A kind of double-sided antistatic ultra-light PET release film and preparation method thereof

A release film, anti-static technology, applied in the direction of conductive coating, film/sheet release liner, film/sheet adhesive, etc., can solve the problem of low release force and low static value, release layer coating Uneven cloth, poor anti-static effect, etc., to achieve low release force, good anti-static effect, and stable peeling force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

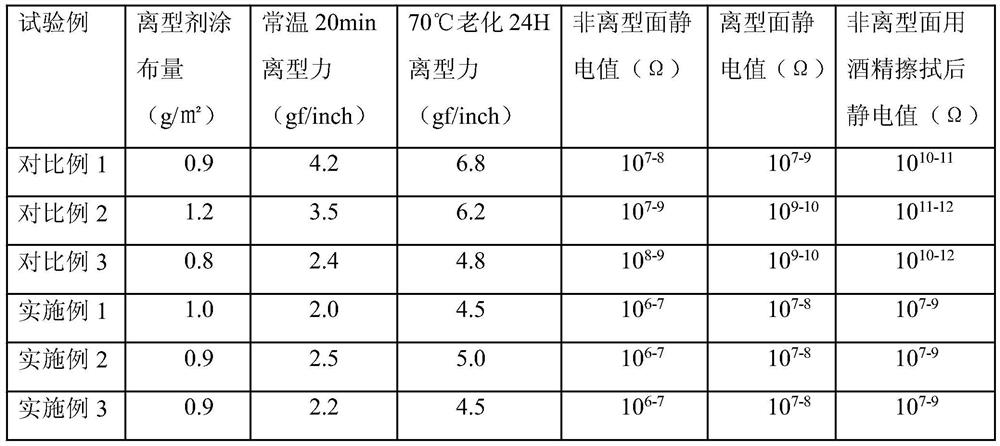

Examples

Embodiment 1

[0038] A double-sided antistatic ultra-light release film, the antistatic liquid is composed of the following raw materials: 100 parts of polythiophene polymer conductive liquid; 550 parts of distilled water; 650 parts of isopropanol; 6.5 parts of curing agent; the release agent is composed of the following raw materials Composition: 100 parts of methyl vinyl siloxane polymer (KCC 1035A), 25 parts of silica diluent (KCC SL3000), 30 parts of non-reactive octamethylcyclotetrasiloxane polymer (KCC 0062A), 30 parts of silane coupling agent (KCC 0016B), 15 parts of composite organofunctional siloxane (KCC0052S), 30 parts of mixture of platinum catalyst and vinyl siloxane polymer (KCC 0011C), organic solvent (100 parts of butanone, 100 parts of ethyl acetate, 150 parts of 120# gasoline, 50 parts of isopropanol) 400 parts.

[0039]According to the above composition, mix the raw materials to prepare the antistatic liquid and the release agent respectively. The base film used is a 50um...

Embodiment 2

[0041] A double-sided antistatic ultra-light release film, the antistatic liquid is composed of the following raw materials: 100 parts of polythiophene polymer conductive liquid, 550 parts of distilled water, 650 parts of isopropanol, and 6.5 parts of curing agent; the release agent is composed of the following raw materials Composition: 100 parts of methyl vinyl siloxane polymer (KCC 1035A), 25 parts of silica diluent (KCC SL3000), 28 parts of non-reactive octamethylcyclotetrasiloxane polymer (KCC 0062A), 30 parts of silane coupling agent (KCC 0016B), 15 parts of composite organofunctional siloxane (KCC0052S), 28 parts of mixture of platinum catalyst and vinyl siloxane polymer (KCC 0011C), organic solvent (150 parts of butanone; 100 parts of ethyl acetate; 150 parts of 120# gasoline; 50 parts of isopropanol) 450 parts.

[0042] According to the above composition, mix the raw materials to prepare the antistatic liquid and the release agent respectively. The base film used is a...

Embodiment 3

[0044] A double-sided antistatic ultra-light release film, the antistatic liquid is composed of the following raw materials: 100 parts of polythiophene polymer conductive liquid; 550 parts of distilled water; 650 parts of isopropanol; 6.5 parts of curing agent. The release agent consists of the following raw materials: 100 parts of methyl vinyl siloxane polymer (KCC 1035A); 25 parts of silicon dioxide diluent (KCC SL3000), non-reactive octamethylcyclotetrasiloxane polymer ( KCC 0062A) 25 parts, silane coupling agent (KCC 0016B) 26 parts, composite organofunctional siloxane (KCC0052S) 15 parts, platinum catalyst and vinyl siloxane polymer mixture (KCC 0011C) 28 parts, organic solvent (150 parts of butanone; 100 parts of ethyl acetate; 150 parts of 120# gasoline; 50 parts of isopropanol) 450 parts.

[0045] According to the above composition, mix the raw materials to prepare the antistatic liquid and the release agent respectively. The base film used is a 50um transparent PET co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| perimeter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com