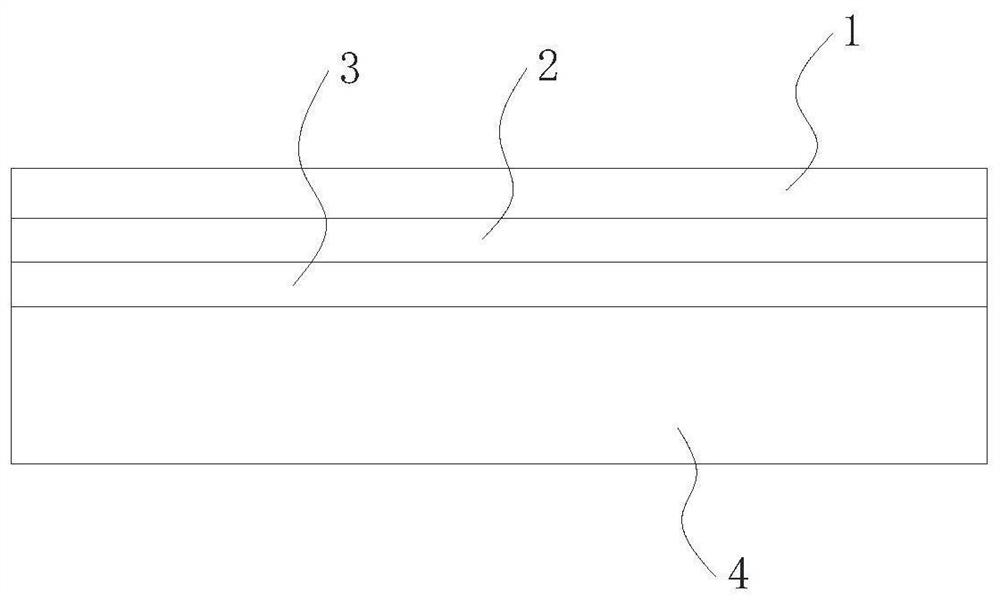

A self-supporting bag packaging material that can be opened by linear tearing and preparation method thereof

A packaging material, a straight-line tearing technology, applied in the field of stand-up pouches, can solve the problems of difficulty in balancing the depth of the laser easy-tear line, damage and air leakage of the stand-up pouch, and failure to achieve easy tearing effect, etc. The effect of low tear strength and easy longitudinal and transverse tearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

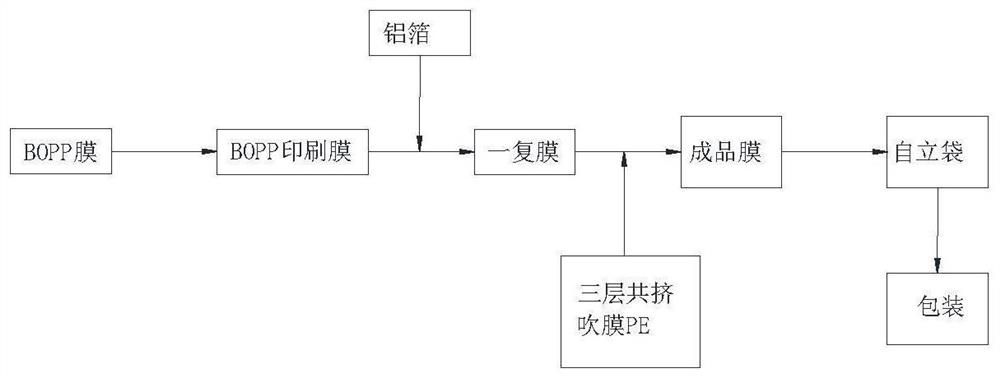

[0052] S1. Printing process: print a layer of ink on the surface of the BOPP film, the printing speed is 150m / min, and the ink is dried and cured at 40°C to form the ink layer 2;

[0053] S2, film blowing process: add corona layer raw materials, intermediate layer raw materials and heat sealing layer raw materials to the three barrels of the co-extrusion machine respectively. The formulas are as follows:

[0054] Corona layer: 50wt% linear low density polyethylene, 49.8wt% low density polyethylene and 0.2wt% processing aid;

[0055] Intermediate layer: 35wt% linear low density polyethylene, 60wt% high density polyethylene and 5wt% polybutene;

[0056] Heat sealing layer: 40wt% metallocene linear low density polyethylene, 58wt% high density polyethylene, 1wt% open masterbatch and 1wt% slip agent.

[0057] Then adopt the three-layer co-extrusion blown film process to make the film to obtain the PE layer 4;

[0058] S3. One-time compounding: dry compounding the BOPP film layer ...

Embodiment 2

[0061] S1. Printing process: print a layer of ink on the surface of the BOPP film, the printing speed is 200m / min, and the ink is dried and cured at 50°C to form the ink layer 2;

[0062] S2, film blowing process: add corona layer raw materials, intermediate layer raw materials and heat sealing layer raw materials to the three barrels of the co-extrusion machine respectively. The formulas are as follows:

[0063] Corona layer: 66.3wt% linear low density polyethylene, 33.3wt% low density polyethylene and 0.4wt% processing aid;

[0064] Intermediate layer: 50.0wt% linear low density polyethylene, 40.0% high density polyethylene and 10.0% polybutene;

[0065] Heat sealing layer: 53.9wt% metallocene linear low density polyethylene, 43.0wt% high density polyethylene, 1.6wt% open masterbatch and 1.5wt% slip agent.

[0066] Then adopt the three-layer co-extrusion blown film process to make the film to obtain the PE layer 4;

[0067] S3. One-time compounding: dry compounding the BOP...

Embodiment 3

[0070] S1. Printing process: print a layer of ink on the surface of the BOPP film, the printing speed is 250m / min, and the ink is dried and cured at 60°C to form the ink layer 2;

[0071] S2, film blowing process: add corona layer raw materials, intermediate layer raw materials and heat sealing layer raw materials to the three barrels of the co-extrusion machine respectively. The formulas are as follows:

[0072] Corona layer: 75wt% linear low density polyethylene, 23wt% low density polyethylene and 2wt% processing aid;

[0073] Intermediate layer: 70wt% linear low density polyethylene, 30wt% high density polyethylene and 20wt% polybutene;

[0074] Heat sealing layer: 40wt% metallocene linear low density polyethylene, 50wt% high density polyethylene, 5wt% open masterbatch and 5wt% slip agent.

[0075] Then adopt the three-layer co-extrusion blown film process to make the film to obtain the PE layer 4;

[0076] S3. One-time compounding: dry compounding the BOPP film layer 1 w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com