Bottom coating agent and film containing bottom coating layer

A technology of primer and primer, applied in the direction of coating, etc., can solve the problems of many influencing factors, cumbersome process flow, difficult cost control, etc., and achieve the effects of simple formula, increased wetting performance, and improved surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

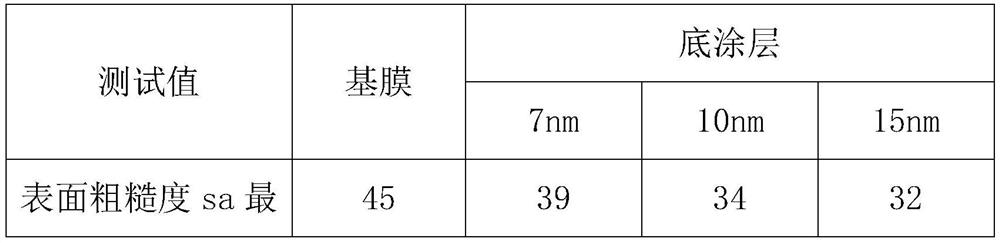

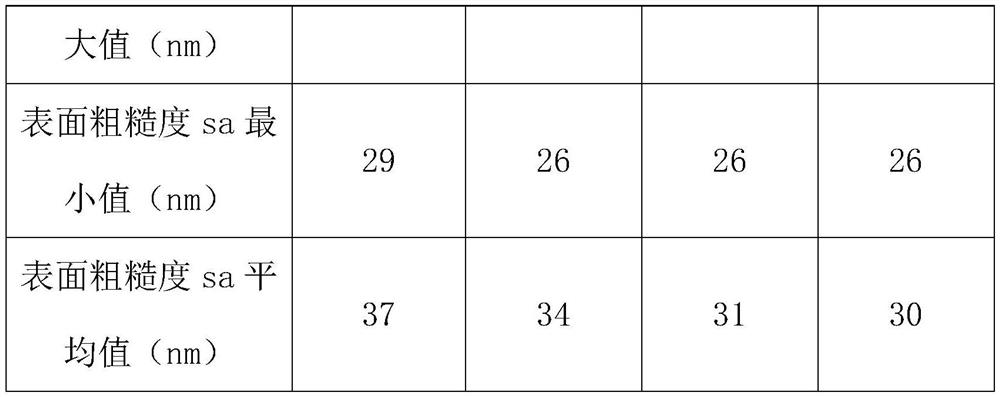

Examples

Embodiment 1

[0019] A primer consisting of reactive silane (the model is AP-1697, the manufacturer is Jiangsu Keqi Polymer Material Research Institute Co., Ltd.) and isopropanol, wherein the mass ratio of reactive silane to isopropanol is 0.05 : 100.

Embodiment 2

[0021] A primer consisting of reactive silane (the model is AP-1697, the manufacturer is Jiangsu Keqi Polymer Material Research Institute Co., Ltd.) and isopropanol, wherein the mass ratio of reactive silane to isopropanol is 0.1 : 150.

Embodiment 3

[0023] A primer consisting of reactive silane (the model is AP-1697, the manufacturer is Jiangsu Keqi Polymer Material Research Institute Co., Ltd.) and a solvent, wherein the mass ratio of reactive silane to solvent is 0.3:150; In terms of mass percentage, the solvent includes the following components: 50% isopropanol and 50% water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com