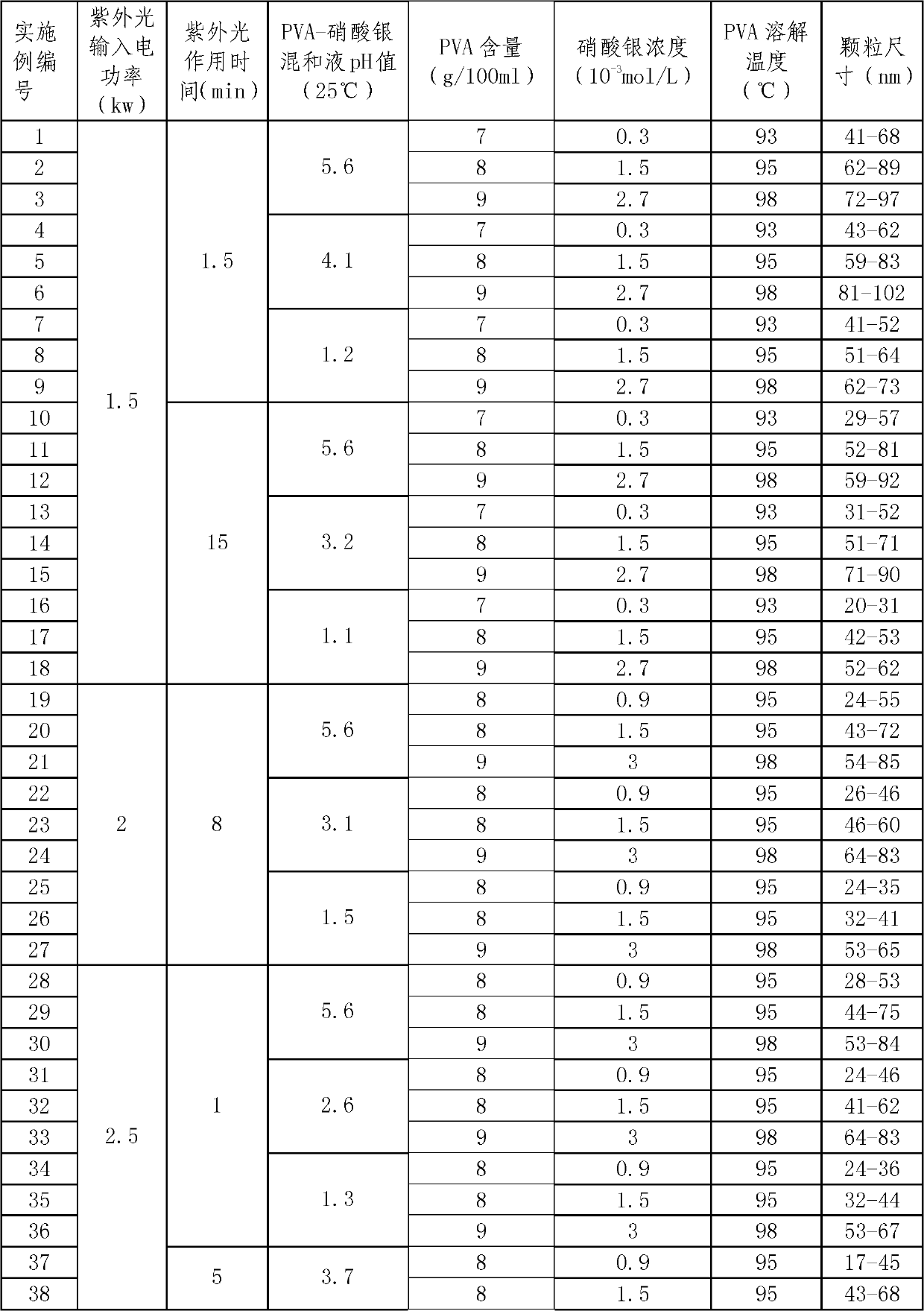

Examples

preparation example Construction

[0021] The preparation method of polyvinyl alcohol embedded silver nano particle composite film of the present invention comprises the following steps:

[0022] ① Preparation of polyvinyl alcohol-silver nitrate solution:

[0023] Dissolve the polyvinyl alcohol powder in deionized water according to the ratio of 7-9g polyvinyl alcohol powder per 100ml of water, and let it stand for swelling; raise the temperature to 93-98°C under the condition of magnetic stirring, return the condenser tube to evaporate the solvent, and heat Until the solution becomes a uniform transparent viscous shape, it is called a polyvinyl alcohol solution. After the polyvinyl alcohol solution is cooled to room temperature in the ambient air, dilute nitric acid is added dropwise to adjust the pH value of the polyvinyl alcohol solution. The value ranges from 1 to 5.6; silver nitrate aqueous solution is added to the polyvinyl alcohol solution to form a polyvinyl alcohol-silver nitrate solution, wherein the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com